Hydroforming technology is revolutionizing the way industries approach complex metal shaping, offering significant advantages over traditional manufacturing processes. As industries shift towards innovative solutions, hydroforming has garnered attention for its unique ability to create lightweight, durable components efficiently. This advanced manufacturing technology, utilized by companies like **LS Hardware Tech Co., Ltd**, is changing the landscape in which products like the sleek and innovative rectangular containment tray are designed and produced.

At the core of hydroforming technology lies the **hydroforming process**, a technique that uses a high-pressure hydraulic fluid to shape metal into complex shapes with precision. This process is highly beneficial for creating complex geometric shapes that would otherwise require multiple steps through traditional methods. Unlike stamping or metal pressing, which can lead to structural weakness, hydroforming maintains the integrity and strength of the material, making it ideal for lightweight yet robust parts. Industries such as automotive, aerospace, and consumer electronics have seen a surge in the use of hydroforming due to its efficiency in producing high-quality components with minimal waste.

The advantages of hydroforming are plentiful. This method offers enhanced flexibility in design, allowing for parts with intricate shapes and contours to be produced in one smooth operation. The **hydroforming advantages** extend to reducing the number of parts needed, which decreases assembly time and cost. Moreover, hydroformed parts typically exhibit superior mechanical properties, including increased strength and reduced weight. The metal formed in this process is less likely to experience micro-cracks or weaknesses, ensuring high durability over time. Such benefits align perfectly with the mission of LS Hardware Tech Co., Ltd, a company that prides itself on delivering high-precision components crafted with innovation at their core.

The practical applications of **hydroforming technology** are vast and varied. From producing lightweight car components to critical structural parts in the aerospace industry, the versatility of hydroforming cannot be overstated. The ability to form both **hydroforming aluminum** and **hydroforming steel** makes this technique highly adaptable to different materials, expanding its application across numerous fields. In the automotive industry, for instance, hydroforming is not only instrumental in crafting chassis and body panels but also in developing performance-enhancing components that improve fuel efficiency by reducing overall vehicle weight.

**LS Hardware Tech Co., Ltd**, leveraging its extensive experience and advanced machining capabilities, has been pivotal in integrating hydroforming technology into its manufacturing processes. Established by Mr. Nick Zhang alongside a team of seasoned engineers, LS has carved a niche for itself in providing innovative solutions to more than 5,000 clients globally. The company specializes in creating high-precision hardware and plastic parts for key industries, including automotive, medical, aerospace, and consumer electronics. With a strong emphasis on quality and reliability, LS has implemented hydroforming techniques to enhance its product offerings, such as the cutting-edge rectangular containment tray.

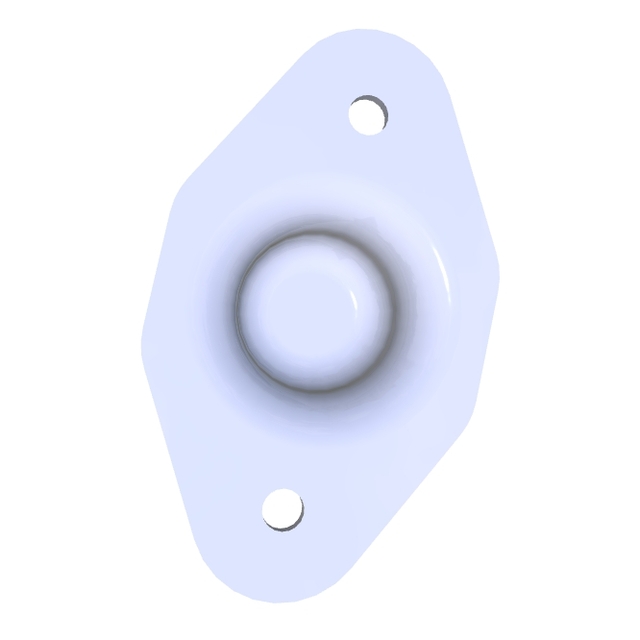

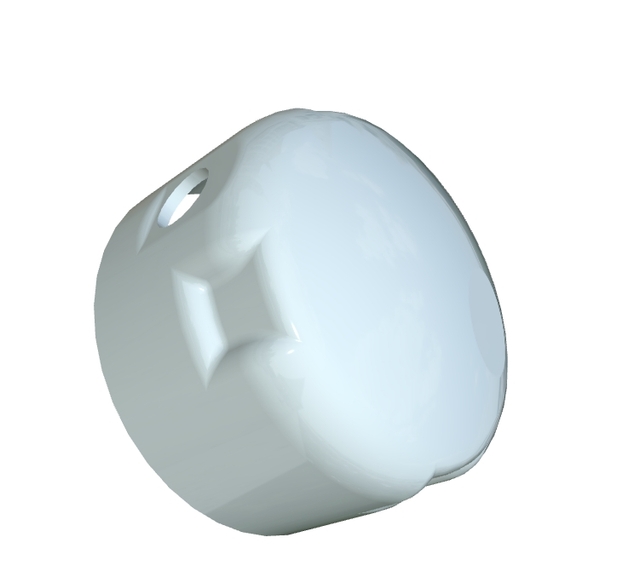

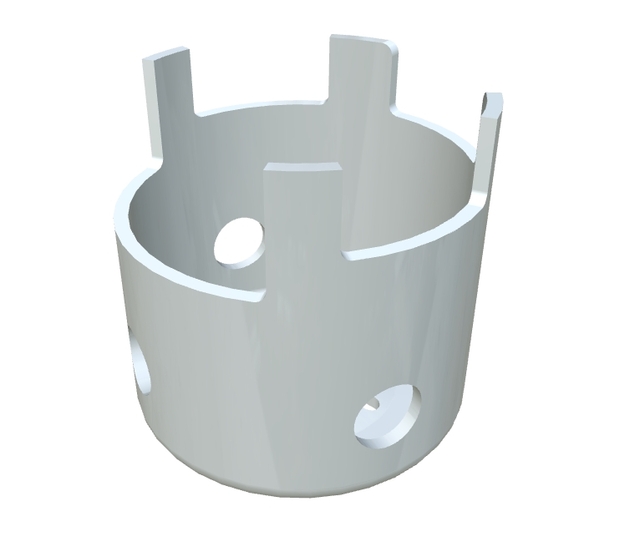

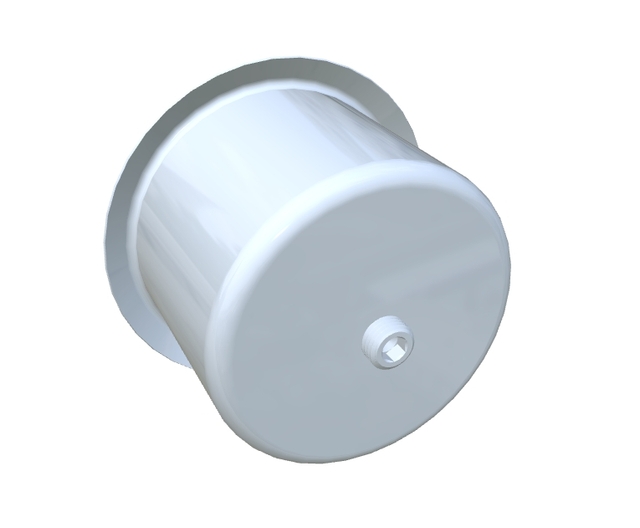

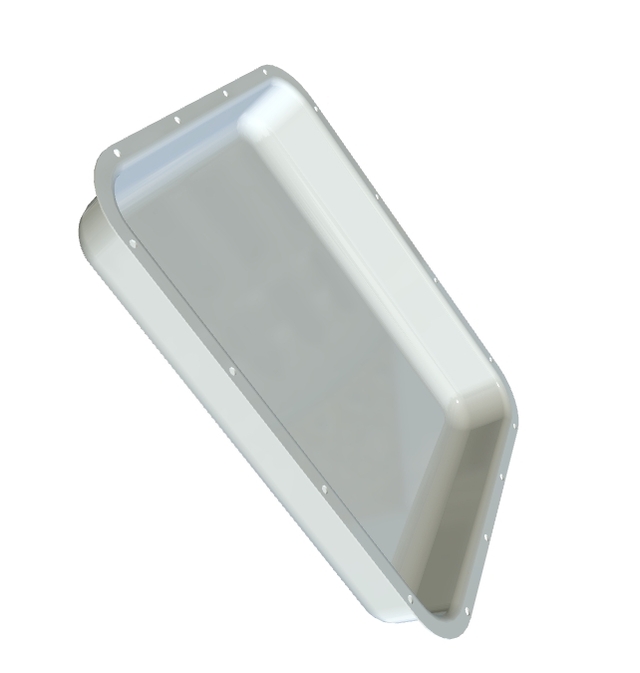

This particular containment tray exemplifies the prowess of hydroforming in producing practical yet aesthetically pleasing products. Crafted from durable, high-grade materials, it features a seamless finish that not only ensures longevity but also enhances fluid management, making it ideal for both industrial and laboratory settings. Its minimalist design, coupled with pre-drilled fastening holes for easy installation, highlights the dual focus on style and functionality. This elegant solution caters to the needs of users seeking efficient product design without compromising on sophistication.

**LS Hardware Tech Co., Ltd** continues to lead the charge in innovative manufacturing processes, with hydroforming playing a critical role in its operational strategy. The company's factory, equipped with over 100 high-end machining centers, ensures high production efficiency and top-notch quality, a testament to their commitment to excellence. With an ISO 9001:2015 certification, LS remains a trusted partner to major factories across China and beyond, with services reaching more than 150 countries. By continually improving processes and embracing technological advancements, LS maintains its mission to empower clients and bring their ideas to life, setting a benchmark of innovation in an ever-evolving global market.

In conclusion, hydroforming technology offers a transformative approach to metal shaping, effectively meeting the demands of modern manufacturing. The seamless integration of this process by LS Hardware Tech Co., Ltd highlights its potential to deliver superior products across various industries. Coupled with a commitment to quality and innovation, hydroforming sets a new standard for manufacturing excellence, enabling the creation of cutting-edge products like the innovative rectangular containment tray. As industries continue to seek more efficient and sustainable production methods, hydroforming is poised to play an ever-increasing role in driving future advancements in design and engineering.

Revolutionize with Innovative Hydroforming Technology

최신 가격 확인하기 >

| Label | Value |

|---|---|

| 상표 | LS 사용자 정의 부품 제조업체 |

| 맞춤형 서비스 | 금속 스탬핑, 프로그레시브 다이 스탬핑, 딥 드로우 스탬핑, 하이드로포밍, 블랭킹 |

| 그리기 형식 | 2D/(PDF/CAD) 、 3D (IGES/STEP/GLB) |

| 재료 기능 | 알루미늄 、 황동 、 브론즈 、 구리 、 경화 금속 、 귀금속 、 스테인레스 스틸 、 합금 、 tpr |

| 견본 | 무료 |

| 공급 능력 | 하루에 100000 조각 |

| 표면 마감 | 맞춤형 마무리 |

| 두께 | 맞춤형 두께 |

| 유형 | 브로치/드릴링/에칭/화학 가공/레이저 가공/밀링/회전/와이어 EDM/빠른 프로토 타이핑/기타 가공 서비스 |

| 서비스 | CNC 가공, 금속 주조, 사출 성형, 판금 제조, 빠른 프로토 타이핑, 3D 프린팅 |

연락하다

LS Manufacturing과 함께 다음 프로젝트를 시작할 준비가 되셨나요?

저희 서비스에 대해 더 자세히 알아보고 목표 달성을 위해 어떻게 도움을 드릴 수 있는지 알고 싶으시면 지금 바로 연락주세요.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., Ltd빠른 납기: 최소 1영업일부터 가능.

ISO 9001, ISO 14001, IATF 16949 및 AS9100D 인증.

100가지 이상의 소재와 50가지 이상의 표면 마감 옵션을 선택할 수 있습니다.

비용 효율적인 대량 생산.

최소 1개부터 주문 가능합니다.