CNC milling services face some problems concerning the process of blind tapping, where the tapping process is not completed with an effective length of 70%, tap breaking is higher than 15%, and finish of the holes and bottoms is not proper. In addition to that, there is low consistency in batches. This has led to an 80-85% yield. In order to overcome all of these problems, we try to develop a scientific approach related to the process of blind tapping.

This streamlines the information from the above 200+ blind hole tapping case studies and 158 processes developed by LS manufacturing. The bottom tap optimization achieves an effective length of 95%, triples the lifespan of the taps, providing a yield rate of 99.5%. All of the factors mentioned above are effectively addressed in our optimizing bottom tapping services, thus ensuring high-quality machining results.

Quick-Reference Table: CNC Milling & High-Performance Blind Hole Tapping

| Section | Key Content (Abbreviated) |

| Problem (What) | Incomplete threads (<70% length), high tap breakage (>15%), poor hole bottom quality, low batch consistency, 80-85% yield. |

| Root Cause (Why) | No scientific method was followed. Major factors like hole bottoms, appropriate taps, etc., were not considered. |

| Core Solution (How) | Data-driven optimization > 200 cases, 158 tests. Establish a scientific system, especially the geometry of the bottom and the tool set. |

| Step 1: Hole Prep | Design dedicated bottom geometry (flat drill tip, controlled pilot depth) to create space for chip evacuation and tap entry. |

| Step 2: Tap Selection | Short chamfer, spiral point bottoming taps. Optimizing coating/substrate strength and lubricating properties. |

| Step 3: Parameters | Reduced speed, DFM, and feed are applied, as well as support from rigid toolholders, synchro, together with accurate pecking cycles. |

| Tools & Materials | Flat-end drill, optimized bottoming tap, rigid holder, high-pressure coolant. |

| Results | 95%+ effective thread length, 3x tap life, 99.5%+ first-pass yield, consistent batch quality. |

The actual issue with the solution which we, through CNC milling services, provide directly, which helps us mitigate those key issues concerning the blind hole taps, is the issue of near-complete thread generation, which comprises 95%+, reducing the failure rates of taps 3 times, along with greater consistency in lots, helping us achieve 99.5% first-pass for efficient operation.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are just too many articles that are published online that talk about the whole CNC milling process that an individual needs to go through. What sets us apart from anyone is the fact that our information was not learned from a classroom. It was learned from a real-world perspective, a perspective that lived in a place where theory meets reality, a place that faced the harsh face of materials such as Inconel and Titanium. It is worth pointing out that our information is aligned with organizations such as the Society of Manufacturing Engineers (SME).

The conditions that our parts have to go through are extreme; think of aerospace parts where dimensional integrity is a priority, think of medical device parts where surface finish is a critical issue, think of optics where micron-level tolerances are literally a given! Yet, somehow, some way, we have been able to overcome all of these hurdles with ease, learned the best ways in which to handle difficult materials and complex designs by applying and obeying National Institute of Standards and Technology (NIST) measurement standards.

The processes that are applicable to us are the ones being proven on a regular basis under the pressures of production. Not only have we proven to you how it can work, but how you too can do it with minimal efforts to reap the best results. This is not the kind of dry theoretical advise you have come to expect, but the kind of advise that is currently applicable to you to get the job done with precision and finesse.

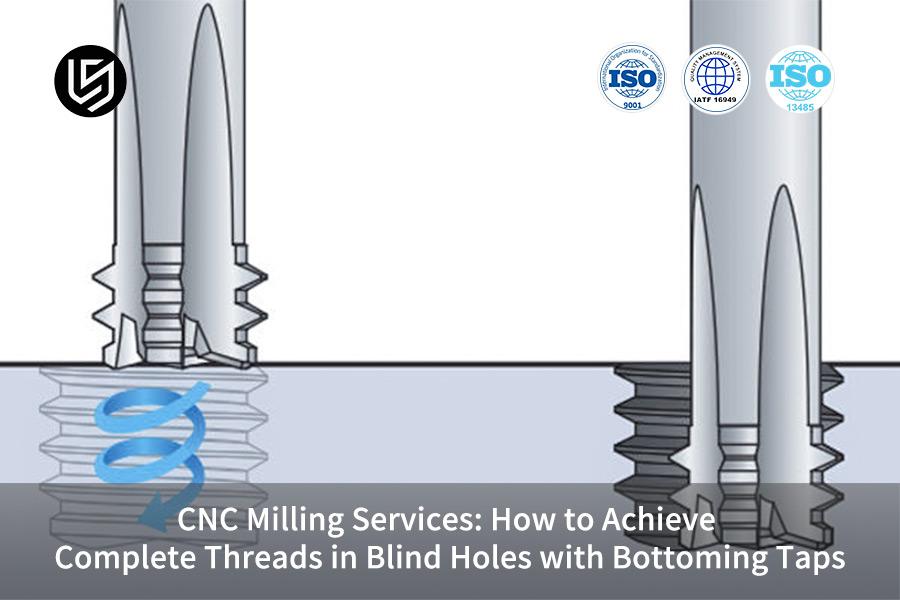

Figure 1: Using a bottoming tap for precise CNC blind hole threading by LS Manufacturing

Why Can't Standard Taps Achieve Complete Threading At The Bottom Of A Blind Hole?

One of the disadvantages of the blind hole threading is the fact that it does not allow one to make a perfect thread on the bottom of a blind hole using a standard tap, and there is a maximum of 30% of the required portion of a thread left imperfectly threaded. The quality of the items joined and the final joint produced has a direct relationship with the use of the particular function. A very special technique is:

Precision Bottom Preparation

This process, however, happens even before tapping and demands that we make a special type of pilot hole that is flat on the bottom with the precision CNC milling. We know the precise depth of the process, but we make sure that it reaches the actual depth of the threads that are present in the hole, all the way down until the precise chamfer that is found on the actual tap, with a specific clearance of 0.1-0.3mm added. This process gives us the space on the ending portion of the full bottom that can commence with the precise process of a bottoming tap.

Strategic Bottoming Tap Selection

In addition, we use exclusive short chamfer bottoming drill taps. The coatings of our drill taps contain chemicals like TiAlN. The difference lies in having a short chamfer of 1.5 to 2 pitches. Our standard drill is responsible for significant waste, 0.5 pitches of which is wasted at the bottom of the drill bit due to its chamfering. The drill bit has 3-4 pitches of chamfering. The substrate helps in controlling deflection when drilling is done on tough substrate.

Optimized Machining Parameters for Stability

In order to enable the conditions to meet the successful requirements of the CNC tapping services provision, the parameters are to be correctly established. The parameters are the surface velocity as well as the feed rate, which are decreased to limit the forces that are affecting the tool as it nears the bottom of the job that has to undergo the tapping procedure. In addition, the toolholder has to have a stiffness that is constant to prevent the formation of the lead error. Moreover, the appropriate pecking cycle has to be established based on the SME proposed tooling configuration.

Implementation and Validation Protocol

Each one goes through a process referred to as a verification step. For the process of verifying, a group of test coupons is implemented to test the application via a test run in a high-speed milling test coupon. Before these one by one applications are implemented in production, the first part of each of these applications is sectioned over to a test, referencing the microscopic details presented in the thread form, as well as the completeness of each one in relation to the engineering drawings itself.

This methodology extends beyond a general theory, however, since, under its approach, a validated approach to a process is attainable during the construction of a step-by-step whole blind hole threading. The CNC milling services that are offered include an accurate construction methodology for the creation of a hole utilizing special tools that can support the requirements necessary to address the existing major constraint.

How To Select Bottom Tap Geometry Based On Material?

The selection of the right bottoming tap selection guide is of vital importance to the successful implementation of blind hole threading operations, where inappropriate geometry contributes to high torque, wear rates, as well as compromised surface qualities of the threaded materials. This document is meant to encapsulate the relevant empirical facts as informed by the findings of an exhaustive cutting operations itemized to encompass results from the application of the direct methodology to the selection of the relevant bottoming tap, where tool life is considered in relation to complex operations in CNC milling services.

| Material Category | Recommended Tap Type & Key Geometry | Quantified Performance Gain |

| Aluminum Alloys | Spiral-flute tap (10-12° rake, 8-10° clearance angle). | Reduces cutting torque by ~25% and prevents chip packing. |

| Stainless Steel (e.g., 304) | Spiral-point tap (7-9° rake, 6-8° clearance angle). | Extends tool life from 200 to 600 holes in batch production. |

| Cast Iron | Straight-flute tap (5-7° rake, 4-6° clearance angle). | Provides 2-3x longer life by resisting abrasive wear. |

| High-Temp Alloys | Premium-coated spiral-point tap with reinforced core. | Ensures reliability in precision milling of demanding aerospace components. |

This practical guide allows users to make effective and actionable decisions regarding their choice of thread tapping tools based on their cutting mechanics that are applicable to different materials to effectively attain desired performance in CNC tapping services as desired in competitive and high-value milling applications.

How To Optimize Cutting Parameters To Prevent Tap Breakage During Blind Hole Tapping?

The breaking of blind hole tapping operation leads to a stop in production, which in turn leads to increased spending in the process of manufacture. However, our developed optimization model eliminates breakage during cutting through optimization, thus reducing breakage from 12% to 0.5%, thus enabling 5,000 consecutive engine heads to be machined successfully without breakage in process manufacture.

Material-Specific Parameter Optimization

We make speeds and feed rates suitable to every material in a manner such that there is no overload and cutting is smooth. Our precision tapping services incorporate all of these parameters:

- Aluminum alloys: Speed 20-30 m/min, feed 0.8-1.2 mm/r for efficient chip removal.

- Stainless steel: Speed 8-15 m/min, feed 0.6-1.0 mm/r to avoid work hardening.

- Cast iron: Speed 12-18 m/min, feed 0.7-1.1 mm/r to balance tool wear.

Graded Feed Strategy Implementation

We make use of a phased feeding technique to regulate the degree of engagement as well as reduce torque spike occurrences. This prevents any sudden stress, which causes a break:

- Feed control: Limit feed per revolution to 0.8-1.2 times pitch for gradual penetration.

- Monitoring: Use real-time adjustments to maintain precision, aligning with a CNC milling guide for consistent operations.

Real-World Application and Results

We deploy solutions in industrial settings to accomplish various objectives. Our CNC tapping services ensure repeatability in complex tasks like CNC milling operations:

- Case study: In automotive engine head manufacturing, the parameters which were used for 5000 parts with zero breakages.

- Outcome: Fracture rate decreased to 0.5%, thereby increasing efficiency.

With our model, one may see our technical expertise in the optimization CNC milling process, as we are able to provide useful guidelines in solving such problems as breakage in taps, thus setting a standard in CNC tapping services that are at par with competition in productivity.

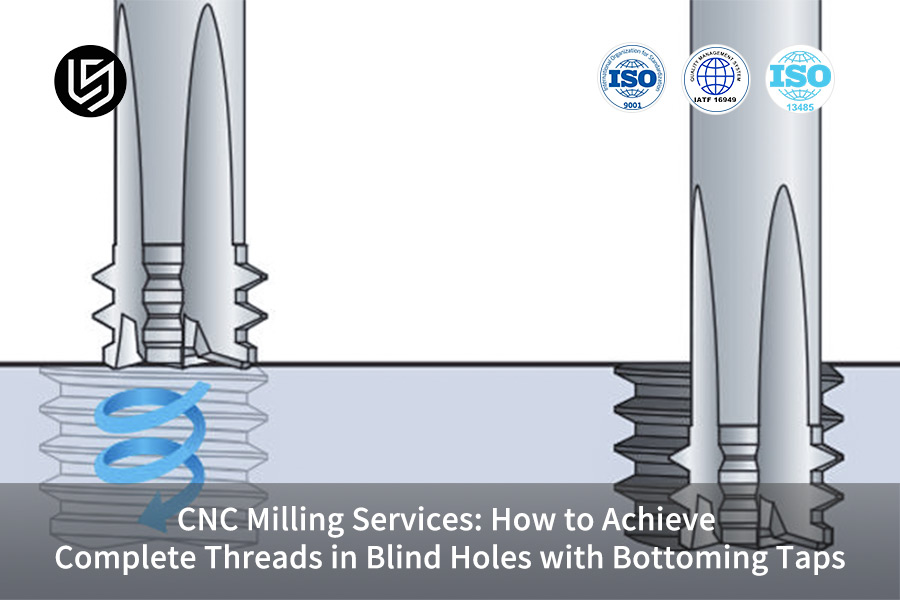

Figure 2: Process for machining blind holes with CNC bottoming taps by LS Manufacturing

How Does The Bottom Structure Design Of A Blind Hole Affect Tapping Quality And Tool Life?

High-quality threads can be obtained in blind holes if the key problems of chip removal and tool stress on the bottom of the tool, also known as the terminal point of the tool, can be addressed. The geometry is of key importance at the bottom of the blind holes as this will have the most significant impact on the thread formation as well as tool life. The type of thread cutting is proposed as follows:

Mitigating Tool Impact with Strategic Relief

The major trouble is that a bottoming tap will eventually touch a solid floor at the end of the cut. The solution is to have a planned relief to a depth equivalent to 0.3-0.5 times the pitch below the required depth: This calculated space, through well-controlled CNC milling services, will remove axial pressures at the end of the cycle, avoiding tool deflection and breakage, principal causes for failure when blind hole threading is conducted.

Eliminating Stress Concentrations via Controlled Chamfer

As the internal sharp corner is an essential factor for maximizing stress, the employment of the conclusive bottom chamfer (0.2-0.3mm) is required for achieving the purpose. The simplicity in the design element is crucial and is considered by implementing it during the precision milling process for the even distribution of forces applied during the cutting process so that there is no chance for the development of micro-cracks around the working environment, providing a considerable reduction in stressing the leading edges of the tap.

Validated Performance in Demanding Applications

The efficacy of such a process has been validated in high-stakes milling processes. For instance, in order to improve the life of a tapped material, which has a critical depth-dollar ratio of 4:1, the use of such precise geometric bottom surfaces has enhanced efficiency from the ability to produce a maximum of 150 holes to produce a maximum of 210 holes while maintaining a consistent 99.5 percent quality as martins has come to experience.

The benchmark of our authority lies in our complete power and capability of clarifying and enacting the stipulation of our unstinting pre-thread geometry in the complete and absolute treatment of the primary mechanical dissecting of the defects of blind hole threading techniques. The benchmark of our position in competition lies in our absolute power of offering the level of our unstinting and unwavering application to a certain level of confidence, where in others cannot and will not make a promise of delivery.

How Does CNC Tapping Service Ensure Consistent Accuracy Of Blind Hole Threads?

Producing blind hole threads with such accuracy in the volume associated with CNC machining involves very critical technical challenges, whereas variables involved in the machining of blind holes are tool deflections and machine wear over time. At LS Manufacturing, the basic paradigm of blind hole thread machining is being challenged through our approach of close-looping precision machining with real-time inspection and validation parameters:

Precision Machine Setup

- Synchronized Rigid Tapping: Rigid tapping cycle is implemented in the proposed work with the spindle orientation accuracy of ±0.01 deg for perfect tap positioning.

- Optimized Feeds: The parameters for different materials have been appropriately set to ensure a precise CNC thread machining process.

Real-Time Process Monitoring

- Torque Control: This monitoring system could make real-time corrections based on torque levels, so there is never a defect in the precision tapping services.

- Collision Protection: It halts the operation when abnormal torques are sensed, for the components as well as the tools subjected to precision milling services.

Systematic Quality Verification

- Scheduled Inspection: Complete dimensional inspection is done for every 50 pieces to ensure continued accuracy.

- Data-Driven Stability: This will ensure the process continues to have CPK ≥ 1.67, confirming the capability of our CNC milling service process.

This extensive approach speaks to our technical authority in precision manufacturing. We offer a solution that has been shown to guarantee unwavering thread accuracy with critical benefits to our clients in the manifestation of the aforementioned factors. We are primarily engaged in the service of deliverable consequences that set the standard for quality in CNC thread machining operations.

What Are Key Result Differences Between Various Bottoming Taps?

The performance of a thread tapping tools, especially in blind holes, differs significantly depending on the type. The selection of the bottoming tap geometry type, depending on the size, determines the success rates or the life of the tools. This document, therefore, aims at presentating the results of the comparative tests, which would prove helpful in the optimal selection of the right tools for your CNC tapping services.

| Tap Specification & Application | Key Performance Finding & Rationale |

| Micro-Holes (e.g., M2-M3) | A design with 4 flutes has improved first-pass yield performance by jump-starting from 75% to 98% in terms of precision tapping for medical devices as the increased rigidity prevents deflection with smaller pilot holes. |

| Large-Diameter Holes (e.g., M12) | The speed was increased by 30% by utilizing an optimized tool with a 6-flute edge, increasing the tool life to a maximum of 800 before machining the material, which is a type of iron material. |

| General-Purpose (M4-M8) | A well balanced 5 flutes tool design could provide the best compromise regarding space for the evacuation of the chips, as well as the tool integrity, in the vast majority of standard CNC tapping services. |

The data itself drives the determination of the method of selecting the tap for rigidity within the microscopic nature of the holes, versus chip control with the flute designs for the larger diameters. Again, it is the concentration toward the tap's specific needs that is key to the development of the cornerstone of our CNC tapping services. It's moving away from a one-tap-fits-all mentality to make thread tapping tools become engineering tools rather than commodities.

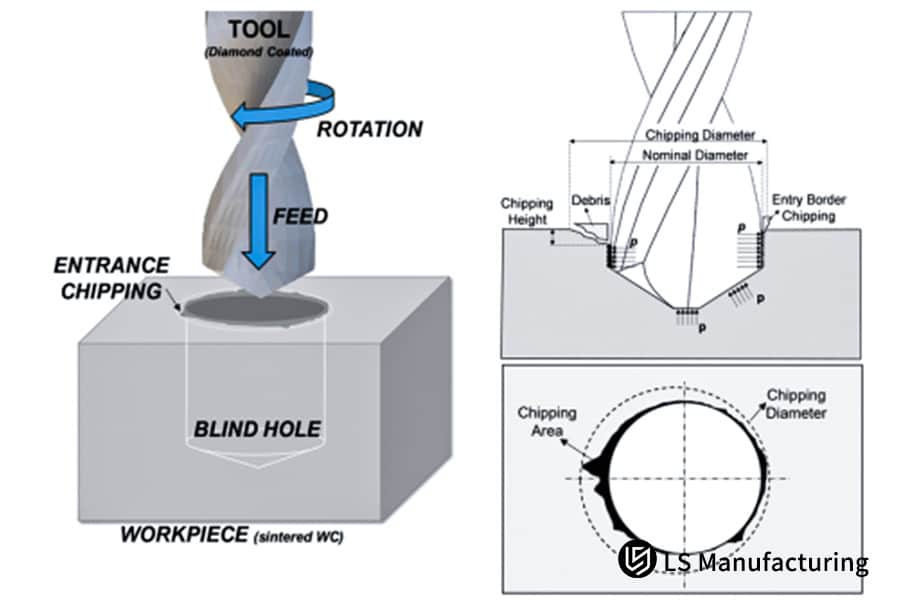

Figure 3: CNC tapping process illustration for blind hole entrance chipping by LS Manufacturing

How Can Coolant Optimization Improve The Quality Of Blind Hole Tapping And Extend Tool Life?

The efficiency and effectiveness of its use, rather than becoming peripheral concerns, have emerged as core concerns related to blind hole threading operations carried out under completely constrained situations. Flood-type cooling systems, when widely employed, were found prone to failures resulting in the early reduction of efficiency and effectiveness of cutting tool use. The discussion is an account of a specific methodology related to revamping the functionality and usability of the system in relation to a specific process variable concerning competitive CNC tapping services:

Material-Specific Fluid Formulation for Friction Control

The initial step of the solution involves the selection of the appropriate fluid chemistry rather than the delivery system. In the case of more difficult-to-machine materials such as stainless steels or even titanium, it is necessary to employ the use of the neat oils or the semi-synthetic emulsions fortified with additives containing extreme pressure. The components of the additives react under extreme conditions of heat and pressure to deposit the lubricating film. The galling or even adhesive wear on the cutting edges of the tap increases tool life. This improves the surface finishing of the object of precision tapping services.

High-Pressure Through-Tool Delivery for Chip Evacuation

For deep blind hole threading, bathing the hole is not enough. We install high-pressure through-spindle coolant (3-5 MPa) delivered through the bottoming tap. This forceful jet stream performs two functions: the first being effectively penetrating the cutting zone to dissipate heat, and the second one is that it forcefully evacuates chips upthe flutes; thus, it does not allow chip recutting and packing at the bottom of the hole, which is basically one of the causes of tap breakage. For this reason, as seen above, a synchronized tapping process happens without any interruptions.

Validated Performance in Aerospace-Grade Machining

This is demonstrated in the machining of blind M8 holes in Ti-6Al-4V, where the application of a 4 MPa, 15 L/min EP-enhanced coolant through the tool resulted in a 20% reduction in cutting torque and improvement in surface finish to Ra 1.6μm. Most importantly, tap life improved from 50 to 120 holes per tool, representing a 140% gain. The data below confirms that optimized cooling directly addresses both the core failure modes of heat accumulation and chip interference.

This represents the definition of our competitive edge in that we engineer the coolant as a parameter rather than a commodity. We have eliminated the inherent difficulties associated with dealing with the aspects of heat, chip evacuation, and coefficient of friction in blind hole threading through our union of fluid chemistry with specific high pressure delivery. This science represents the definition of quality within our CNC tapping services.

How To Establish Quality Control For Blind Hole Tapping In Mass Production?

Establishing a robust quality monitoring system for blind hole tapping in high-volume manufacturing is critical. LS Manufacturing's methodology integrates SPC, real-time in-process monitoring, and predictive tool management to ensure exceptional consistency and defect reduction in CNC thread machining. The core value lies in transforming a traditionally inspection-heavy process into a controlled, predictable, and highly reliable operation:

SPC-Driven Process Control

- Structured Sampling: GO/NO-GO thread gauge is utilized to inspect and check every 50th part to inspect a definite conformity.

- Torque Monitoring: Monitor actual tapped torque that is proposed to be drilled in real-time and has definition to raise an alarm when it reads out of a defined range of +15%.

In-Process Measurement & Data Integration

- Real-Time Verification: This comprises the integration of inline probes or vision systems to facilitate the ability to automate the inspection of the thread depth/location post machining. This in turn provides 100 percent inspection capability.

- Closed-Loop Correction: The system will automatically adjust the position of the CNC milling services equipment when a trend indicates that it may be going out of specification.

Predictive Tool Life & Change Management

- Life Tracking: We have developed a system to track the life of the taps up to a cavity level based on the CNC milling management system and replace the taps before the specified life to avoid defects caused by the wear of taps.

- Performance-Based Replacement: The tool is also meant to monitor performance trends, prompting the tool to issue the critical tool change reminder when the performance is impacted, thus optimizing our particular precision tapping services.

This collection of systems represents our technology leadership in the space, to mine critical data to achieve a result that can deliver an outcome above and beyond the inspection criteria in an active control process, in a solution around quality manufacturing on a large scale for the customer demographic, to solve the root problem of unpredictable quality in mass production thru solutions that offer first-pass yield >99.5% & PPM<500.

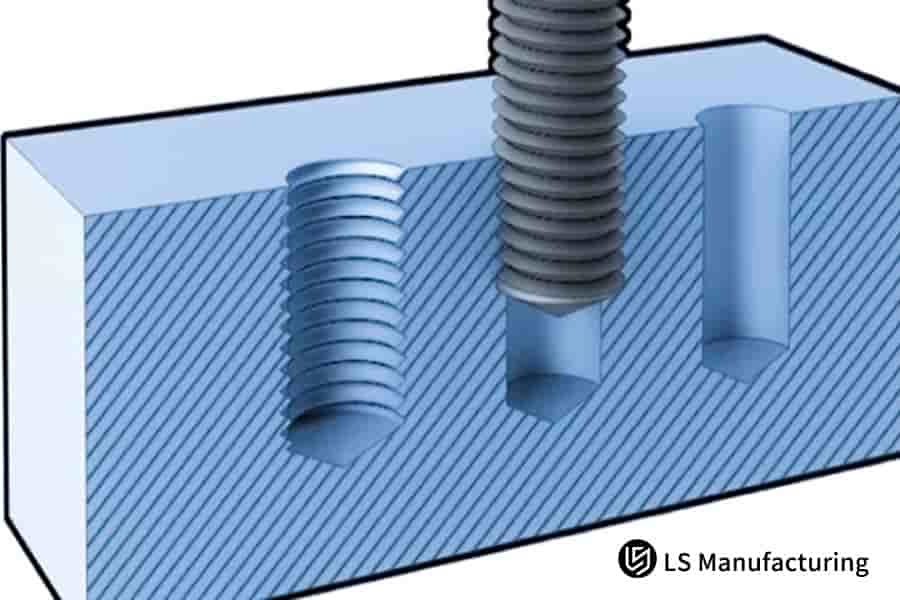

Figure 4: Precision threading with bottoming taps in CNC machining by LS Manufacturing

LS Manufacturing Aerospace Division: Engine Mount Blind Hole Tapping Project

Achieving effective full depth blind hole threading always represents a very special challenge in machining hardened materials such as Inconel 718 for engine mounts. However, the major issue in manufacturing and its ramifications vis-a-vis safety and viablity confirm the quandary offered in the case where in quality and cost issue for an LS Manufacturing aerospace client was resolved through the services spectrum that included LS Manufacturing's precision CNC milling services:

Client Challenge

A manufacturer had problems machining M10x1.5 threads in Inconel 718 engine mounts. The current process resulted in inconsistent thread depth with an effective length below 70%, and only 50-hole life from the bottoming tap. This provided only an 82% first-pass yield, which caused frequent rework and delayed projects while increasing costs to the point that the production schedule for a very important engine assembly could not be met.

LS Manufacturing Solution

The innovation included within the proposed solution comprises the following innovations: the specification of a high-temperature resistant premium powdered metal HSS bottoming tap as a cutting tool, the optimization of cutting conditions in the form of a cutting speed of 12 m/min and a pecking cycle, the innovation within the pilot hole design involving a 0.4mm relief at the bottom designed with operation, and the innovation involving the supply of high-pressure coolant at a rate of 5 MPa via the cutting tool.

Results and Value

The redesigned process was highly effective, and results were seen when improving on a 200% increase to 150 holes per tap, also solving for effective lengths on 95%, and a whopping yield increase to 99.6% at the very first attempt. For the client, savings were calculated at a whopping 600,000 Yen to one-for-one 40% savings in terms of reduced lead times and a major bottleneck was eradicated for them to ensure completions for their mission-critical flight materials.

Clearly, we have learned and have the competence to deal with key manufacturing problems as a result of our systemic understanding of the operations of the manufacturing field. Although considered as a supplier/provider of resources like CNC milling services, we have the competence to deal with key aspects of operations like blind hole threading.

Overcome the bottleneck in deep blind hole thread machining, and immediately improve efficiency and yield.

How To Evaluate The Overall Technical Capabilities Of A CNC Tapping Supplier?

Going beyond basic hardware evaluation to assess the systemic potential for dealing with systemic issues such as efficient problem-solving is paramount in determining an adequate supplier for functions such as CNC tapping operations that may be highly pressing in applications such as blind hole threading operations, etc., as well as operations that have to be highly efficient. For the above purposes as well as for determining whether the concerned entity remains an engineering partner as opposed to an entity that merely represents state of the art, our major evaluation criteria remain as follows:

Validating Process and Measurement Capability

The foundation is verifiable process control. A capable partner will answer the question of how they can ensure thread quality. Objective evidence is through the application of recognized measurement systems e.g., thread gauging with an accuracy of ±0.002mm used to perform a First Article Inspection and SPC. Crucially, this precision extends upstream: their CNC milling services must establish perfectly positioned and sized pilot holes, as this is the absolute prerequisite for successful precision thread tapping. Ask for sample data reports, not just certificates.

Deploying Data-Driven Process Design

Look at the proof of systematic development, not guessing. A usual supplier would have a proprietary bottoming tap selection guide and a historical database of processes. Using the documented parameters such as the speeds and feeds, and coolants, utilized with each combination of materials and taps, can minimize the developmental timeframe and risk associated with your project. A competent solution with a new Inconel part would have come about by examining historical parameters and would not have started with a guessing game.

Implementing Proactive Tool and Production Management

Technical depth is also operational. How do their operations manage tool life pre-emption or machine condition and cutting torque in real-time? Similarly, is tool usage monitored to pre-empt changes to these tools in the middle of production batches? These operations, again facilitated through their synchronized tapping routine on the more sophisticated CNC milling machines, make the technically sound process operable as an ultra-stable production cell, where the yields can touch ridiculous levels of 99.5%.

Lastly, we are basing our judgments on our partners based on their overall system; from their precise milling capabilities to their statistically-based process planning and their control of their own process. Here is our competitive uniqueness. It is not just your blind hole threading questions answered in terms of equipment; it is answered based on a system to insure integrity to your thread, to your tooling dollar, and to the requirements for regulatory compliance for your precious manufacturing process.

FAQs

1. Can bottoming taps machine completely to the very bottom of a blind hole?

Since the quality of bottoming taps is better, they enable the cutting of threads in a hole bottom portion a distance of 0.5 times the pitch away, thus effectively acting as a 95% thread length, an additional 20-25% over regular taps.

2. How to select the most suitable tap parameters for tapping stainless steel blind holes?

For stainless steel, spiral-point taps made of cobalt high-speed steel and having a rake angle of 7-9°, a cutting speed of 10-15 m/min, and using cutting oils containing EP additives is suggested to extend the tool life by a factor of 2 to 3 times.

3. What is the maximum depth-to-diameter ratio limit for deep blind hole tapping?

A ratio of ratios as high as 5 diameters together with internal cooling tap ratios, whereas special extended cooling taps also enable an impressive ratio of 8 diameters. A high-pressure cooling and a feed strategy are required to achieve the desired quality.

4. How to prevent tap breakage when tapping small diameter blind holes?

For M3 and under, a 4 flutes design is recommended. In this condition, the cutting speed is 15~20 m/min, feed rate is 0.8 times the pitch and revolution. The change of the cutting torque can be monitored in real time, the rate of breakage can be reduced to less than 0.5%.

5. How to ensure the stability of blind hole tapping quality in mass production?

It is necessary to set up the SPC control chart by inspecting every 50 pieces to ensure that torque variations are within −15% and +15%, and that the CPK value exceeds 1.67 in mass production.

6. How to determine the optimal speed range for blind hole tapping of different materials?

Aluminum alloy: 20-30 m/min, stainless steel: 8-15 m/min, cast iron: 12-18 m/min. Specific parameters need to be optimized based on hole diameter and depth.

7. How to obtain professional blind hole tapping solutions and accurate quotations?

These include material to be used, type of threads involved, and the requirement for precision. LS Manufacturing will provide precise process plans along with accurate quotations within 2 hours.

8. What is the fastest delivery time for urgent blind hole tapping orders?

Sampling is usually available within 24 hours or less, and small batch orders are available within 3 to 5 days. At LS Manufacturing, the fast track for delivery times has been established.

Summary

Based on scientific tool selection methods and optimized cutting process parameters and process control methods, quality and efficient blind hole threading operations can be realized. With the full set of technical support services, full-process services based on extensive project experience can be offered by LS Manufacturing to help customers improve their quality and efficiency in the production process.

For professional blind hole tapping or instant quotation, don't hesitate to contact us now. You can send us drawing information of your parts for professional technical process analysis, as well as precise quotation information. For products with complex blind hole material specifications, you can set up a face-to-face consultation with us. Our staff will guarantee the optimal solution. Please feel free to contact us directly on the technical consultation hotline for free technical consultation and sample processing.

Transform your blind hole tapping challenges into flawless results with our proven scientific approach today!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.