Online custom CNC milling services are the solution to today's pressing manufacturing challenges. Companies face urgent deadlines, inconsistent supplier quality, and high communication costs. The lack of transparent quoting and intellectual property concerns further complicate rapid prototyping and small-batch production of complex parts.

Custom CNC milling on the Internet closes the gap that existed between the conventional ways of manufacturing and the new abilities of the Internet. In this scenario, the problem arises from the ineffectiveness of the previous manufacturers in dealing with the complicated geometries, using the sophisticated Internet solution. The current company, LS Manufacturing, combines knowledge and a functional Internet platform that offers control.

Online Custom CNC Milling Services Quick-Reference Guide

| Category | Key Points |

| What it is | An online platform for custom CNC machined parts from three-dimensional files. |

| Key Materials | Metals (Alum., Steel), Plastics (ABS, Nylon), Composites. |

| Capabilities | 3 & 5-axis milling, Precision machining, |

| Main Applications | Prototypes, Functional testing, Tooling |

| Key Benefits | Quick quotes, There's no tooling cost, Quick turnaround, Design flexibility. |

| Cost Drivers | Material, Part size/complexity, Machining time, Quantity, Finish. |

| Standard Lead Time | 1 to 3 days, depending upon complexity. |

| Ordering Flow | Upload design → Get instant quote → Review DFM → Order → Ship. |

Online CNC milling services provide an optimized and on-demand approach to manufacturing. The procedure involves uploading 3D designs to allow easy quotation and rapid machining of accurate parts, mainly utilized in prototyping and small-batch production. The key benefits of online CNC milling services lie in their quick turnaround times, economic scale of small-batch production, and ability to leverage CNC milling technology without the need for a minimum scale of operation. Successful implementation becomes design manufacturability-driven.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

This tutorial originated from the ‘shop floor’ experience, and all the techniques discussed in this document have been implemented in the internet-field in practice. More than 15 years of experience in the internet-field, delivering custom CNC milling services in aerospace/medical, which requires the tightest tolerance, has given us ‘all the secrets’ in this document.

The level of our expertise can be judged by the number of precise components we deliver on an average annual basis. We find ourselves dealing with challenges every day with regards to geometry and specialty alloys, with our main thrust always on efficiency without ever having to suffer any loss with regard to quality. The level of our expertise works on guidelines set by the Society of Manufacturing Engineers (SME).

You are able to tap into the benefits of having a partner that strives for excellence. We recognize that the important aspects that have led to the success of our milled parts are also important in the success of your end product. The best practices that have learned from more than 50,000 parts seek to integrate into your design team in our pursuit that adheres to the guidelines established by the US Environmental Protection Agency (US EPA).

Figure 1: Personalized CNC milling quote and services by LS Manufacturing

Why Choose An Online Custom CNC Milling Service Provider?

Using the CNC milling service available on the internet is a change that truly transforms the face of precision component purchase. Compared with the conventional process of purchase, the benefits that an online custom CNC milling supplier can provide are numerous. The reason why this is the way that the innovation teams interact with each other the most can be attributed to the aforementioned benefits.

| Advantage | Brief Description |

| Instant 24/7 Quoting | You simply upload your model and get an instant quote and begin working in minutes. |

| Standardized Digital Process | Reduces the possibility of human error and guarantees a consistency of process from quote to fulfillment. |

| Secure IP & Doc. Management | Your designs are protected with the help of an encrypted document management software. |

| Full Process Transparency | The whole process of the orders being fulfilled can be tracked. |

Therefore, to summarize, involving the online CNC milling service outfitter and manufacturer for your CNC milling requirements, or capacity, more than the capability to conveniently perform your milling procedure, it’s actually innovation and advancement. The traditional means through which you perform your milling procedure takes time, and that process for most people has remained blank, or black, while the modern and new means through which you will interact with your CNC milling manufacturer and outfitter for your milling procedure will be numeric, or digital.

How Can You Achieve Fast And High-Precision Machining Of Your Complex Part Designs?

For the creation of complex designs on precision physical components, it is necessary that the technology is advanced. Being experts in precision CNC milling, it can be guaranteed that even the most complex parts rapid machining tasks will be completed with unwavering accuracy.

| Technical Capability | Brief Description |

| Multi-Axis Machining | The CNC 5-axis machines we own allow us to perform single-pass machining on complex geometries. |

| Robust Quality Control | We adhere to strict standards (e.g., ISO 2768-M) and utilize CMMs to verify dimensional accuracy at every critical stage. |

| Material Expertise | Having the knowledge base of the special properties of tricky materials such as Titanium and PEEK ensures the optimised outcome. |

In conclusion, this synergy between us and the technology we have access to makes us second to none. With the state-of-the-art technology available along with the in-process verification at CNC milling, the transfer process of the file to the produced parts will be seamless. Further, this is simply what we are and represent, the trusted CNC milling manufacturer for the project that will require the elements of both rapidity and utmost high-quality work.

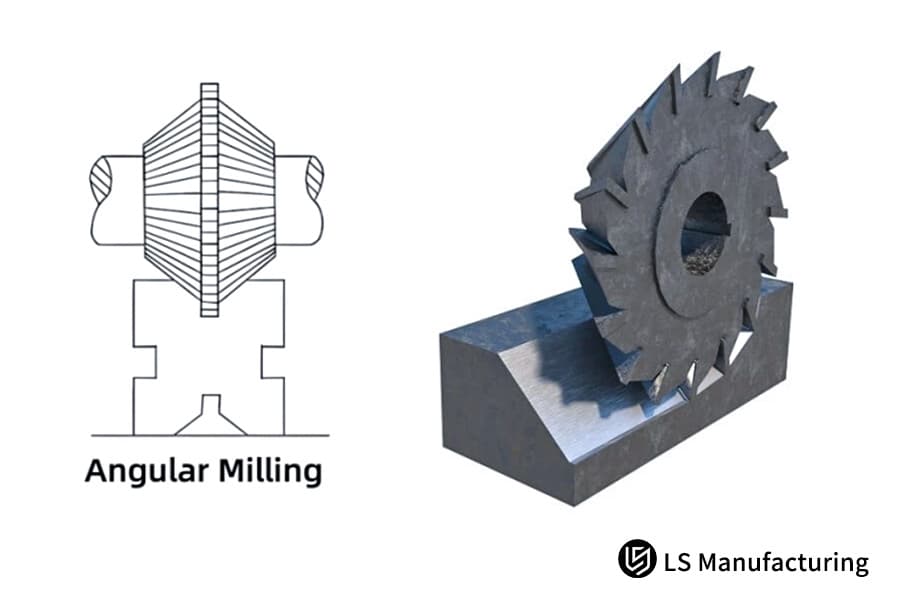

Figure 2: Custom prototype manufacturing with precision angular milling expertise by LS Manufacturing

Can Competitive Pricing Be Obtained For Small-Batch Prototypes And Production Orders?

This question of offering the right price with small production runs forms the very core of how we perform at CNC milling. The major opinion poll highlights that low-volume CNC milling imposes a massive additional-cost burden. This notion holds little actual value when substantiated with the application of highly intelligent digital technology incorporated into the pursuit of maximum optimisation strategies with every quote. In the underlisted points, this will underscore the strategies that we will apply at CNC milling so that your project turns out both optimised and of the highest level.

Transparent & Optimized Initial Costing

The online CNC milling quote facility at the CNC Milling service provider network provides more than the mere costing quotation. This facility not only assists to process the submitted 3D File instantly, but can provide the ‘DFM Design for Manufacturability suggestions' to avoid material wastage through ‘scrap generation.’ This will have the direct bearing at the behest of optimisation at the initial costing front, absolutely unscathed at the designs stage with not the least negation.

Strategic Production Planning for Efficiency

We specialize in the economies of small-scale production. Our advanced scheduling system intelligently groups similar low-volume CNC milling orders from different clients on shared production runs, allowing us to distribute fixed machine setup costs. This collective efficiency translates directly into more favorable CNC milling service pricing for each individual customer.

Long-Term Partnership Investment

We understand prototype development and production and the mass production process. By giving you the best price possible for your units of initial production, we plant the seeds of a business partnership with you. Now, with your business with us, you deserve the very best prices possible for your production projects at affordable prices because of your business with us.

Value Added to Unit Costs

Competition pricing, in no way opportunistic or easily peddled away in favor of quality, instead involves reducing fat, which in turn means that, given the developments in technology as well as the in-house competence with regard to the tooling aspect, delays or costs that could otherwise have been incurred in the outsourcing process would no longer be an issue, as regards us. Finally, the value added to your unit costs would bring along additional benefits of qualities and services.

In summary, competitive pricing for small batches is achieved through smart technology and efficient operations, not by compromising quality. Our transparent online CNC milling quote and strategic production planning are designed to make low-volume CNC milling accessible. This allows you to manage your project budget effectively while receiving the high standard of quality and reliability that defines our CNC milling service pricing philosophy, making innovation both feasible and cost-effective.

What Are The Key Process Points That Require Special Attention When CNC Milling Aluminum Parts?

Achieving high quality in aluminum CNC milling, there are special aspects that need to be borne in mind. The material, although proving to be very suitable, in the context of thermal deformation, may be a problem with the material used. Here is how we ensure successful outcomes for your precision parts machining projects:

Distortion/Part Holding

The material aluminum has more thermal expansion characteristics. This means that the distortion of the force created due to the machining process and the generation of the expansion of the part through the process of machining would be even more. We utilize “low stress” part holders, contributing less to the clamping forces and machining process techniques for part distortions and part holding. It helps us to eliminate the stability problems, which become the point of major concern while precision parts machining.

Superior Surface Finish Optimization

The aluminum materials can be termed as soft materials to some extent. In contrast to that, regarding the creation of an extremely skilfull process for the handling of aluminum materials, a mirror surface finish is necessary. The process regarding the creation of the extremely skilfull machining process, taking into account the concept of high speed machining, will somehow assist in dealing with the issues related to built-up edge to some extent in readiness to optimize the surface finish.

Effective Chips and Tool Life

The aluminum material has high ductility properties. This implies that the chip will be stringy. Therefore, the process of re-cutting the chip will be possible if the removal of the chips outside the workstation has failed. The approach that will be applied to provide a solution to the problem stated above will entail the application of the cooling technology or path programs that encourage the removal of the chips. The removal of the chips plays a crucial role in aluminum alloy CNC milling process.

Choosing the Most Suitable Alloy and Hardness

Aluminum, as a material, is not just one, and this is among the factors we examine when we give our recommendation on the kind of material or alloy that we shall be using, whether it is the common ones, which are also named 6061-T6, or the other kind of material, which is actually much harder, and this is also named 7075, depending on the use of the said material, beginning with its selection based on the machining attributes, specifically its hardness.

The process of aluminum alloy CNC milling for the task involves some level of expertise. The expertise that our firm has, in relation to the issue of competitiveness and customers, can be partly attributed to the expertise that exists in the CNC milling process in the manner of dealing with the aforementioned issues.

Figure 3: Online precision machining services for intricate metal parts and components by LS Manufacturing

LS Manufacturing Success Story: Customized Precision Housing Components For The Medical Device Industry

In the fast-paced medical device sector, where precision engineering and rapid iteration are paramount, selecting the right manufacturing partner is crucial. Our partnership with a portable analyzer developer demonstrates how our online CNC milling service transforms complex challenges into successful outcomes: leveraging precision machining, advanced multi-axis milling, and a streamlined digital workflow to accelerate product development.

Client Challenge

One of the biggest problems that would be faced by one of the suppliers in this market would be that they had to develop a design for this portable analyzer packaged in aluminum. This was achieved by the supplier since they managed to create prototypes and actual pieces in a period of one month. They could not display this level of tolerance since it would be about or close to ±0.05mm because they have not attained this medical finish.

LS Manufacturing Solution

In fact, ourselves, along with the knowledge that we possess, also provide a speedy solution to the DFM process within two hours, along with getting the online quote for us. Indeed, the solution to the proposal that was prepared for the company that we represent included a speedy prototype, milling of the critical components using the assistance of the 5-axis machine, along with another special surface finish process that has high surface finish with respect to the tests placed upon with regard to cleanness, as demanded by Industry Standards.

Results and Value

It took only 5 business days for the first order related to the construction of 10 correct models, which helped the customer evaluate the efficiency of the models directly used. The second order, related to the production of 100 models, required 15 days, showing a reduction of 30 percent in the production time. This led to the winning of the contract for the provision of services in long-term production due to the commercial pathway.

In summary, this case highlights that in critical product development cycles, a partner with integrated digital manufacturing and deep CNC expertise is vital. Besides the provision of components, we brought along the following turn-key solution: rapid prototyping, manufacturing, and procurement. As aforementioned, our process protected risk regarding the launch of the product for the client, thereby securing the alliance which realizes that precision of manufacture translates to the facilitator of medical innovation.

In case you are experiencing challenges in machining your precision medical cases, you can click the link below for guidance.

How Can Prototype CNC Milling Be Seamlessly Transitioned To Mass Production?

The scale up component: This is one among those components that shall demand so much knowledge and so much expertise when it comes to the problems that may be encountered during this scale up process. In so far as the issue concerning LS Manufacturing and from the very relevant point of view concerning this issue as it pertains to our clients, it shall, of course, go for a seamless process concerning our clients concerning the issue that we give our clients everything that falls within our scope, from the conceptual phase of testing up to the other phase of mass production.

Unity Process & Data Continuity:

If we are to address the problem before us, first of all, there would be the prototype CNC milling. This, of course, would be the first step that would need to be accomplished on the CNC machine, and this specific process would, at the current moment, be in the implementation phases. Second, the parameters of the machine would need a digital format. This, of course, would occur after the completion of the prototype machining process. This, of course, would take care of the requirements because we would be utilizing the same thing that was used in the previous step.

Consistency in the quality, irrespective of the size

Being the only CNC milling manufacturer, we use the same staff of engineers for the production of one unit, along with one thousand, using the same process. This is an important aspect, considering the fact that it is because of this that we have been able to deliver the same quality, irrespective of the size, which helped your small batch production become successful in the micro industries.

Flexible and Scalable Production Capacity

Business for scaling purposes for us. This will allow us to scale from the prototype phase up to the massive production phase from hundreds to thousands. Of course, with possible delays from suppliers to suppliers. This will allow us to scale the production capacity with the flexibility of production capacity for small batch production units. We will readily help you enter the market with confidence.

Reduced Risk & Total Cost Efficiency

Risks will not exist because of this phase because all the processes will be taken care of by different individuals and different processes associated with them. This eliminates the cost associated with the re-qualification process because of Design for Manufacturing.

As concluding remarks, though it is not an easy task to accomplish easier transition from prototype production to production, yet as it has to occur, our tool not only intends to make it easier but also remove any possibility of risk-oriented production. As associated with the production process itself for prototype CNC milling through small batch production, our intention remains associated with your growth with your invention itself.

Figure 4: CNC machining services for prototyping aluminum parts in low volumes by LS Manufacturing

FAQs

1. Is the price being given for the lineup correct? What kind of papers I have to fill out?

The tool utilizes the ‘real-time processes database’ and ‘an extremely accurate quote algorithm based on AI,’ as defined in the release. It is enough if the user has possession of the 3D file in the STEP/IGS format, as well as the material that the user wants to replace with the new shape.

2. What is the Minimum Order Quantity (MOQ)?

In addition, we also make it easier for you in the production process, starting from prototype production, mass production, without limits on the minimum production requirement needed. This also includes the process of verification or trial production. We can make a plan according to your requirement.

3. How do I ensure the security of my design intellectual property (IP)?

We also agree to abide by all terms and conditions of any confidentiality agreements (NDAs) in existence, utilizing the latest mechanisms for secure transmission of data with isolated storage. Your data will remain under our sole control from the time you upload it until the end of production.

4. What is the typical delivery cycle?

The prototype will take at least 3-5 working days to set up, depending on the complexity level of the designs involved. In cases of bulk production, the production schedule will be decided, including the delivery procedure.

5. What quality inspection reports are provided?

We supply the entire process for quality documentation, together with the report for first parts inspection, the CMM parts inspection report in actual size, and the material certification documents. Every production batch of the components has a traceability number which sustains the trail of the quality.

6. What happens if problems are found after parts arrive?

We are dedicated to the quality process and will assume complete liability for any flaws and issues that may possibly arise. Regarding the issue of products that do not conform to specifications, our company provides free rework and remanufacturing and expedited production that will in no way affect schedules.

7. Do you provide Design for Manufacturability (DFM) feedback?

Free analysis will be offered in all quotes. The engineers will help you in DFM analysis as far as free analysis is concerned, which will help them in giving professional advice regarding DFM. Hence, they will help you in not facing these problems in your designs in the initial stages.

8. What material options are supported?

We support many materials like aluminium alloys, stainless steel materials, titanium materials, engineering plastics, etc. The safety stock of various components is also held. Special components made of various materials are also purchased as per requirement.

Summary

Being able to rely on a customized online CNC machining service for your project can offer something far more significant than simply an ordering process – a crucial decision that can, in fact, optimize manufacturing efficiency, as well as the reliability of your supply chain.

At LS Manufacturing, we have simply determined that instead of falling behind with outdated technology, we too want to serve as the manufacturing supplier of choice for the leading corporations in a vast number of industries. Your project, too, can benefit from maximum productivity, as well as our expertise.

Get a personalized quote now and unlock the manufacturing potential of your products. Click to contact us!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.