Sofortangebot

Sofortangebot Schnelles Prototyping

Schnelles Prototyping Großserienproduktion

Großserienproduktion

Sofortangebot für Ihre Hydroforming-Anforderungen

LS Manufacturing bietet Ihnen schnelle und präzise Angebote für Hydroforming-Projekte. Dank einer vielfältigen Materialauswahl, Oberflächenbearbeitungsmöglichkeiten und hochpräziser Umformtechnik liefert unser Angebotssystem innerhalb weniger Minuten maßgeschneiderte und wettbewerbsfähige Preise, die genau auf Ihre Bedürfnisse zugeschnitten sind.

Über 30 Materialoptionen: Formmetalle wie Edelstahl, Aluminium, Messing, Kupfer und Titan ermöglichen die Herstellung leichter, langlebiger und robuster Bauteile, die für verschiedene Branchen geeignet sind.

Über 20 Oberflächenveredelungsoptionen: Werten Sie Ihre Teile mit Veredelungsverfahren wie Anodisieren, Pulverbeschichten, Polieren und Galvanisieren auf. Die Lieferzeiten betragen im Durchschnitt 3-7 Tage für optimale Leistung und Ästhetik.

Präzision bis zu ±0,1 mm: Erzielen Sie enge Toleranzen und glatte, präzise Oberflächen für komplexe Formen und detaillierte Teile und gewährleisten Sie so, dass alle Komponenten den exakten Spezifikationen entsprechen.

ITAR-registriert

ITAR-registriert ISO 9001:2015, ISO 13485:2016, AS9100D und IATF 16949:2016 zertifiziert

ISO 9001:2015, ISO 13485:2016, AS9100D und IATF 16949:2016 zertifiziert

Laden Sie Ihr Design hoch und erhalten Sie jetzt ein Sofortangebot!

Erhalten Sie sofortige Preisinformationen, Projektlaufzeiten und DFM-Feedback.

STEP | STP | SLDPRT | STL | DXF | IPT | X_T | X_B | 3DXML | CATPART | PRT | SAT | 3MF | JT files

Dateigröße: ≤15MB

Von Ingenieuren und Einkaufsleitern der weltweit erfolgreichsten Unternehmen geschätzt.

hydroforming-introduction.h1Tilte

Bei LS Manufacturing sind wir auf Hydroforming spezialisiert und bieten innovative Lösungen für die präzise und effiziente Formgebung von Metallbauteilen. Unsere nach ISO 9001:2015 zertifizierten Prozesse nutzen fortschrittliche Hydroforming-Technologie zur Herstellung komplexer, leichter Strukturen mit exzellenter Festigkeit und Langlebigkeit. Dieses Verfahren eignet sich besonders für Werkstoffe wie Aluminium, Stahl und andere Legierungen und ermöglicht die Fertigung komplexer Formen bei minimalem Materialverbrauch und reduzierten Produktionskosten. Ob Prototypen oder Großserienfertigung – unser erfahrenes Team entwickelt hochwertige und kosteneffiziente Hydroforming-Lösungen, die exakt auf Ihre Projektanforderungen zugeschnitten sind.

hydroforming-introduction.bullet1

hydroforming-introduction.bullet2

hydroforming-introduction.bullet3

hydroforming-introduction.bullet4

Hydroforming Service

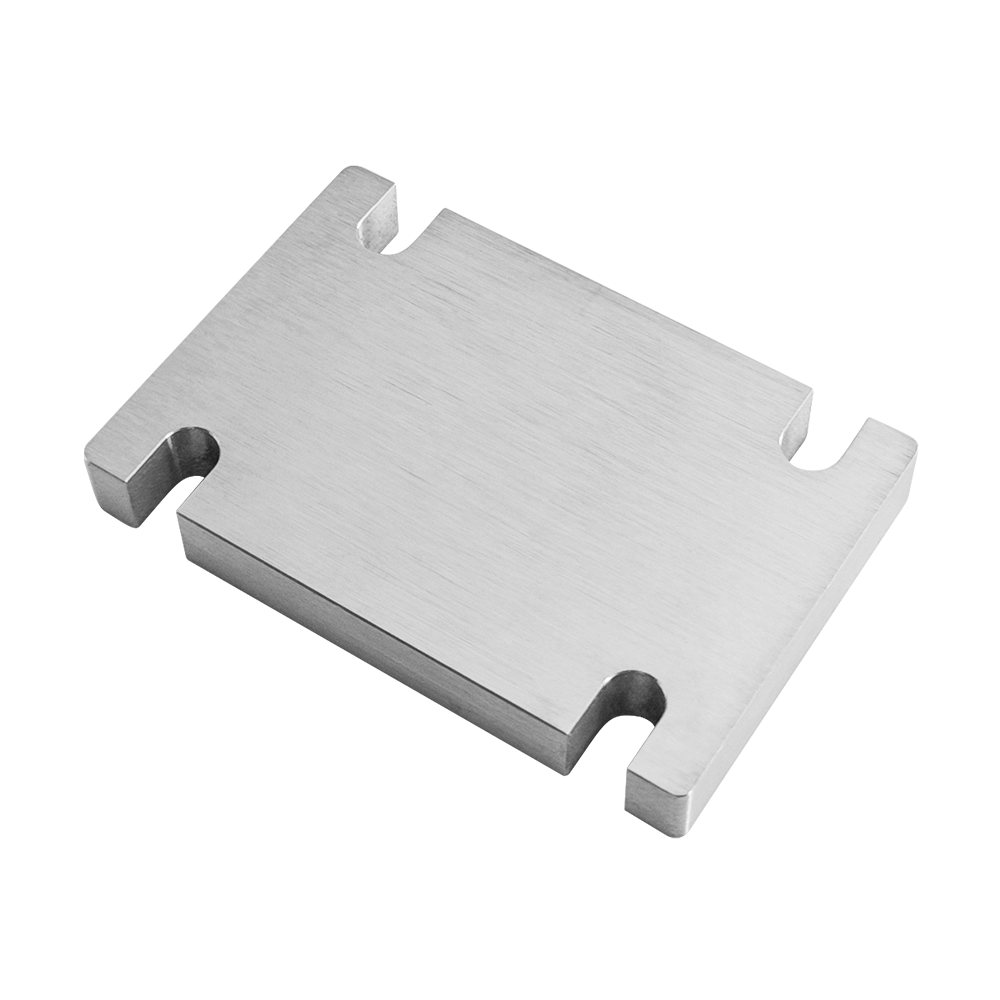

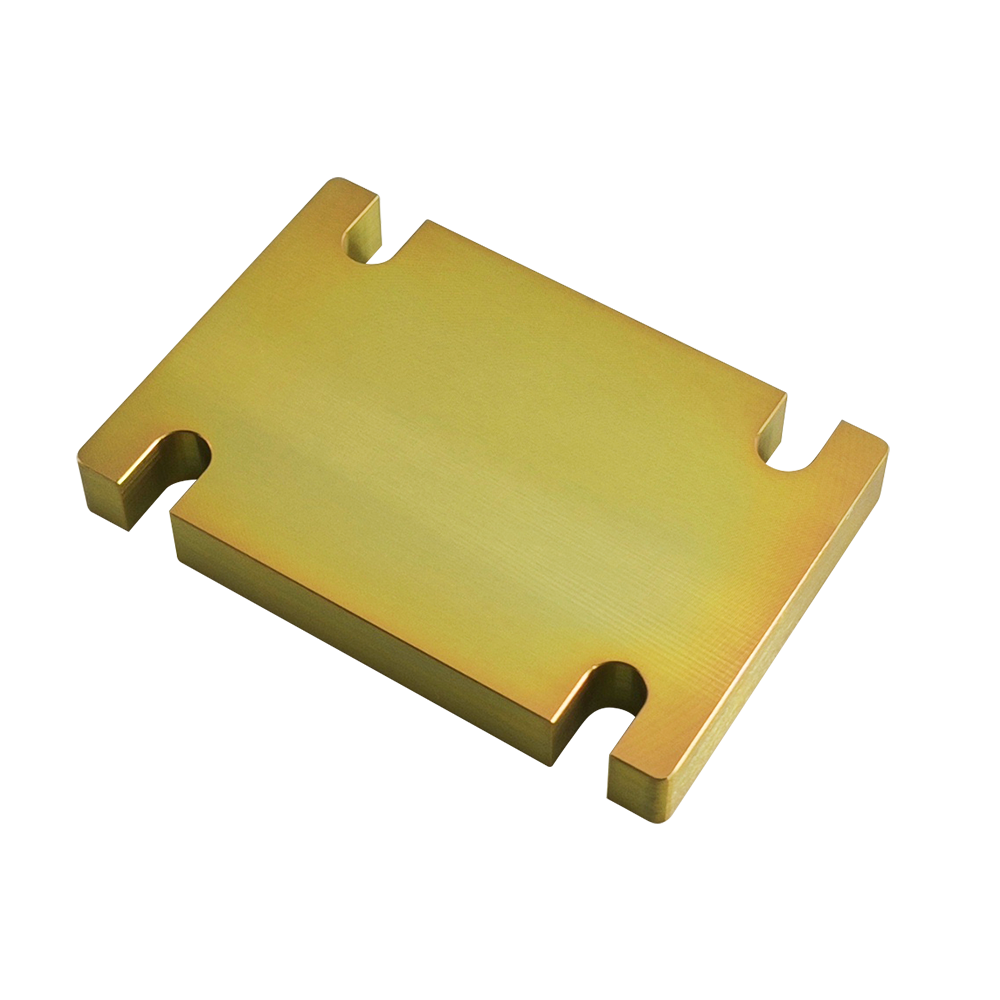

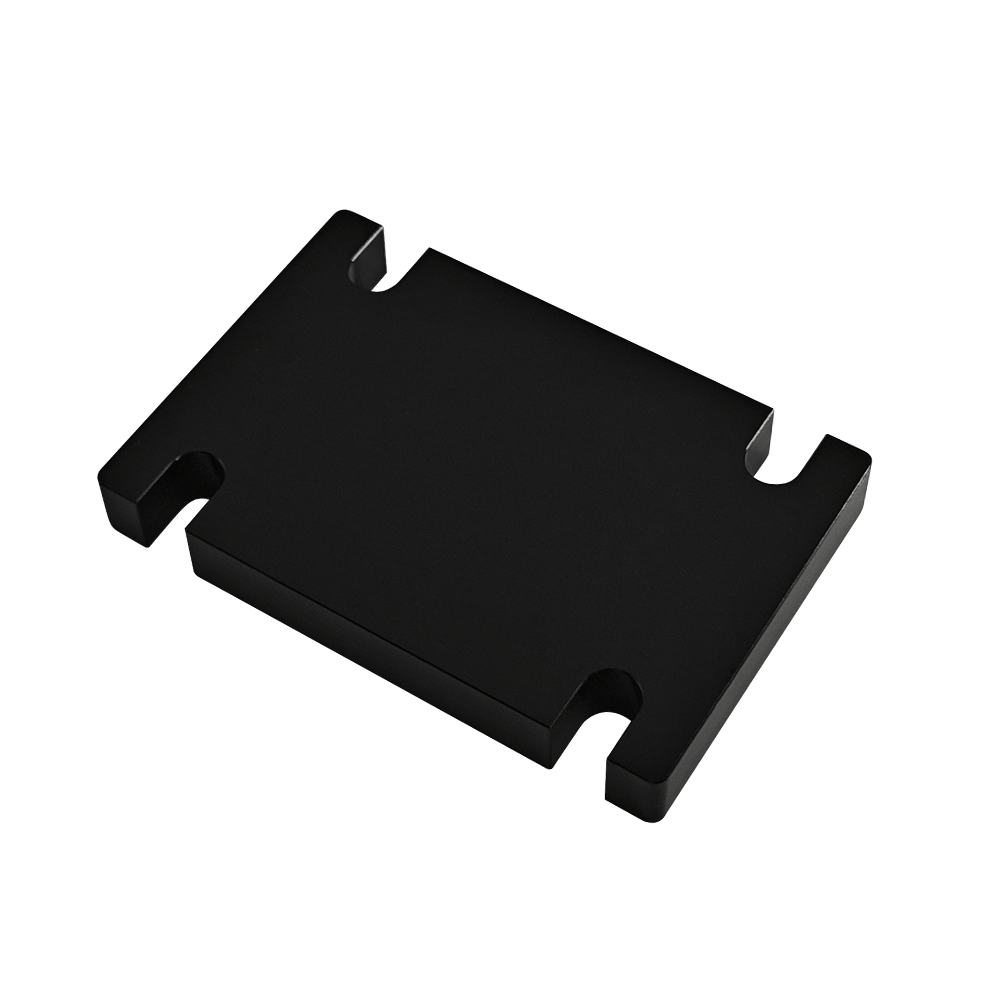

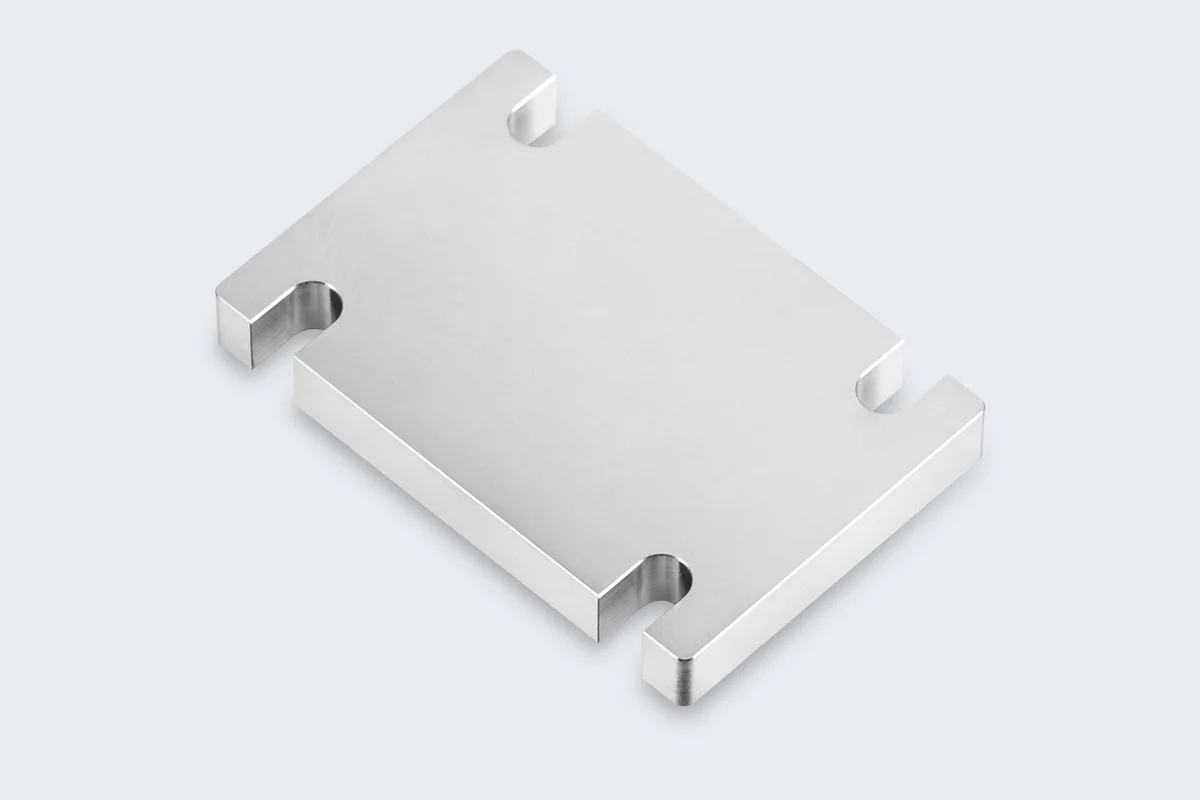

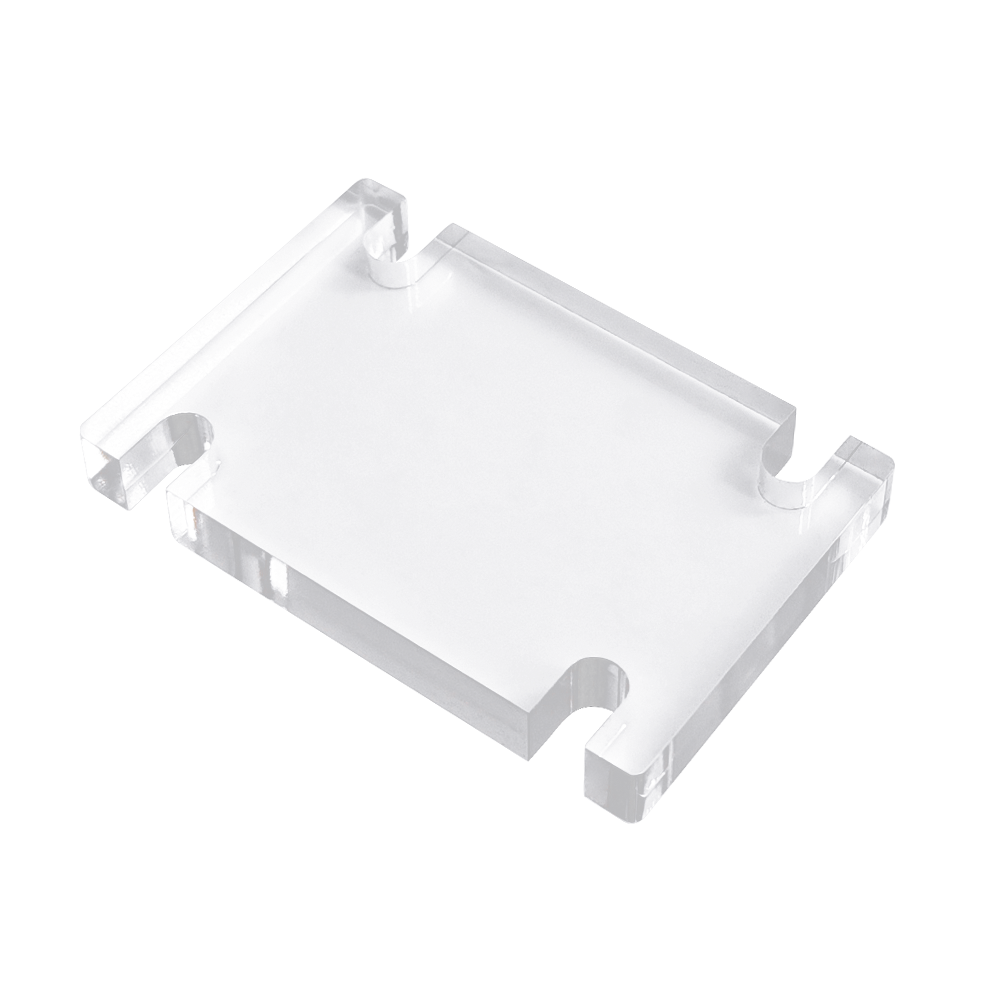

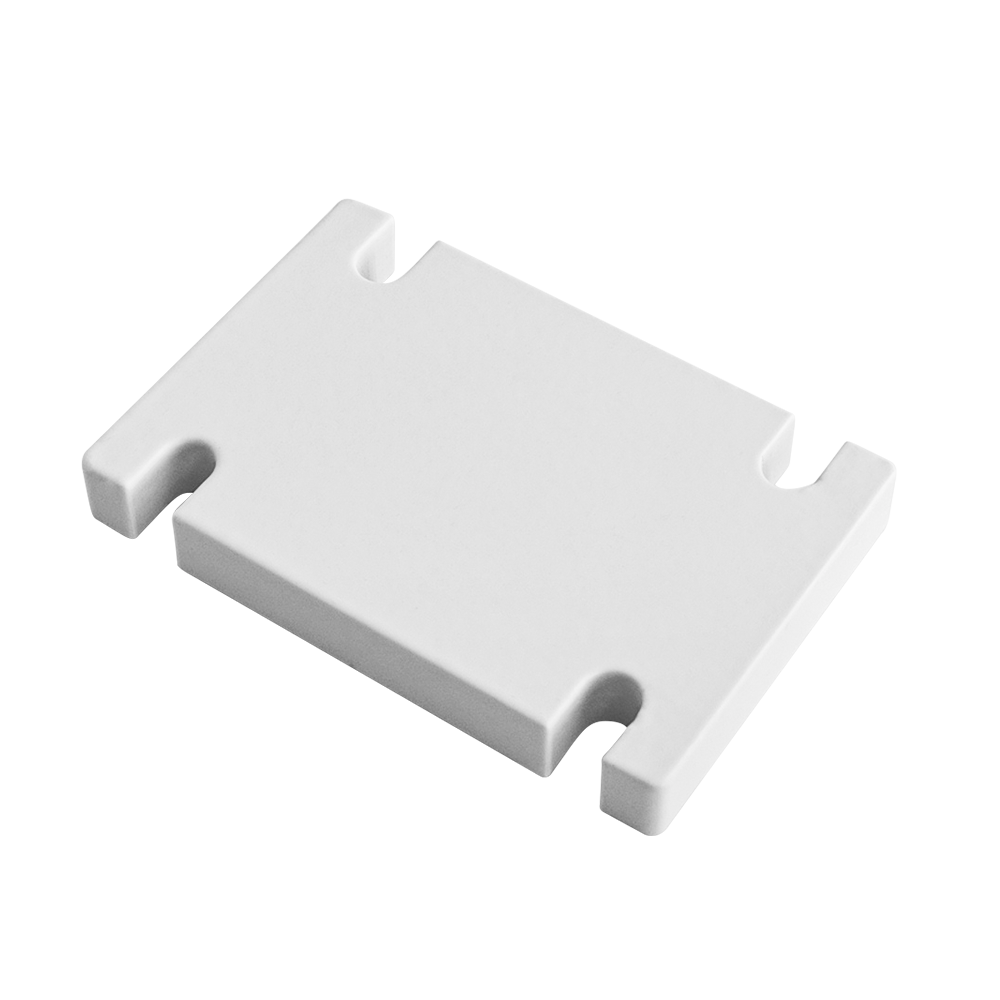

Hydroforming Produktpräsentation

Unsere Hydroforming-Dienstleistungen bieten innovative Lösungen zur Formgebung von Metallbauteilen mittels Hochdruckflüssigkeiten und ermöglichen so komplexe Geometrien und Leichtbaustrukturen. Jedes Bauteil demonstriert unsere Fähigkeit, gleichmäßige Wandstärken und eine außergewöhnliche Oberflächenqualität zu erzielen und eignet sich daher ideal für Anwendungen in der Automobil-, Luft- und Raumfahrt- sowie Fertigungsindustrie.

Hydroforming Toleranzen

LS Manufacturing ist spezialisiert auf Hydroforming mit Toleranzen von ±0,5 mm bis ±1,0 mm, abhängig vom Material und der Komplexität des Bauteils. Unser Hydroforming-Verfahren ermöglicht die Herstellung leichter, hochfester Teile mit komplexen Geometrien und glatten Oberflächen und eignet sich daher ideal für vielfältige Anwendungen in der Automobil-, Luft- und Raumfahrt- sowie Industriebranche.

Besonderheit

Beschreibung

Maximale Teilegröße

1,5 m x 1,5 m

Metallbiegekräfte

Bis zu 1000 Tonnen

Biegelinienlänge

Bis zu 7200 mm

Biegedicke

Bis zu 60 mm

Allgemeine Toleranzen

Unsere Normen für das Metallbiegen basieren auf ISO 2768.

An Kante/Loch biegen, einseitige Oberfläche

+/- 0,254 mm (+/- 0,010 Zoll)

Hydroforming Materialauswahl

Unsere Hydroforming-Dienstleistungen nutzen eine Reihe von Werkstoffen, darunter Aluminium, Edelstahl und hochfeste Stähle, um komplexe, leichte Strukturen mit exzellenter Maßgenauigkeit herzustellen. Diese Werkstoffe werden aufgrund ihrer Beständigkeit gegenüber Hochdruckanwendungen ausgewählt, wodurch die Fertigung komplexer Formen ohne aufwendige Werkzeugausstattung möglich ist. Hydroforming ist besonders vorteilhaft für Anwendungen in der Automobil- und Luftfahrtindustrie, wo leichte und robuste Bauteile unerlässlich sind.

Metalle

- Titan

- Stahl

- Edelstahl

- Magnesium

- Zinklegierung

- Chrom-Nickel-Legierung

- Messing

- Kupfer

- Aluminium

- Bronze

- Kaltgewalzter Stahl

- Nickel

- Silber-Zinn-Oxid

- Gusseisen

Titan ist bekannt für seine hohe Festigkeit, sein geringes Gewicht und seine Korrosionsbeständigkeit. Wir verarbeiten Sorten wie Ti-6Al-4V, Ti-5Al-2,5Sn, Ti-6Al-4V ELI und Ti-Grade 2, die in der Luft- und Raumfahrt, bei medizinischen Implantaten und Sportgeräten weit verbreitet sind.

Kunststoffe

- HDPE

- PP

- PE

- HAUSTIER

- PMMA

- POM

- PPS

- PVC

- FR-4

- SPÄHEN

- ABS

- PC

- PA

- HÜFTEN

- LDPE

- PBT

- PPA

- PAI

- PS

- PTFE (Teflon)

- UPE

- Bakelit

HDPE bietet hohe Festigkeit und Beständigkeit gegen Stöße und Chemikalien. Wir befürworten seine Verwendung in Behältern, Rohrleitungen und Geokunststoffdichtungsbahnen.

Wir bieten kundenspezifische Anpassungen an Ihre individuellen Materialanforderungen an. Sollten Sie ein hier nicht aufgeführtes Material benötigen, kann unser Team es beschaffen und so verarbeiten, dass es Ihren genauen Bedürfnissen entspricht.

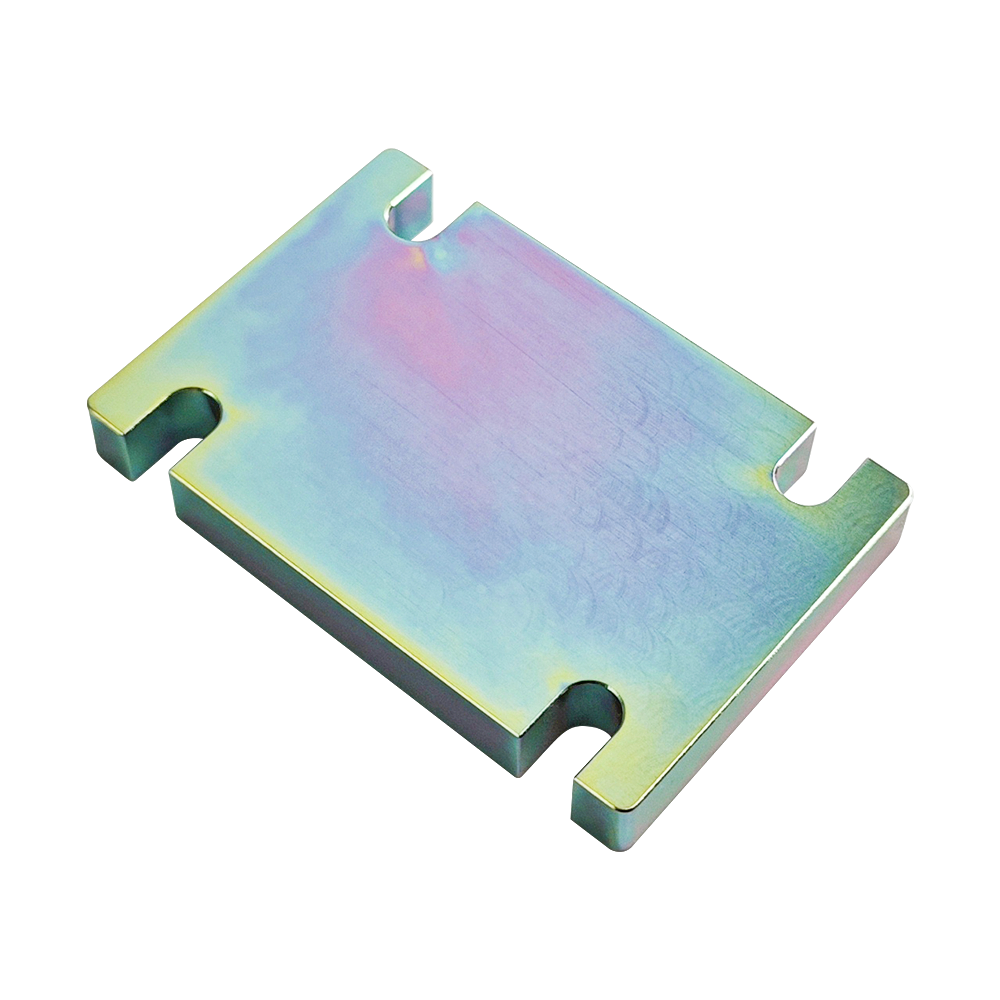

Hydroforming Oberflächenveredelung

Die Oberflächenbearbeitung ist beim Hydroforming entscheidend für die Qualität und Funktionalität der geformten Bauteile. Unser Hydroforming-Verfahren ermöglicht komplexe Formen und Leichtbaukonstruktionen. Nachbearbeitungsverfahren wie Polieren, Beschichten und Oberflächenhärten verbessern die Oberflächenglätte, die Korrosionsbeständigkeit und die Gesamtlebensdauer und gewährleisten so optimale Ergebnisse in vielfältigen Anwendungen.

Anodisieren Glänzend

Bei der Anodisierung Typ I wird eine schützende Oxidschicht auf dem Aluminium erzeugt, die Korrosions- und Verschleißbeständigkeit bietet.

Kugelstrahlen

Ein Verfahren, bei dem ein Luftstrom genutzt wird, um feine Partikel durch das Material zu schleudern und so eine Oberfläche zu reinigen, zu glätten oder zu strukturieren.

Schwarz oxidieren

Schwarzoxid ist eine Konversionsbeschichtung, die nur einen minimalen Korrosionsschutz bietet und aus optischen Gründen verwendet wird.

Sandstrahlen + Schwarzanodisieren

Ein Verfahren, bei dem ein Luftstrom genutzt wird, um feine Partikel durch das Material zu schleudern und so eine Oberfläche zu reinigen, zu glätten oder zu strukturieren.

Bürste

Durch das Bürsten entsteht eine satinartige Textur auf Metalloberflächen, wodurch deren Aussehen verbessert und Reflexionen reduziert werden.

Anodisierung Typ II (glänzend, matt)

.png)

Bei der Anodisierung Typ II wird eine schützende Oxidschicht auf Aluminium erzeugt, die Korrosions- und Verschleißbeständigkeit bietet.

Goldchromat

Die Verchromung sorgt für eine helle, spiegelähnliche Oberfläche und verbessert die Verschleiß- und Korrosionsbeständigkeit.

Polieren + Schwarz eloxieren

Durch Polieren werden die Oberflächenbeschaffenheit und der Glanz von Metallen verbessert, indem Kratzer und Unreinheiten entfernt werden.

Polieren + Klar eloxieren

Durch Polieren werden die Oberflächenbeschaffenheit und der Glanz von Metallen verbessert, indem Kratzer und Unreinheiten entfernt werden.

Dampfpolitur

Dampfpolieren ist eine Technik zur Verbesserung der Transparenz und Glätte von Kunststoffbauteilen.

Weiße Pulverbeschichtung - Flach

Die Pulverbeschichtung sorgt für eine langlebige und hochwertige Oberfläche, die das Aussehen und die Korrosionsbeständigkeit von Metallen verbessert.

Verzinkung

Durch Verzinken wird eine schützende Zinkschicht auf Stahl oder Eisen aufgebracht, wodurch die Korrosionsbeständigkeit erhöht wird.

Hydroforming Vorteile und Merkmale

Unsere Hydroforming-Dienstleistungen bieten innovative Lösungen für die Herstellung komplexer, hochfester Metallteile mit höchster Präzision und Effizienz. LS Manufacturing ist spezialisiert auf Hydroforming-Verfahren für verschiedenste Branchen und gewährleistet so die Fertigung hochwertiger Komponenten, die anspruchsvollen Spezifikationen gerecht werden. Deshalb sind wir Ihr bevorzugter Partner für Hydroforming.

Hohe Präzision und komplexe Formen

Hydroforming ermöglicht die Herstellung komplexer Formen und tiefer Ziehungen bei gleichzeitig außergewöhnlicher Maßgenauigkeit. Diese Eigenschaft ist unerlässlich für Anwendungen in Branchen wie der Automobil-, Luft- und Raumfahrt- sowie der HLK-Industrie, wo die Komplexität des Designs von entscheidender Bedeutung ist.

Materialeffizienz

Das Hydroforming-Verfahren optimiert den Materialeinsatz, reduziert Abfall und maximiert gleichzeitig Festigkeit und Integrität des Endprodukts. Diese Methode ist besonders vorteilhaft für Leichtmetalllegierungen und ermöglicht die Herstellung von festen und dennoch leichten Bauteilen.

Erhöhte Festigkeit und Haltbarkeit

Durch Hydroforming hergestellte Bauteile weisen typischerweise verbesserte mechanische Eigenschaften auf, darunter höhere Festigkeit und Dauerfestigkeit. Daher ist Hydroforming eine ideale Wahl für Komponenten, die in anspruchsvollen Anwendungen hohen Belastungen standhalten müssen.

Reduzierte Sekundäroperationen

Durch Hydroforming entfällt häufig die Notwendigkeit zusätzlicher Bearbeitungsschritte, was kürzere Lieferzeiten und geringere Produktionskosten ermöglicht. Diese Effizienz optimiert den gesamten Fertigungsprozess und beschleunigt die Markteinführung Ihrer Produkte.

Skalierbarkeit von Prototypen bis zur Serienproduktion

Unsere Hydroforming-Dienstleistungen sind skalierbar und eignen sich sowohl für Kleinserien als auch für die Großserienfertigung. Wir wickeln Aufträge unterschiedlicher Größe effizient ab und gewährleisten so die nötige Flexibilität für Ihre Projektanforderungen.

Umfassende Qualitätssicherung

Wir setzen im gesamten Hydroforming-Prozess strenge Qualitätskontrollmaßnahmen ein. Unsere fortschrittlichen Prüfverfahren und die Zertifizierungen nach ISO 9001, ISO 14001, IATF 16949 und AS9100D gewährleisten, dass jedes Bauteil höchsten Ansprüchen an Leistung und Zuverlässigkeit genügt.

Hydroforming Fallstudien

Unsere Hydroforming-Dienstleistungen wurden bereits erfolgreich in verschiedenen Branchen eingesetzt. Nachfolgend einige Beispiele, die unsere Fähigkeit zur Herstellung hochwertiger, komplexer Formen und Bauteile verdeutlichen, die auf spezifische Branchenbedürfnisse zugeschnitten sind:

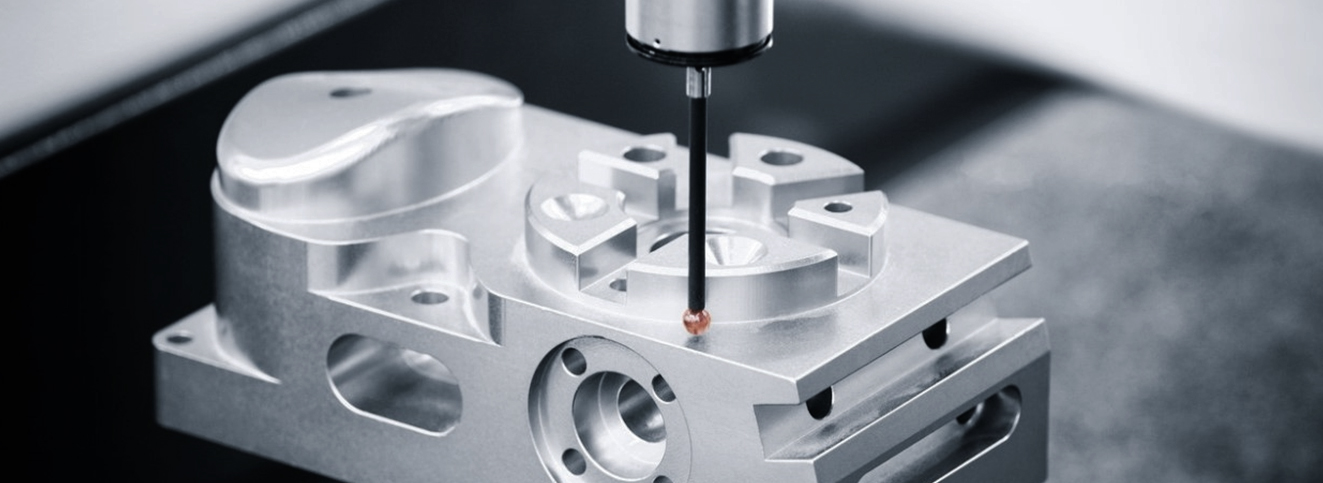

Hydroforming Qualitätskontrolle

Bei LS Manufacturing sind wir auf Hydroforming spezialisiert, ein Verfahren, mit dem wir komplexe Formen mit hoher Präzision und exzellenter Materialintegrität herstellen können. Unsere fortschrittliche Hydroforming-Technologie ermöglicht uns die Fertigung leichter und gleichzeitig robuster Bauteile für vielfältige Anwendungen. Strenge Qualitätskontrollen gewährleisten, dass jedes hydrogeformte Teil höchsten Qualitäts- und Leistungsstandards entspricht.

Prozessbegleitende Inspektionen

Unsere Qualitätskontrolle beginnt mit prozessbegleitenden Prüfungen, bei denen jedes Teil in verschiedenen Produktionsphasen kontrolliert wird, um die Einhaltung der Konstruktionsvorgaben sicherzustellen. Dieser proaktive Ansatz hilft, etwaige Probleme frühzeitig im Fertigungsprozess zu erkennen und zu beheben.

Endabnahmen

Bevor ein Bauteil unser Werk verlässt, wird es einer gründlichen Endkontrolle unterzogen, um seine Qualität und Präzision zu gewährleisten. Wir verwenden modernste Messinstrumente und -verfahren, um sicherzustellen, dass jedes Bauteil die geforderten Spezifikationen und Normen erfüllt.

Präzisionsmessgeräte

Wir setzen modernste Präzisionsmessgeräte ein, darunter Koordinatenmessgeräte (KMG) und Laserscanner, um sicherzustellen, dass unsere hydrogeformten Bauteile enge Toleranzen und Spezifikationen erfüllen. Diese Werkzeuge ermöglichen es uns, während des gesamten Hydroforming-Prozesses ein hohes Maß an Genauigkeit und Qualität zu gewährleisten.

ISO 9001-, ISO 14001-, IATF 16949- und AS9100D-Zertifizierung

Unser Qualitätsanspruch wird durch unsere Zertifizierungen nach ISO 9001, ISO 14001, IATF 16949 und AS9100D belegt. Diese internationalen Standards gewährleisten, dass unser Qualitätsmanagementsystem effektiv ist und sich kontinuierlich verbessert, sodass wir unseren Kunden stets Produkte von gleichbleibend hoher Qualität liefern können.

Kontinuierliche Verbesserung

Wir glauben an kontinuierliche Verbesserung und überprüfen regelmäßig unsere Prozesse und Vorgehensweisen, um Optimierungspotenzial zu identifizieren. Durch Investitionen in modernste Technologien und die Weiterbildung unserer Mitarbeiter streben wir danach, unseren Ruf für Qualität und Innovation zu wahren.

Benötigen Sie Hilfe? Wir sind für Sie da.

Bei Fragen oder falls Sie Hilfe benötigen, steht Ihnen unser Team rund um die Uhr zur Verfügung. Kontaktieren Sie uns über einen der untenstehenden Wege.

Wir verstehen, dass Sie möglicherweise Fragen zu unserer Dienstleistung im Bereich Hydroforming haben. Hier finden Sie Antworten auf einige der häufigsten Fragen, die Ihnen helfen sollen, unsere Kompetenzen und Prozesse besser zu verstehen. Sollten Sie weitere Unterstützung benötigen, steht Ihnen unser Team jederzeit gerne zur Verfügung.

Was unsere Kunden über uns sagen

Die Worte unserer Kunden wiegen mehr als unsere eigenen. Sehen Sie selbst, was unsere zufriedenen Kunden darüber gesagt haben, wie wir ihre Anforderungen erfüllt haben.

Hydroforming Neueste Nachrichten

Bleiben Sie mit den neuesten Nachrichten und Ankündigungen von LS Manufacturing auf dem Laufenden. Entdecken Sie unsere aktuellen Artikel weiter unten.