In the realm of precision CNC stainless steel thread turning, do you find yourself amid the following challenges on a regular basis: excessive tool wear rates, unstable thread precision, and inability to boost production efficiency? These seemingly unrelated technical pain points all lead to the same outcome: runaway production costs.

This is not a general theory overview, but the ultimate guide refined by LS Manufacturing based on rich success stories. We will cut to the chase, systematically exposing the best practices for machining stainless steel threads, from key selection of state-of-the-art tools to meticulous control of precision throughout the whole process. If you would like to maximize tool life, boost product yields, or maximize cycle time, this article will provide you with solutions that work.

Through intense reading, you will learn in-depth the core skills of CNC stainless steel thread turning and master actually the art of CNC thread precision control and get over the technical barriers that have long plagued you and achieve a breakthrough in efficiency and quality. To save you time, here’s a quick overview of the core conclusions.

CNC Stainless Steel Thread Turning Core Quick Reference

| Topic | Key Parameters/Selection | Key Points |

| Tool Material | Ultra-fine-grain carbide is the recommended material. | It ensures maximum wear resistance and toughness in the optimal ratio, well suited for high-speed machining. |

| Tool Coating | PVD (TiAlN, AlCrN) | It provides excellent hardness, low friction, and good thermal stability with built-up edge resistance. |

| Tip Shape | Full-profile thread cutter | It gives exact thread profile and prevents secondary finishing. V-profile or finishing only are proprietary profiles. |

| Cutting Speed (Vc) | 80-150 m/min | Depending on specific grade of stainless steel and state of heat treatment. In austenitic grades (e.g., 304), use lower or mid-range. |

| Feed | Same as pitch (P) | Constant lead is used in CNC programming, i.e., feed per revolution = pitch. |

| Deep Cut | Progressive layered cutting | First deep, then progressive reducing layers. Finishing allowance: Smoothness 0.05-0.1mm. |

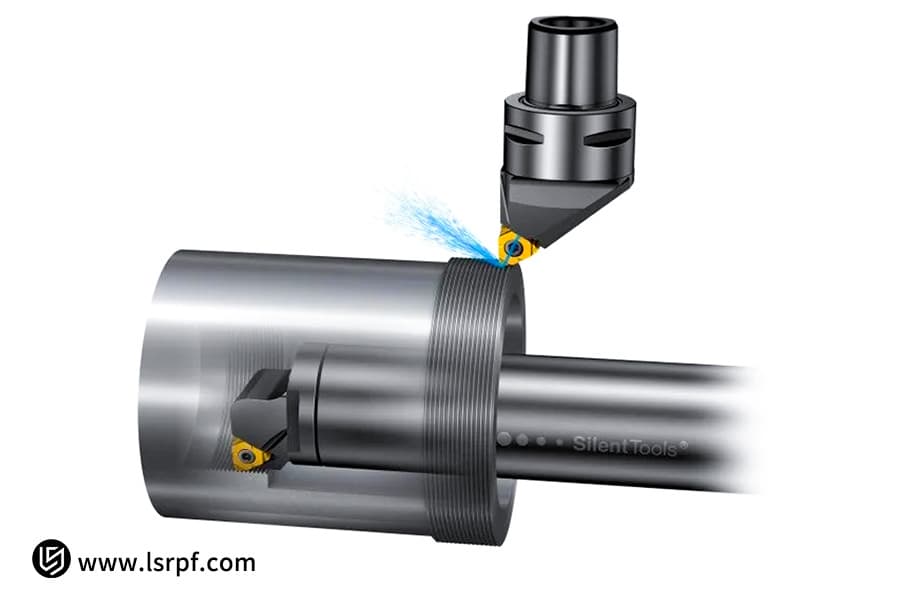

| Cooling | Internal high-pressure cooling | Forcing chip ejection and cooling are essential to stainless steel thread accuracy and surface integrity. |

| Thread profile inspection | Using thread micrometer/ring gauge | It is essential for first-piece inspection in mass production, with sampling still used to check pitch diameter and accuracy of fit. |

This convenient reference chart summarizes the key technical requirements for machining stainless steel threads. The key to success is selecting the right tool (grade and coating), applying high-pressure internal cooling, and strictly adhering to a step-down cutting technique.

Strictly adhering to these tried-and-true best practices will considerably improve your process stability, thread quality, and production efficiency, while not enabling overall costs to get completely out of hand.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

LS Manufacturing represents the culmination of over two decades of practical experience in precision manufacturing. LS Manufacturing solves your problems on a daily basis—high-strength aerospace fasteners to medical device precision threads, stainless steel thread turning is a highly developed aspect of our fundamental technology platform. Our solutions are tested and refined through thousands of production hours in our state-of-the-art CNC workshop, where they may be put into effect immediately at your factory and create real value.

This is founded on the physical problems that LS Manufacturing has solved for you. For example, we helped a customer overcome the accuracy problems of 304 stainless steel hydraulic fitting threads. By replacing a generic coated tool with an AlCrN-coated tool that's suited for our harsh working conditions, and optimizing high-pressure coolant parameters and stacked cutting strategies, we were able to increase tool life by 40% without compromising thread accuracy within a constant 6g tolerance.

This is the LS Manufacturing guarantee: Just experience-driven solutions and facts, to help you transform machining issues into core strengths.

Why Is Stainless Steel A Challenging Material For CNC Thread Turning?

The challenges in stainless steel CNC thread turning are a direct result of the material's inherent characteristics. Compared to usual steel, the range of stainless steel properties places extremely rigorous requirements on tooling and processes in CNC thread turning. The particular challenges result from the following three intrinsic characteristics:

1. Significant tendency to work hardening:

Stainless steel exhibits high ductility. The machining surface will experience plastic deformation under the cutting edge pressure rather than even delamination, accompanied by a sudden rise in surface hardness. Not only is this harder to cut subsequently, but it also quick-wears the tool edge like an abrasive, causing thread distortion and surface roughness.

2. High Toughness and Strength:

Stainless steel can take in a great amount of energy without fracture and possesses lower chip curl tendency and fracture. Under the restricted chip area in thread turning, long and hard chips are prone to get stuck in the tool or workpiece and chip and scratch the machined surface.

3. Poor Thermal Conductivity:

Stainless steel is a severe cutter heat conductor, which retains the majority of the heat from being carried away in the chips and instead localizes to the narrow tool tip area. Sufferingly severe local temperatures embrittle the workpiece material (maximizing work hardening) and create extensive diffuse wear and plastic deformation of the tool, directly resulting in a severe reduction in tool life.

It is the combination of work hardening, toughness, and thermal conductivity that is low which creates CNC turning stainless steel threads so much of a norm problem. It is only through a total grasp of the causes that we can develop effective solutions to ensure quality as well as cost-effective machining.

What Are The Three Core Factors To Consider When Choosing A Stainless Steel Threading Tool?

To choose CNC turning tools, stainless steel thread turning tools involve more than comparing models; it's a decision-making exercise to find the ideal compromise among three interdependent basic factors. Clever trade-offs can greatly improve efficiency and quality, or destructive trade-offs can be very expensive. Each of these three basic factors must be weighed carefully:

1. Tool substrate material and coating:

- Toughness priority: When cutting interrupted, irregular allowance stock, or austenitic stainless alloys such as 304, a tougher carbide substrate is required to prevent chipping.

- Wear resistance priority: When making continuous cuts, high-silicon martensitic stainless, or where increased tool life is required, an ultra-fine-grained substrate of higher hardness must be selected, in combination with a wear-resistant coating such as AlCrN to resist high-temperature wear.

2. Geometry and Angles:

- Sharp Cutting: The high rake angle and sharp cutting edge successfully minimize cutting forces, reduce the tendency of stainless steel to work-harden, and yield a smoother finished surface. This can, however, slightly reduce the strength of the cutting edge.

- Reinforced Cutting Edge: A low rake angle and passivated cutting edge provide more strength and impact resistance, but for more severe cutting operations. But this comes at the cost of increased cutting forces.

3. Nose Radius:

- A small nose radius provides undercutting of the thread profile and is therefore of maximum importance for cutting fine-pitch threads that require a sharp profile. This also reduces cutting forces.

- A larger nose radius significantly increases tool tip strength, improves heat dissipation, and reduces surface roughness. However, a radius that is too large may increase cutting forces and may affect the profile.

Choosing the best tool for turning stainless steel threads is really a precise "three-dimensional balance" of workpiece material, thread demands, and machine tool conditions. Effective comprehension of this choice-making practice is fundamental to the realization of efficient and high-quality CNC stainless steel thread machining.

How To Optimize Cutting Parameters To Address Chatter And Burrs?

Chatter and burrs are inherent problems in precision stainless steel thread turning. Causality is unstable cutting forces, work hardening, and improper evacuation of chips. In order to address them in a systemic manner, precision CNC thread turning technology mastery and stable turning by simultaneous optimization of parameters are necessary. The following are the main optimization measures:

| Parameter Category | Optimization Strategy | Core Issues Addressed |

| Speed (Vc) | Avoid low-speed ranges of resonance and use medium-to-high linear velocities (e.g., 120-180 m/min) to impart smooth cutting. | Damp and reduce chatter and oscillations in cutting force. |

| Deep of Cut (Ap) | Utilize rigidly "decreasing" layered cutting, with a finishing allowance of 0.05-0.1mm. | Reduce work hardening, improve surface finish, and eliminate chatter marks. |

| Cooling Method | Employ high-pressure internal cooling (pressure ≥7 MPa) to enable precise cooling and forced chip breaking. | Possibly restrict thermal stress, avoid chip entanglement and scratching, and reduce burrs at the root. |

The philosophy of best practice machining of stainless steel threads is the methodical combination of medium-to-high speeds, diminished depths of cut, and a high-pressure internal cooling method.

This set of parameters is utilized to effectively eliminate tool chatter and work hardening, enabling clean chip breaking, an absolute safety feature ensuring superior thread finishes and improved tool life.

What Other Systems, Besides Machine Tools, Are Needed To Ensure Thread Accuracy?

In high-precision CNC machining of threads, advanced machine tools are only the beginning. For even practical implementation of CNC thread accuracy, there needs to be a comprehensive, integrated system of measurement and quality control instituted throughout the whole process of machining to produce each product to hold to rigid tolerances on a consistent basis. The system has two important components:

1. Real-time Monitoring During Processing:

After critical processing operations, we use a non-contact in-process gage probe. The probe rapidly measures such critical dimensions as pitch and major diameters of the thread without stopping the spindle. If there is dimensional drift due to micro-wear of the tool, the system will automatically compensate or raise an alarm so that preventive quality control can be ensured and batch scrap minimized.

2. Final Inspection after Processing:

- Functional Verification: Thread go/no-go gauges are more appropriately utilized for 100% high-speed inspection, directly measuring thread engagement and product assembly functionality.

- Precision Analysis: For the first and last sections, or for key orders, high-precision optical projectors or thread measuring machines incorporated in them are used. Such equipment can magnify and project the profile of the thread to be compared with standard drawings accurately, measure microscopic factors such as thread angle and pitch with high precision and provide authoritative data backing for precision.

By integrating the real-time performance of on-line inspection and the precision of end-of-line testing systems, we have established a quality safeguard greater than the performance capability of machine tools themselves.

The high-precision CNC thread processing technology system is the ultimate assurance for efficient CNC thread accuracy control and ensuring the reliability of every product.

How To Improve The Efficiency Of Stainless Steel Thread Processing In Mass Production?

In order to break mass production efficiency barriers for stainless steel CNC threading processing, we must shift our focus from specific technical aspects and toward optimizing the entire production system. To do this, we must institute better management techniques to optimize cost and efficiency in high-volume manufacturing.

1. Tool Standardization and Inventory Reduction:

Consolidation of the various disparate tool models into a small number of proven standard models. Not just simpler to code and execute, reducing errors, but it also reduces tool buying and administering costs by a great extent through central buying and stock control, the foundation for cost-saving stainless steel CNC thread machining.

2. Fixture Solutions and Process Innovation:

Relieving traditional single-part turning thinking. Simultaneous multi-axis turning centers or fixture planning optimization to perform a sequence of operations in a single setup can increase output per unit time by several orders of magnitude. Process innovation is the easiest way to improve overall efficiency in CNC stainless steel thread turning.

3. Implement a Preventive Tool Change Plan:

Create a spurt tool change strategy on the basis of accurate machining data and tool life data. Tool change prior to tool wear can effectively avoid batch quality defects and machine downtime as a result of excessive tool wear, bringing stability and continuity to the production line.

By incorporating standardization, process innovation, and preventive maintenance systems, an organization is able to create a stable, efficient, and controllable production system. This not only saves the entire expense of stainless steel CNC thread machining but also makes sense with volume competition superiority in the long run.

How Did LS Manufacturing Solve The Problem Of 304 Stainless Steel Port Thread Leakage?

In stainless steel CNC thread machining, leaking seal threads has long been a technology bottleneck for nearly every manufacturer. The following case shows how LS Manufacturing methodically solved that problem.

1. Customer Dilemma:

A hydraulic components firm was plagued by the problem of machining NPT taper pipe threads on its 304 SS valve manifolds: the thread seal leak rate was up to 30% during high-pressure testing, and tool life was unusually low. Not only was this making production cost-prohibitive, but it was also severely impacting the customer's market image and order fulfillment through excessive rework and shipments behind schedule.

2. LS Manufacturing Solution:

With meticulous analysis, our engineering department discovered that the leak originated from microcracks on the thread surface caused by work hardening. In this regard, we designed a special solution:

- First, we developed a dedicated stainless steel thread turning tool with a dedicated AlCrN coating, considerably boosting the wear resistance and anti-adhesion performance of the cutting edge in work-hardened materials.

- Second, we optimized the turning path and layered cutting condition to effectively dissipate the cutting heat and stress.

- Third, we enhanced focus and jetting accuracy of the high-pressure inner cooling to ensure chips are correctly cleared from the machining area in a timely manner.

3. Achievements and Value:

With this solution in place, outstanding results were achieved: the leakage rate of the thread on the valve block when subjected to high-pressure testing was reduced from 30% to below 0.5%, tool life was increased by three times, and the overall machining cost per unit was reduced by approximately 40%. This achievement not only fully met the customer's quality issues and earned customer satisfaction for the stability of their product but also secured a major order.

This case indicates that the application of mastery in CNC thread accuracy through systematic process optimization can bring technological gains to the economic benefits and significant market competitiveness directly.

What Are The Differences In Technology And Tooling For Internal And External Thread Turning?

In the selection of machining best practice for stainless steel threads, internal and external thread turning present various technical issues. Deep understanding of the fundamental differences between the two tooling types in respect of chip evacuation, stiffness, and visibility is required for an appropriate decision in choosing the right CNC turning tool.

1. Chip Evacuation Direction and Cooling Strategy:

- External threads: Chips tend to drop naturally outward, and chip evacuation is thereby quite easy. Nevertheless, high-pressure coolant must still be directed to avoid long chips to be tangled in the workpiece.

- Internal threads: Chip evacuation is a major problem. Chips must be removed in a reverse direction through a small bore, simply causing blockage and scratches on the surface that has been machined. Therefore, high pressure internal coolant toolholder is needed, utilizing the pressure of the coolant to force chip breaking and evacuation.

2. System Rigidity Differences:

- External threads: Minimum tool overhang provides maximum system rigidity, enabling higher cutting parameters and minimizing tool chatter.

- Internal threads: High toolholder aspect ratio reduces rigidity significantly, and therefore it is the most vulnerable link in the operation. A vibration-resistant toolholder with added thickness has to be selected, and cutting parameters must be decreased accordingly to suppress vibration.

3. Process Visibility and Interference:

- External threads: The cutting process is visible directly to the operator, which provides better monitoring.

- Internal threads: Internal cutting cannot be observed, making tool setting and monitoring difficult. Tool choice should prioritize anti-interference features (e.g., low clearance angle) to prevent toolholder contact with the hole wall. This is directly related to machining safety and success rate.

Internal threading is actually an enclosed space operation, while external threading is done in open spaces. This set of expert solutions represents the core of best practices in stainless steel threading, serving various scenarios and resulting in consistently great threads.

Small-Diameter Or Deep-Hole Threading: What Solutions Does LS Manufacturing Offer?

Small-diameter and deep-hole threading is a gigantic issue in precision CNC threading technology. Some of the most notable problems are chip evacuation, tool rigidity, and limited view. LS Manufacturing, with its extensive history and innovative methodology, offers customers numerous tested and proven specialized solutions. LS Manufacturing technical solutions address the following three primary areas:

1. Specialized Tool Applications:

For most hole diameters, LS Manufacturing stresses solid carbide thread milling cutters that are very rigid. Especially for micro-diameter holes smaller than M6, the one-shot, full-profile design prevents chip interference, virtually ensuring profile integrity and dimensional accuracy.

2. Customized Tooling Support:

In order to neutralize toolholder vibration-caused thread chatter in deep-hole machining, LS Manufacturing can design special toolholders with guide rings or vibration-damping features. Special tooling such as this significantly increases rigidity of the machining system so stable cutting is possible even under extended overhangs.

3. Unique Programming and Process Techniques:

LS Manufacturing has developed a "segmented retraction" programming method for deep-hole threading. In this method, a CNC program is used on a periodic basis to retract the tool radially by some amount during rotation, forcing chip breaking. This addresses the significant pain area of continuous, prolonged chip jamming and enables safe and smooth machining.

With the challenge of machining small-diameter and deep-hole threads, LS Manufacturing has successfully transformed apparently impossible thread machining tasks into stable and reliable mass production processes with a comprehensive solution of "dedicated tooling + customized tooling + special programming."

Why Is LS Manufacturing Your Ultimate Partner For Stainless Steel Thread Turning?

With advance and difficult stainless steel CNC thread turning business, winning isn't merely a matter of cutting-edge technology, but also a total partner that is able to provide total service. LS Manufacturing is this sort of partner. By the integration of engineering capability and services, we transform successful stainless steel thread turning best practices into a sustained competitive advantage for our customers. We differ in three essential aspects:

1. Proactive Engineering Support:

LS Manufacturing is highly involved in our customers' production and R&D activities, from manufacturability analysis in the early stages to custom tooling and parameter recommendations. This ensures that projects are set on the optimal process foundation at the outset and significantly minimizes future risks.

2. Stable Quality Control Throughout the Entire Process:

LS Manufacturing does not just provide technical solutions but also helps customers design and optimize every quality control node from raw materials to shipment of final products to ensure highly consistent and dependable stainless steel CNC thread turning results for every product.

3. Efficient and Rapid Response:

With unexpected technical issues on-site, LS Manufacturing engineers can provide timely technical diagnosis and solutions to prevent production downtime and ensure delivery timelines.

LS Manufacturing will help you overcome these challenges and seamlessly integrate successful stainless steel threading best practices into your production process, so that you establish a long-lasting competitive advantage.

FAQs

1. What are the differences in tool selection when machining austenitic stainless steel (such as 304) and martensitic stainless steel (such as 420)?

When cutting hard 304 stainless steel, tools should be selected with sharp cutting edges and PVD coatings to minimize the work hardening tendency and facilitate chip evacuation smoothly. Harder carbide substrate tools and reinforced cutting edge design tools are ideal for cutting harder 420 stainless steel to withstand interrupted cuts' shock. Proper tool choice is the foundation of best practice stainless steel threading and can in fact extend tool life by a factor of nearly 30%.

2. What are the most common causes of precision loss in stainless steel thread turning?

The primary causes of precision loss are variations in tool tip shape as a result of tool wear and tool deflection by work hardening. These have a direct effect on changing the actual cutting path, and pitch diameter and pitch errors result. Precision CNC thread machining technology, firm control of tool life, and direct cutting temperature control in real-time using high-pressure internal coolant are required to prevent precision distortion at the root and ensure thread quality stability in the long term.

3. My project has a large batch size. How does LS Manufacturing ensure consistency across all threaded parts?

LS Manufacturing guarantees batch consistency in a three-step process: one, we develop highly detailed standardized work instructions; two, we implement statistical process control for the whole manufacturing process with real-time monitoring of important dimensional trends; and three, we use high-precision in-line measurement and periodic spot checks to ensure accuracy from piece number one to 100,000. This rigorous system of stainless steel thread machining best practices is the main guarantee for producing zero-variability batch material.

4. Besides turning, does LS Manufacturing offer other high-difficulty thread machining services?

Yes. LS Manufacturing offers complete range of high-complexity thread machining solutions. We utilize thread milling for asymmetrical parts, deep blind hole threads, or heat-treated hard materials; grinding for highest precision medical parts; and flow forming for parts requiring greater fiber flow. Overall, these advanced precision CNC thread capabilities comprise our complete matrix of capacities to tackle difficult-to-thread applications.

Summary

Efficiently gaining stainless steel thread turning is a demanding process that involves materials science, tooling technology, and accuracy control. LS Manufacturing, with its vast industry expertise and ample hands-on experience, has turned this complex process into a reliable, efficient, and standard procedure.

We not only offer established stainless steel threading best practices, but are dedicated to integrating cutting-edge precision CNC threading technology into every phase of your manufacturing process, essentially improving your manufacturing competitiveness.

Act now and bring your problems to us! Contact LS Manufacturing today and upload your part drawings directly onto our website. LS Manufacturing experts will provide you with an instant CNC turning quote within 24 hours, including customized tooling recommendations and key process parameters. With LS Manufacturing, you are choosing a scientific approach to production problems and partnership to develop overall enhancements in accuracy, efficiency, and reliability.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.