The advent of the hydroforming process has revolutionized manufacturing techniques across various industries, proving to be a game-changer with its numerous applications and standout advantages. At the heart of this technological evolution lies the concept of hydroforming technology, which fundamentally reshapes materials through high-pressure means, creating components that are both intricate and durable. Initialization of the hydroforming process involves taking advantage of hydraulic fluid pressure to manipulate a piece of metal into the desired form, making it a preferred choice for producing lightweight, strong, and intricate designs.

Hydroforming techniques are typically applied in the automotive, aerospace, and appliance industries where precision and durability are paramount. Utilizing hydroforming machines, manufacturers are able to produce complex shapes and geometries that are often unattainable through traditional metal forming methods. The versatility of hydroforming materials, which ranges from aluminum and stainless steel to copper and titanium, allows for broad application across different manufacturing needs. This adaptability contributes significantly to the hydroforming advantages, making it an enticing choice for producing components that require specific characteristics like reduced weight and enhanced strength.

The process of high-pressure hydroforming is particularly beneficial for industries demanding high strength-to-weight ratio components. Coupled with the sophistication of modern hydroforming machines, it's possible to achieve seamless and resilient structures with minimal material waste—a principle benefit that has considerable economic implications. This efficiency also emerges from minimized need for welding or additional joinery, which in turn results in cleaner, stronger parts, boosting both quality and structural integrity.

Located at the crossroads of innovation and precision, LS Hardware Tech Co., Ltd has embraced the advent of hydroforming technology to advance its manufacturing solutions. Founded by Mr. Nick Zhang alongside a cadre of veteran engineers, LS has excelled in crafting high-precision parts for an array of sectors, highlighted by automotive, medical devices, consumer electronics, and aerospace industries. With over two decades in operation, LS stands on a foundation of expertise, outfitted with over 100 high-end machining centers, reflecting their dedication to high production efficiency and premium product quality.

True to its ethos, LS marries tried-and-tested manufacturing prowess with the pioneering nature of modern technologies such as the hydroforming process. This synergy ensures they can consistently deliver on their mission to provide innovative solutions that empower clients worldwide—meeting the complexity of today’s manufacturing challenges head-on. Their ISO 9001:2015 certification underscores their commitment to quality, assuring clients of the reliability and standard of their offerings.

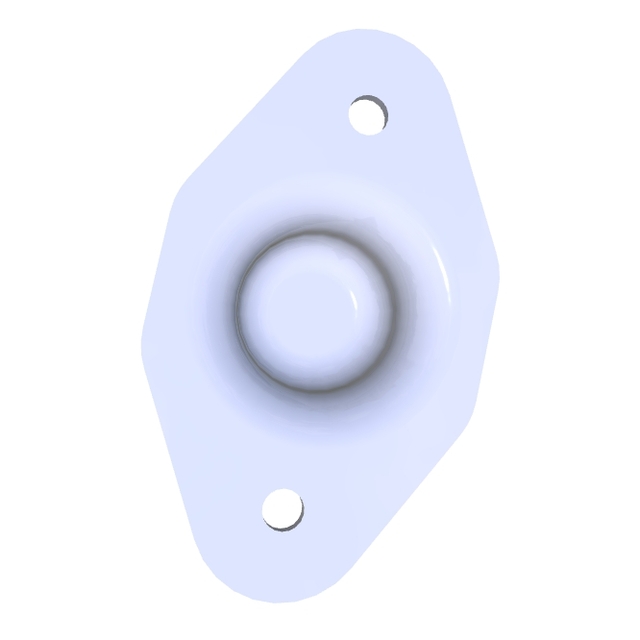

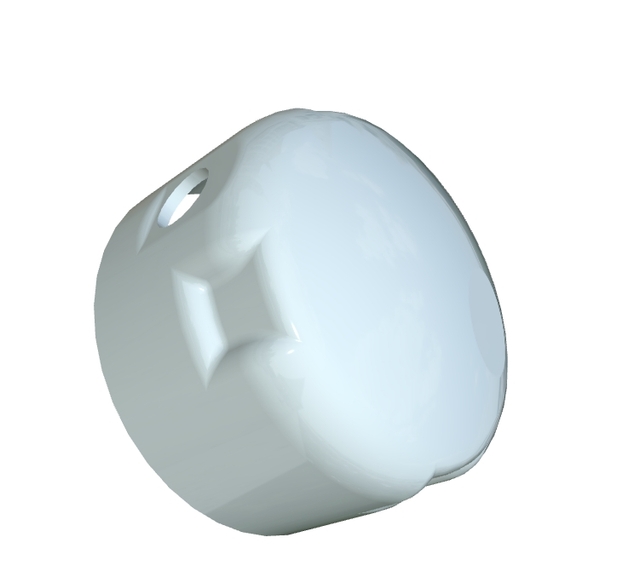

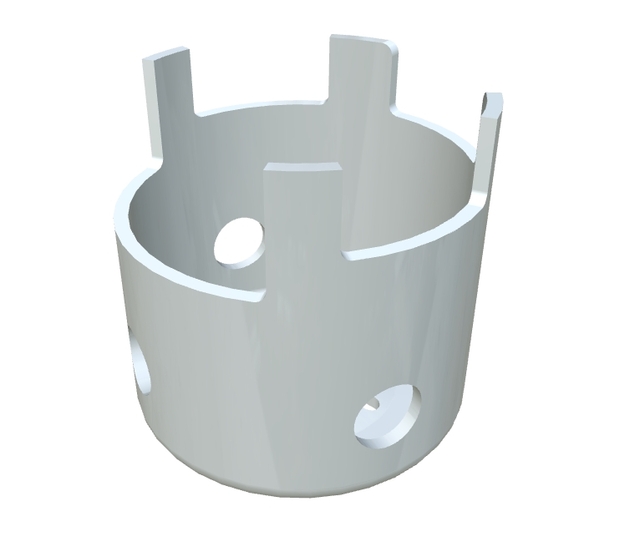

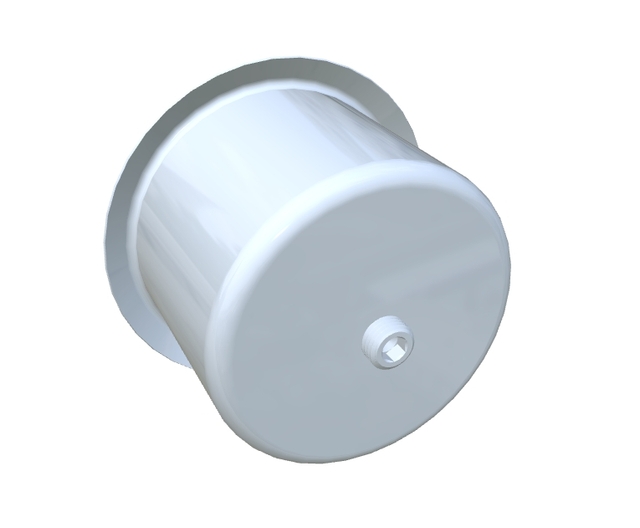

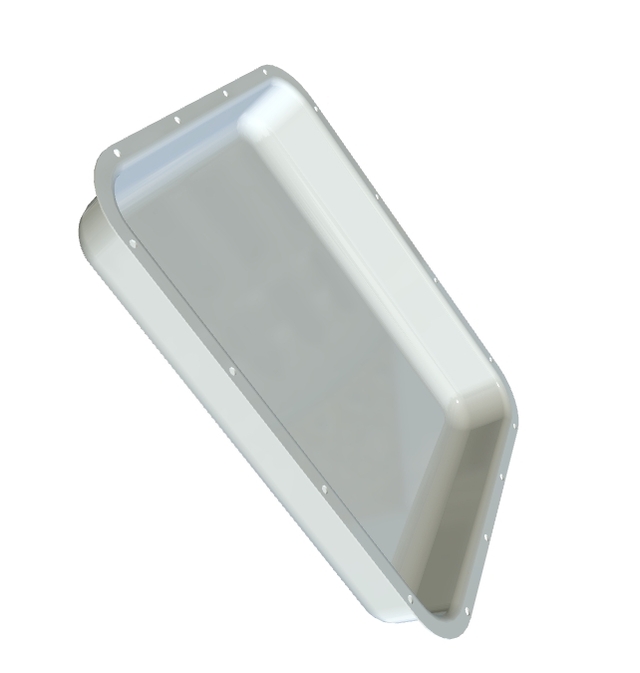

In a move towards modern smart technology, LS Hardware Tech Co., Ltd has recently unveiled an innovation beyond traditional manufacturing: the Wall Smart Plug. Blending sleek design with practicality, this compact device embodies a new era of smart home integration. Crafted from high-gloss, pearl-white materials, it not only enhances visual appeal with its minimalist aesthetic but also meets durability needs, making it an ideal home or office addition.

The Wall Smart Plug is a testament to how technology can interlace with everyday life to enhance efficiency and utility. With its smart functionality, users can monitor and control power usage remotely via a dedicated app, promoting energy efficiency and convenience. This elegantly designed single outlet seamlessly blends into any decor, positioning itself as an unobtrusive essential in the smart home ecosystem. Moreover, its sleek, streamlined contours reflect a touch of elegance that caters to the tech-savvy user who prizes both aesthetic pleasure and practical utility. This product effectively embodies LS’s commitment to pushing the boundaries of what's possible, representing their quest to blend sophistication with functionality.

In a world where industry demands are constantly evolving, LS Hardware Tech Co., Ltd. stands poised to meet these challenges with forward-thinking solutions—illustrating how hydroforming technology can be strategically applied to both standard manufacturing paradigms and innovative smart solutions. As the discussions in manufacturing circles continue to emphasize sustainability and efficiency, the spotlight on hydroforming technology remains bright, capturing the interest of industries that seek versatile, high-quality manufacturing options.

Revolutionizing Industries: Hydroforming Process Advantages & Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Stamping, Progressive Die Stamping, Hydroforming, Deep Draw Stamping, Blanking |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Exploring the Hydroforming Process: Advantages & Applications

Revolutionizing Industries: Hydroforming Process Advantages & Applications

Revolutionizing Manufacturing with Hydroforming Techniques

Exploring the Hydroforming Process: Applications, Advantages & Technology

Revolutionize with Innovative Hydroforming Technology

Exploring Hydroforming Technology: Advancements and Applications

Exploring Hydroforming Process: Advantages & Applications

Revolutionizing Part Fabrication: The Hydroforming Process