In the ever-evolving landscape of modern manufacturing, the role of **sheet metal fabrication** has become increasingly pivotal. As industries continuously push the boundaries of innovation and efficiency, the demand for high-quality, precise metal fabrication services has seen a substantial rise. LS Hardware Tech Co., Ltd is at the forefront of this demand, delivering unmatched capabilities in custom sheet metal fabrication that cater to a myriad of industries worldwide.

Sheet metal fabrication is a versatile process that involves the cutting, bending, and manufacturing of metal sheets into specifically desired shapes and products. This process is fundamental to the creation of components and structures that support a wide array of industries, including automotive, aerospace, consumer electronics, and industrial equipment. With over 20 years of expertise, LS Hardware Tech has mastered this craft, offering cutting-edge solutions that are both innovative and reliable.

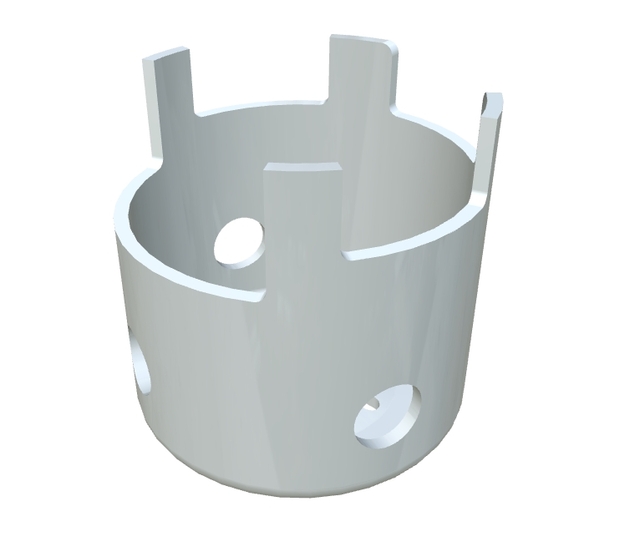

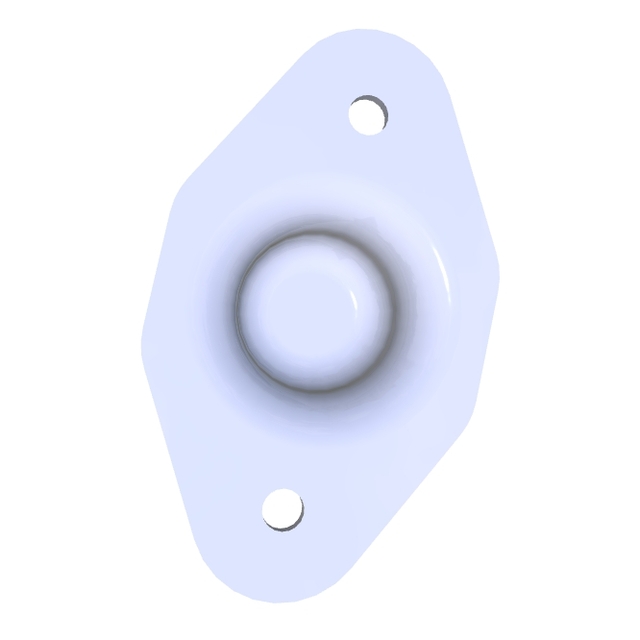

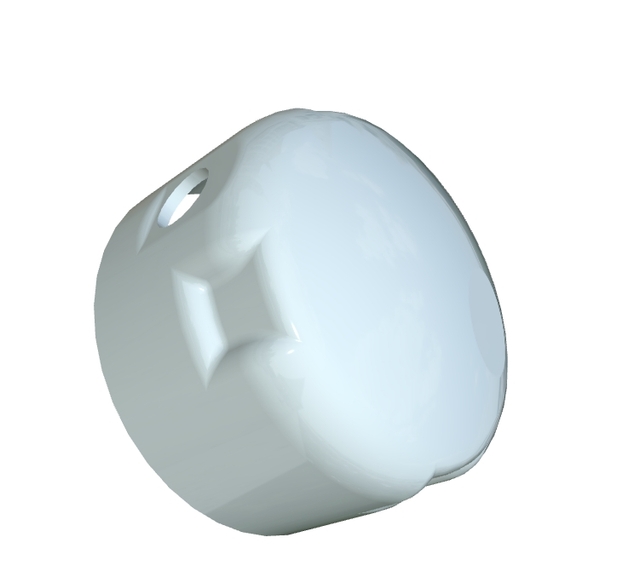

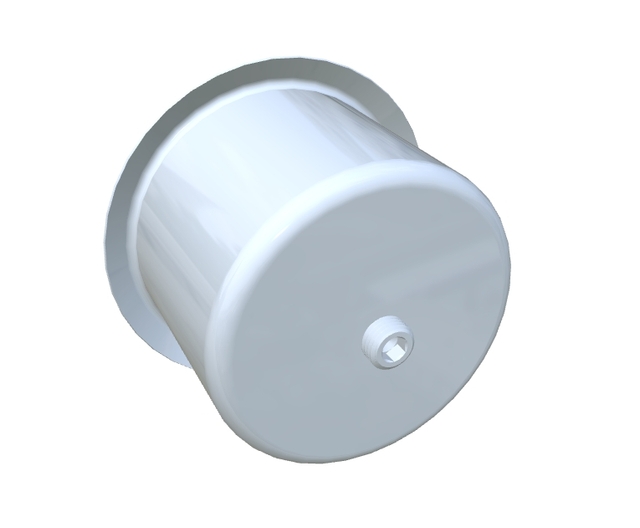

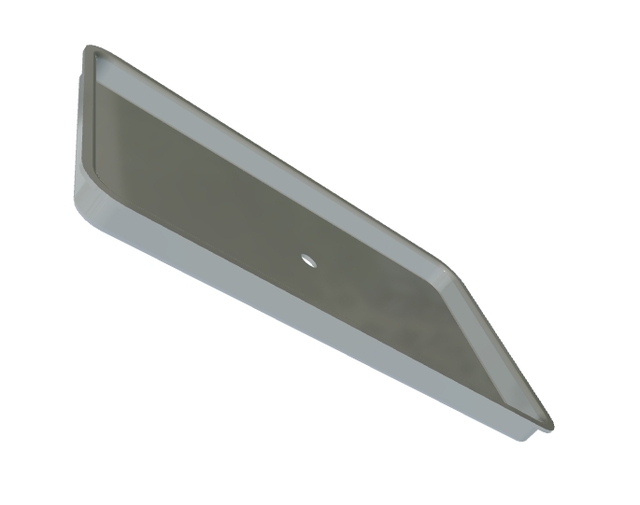

The Multi-Angle Mounting Bracket is one such product that exemplifies the precision and versatility of LS Hardware Tech's sheet metal fabrication capabilities. Engineered for robust performance, this bracket seamlessly integrates into various installations, providing stability and support without compromising on aesthetics. The sleek metallic finish not only ensures longevity but also enhances the modern appeal of the spaces it is utilized in. These attributes make it an ideal choice for both industrial and home applications, exemplifying LS Hardware Tech’s commitment to quality and innovation.

At the heart of LS Hardware Tech's success in the metal fabrication industry is their state-of-the-art facility, housing over 100 high-end machining centers. This infrastructure enables the company to deliver top-quality products with unparalleled production efficiency. Certified to ISO 9001:2015 standards, LS Hardware Tech is a trusted partner for major factories in China and extends its services to more than 150 countries and regions worldwide.

A key service provided by LS Hardware Tech is custom sheet metal fabrication. By leveraging advanced technologies such as laser cutting in sheet metal, the company ensures precision and accuracy in every project. Laser cutting offers a high degree of precision and is capable of creating complex designs that would be challenging to achieve with traditional methods. This technique is essential in the creation of custom brackets, panels, enclosures, and other components that are critical to various applications.

Additionally, the company's expertise extends to the intricate process of sheet metal design and bending. These services ensure that clients receive products that not only fit their specifications but also optimize performance and functionality. With a combination of strategic holes and an angular design, the Multi-Angle Mounting Bracket simplifies complex setups, enhancing load distribution to provide secure and stylish mounting solutions.

LS Hardware Tech's dedication to innovation is evident in its continuous improvement of processes and capabilities to meet the evolving demands of its clients. By understanding the unique challenges faced by industries such as automotive, medical devices, and consumer electronics, the company strives to deliver manufacturing solutions that empower its clients to bring their ideas to life. This customer-centric approach sets LS Hardware Tech apart as a leader in the field of sheet metal fabrication.

With a seasoned team of experienced engineers led by founder Mr. Nick Zhang, LS Hardware Tech prides itself on being at the technological forefront of metal fabrication. Mr. Zhang and his team have cemented their reputation as experts, having provided efficient solutions to over 5,000 clients. This extensive experience, combined with a hunger for innovation, allows LS Hardware Tech to not only meet but exceed the expectations of their clients.

In conclusion, the role of sheet metal fabrication in modern manufacturing cannot be overstated. It is the backbone of precision and quality in product development and plays a crucial role in the innovation and efficiency of industries worldwide. With LS Hardware Tech Co., Ltd leading the charge, clients are assured of products and services that are at the zenith of excellence. Whether it's custom sheet metal fabrication, laser cutting, or metal bending, LS Hardware Tech stands as a beacon of reliability and ingenuity in the metal fabrication industry, delivering solutions that cater to a wide range of applications and industries.

Sheet Metal Fabrication: Key to Modern Manufacturing

Obtenir le dernier prix >

| Label | Value |

|---|---|

| Marque | Fabricants de pièces personnalisées LS |

| Service de personnalisation | Fabrication de tôlerie, Découpe laser, Flexion, Soudage, Estampillage |

| Format de dessin | 2D / (PDF / CAD) 、 3D (IGES / Step / GLB) |

| Capacités matérielles | Aluminium 、 Laiton 、 Bronze 、 Cuivre 、 Métaux durcis 、 Métaux précieux 、 Arec inoxydable 、 Alloys 、 TPR |

| Échantillon | Gratuit |

| Capacité d'offre | 100000 pièces par jour |

| Finition de surface | Finition personnalisée |

| Épaisseur | Épaisseur personnalisée |

| Taper | Broaching / Drilling / graving / Chemical Machining / Laser Usining / Milling / Turning / Wire EDM / Rapid Prototyping / autres services d'usinage |

| Services | Usinage CNC, moulage métallique, moulure d'injection, fabrication de tôles, prototypage rapide, impression 3D |

Contact

Prêt à démarrer votre prochain projet avec LS Manufacturing ?

Contactez-nous dès aujourd'hui pour en savoir plus sur nos services et sur la manière dont nous pouvons vous aider à atteindre vos objectifs.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdDélais de livraison rapides à partir d'un seul jour ouvrable.

Certifications ISO 9001, ISO 14001, IATF 16949 et AS9100D.

Plus de 100 matériaux disponibles, avec plus de 50 options de finition de surface.

Production de masse rentable.

Commandez à partir d'une seule pièce.