Stamping techniques represent a fascinating blend of artistry and industrial precision, bridging the gap between creativity and function. At the heart of many industrial and creative processes, the technique of stamping serves different industries ranging from metal and rubber stamping to the burgeoning stamping business that encapsulates handmade and custom stamping. When it comes to innovation in stamping, LS Hardware Tech Co., Ltd stands out with their extensive expertise in manufacturing high-precision parts. Over the years, the company has become renowned for providing highly efficient stamping solutions across multiple industries.

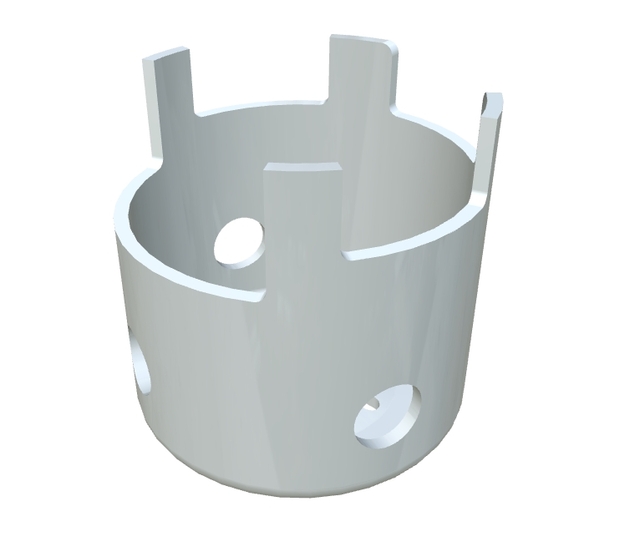

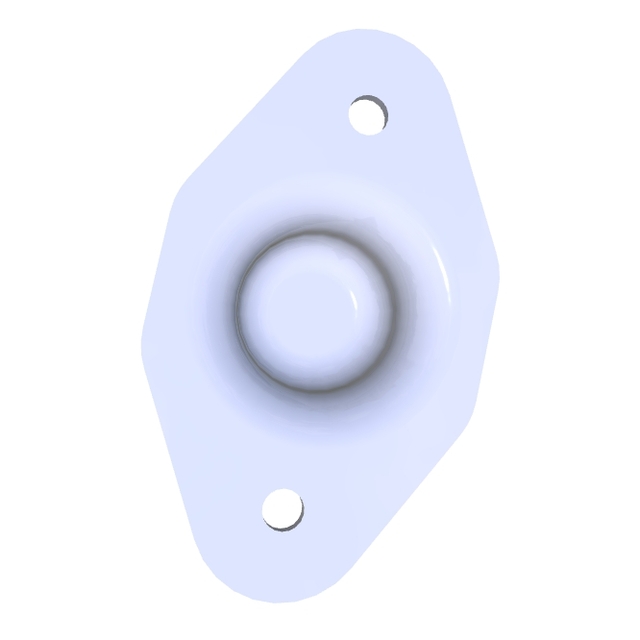

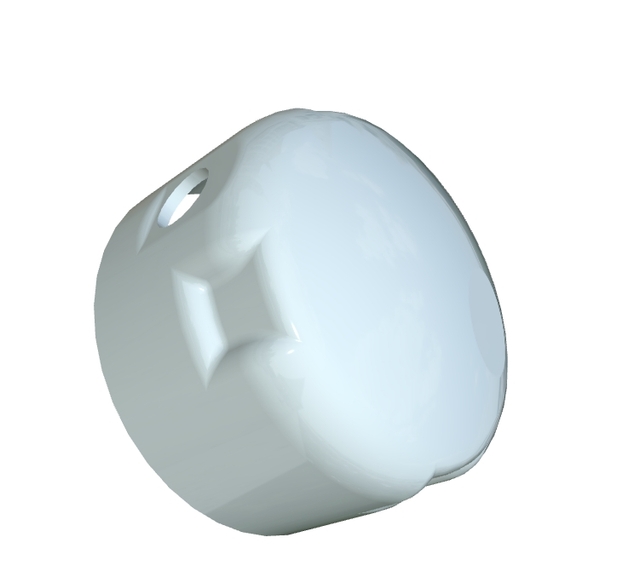

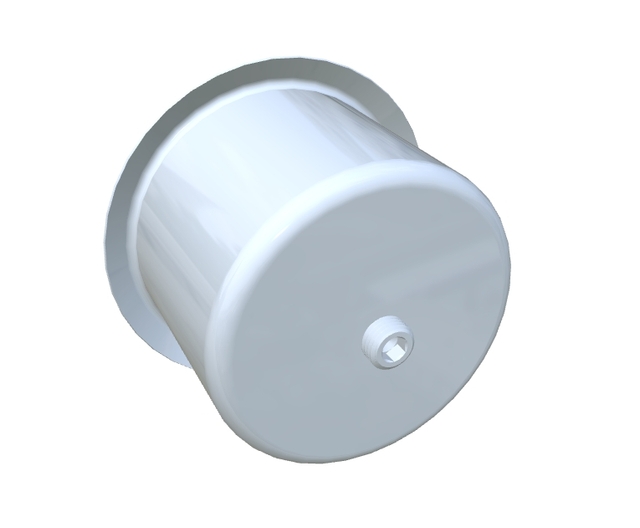

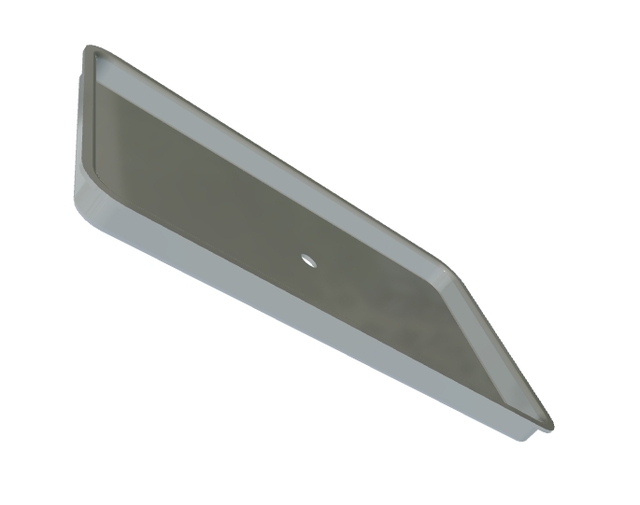

When talking about stamping tools, one cannot ignore the importance of high-quality materials and innovative designs. Take, for instance, LS Hardware Tech Co., Ltd's launch of the Rose Quartz Modular Panel. This product integrates the vibrant aesthetics desired in modern construction projects with the durability and easy customization essential for builders and DIY enthusiasts. The Rose Quartz Modular Panel, with its precision-cut connectors, seamlessly integrates with other panels to provide a perfect finish that elevates any project with its sophisticated rose hue.

The company, founded by Mr. Nick Zhang alongside a team of seasoned engineers, has spent over two decades honing their expertise in stamping techniques, enriching the lives of countless clients in over 150 countries. With an expansive factory boasting over 100 high-end machining centers, LS Hardware Tech Co., Ltd ensures high production efficiency. Known for delivering innovative solutions, the company meets the full range of needs from prototypes to mass production for various sectors, including automotive, medical devices, consumer electronics, aerospace, and industrial equipment.

Rubber stamping, a specific stamping technique, offers its unique advantages in both industrial applications and creative processes. The art and science behind rubber stamping involve creating precise, durable shapes that are reproducible across millions of items. This versatility is enhanced with stamping supplies that match LS's high precision and quality standards. The reliability of these supplies and tools ensures that even in large-scale production, every stamped piece retains its intended shape and function.

Metal stamping, another crucial stamping technique, requires meticulous precision and durable materials to withstand the rigors of large-scale production needs. LS Hardware's focus on quality is evidenced through their ISO 9001:2015 certification, reflecting their commitment to high standards in all facets of production. This technique is especially valuable in industries such as automotive and aerospace, where precision is non-negotiable and every component is critical to the safety and efficacy of the finished product.

Additionally, the rise of handmade stamping and custom stamping signifies a personalized approach to stamping tools and techniques. Empowered by technology and innovative manufacturing processes offered by leaders like LS Hardware, artisans and businesses alike can create tailor-made solutions that cater to individual tastes and preferences while maintaining the highest quality standards.

The stamping business itself is experiencing significant growth, driven by the need for high-quality, customizable solutions in various industries. LS Hardware’s commitment to remaining at the forefront of technology means continually improving processes and capacities to meet evolving customer needs. They achieve this through sustained investment in cutting-edge machinery and a relentless dedication to quality.

LS Hardware Tech Co., Ltd’s Rose Quartz Modular Panel exemplifies the pinnacle of how aesthetic excellence and functionality can intertwine seamlessly through innovative stamping techniques. This integration is a testament to the company’s mission to provide clients with pioneering manufacturing solutions that transform ideas into reality.

In conclusion, understanding and mastering stamping techniques opens up a realm of possibilities in both creative and industrial chapters of production and design. Anchored by a narrative of innovation, precision, and customer-oriented approaches, companies like LS Hardware Tech Co., Ltd prove that stamping can indeed be a sophisticated art form, carving a promising future for various industries through meticulous craftsmanship and engineering excellence.

Exploring Advanced Stamping Techniques and Applications

Obtenir le dernier prix >

| Label | Value |

|---|---|

| Marque | Fabricants de pièces personnalisées LS |

| Service de personnalisation | Découpe laser, Fabrication de tôlerie, Flexion, Estampillage, Soudage |

| Format de dessin | 2D / (PDF / CAD) 、 3D (IGES / Step / GLB) |

| Capacités matérielles | Aluminium 、 Laiton 、 Bronze 、 Cuivre 、 Métaux durcis 、 Métaux précieux 、 Arec inoxydable 、 Alloys 、 TPR |

| Échantillon | Gratuit |

| Capacité d'offre | 100000 pièces par jour |

| Finition de surface | Finition personnalisée |

| Épaisseur | Épaisseur personnalisée |

| Taper | Broaching / Drilling / graving / Chemical Machining / Laser Usining / Milling / Turning / Wire EDM / Rapid Prototyping / autres services d'usinage |

| Services | Usinage CNC, moulage métallique, moulure d'injection, fabrication de tôles, prototypage rapide, impression 3D |

Contact

Prêt à démarrer votre prochain projet avec LS Manufacturing ?

Contactez-nous dès aujourd'hui pour en savoir plus sur nos services et sur la manière dont nous pouvons vous aider à atteindre vos objectifs.

LS Manufacturing

LS ManufacturingDélais de livraison rapides à partir d'un seul jour ouvrable.

Certifications ISO 9001, ISO 14001, IATF 16949 et AS9100D.

Plus de 100 matériaux disponibles, avec plus de 50 options de finition de surface.

Production de masse rentable.

Commandez à partir d'une seule pièce.