In the ever-evolving world of advanced manufacturing, hydroforming technology stands out as a cutting-edge method that offers versatility and efficiency in shaping complex parts. This sophisticated process is used to form metals into lightweight and durable components, making it a critical component in industries that demand high precision and quality. At the forefront of this innovative technology is LS Hardware Tech Co., Ltd, a leading company that leverages hydroforming to deliver exceptional manufacturing solutions to its global clientele.

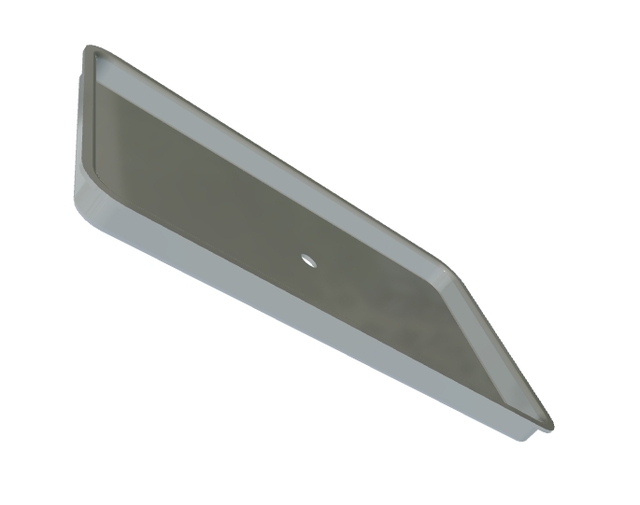

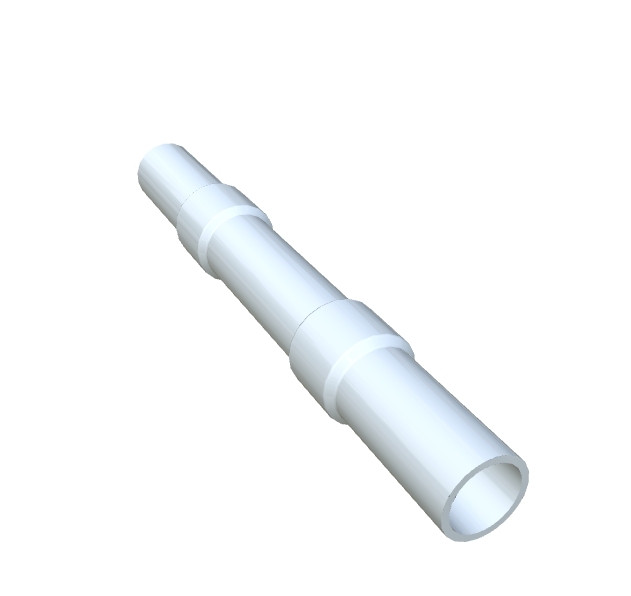

Hydroforming technology involves the direct shaping of a metal blank into a desired form using a high-pressure hydraulic fluid. Unlike traditional stamping processes, hydroforming enables the creation of smooth, deep contours without the need for welding seams or creating multiple parts. This process not only enhances the structural integrity of the components but also helps reduce material waste, making it an attractive option for environmentally conscious manufacturers. The advantages of hydroforming are particularly evident when comparing hydroforming vs stamping, as hydroforming allows for more intricate designs and offers superior surface finishes.

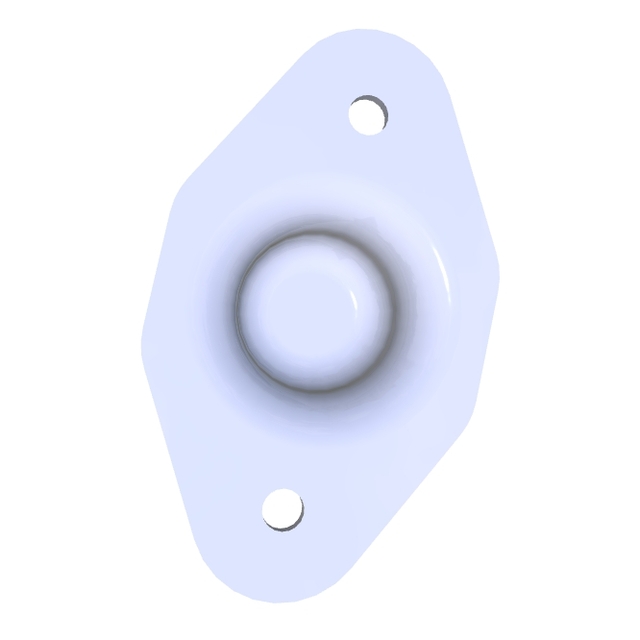

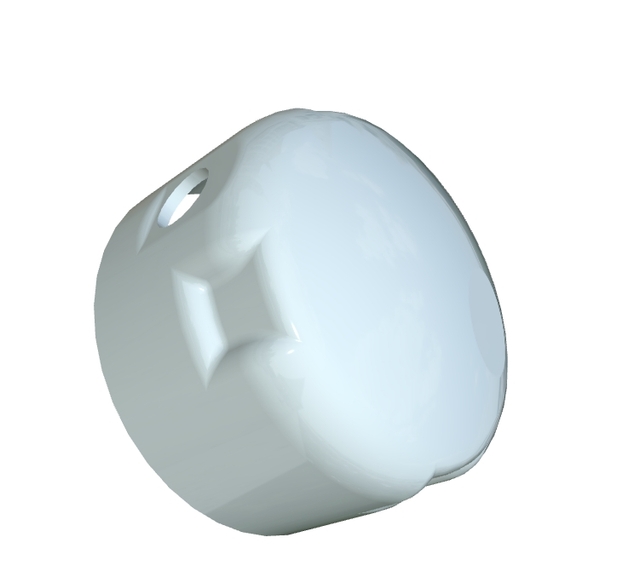

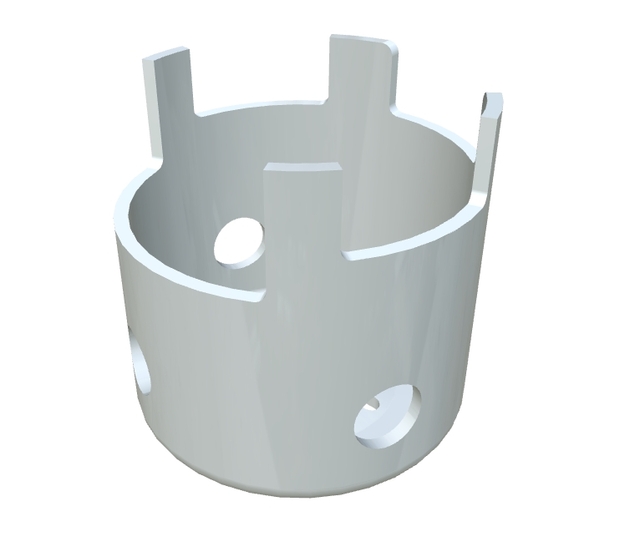

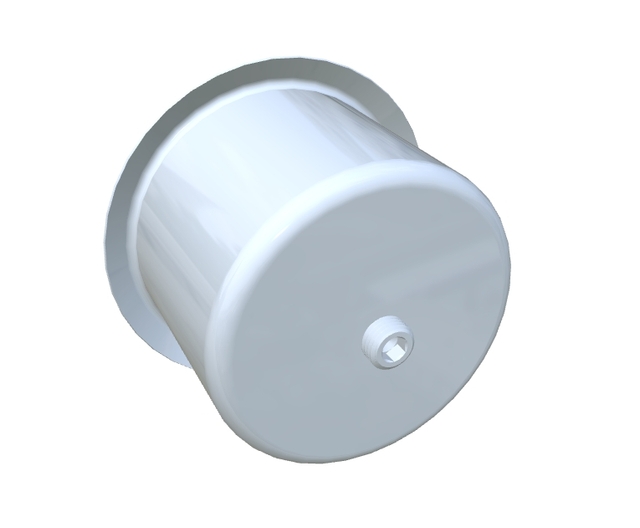

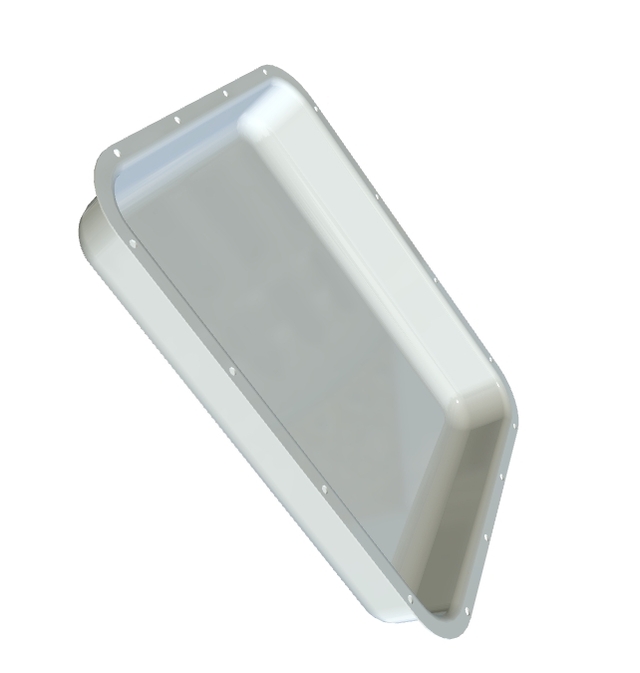

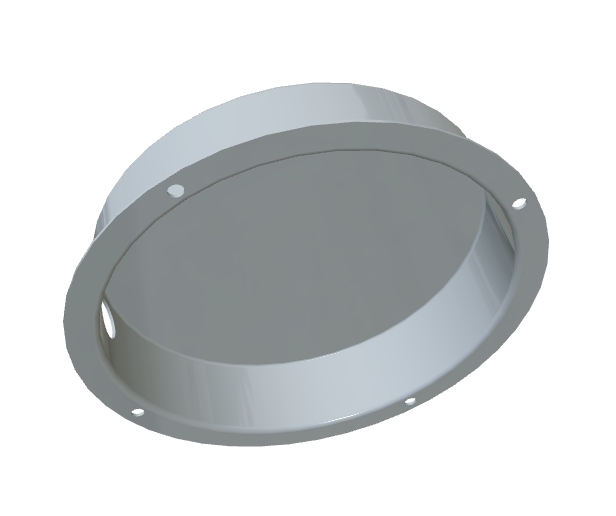

One of the standout products featured by LS Hardware Tech Co., Ltd is the circular duct plate, a perfect embodiment of the benefits of hydroforming technology. Crafted from high-quality metal, this duct plate showcases the precision engineering and ease of installation that LS is renowned for. The circular duct plate is not only built to withstand the rigorous demands of both commercial and residential applications but is also aesthetically refined with a polished finish that ensures resistance to corrosion and wear. Its pre-drilled holes allow for quick and hassle-free mounting, a feature that aligns perfectly with LS's commitment to combining functionality with style.

LS Hardware Tech Co., Ltd, established by Mr. Nick Zhang and his team of seasoned engineers, has made significant strides in advancing the capabilities of hydroforming to produce high-precision parts for a broad spectrum of industries including automotive, medical devices, consumer electronics, aerospace, and industrial equipment. Backed by ISO 9001:2015 certification, LS is dedicated to maintaining top-tier quality and providing clients with innovative manufacturing solutions. The company's state-of-the-art facility, equipped with over 100 high-end machining centers, enhances their ability to offer efficient and flexible production capabilities, whether for prototypes or large-scale manufacturing.

Hydroforming applications are extensive and varied, demonstrating the process's adaptability to diverse manufacturing challenges. For instance, in the automotive industry, hydroforming is utilized to produce lightweight yet sturdy components, contributing to fuel efficiency and performance enhancements. Similarly, in aerospace and industrial equipment manufacturing, the ability to fabricate complex shapes with minimal joint seams is invaluable, as it allows for improved aerodynamics and strength.

The future of hydroforming technology continues to evolve, with continuous improvements in machinery and techniques aimed at enhancing productivity and expanding the range of materials that can be effectively hydroformed. Companies like LS are at the forefront of these advancements, perpetually seeking to refine their processes and capabilities to meet the ever-changing demands of their customers. By doing so, LS not only maintains its leadership position in the field but also empowers its clients to bring their innovative ideas to life with unparalleled precision and quality.

Thus, as industries continue to adopt more sustainable and efficient manufacturing practices, hydroforming technology emerges as a pivotal method in the production of high-quality metal components. LS Hardware Tech Co., Ltd exemplifies how mastery over this technology can result in superior products such as the circular duct plate, which meets the highest standards of performance while offering a visually appealing solution for modern ventilation systems. Indeed, as hydroforming continues to shape the future of manufacturing, companies that embrace this technology will remain at the cutting edge of industrial innovation.

Exploring Hydroforming Technology: Advancements and Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping, Blanking |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Exploring the Hydroforming Process: Advantages & Applications

Revolutionizing Industries: Hydroforming Process Advantages & Applications

Revolutionizing Manufacturing with Hydroforming Techniques

Exploring the Hydroforming Process: Applications, Advantages & Technology

Revolutionize with Innovative Hydroforming Technology

Exploring Hydroforming Technology: Advancements and Applications

Exploring Hydroforming Process: Advantages & Applications

Revolutionizing Part Fabrication: The Hydroforming Process