In the world of creativity and craftsmanship, mastering stamping techniques has become an essential skill for artists, hobbyists, and industrial designers alike. Stamping encompasses a broad range of methods, each offering unique applications and benefits, from paper crafting to metalworks. Whether you're diving into the world of rubber stamping for card-making or exploring metal stamping to add intricate designs to your DIY projects, understanding these techniques is crucial.

Stamping techniques often start with rubber stamping, a versatile method used by artists and crafters to create beautiful patterns on paper, fabric, and other surfaces. Rubber stamping allows for endless design possibilities, whether it's crafting personal greeting cards or designing custom gifts. This technique typically involves the use of stamp design tools and various ink colors to produce vibrant results. For those interested in making their own stamps, an array of stamp making supplies like carving tools, rubber sheets, and ink pads are readily available. As your interest grows, so does your stamp collection, expanding with unique, personalized designs.

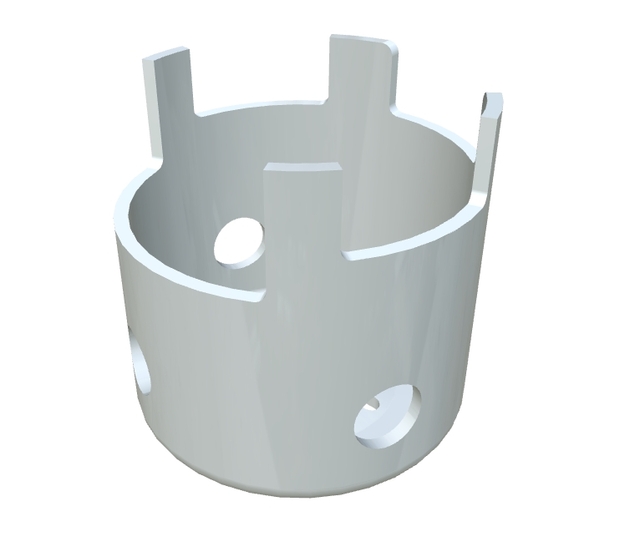

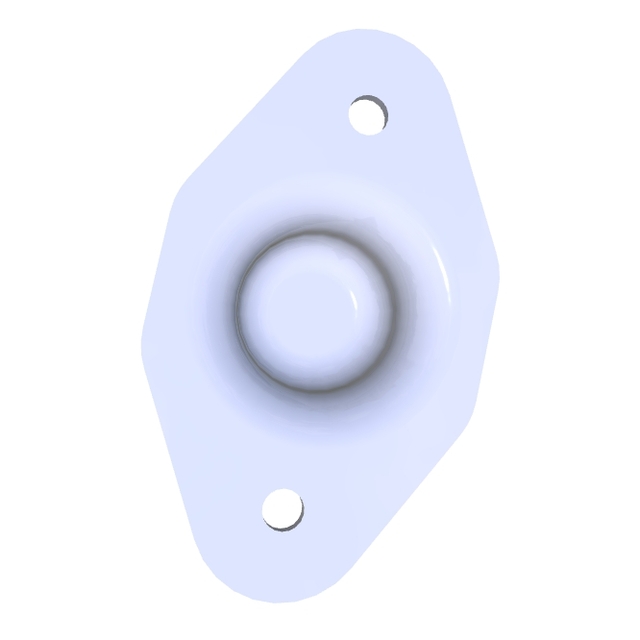

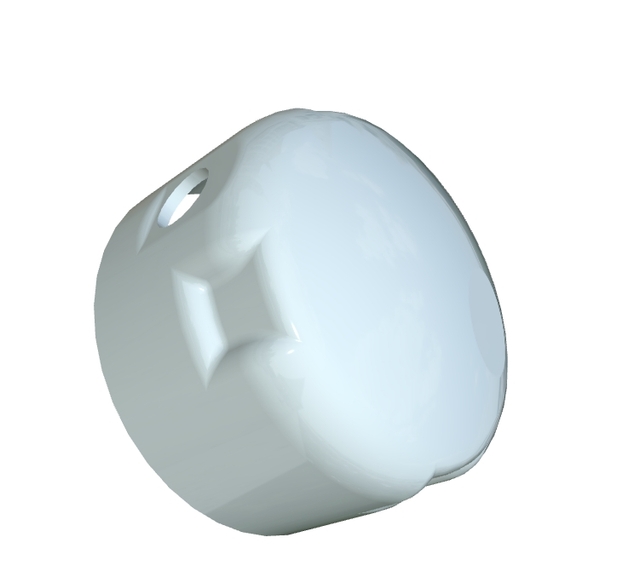

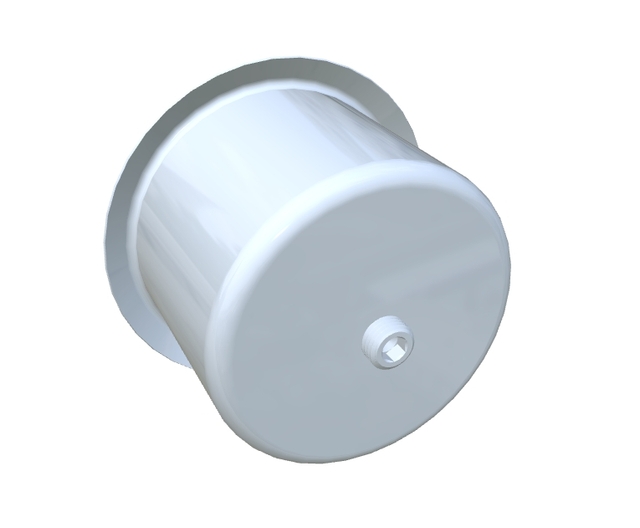

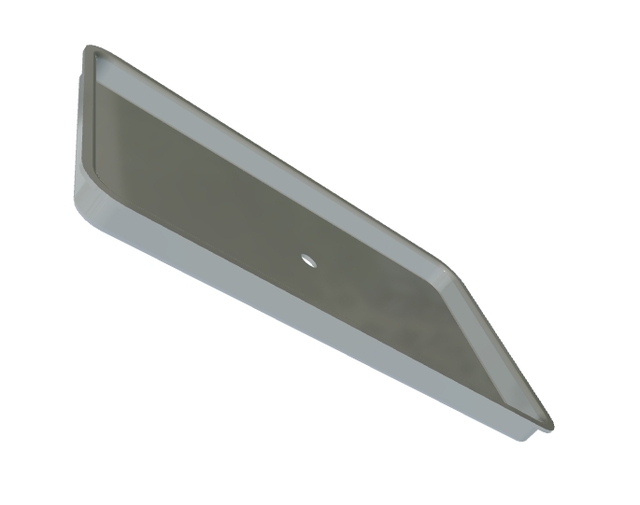

On the industrial side, metal stamping is an essential technique used in manufacturing and construction. Companies like LS Hardware Tech Co., Ltd have embraced metal stamping to produce high-quality components such as the innovative L-Bracket Connector. This piece exemplifies the pinnacle of stamping craftsmanship, combining durability and functionality with modern design sensibilities. Crafted from robust materials, the L-Bracket Connector offers unparalleled stability and support for structural assemblies, making it ideal for both industrial and DIY applications.

The L-Bracket Connector stands out with its sleek, angled design, which not only maximizes space efficiency but also integrates seamlessly into various setups. Its pre-drilled holes simplify the installation process, allowing for precise alignment and secure fastening. This versatility enables adaptation to diverse surfaces, proving ideal for supporting shelves, reinforcing frames, and executing complex architectural projects. It's an embodiment of stamping techniques utilized in hardware, ensuring resilience and longevity in construction endeavors.

The LS company, established by Mr. Nick Zhang and his team of expert engineers, has built a reputation over two decades as a leader in manufacturing hardware and plastic parts. Recognized for providing efficient solutions to a vast clientele, LS Hardware Tech Co., Ltd emphasizes cutting-edge technology and precision in production processes. With a highly advanced factory featuring over 100 top-tier machining centers, LS ensures high production efficiency and superior product quality.

As an ISO 9001:2015 certified company, LS Hardware Tech Co., Ltd partners with major factories across China and services extend to over 150 countries worldwide. Their specialization in high-precision parts serves industries like automotive, medical devices, consumer electronics, aerospace, and industrial equipment, offering comprehensive services from prototype development to mass production. Constantly striving for innovation, LS empowers clients to realize their creative visions, staying at the forefront of technological advancements in stamping and hardware manufacturing.

Whether applied in artistic creation or industrial innovation, stamping techniques continue to evolve, offering boundless opportunities for exploration and development. The L-Bracket Connector from LS Hardware Tech epitomizes how these techniques can culminate in products that not only meet but exceed modern design and functionality expectations, catering to a diverse range of applications. Embrace the world of stamping and discover how its techniques can enhance your projects today.

Mastering Stamping Techniques for Creative and Industrial Innovation

Obtenir le dernier prix >

| Label | Value |

|---|---|

| Marque | Fabricants de pièces personnalisées LS |

| Service de personnalisation | Fabrication de tôles, Découpe Laser, Pliage, Estampillage, Soudage |

| Format de dessin | 2D / (PDF / CAD) 、 3D (IGES / Step / GLB) |

| Capacités matérielles | Aluminium 、 Laiton 、 Bronze 、 Cuivre 、 Métaux durcis 、 Métaux précieux 、 Arec inoxydable 、 Alloys 、 TPR |

| Échantillon | Gratuit |

| Capacité d'offre | 100000 pièces par jour |

| Finition de surface | Finition personnalisée |

| Épaisseur | Épaisseur personnalisée |

| Taper | Broaching / Drilling / graving / Chemical Machining / Laser Usining / Milling / Turning / Wire EDM / Rapid Prototyping / autres services d'usinage |

| Services | Usinage CNC, moulage métallique, moulure d'injection, fabrication de tôles, prototypage rapide, impression 3D |

Contact

Prêt à démarrer votre prochain projet avec LS Manufacturing ?

Contactez-nous dès aujourd'hui pour en savoir plus sur nos services et sur la manière dont nous pouvons vous aider à atteindre vos objectifs.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdDélais de livraison rapides à partir d'un seul jour ouvrable.

Certifications ISO 9001, ISO 14001, IATF 16949 et AS9100D.

Plus de 100 matériaux disponibles, avec plus de 50 options de finition de surface.

Production de masse rentable.

Commandez à partir d'une seule pièce.