In the world of manufacturing, precision and efficiency are paramount. This is particularly true in the realm of progressive die stamping, a process that plays a critical role in shaping various metal parts and components for a wide array of industries. At the forefront of this specialized manufacturing technique is LS Hardware Tech Co., Ltd, a company known for its expertise in producing high-quality parts using advanced technologies.

Progressive die stamping is an automated process used to create metal parts with high precision and efficiency. During progressive die stamping, a strip or coil of metal moves through a series of stations on a stamping press. Each station performs a different operation, such as cutting, bending, or punching, to form the desired shape of the component. This process allows for the continuous production of parts, making it ideal for high-volume manufacturing. LS Hardware Tech Co., Ltd excels in this domain, thanks to its state-of-the-art facilities and the team’s commitment to excellence. With over 20 years of experience in the field, Nick Zhang and his team have built a reputation for delivering top-quality metal stamping services.

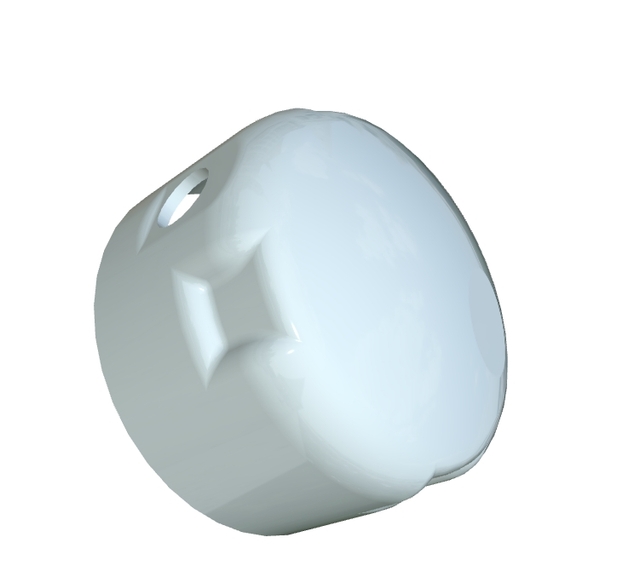

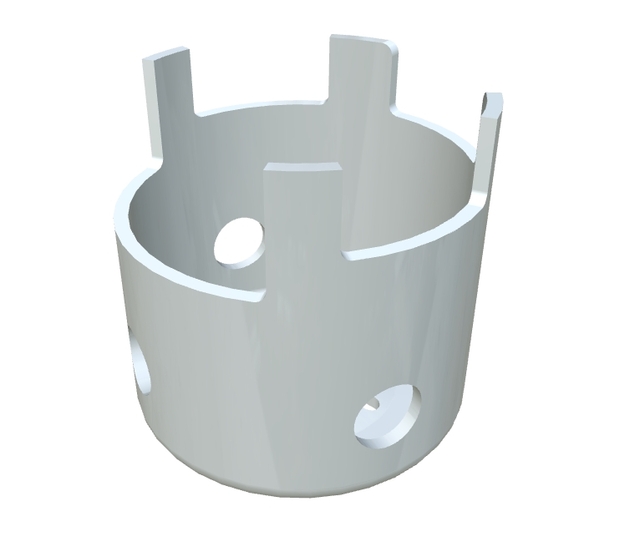

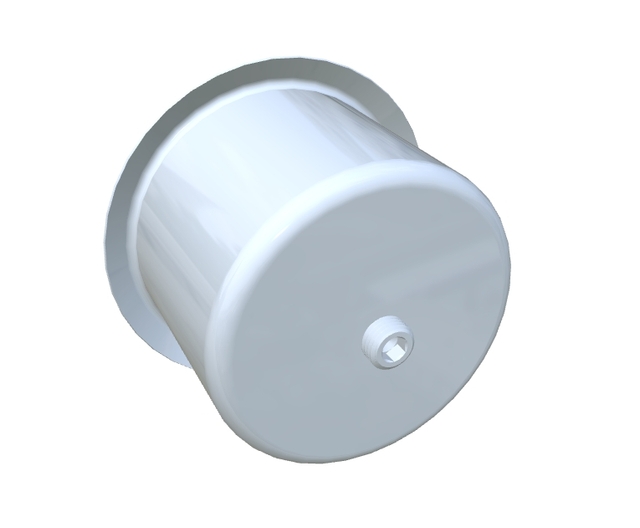

One of the key products offered by LS Hardware Tech Co., Ltd is their innovative bracket design, which exemplifies the company’s prowess in precision stamping and progressive die manufacturing. This bracket stands out not only for its robust functionality but also for its elegant aesthetic appeal. Crafted from high-quality, durable materials, the bracket is designed to provide reliable support while maintaining a sleek, modern appearance. The curved silhouette of the bracket is not just for aesthetic purposes but is meticulously engineered to ensure optimum stability and longevity. The smooth finish accentuates its contemporary design, making it a versatile addition to both structural and interior projects.

The bespoke design of LS Hardware Tech’s bracket allows it to integrate seamlessly into a variety of settings, whether it’s for shelving, supports, or decorative elements. This versatility is a testament to the company’s expertise in stamping die design and custom metal stamping, ensuring that each piece not only meets but exceeds the expectations of their clients. As part of LS Hardware Tech Co., Ltd’s dedication to innovation, they continuously strive to enhance their progressive die technology, staying ahead in a competitive industry.

LS Hardware Tech Co., Ltd is not just focused on producing excellent products but also on providing their services worldwide. With a factory equipped with over 100 high-end machining centers, they deliver exceptional production efficiency that meets the growing demands of the global market. The company's commitment to quality is underscored by its ISO 9001:2015 certification, which assures clients of its adherence to the highest international standards. Serving over 150 countries, LS Hardware Tech Co., Ltd has become a trusted partner to renowned factories across various sectors, from automotive and aerospace to consumer electronics and medical devices.

Beyond their innovative products and services, LS Hardware Tech Co., Ltd prides itself on its mission to empower clients by providing solutions that bring their ideas to life. The experts in the company understand the significance of adapting to the evolving needs of customers, and thus, they continually improve their processes and capabilities. By embracing new technologies and methodologies in progressive die stamping, they are able to offer precision that aligns with their clients' unique specifications.

In conclusion, progressive die stamping is an integral part of modern manufacturing, offering precision, efficiency, and versatility. LS Hardware Tech Co., Ltd stands out in this field with its commitment to innovation and quality, supported by years of expertise and a robust operational infrastructure. Their progressive die manufacturing processes ensure the production of high-quality metal components that serve a wide range of industries. As they continue to provide cutting-edge automotive stamping solutions and high-quality products like their sleek bracket design, LS Hardware Tech Co., Ltd reaffirms its position as a leader in the manufacturing sector, poised to meet the challenges of tomorrow's industries head-on.

Progressive Die Stamping: Precision & Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Deep Draw Stamping, Progressive Die Stamping, Hydroforming, Blanking, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Progressive Die Stamping: Revolutionizing Metal Fabrication

Progressive Die Stamping: Innovative Metalwork Techniques

Revolutionizing Manufacturing with Progressive Die Stamping

Mastering Progressive Die Stamping: A Key to Precision

Progressive Die Stamping: Elevating Metal Component Production

Progressive Die Stamping: Precision & Innovation

Progressive Die Stamping: Efficiency in Metal Stamping Solutions

Progressive Die Stamping: Precision Meets Innovation