Progressive die stamping is revolutionizing the manufacturing industry with its efficiency and precision. As a leading technique in metalworking, it has become integral in producing complex stampings with superior accuracy and high consistency. At LS Hardware Tech Co., Ltd, we harness this capability to deliver exemplary results across various sectors, including automotive, aerospace, and consumer electronics. With over two decades of expertise spearheaded by Mr. Nick Zhang and his team of skilled engineers, our company stands at the pinnacle of advanced manufacturing solutions.

One of the keys to our success is our comprehensive die design process. Employing state-of-the-art methodologies, our team creates progressive dies that enable the seamless operation required in sheet metal fabrication. This approach allows for the continuous and efficient production of automotive stamping parts and other high-demand components. By aligning with global quality standards, LS Hardware Tech Co., Ltd ensures that each progressive die stamping process is executed with high precision, meeting the rigorous demands of industries worldwide.

The stamping process is central to crafting parts that meet exact specifications. Using our advanced machining centers, equipped with over 100 high-end machines, we produce high-precision stamping components designed to fit a multitude of applications. This is vital for industries that rely on meticulous and reliable hardware, such as medical devices and industrial equipment. Coupled with our ISO 9001:2015 certification, we affirm our commitment to delivering not only top-quality products but also innovative solutions that enhance productivity and efficiency for our clients.

Our progressive die stamping services are a testament to our mission: to empower clients to bring their ideas to life. By implementing advanced techniques and continually improving our processes, LS Hardware Tech Co., Ltd remains at the forefront of technology. This dedication ensures that our partners receive not just components, but solutions crafted with precision and care—solutions that drive their achievements in their respective fields.

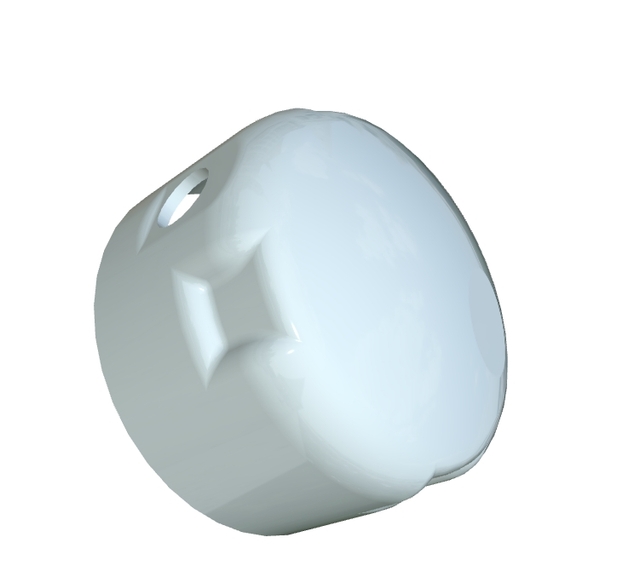

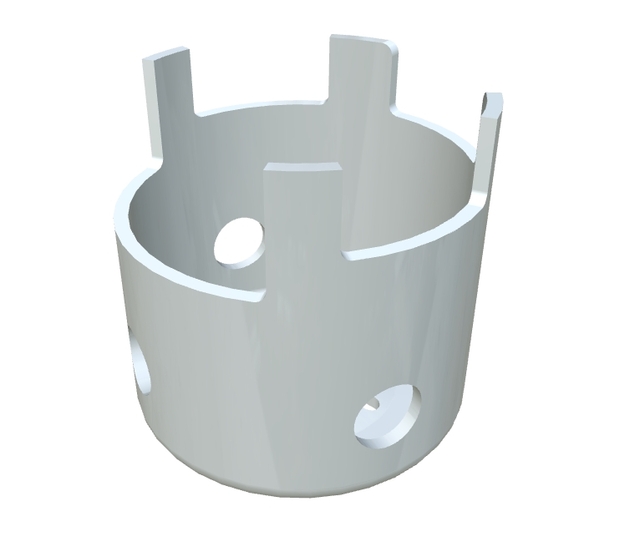

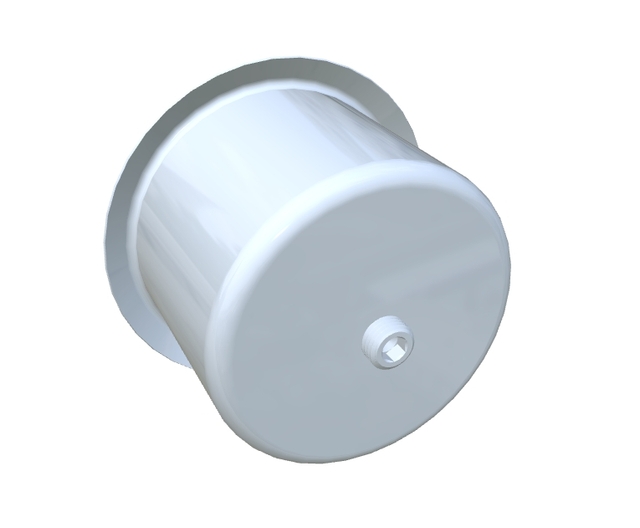

Moreover, our expertise in progressive die stamping is complemented by the sleek and sophisticated Inline Water Filter. This product exemplifies our commitment to merging functionality with design, providing users with a superior filtration experience. The minimalistic and polished aesthetic of the Inline Water Filter is the result of finely tuned manufacturing processes, utilizing the very same precision that underlines our die stamping operations.

As we continue to extend our services to over 150 countries and regions, LS Hardware Tech Co., Ltd continues to build relationships as a trusted partner, offering unmatched expertise and solutions. Our journey of innovation is steadfast, powered by our dedicated engineers and fueled by a passion for excellence in manufacturing. It is this unwavering commitment to quality and innovation that has positioned us as leaders in the industry, helping businesses and industries realize their potential through the power of advanced manufacturing techniques like progressive die stamping.

Revolutionizing Manufacturing with Progressive Die Stamping

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Deep Draw Stamping, Progressive Die Stamping, Hydroforming, Blanking, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.