In the ever-evolving landscape of manufacturing, deep draw stamping has emerged as a cornerstone process, transforming the way metal components are produced. Deep draw stamping, synonymous with precision and efficiency, is the backbone of numerous industries, facilitating the creation of intricate designs with unmatched consistency. LS Hardware Tech Co., Ltd, a pioneering name in the field, exemplifies excellence in custom metal fabrication, offering state-of-the-art solutions that meet the most rigorous standards of quality and performance.

Founded by the visionary entrepreneur Mr. Nick Zhang with a skilled team of engineers, LS Hardware Tech Co., Ltd has etched its name in the industry with over two decades of unparalleled experience. Establishing itself as a beacon of innovation and reliability, the company specializes in manufacturing both hardware and plastic parts. With a clientele that includes more than 5,000 satisfied customers globally, LS Hardware Tech has proven its mettle in precision deep draw stamping, crafting high-quality products that cater to diverse sectors such as automotive, medical devices, consumer electronics, aerospace, and industrial equipment.

The cornerstone of LS Hardware Tech's success is its unwavering commitment to quality and technological advancement. With an ISO 9001:2015 certification, the company's factory boasts over 100 high-end machining centers that enhance production efficiency and product excellence. This dedication to precision is manifest in their latest offering: the UltraFlow Compact Filter. Engineered with meticulous attention to detail, this filter represents a leap forward in fluid filtration technology.

Deep draw stamping is not merely a process; it is an art that transforms metal sheets into complex, three-dimensional shapes through a series of carefully controlled operations. This method enables the production of deep drawn parts with consistent wall thickness and flawless structural integrity. By stretching metal material with a die, deep drawing allows for the creation of components such as automotive body panels, fuel tanks, and even household appliances, where durability and consistency are paramount.

What sets deep draw stamping apart is its ability to accommodate various materials like aluminum, steel, copper, and brass, each offering unique properties suited to specific applications. This flexibility, combined with precision engineering, enables custom metal fabrication that can be tailored to the specific needs of clients. LS Hardware Tech’s prowess in the stamping process is underscored by its ability to deliver parts with extraordinary precision, meeting exacting design requirements while minimizing waste.

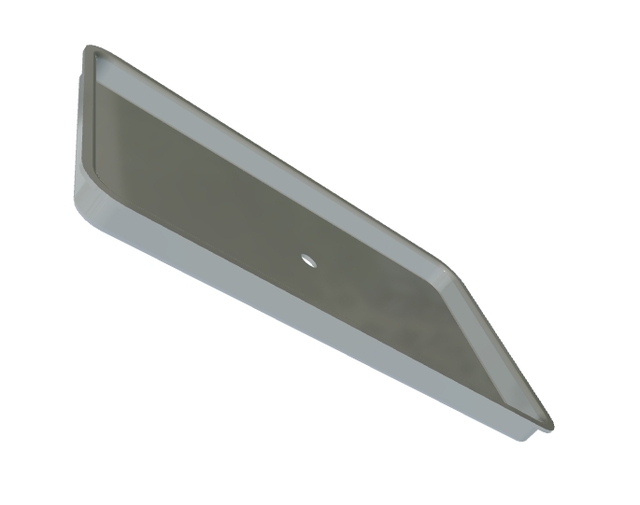

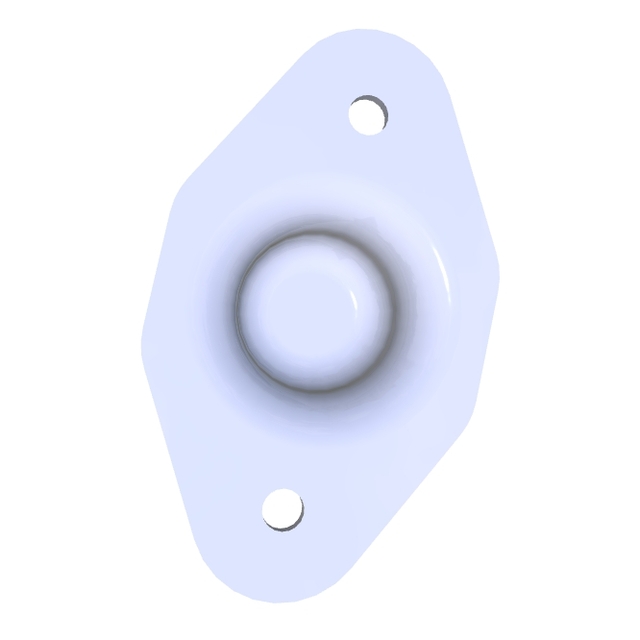

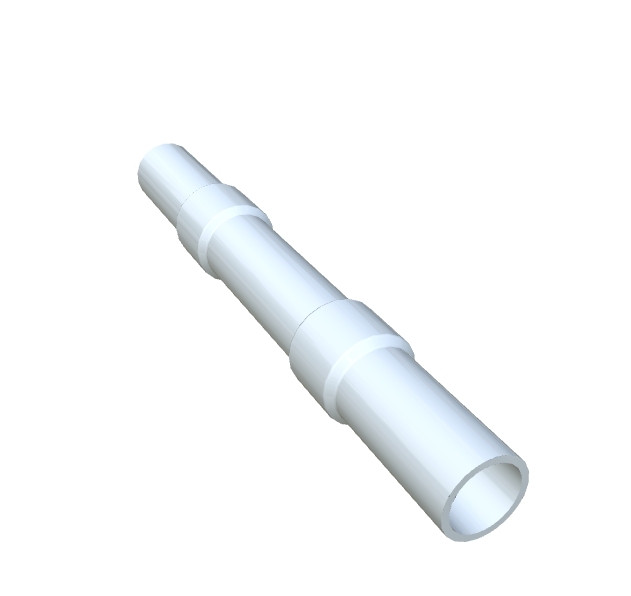

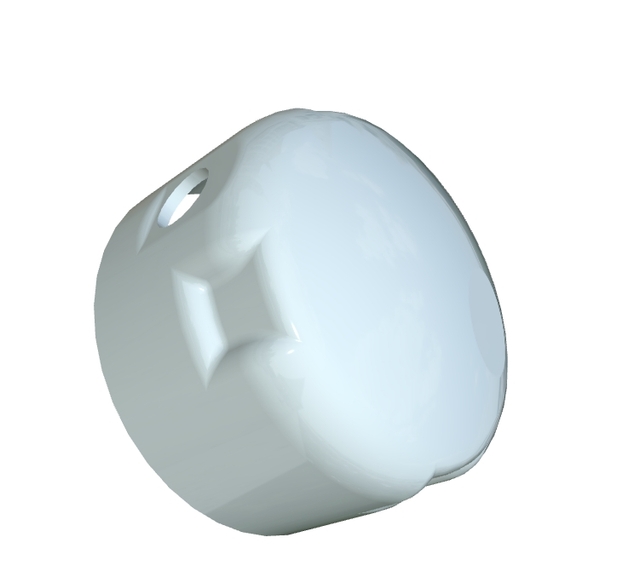

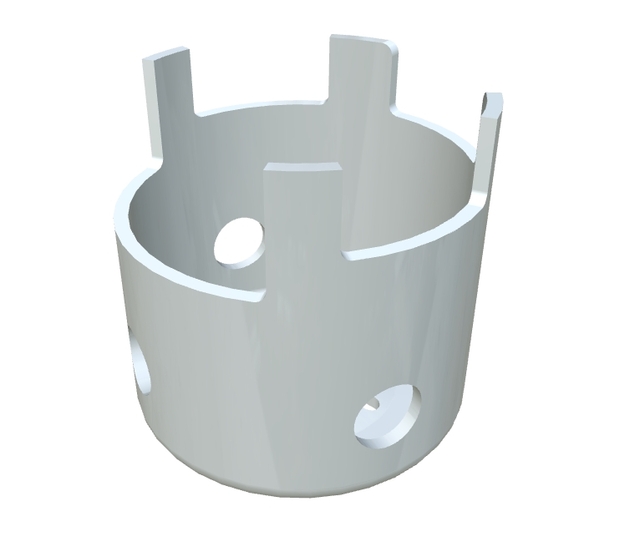

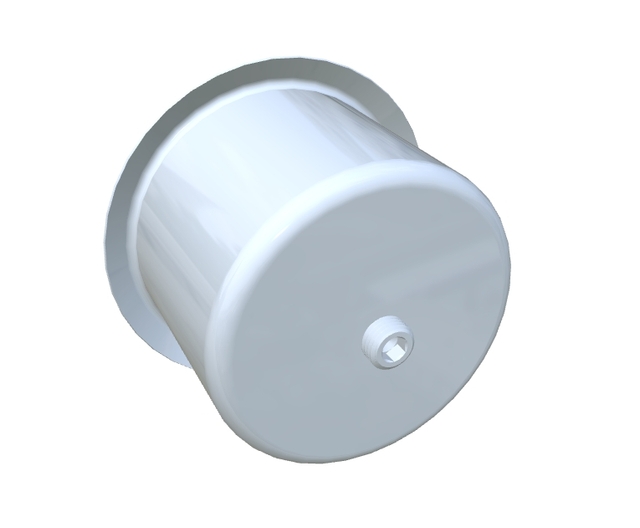

As industries continue to demand innovative solutions, the applications of deep draw stamping are expanding. The custom metal fabrication expertise at LS Hardware Tech is evident in its ability to integrate deep drawing metal techniques into the development of new products. The UltraFlow Compact Filter is a prime example of such innovation, blending cutting-edge design with practical functionality. Its sleek cylindrical design is not only aesthetically pleasing but also highly efficient, offering a high-performance filtration system that ensures pure, clean fluid in both residential and commercial settings.

The UltraFlow Compact Filter boasts a compact design that facilitates easy installation and maintenance, a hallmark of LS Hardware Tech's commitment to making precision engineering accessible and user-friendly. The small port in the front enhances connectivity and ease of use, fitting seamlessly into any modern environment. This product exemplifies the expert application of deep draw stamping in creating components that embody both elegance and efficiency.

In a market where precision and reliability are non-negotiable, LS Hardware Tech Co., Ltd stands out as a trusted partner for companies worldwide. Their mission to deliver innovative manufacturing solutions empowers clients to realize their visions, backed by a robust foundation of advanced technology and continuous process improvement. With a customer base that spans more than 150 countries, LS Hardware Tech's reach and impact are truly global, establishing a benchmark for excellence in the realm of deep draw stamping applications.

Looking to the future, LS Hardware Tech Co., Ltd remains at the forefront of technological advancements, continually refining their capabilities to meet the evolving needs of their clients. The company's commitment to fostering innovation ensures that they are not only meeting the demands of today but are also poised to tackle the challenges of tomorrow. By harnessing the power of deep draw stamping and precision engineering, LS Hardware Tech is charting a course for a future where creativity and precision converge to deliver superior products and solutions.

In conclusion, the process of deep draw stamping, as perfected by experts like LS Hardware Tech Co., Ltd, underscores the importance of precision in the manufacturing industry. With their dedication to quality, commitment to innovation, and focus on customer satisfaction, LS Hardware Tech is more than just a supplier – it is a partner in pushing the boundaries of what's possible in custom metal fabrication and beyond.

No data

Deep Draw Stamping: Precision & Applications

最新価格を入手 >

| Label | Value |

|---|---|

| ブランド | LSカスタムパーツメーカー |

| カスタマイズサービス | 金属プレス加工, プログレッシブダイスタンピング, 深絞りスタンピング, ハイドロフォーミング, ブランク |

| 描画形式 | 2d/(pdf/cad)、3d(iges/step/glb) |

| 材料能力 | アルミニウム、真鍮、銅、銅、硬化金属、貴金属、ステンレス鋼、合金、TPR |

| サンプル | 無料 |

| 供給能力 | 1日あたり100000個 |

| 表面仕上げ | カスタマイズされた仕上げ |

| 厚さ | カスタマイズされた厚さ |

| タイプ | ブローチ/掘削/エッチング/化学機械加工/レーザー加工/ミリング/ターニング/ワイヤーEDM/ラピッドプロトタイピング/その他の機械加工サービス |

| サービス | CNCの機械加工、金属鋳造、射出成形、板金製造、迅速なプロトタイピング、3D印刷 |

類似製品を探す

製品説明

レビュー

接触

LS Manufacturing で次のプロジェクトを始める準備はできていますか?

当社のサービスの詳細と、お客様の目標達成を当社がどのようにサポートできるかを知りたい場合は、今すぐお問い合わせください。

LS Manufacturing

LS Manufacturingわずか 1 営業日から始まる迅速なリード タイム。

ISO 9001、ISO 14001、IATF 16949、AS9100D 認証。

100 種類以上の素材と 50 種類以上の表面仕上げオプションをご用意しています。

コスト効率の良い大量生産。

1個からご注文いただけます。