CNC milling materials are fundamental to precision manufacturing, yet selecting the optimal one presents a significant challenge. After all, it has to do with continuous compromising by the engineers and procurement managers between part quality and accuracy, aggressive cost control, and compressed lead times. A wrong choice of material would directly influence project delays, blowing of budgets, and even product failure hence affecting overall competitiveness.

Choosing the right CNC milling materials is a critical first step in any project. This guide by LS Manufacturing, a leading CNC machining manufacturer, will hep you navigate this complex decision, ensuring you achieve precision CNC machining results while optimizing for cost-effective CNC machining.

Quick-Reference Guide To CNC Milling Materials

| Key Decision Factor | Recommended Material |

Core Advantages |

Typical Applications |

|

Lightweight & High Strength-to-Weight Ratio |

Capable Aluminum, 6061, 7075 for example |

Easy to machine, corrosion resistant, and affordable. |

Aerospace frames, automotive parts, electric housing. |

|

High Strength & anti - Corrosion SR |

Stainless Steel 304, 316 |

Excellent in mechanical properties and durability. |

Surgical tools, food machinery, marine parts. |

|

High Temperature & Biocompatibility |

Ti Alloy; Ti-6Al-4V |

Excellent strength-to-weight ratio; exceptional heat resistance. |

Aircraft engine parts, medical implants, race parts |

|

Better Thermal/Electrical Conduction |

Copper & Brass |

Excellent to good machinability and antimicrobial. |

Electrical connectors, heat sinks, valves and fittings. |

|

Low Cost & Light Insulation |

Transportation-Engineering Plastics, eg. POM, Nylon |

Self-lubricating and chemical resistant. |

Gears, bearings, insulation covers, low-stress parts |

The following guide provides a starting point based on key design goals. Wondering how to choose CNC materials for your specific application? The table below provides a quick comparison of common CNC milling materials to guide your selection between options like CNC aluminum vs stainless steel. Once the key performance requirements have been satisfied, further evaluate the material's critical properties, its machinability, overall cost, and availability, and collaborate with your manufacturing partners to confirm that the final selection will meet all of the very particular needs of the application.

Figure 1: Material selection and process flow for CNC milling by LS Manufacturing

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Theoretical concepts mean little in our guidance, as this was founded in real manufacturing environments. Our expertise spans the entire spectrum of CNC machining services, from rapid prototyping to full-scale production. The data and case studies shared here are drawn from this vast experience. We have successfully delivered more than 50,000 custom parts made from high-strength aerospace alloys to biocompatible medical materials. This direct experience confirms that when it comes to the most stringent of tolerances and application scenarios, insights from us shall have merit.

Advanced modeling tools, like PTC (Creo), are developing and refining machining strategies well in advance for particular materials before the cut of even a single piece of metal. In so doing, scraps are reduced without giving up precision. All of our operational practices are created to be compliant with, or surpass those set forth by, the Occupational Safety and Health Administration (OSHA), so recommendations that we can make about how to handle different materials in practice take into consideration not just operator safety but the integrity of the parts as well.

That means it is from a large portfolio that these strategies and material insights are shared. We extend that earned practical knowledge in helping you understand how to choose CNC milling materials and avoid costly pitfalls. These will help in bridging the gap in making dependable manufacturing results from data sheets.

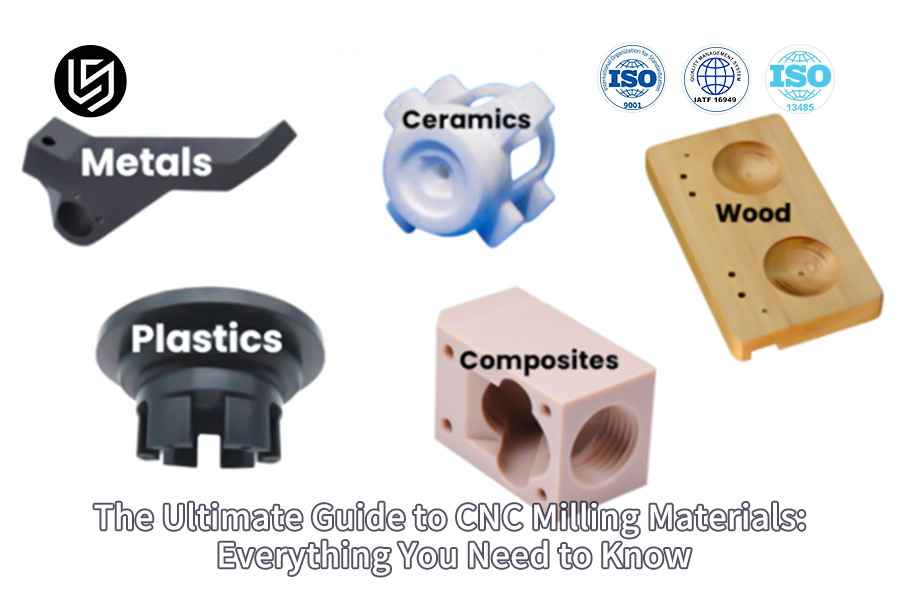

What Is The Principle Of CNC Milling?

The operating principle of the process of CNC milling: It is basically a process of taking away material from a workpiece by rotation, commonly multi-point cutting tools.

1.The relative motion of the tool and workpiece

In the CNC milling process, with regard to the spindle the tool rotates at high speed to form the main motion, while the workpiece moves in respect to the tool, termed feed motion. Work can be fixed when it needs the tool to finish the main movement and feeding at the same time.

2.Cutting force factor

The generation of the cutting force is from the contact of the cutting part of the tool with the workpiece surface, which is the key to remove the surface material of the workpiece. Actually, the magnitude of the cutting force is related to many factors, such as the number of cutting edges, edge angle, rotation speed, feed rate, and cutting depth.

3.Material removal

Under the action of a cutting force, the cutting edge of the tool cuts the workpiece along its surface, gradually removing superfluous material from it. A few working surfaces of the workpiece can be treated; it is performed by three-axis movement of the tool.

4.Processing parameters

he three major parameters in the CNC milling include the cutting speed, feed rate, and depth of cut. The cutting speed is the mean linear speed of the tool with respect to the workpiece surface. The material removal rate depends largely on this. Feed speed refers to the amount fed by the tool in every unit of time. These are very important regarding their effect on the roughness of the machined surface and efficiency of the processing. Depth of cut is the depth for every cut of the workpiece, and it will determine how much material is going to be taken out with each cut.

5.Processing effect

This method of regulation mainly adjusts the effect of milling processing, which includes the precision of the processing, surface roughness, and efficiency of the processing. Reasonable selection of a cutting amount and tool type will enable high-precision control over the shape and size of the workpiece.

6.Type of milling machine

Traditional places where the processing of CNC milling is performed are milling machines. Quite a number of varieties exist; for example, there are horizontal milling machines and vertical milling machines, gantry milling machines among others. They can be applied to the milling process task in various sizes and of various complexity levels, and they represent indispensable equipment in modern manufacturing.

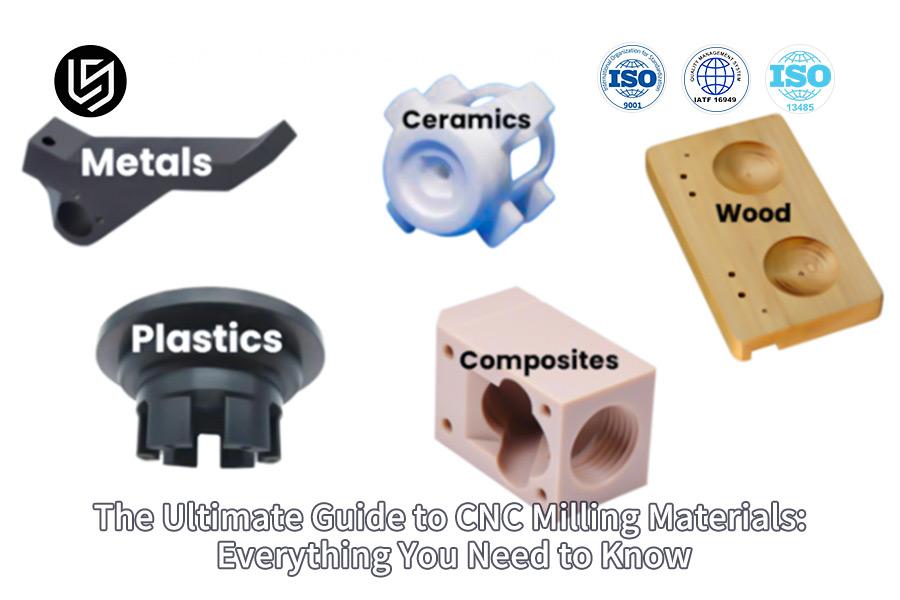

What Materials Are Used In CNC Milling?

A common question we receive is, "What materials can be CNC milled?" The range is extensive, covering various metals and plastics to meet diverse industry needs. Here is a list of some commonly used CNC machining materials:

1. Metal materials

Metal materials are one of the most common and widely used CNC machining materials. They are characterized by high strength, good resistance to corrosion, thermal conductivity and meet different requirements of complex and precise processing. In general, the following are some of the commonly applied metal materials in use:

|

Material |

Feature |

|

Aluminum-Excellent |

Machinability combined with high strength-to-weight ratio and better corrosion resistance, makes this material ideal for strong, light-weight machine parts. |

|

Stainless steel |

The stainless steel has the highest corrosion resistance, high strength, excellent toughness and good ease of fabrication; very suitable for heavy machining operations |

|

Copper |

Copper contains such features as extremely good heat and electrical conductivity along with high plasticity. Besides, this metal is very ductile, resistant to corrosion, and easily weldable. |

|

Titanium |

This is a metal featuring an excellent strength-to-weight ratio, low thermal expansion, high corrosion resistance; sterilizable and biocompatible for machining. |

|

Brass |

Brass has desirable properties for a number of applications. It is of low friction, excellent electrical conductivity and has the appearance of gold in color. |

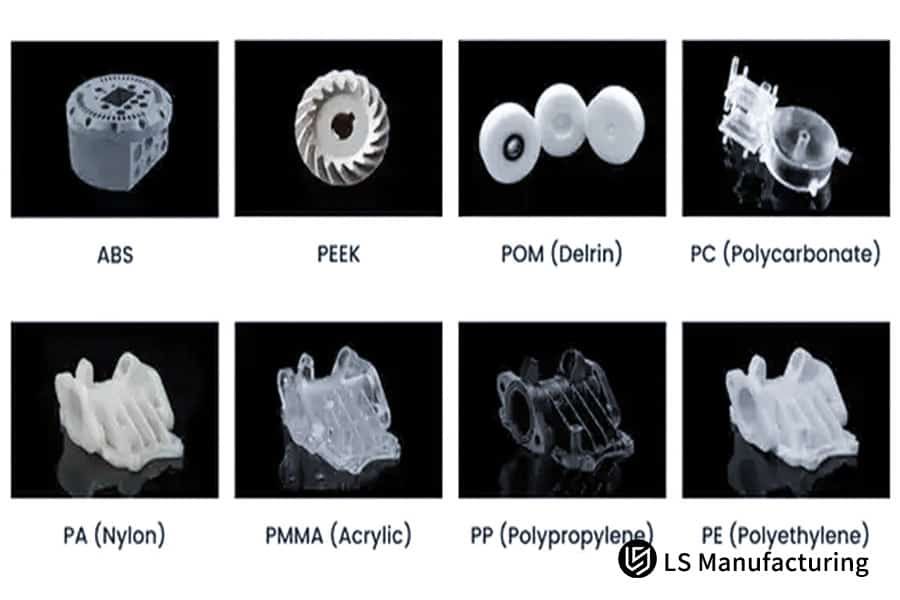

2. Plastic material

Speaking of the popularity of options for Computer Numerical Control (CNC) milling, plastic is still one of the favourite choices because a wide range of options is available at relatively low prices and much faster machining time is needed. Here are some commonCNC milling plastic materials:

3. ABS plastic

There are three kinds of monomers contained in ABS plastic, which include acrylonitrile, butadiene, and styrene. The characteristics of the materials are as follows: the raw materials can be easily available, good overall performance, low price, and wide application. It is a kind of engineering plastic and one of the most widely used materials within manufacturing and chemical industries. The material is hard, firm, rigid. Its major application fields are the casings of home appliances and auto parts.

4. Nylon (PA)

A kind of polymer containing amide groups in repeating units of macromolecular main chain, it had toughness, abrasion resistance, self-lubrication, and large operating temperature range. It can replace copper and all kinds of non-ferrous metals for the making of mechanical, chemical, and electrical products such as diesel fuel pump gears, water pumps, high-pressure seals, and oil pipes as new engineering materials.

5. Polyoxymethylene resin (POM)

POM is a kind of synthetic resin and also called polyoxymethylene resin. It boasts characteristics like high rigidity, high hardness, light in weight and wear resistant. For these reasons, it generally replaces metal plastics. Its major application fields range from gear, bearing, auto part, machine tool, daily necessity to pipe and accessory, precision instrument, building material industries.

5. Organic glass (PMMA)

It is divided into four categories-colorless and transparent, colorful and transparent, pearlescent and embossed organic glass. It is highly transparent, with superior chemical stability, mechanical performance, and resistance to weathering. It is easily colored, easily processed and in possession of an attractive appearance. It is widely used in lamps and decorative appliances.

6. Polycarbonate (PC)

PC is a kind of thermoplastic engineering plastic, with high mechanical, optical, electrical, and thermal properties. These are ultra-tough, easy-to-process thermoplastics used in almost every aspect of life: from household appliances to automotive lighting, medical instruments, and packaging containers.

7. Polypropylene (PP)

Polypropylene is one kind of thermoplastic synthetic resin with superior properties, including chemical resistance and heat resistance, electrical insulation, high mechanical strength, and good processing property of high wear resistance. With versatile properties, it has been widely used in machinery, automobiles, electronics, building, textiles, packaging, agriculture, forestry, fishery, and food processing.

8. Polyetheretherketone (PEEK)

PEEK is a special engineering plastic with superior properties, including high temperature resistance, self-lubrication, easy processing, and high mechanical strength. Huge ranges of mechanical parts can be manufactured and processed, including automobile gears, oil screens, shift starters, aircraft engine parts, automatic washing machine wheels, and medical equipment parts.

9. Polyvinyl chloride (PVC)

Although this material does tend to warp and may necessitate larger machining allowances in order to attain required tolerances, it does have a number of advantages relative to other applications: being low-cost and easy to process.

More than precision CNC machining; Besides effective medical device manufacturing, there is Strategic Partnership too. This case study shall prove how value engineering and application-specific design surmount the critical barriers while maintaining full regulatory compliance and exemplary standards for performance.

Figure 2: A Curated collection of CNC machined metal designsy by LS Manufacturing

LS Manufacturing Medical Case: Affordable CNC Machining For Surgical Navigation Components

Faced with rigid demands brought about by precision medicine, this medical device startup firm was facing a dual challenge related to cost and efficiency in developing the structural parts of next-generation surgical navigation systems. With the pursuit of high-performance, high-cost titanium alloy materials, long processing cycles put them under great pressure in light of their already tight R&D budget and product launch window.

Customer Challenge

This startup medical device firm is designing a Surgical Navigation System, which includes highly precisioned structure parts with lightweight design and surface biocompatibility. Unfortunately, their original specification in titanium alloy wrought unsustainable pressures through exceptionally high material costs and extended machining cycles onto both their development budget and critical market launch timeline within the competitive landscape of medical devices.

LS Manufacturing Solution

Detailed in-depth application analysis showed that, though the parts definitely required medical-grade durability, the nature of the parts themselves was non-implantable. We suggested substituting these parts with high-grade aluminum alloy, further treated with the specialized hard anodizing surface finishing. Indeed, this provided a novel approach toward maintaining equivalent mechanical properties while providing superior wear resistance through anodized coating technology, which easily surpasses the needs of medical sterilization.

Results Delivered

The added value came from the strategic cost optimization of the engineered solution. In such a way, the customer could reduce about 40% of unit manufacturing costs while improving all the performance specifications-the real example of cost-effective CNC machining. Great machinability similarly contributed about 35% of the total reduction in the project timeline, enabling timely product launch and significant first-mover advantage in their target market segment.

This case highlights how our engineering team and DFM analysis can transform your approach to selecting CNC milling materials, directly impacting the cost-effectiveness and speed of your project. For a personalized CNC milling service quote, contact us today.

Ready to move forward with your precision CNC machining project? LS Manufacturing is here to provide expert CNC machining services. Submit your design for a free CNC milling service quote and DFM analysis to get started.

What Are The Advantages Of CNC Milling?

Computer Numerical Control milling is one variety of modern machining technology. It principally employs computers, precision machinery, and automation technologies in its working and thereby has a number of merits to modern manufacturing. The major advantages of CNC milling are explained below.

- It possesses a high degree of automation with a high degree of precision: CNC machine tools are able to make the programmed automatic and complex processing without human interference; hence, high production efficiency can be realized since human errors are lessened.

- It also has the property of high flexibility: Only a few simple changes in the program are needed for a CNC system to produce products with different designs. Thus, the CNC systems could be applied to small batch diversified production accordingly.

- Efficiency enhancement: Under multitasking/multi-coordinate linkage, some pieces with complicated shapes can be treated with the assistance of a CNC machine. Changes in the shape and size of the workpiece can be realized only by means of modifications in the CNC program. Besides, very often a CNC machine is free from an operator during all working cycles, which increases the productivity further.

- High security: Most of the functions of the CNC machine tools are operated automatically in the process; hence, there remains less chance for the worker to come in direct contact with machinery or any dangerous instruments, and that makes the workplace safer.

- Wide range of applications: It has a very wide range of applications, ranging from aerospace industries, the car-manufacturing industry, medical equipment, mold manufacturing, and so on.

What Are Some Of The Disadvantages With A CNC Milling Machine?

While CNC milling has become an essential manufacturing tool in the modern era, working with it has a lot of disadvantages at certain points. Disadvantages of CNC Milling:

- High requirement for maintenance personnel: While CNC requires low quality in operators, it surely does require very high technical demands from the maintenance personnel.

- The operation route is difficult to control: Because the route of CNC is quite different from any other ordinary machine tool; in addition, some experience and expertise are needed during programming and debugging.

- Difficult to repair: As there are so many electronic and mechanical devices integrated into just one single CNC machine tool, in the case of failures in some parts, repairs could get complicated and hard.

- Possible processing problems: Poor surface finish, vibration or chatter, broken tool, parts out of the range of tolerance, poor dimensional accuracy amongst other processing problems that may arise. These could be due to so many causes like tool wear, poor cutting parameters, or poor rigidity of the machine tool.

Figure 3: Key polymer materials for CNC machining applications by LS Manufacturing

What Do You Need To Focus On When Choosing A CNC Milling Manufacturer?

What matters the most is finding an appropriate partner for CNC machining services. The factors that will be taken to attention could be:

1.Ability performance

- Manufacturing equipment: Check whether it is equipped with advanced milling machines that are computer-controlled and of a terminal type. Such a machine normally has merits such as easy and simple in operating, stability in performance, high efficiency in production.

- Technical capability: It refers to whether the rich experience in milling the aluminum block exists within the technical team of the manufacturer, whether it can solve some complex problems in processing autonomously, and promote technological innovation and improvement.

2.Quality control

- Quality Procedures: Know the inspection procedure followed by them. The system should contain a record for inspecting parts in every stage of production with respect to dimensional accuracy, surface finish, and overall quality meeting your needs.

- Quality Certifications: The quality certification represents the applicable standard of quality concerning the document certified, issued by the manufacturer of that particular document. Examples may include ISO 9001, showing that a company adheres to a quality management system.

3. Order time Capability

- Establish their capability: Regarding the workload they are currently undertaking and whether they can deliver projects within your stipulated timeframe. Consider quantity requirement of parts and average production lots.

- Communication and Transparency: For example, they would let you know whether such and such time of delivery would work out or not; delays, too. Clarity over all aspects would keep you prepared at every step and avoid bottlenecks in the projects.

4. Cost

- Competitive Quotations: Get quotations from more than one manufacturer. While the costs are an issue, go for quality and features rather than for the lowest price.

- Itemization: Quotation should be sought in an itemized form for all the costs intended for machining, material finishing and any other additional costs that might accrue. This shall give ease of comparison against quotes that are more specific.

- Value for Money: Overall consideration of the value proposition-the highest price quotation is not often the best value if the required quality, capability, or on-time delivery cannot be guaranteed.

5. Credibility and reputation

- Industry reputation: It is good to know what prestige and repute the company manufacturing these items has, and go for the manufacturer with a good track record and wide recognition.

- Customer reviews: The reviews and feedback provided by other customers can be looked upon to get an idea of what quality of service the customer can receive from the manufacturer and what kind of product quality is made available to satisfy the demands of customers.

LS Manufacturing: Your Best CNC Milling Partner

LS Manufacturing is a professional company in milling services. With advanced equipment and abundant processing experience, we are familiar with all kinds of processing materials and processes. We provide all kinds of customized solutions according to customers' requirements. Whether for small batches, batch production, or large-scale production, the product quality and delivery time can be guaranteed. Welcome your inquiry, our company is committed to serving you with the best service and being your first choice partner.

Figure 4: A collection of precision CNC milled industrial parts by LS Manufacturing

FAQs

1. How does CNC milling differ, say, from aluminum to stainless steel?

One key variable would be that of material cost. Generally, the aluminum CNC milling tend to be the least costly, followed by stainless steel; again, though, the final cost factoring in material price, machining time, and tool wear may vary. For more precise aluminum vs steel CNC milling quote, we would advise you to submit your drawings for a quote in full transparency.

2. How to choose the perfect material for an aerospace prototype on CNC?

The major factor is high strength-to-weight. Material Construction material typically includes aluminum 7075, while high heat areas are made from titanium. Our professional engineers will be able to help advise using this CNC material selection guide to meet any specific needs for performance and budget.

3. What's so special about the experience of LS Manufacturing in the machining of such high-performance engineering plastics as PEEK?

Yes, we have plenty of experience. The trick lies in avoiding deformation by properly managing the heat and clamping. We make sure that special tool paths and parameters are used in assuring dimensional stability in such CNC machining materials.

4. What other factors contribute, besides material, to the final cost and lead time for CNC milled parts?

All these factors influence cost and time: part complexity, tolerances, surface finish, order quantity. You can save a lot with optimization of your designs according to the principles of DFM analysis. We give one free DFM report with every quotation.

5. Can you provide samples of multiple materials for testing and comparison?

Of course, we highly recommend prototyping before mass production. We are able to use the same program in creating your samples using different materials - aluminum, nylon, POM, etc. - so you will be visually able to test functionality, feel, compare performance, and make the most reliable data-driven decisions for final production.

6. Balance between materials strength and machining difficulty in CNC milling.

The more detailed your drawing is, the more accurate your quote will be. Upload your CAD file for a free, instant CNC milling service quote and DFM analysis from LS Manufacturing.

7. My design features thin walls; what material is easier to machine and has less likelihood of deforming?

Either an aluminum alloy or POM is recommended for features with thin walls. Both exhibit good rigidity and dimensional stability and are less likely to deform under the cutting forces from finishing. Strategies include small depths of cut, high rotational speeds, and micro-milling technology in order to guarantee precision of thin-walled features.

8. How do I get a accurate CNC milling service quote?

The most accurate quote requires a detailed drawing. Upload your CAD file to LS Manufacturing for a free, instant quote and DFM analysis that considers material, design, and quantity.

Summary

Material selection is the very cornerstone of any CNC milling project. It directly influences the performance and life of the part, its price as well as production efficiency. Below, one can find a guide to CNC milling materials, it carries detailed information with the aim of making it easier to understand logical thinking behind material selection and why co-operation with the experienced partner is so important.

No material selection challenge has to stand in the way of your innovation momentum. As your primary CNC machining manufacturer, LS Manufacturing is capable of turning your designs into high-quality products. Now send us your CAD drawings for efficient online quotation and professional DFM analysis. Let's drive your project forward together!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.