Tapping vs milling is a classic trade-off problem faced by the manufacturers in achieving a subtle balance between costs and quality. The conventional tapping method could be the cause for the breakage of taps and the inaccuracy of the test results, whereas on the other hand, the thread milling technique requires extra expenditure of money.

However, the drawback in that case is that it results in a loss of a systematic process for evaluating a process. In some cases, it results in choosing the incorrect process, which, in turn, results in additional expenditure pertaining to cost as well as quality concerns. Evidently, a systematic guideline is required for systematic differentiation between the tapping and milling process. To save you time, the following is a detailed explanation.

Tapping VS Milling: Quick Reference

| Aspect | Tapping | Milling |

| Cost | Cost of tools | High tool cost |

| Speed | Fast cycle time | Slow cycle time |

| Flexibility | Fixed size | One tool, multiple sizes |

| Precision | Good | Excellent |

| Risk | High breakage | Low breakage |

| Best For | High volume | Low volume, high precision |

Even tapping proves highly beneficial for mass production, enabling rapid output with a notably economical cost per unit. In contrast, milling offers greater versatility and superior dimensional precision. Furthermore, CNC milling tools typically have a significantly extended operational life compared to a standard tap, making them more suitable for complex or durable component manufacturing over longer production runs.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There exist hundreds of articles concerning tapping and milling. What is different about this article? Well, this article is based on experience, not theories. As a representative of LS Manufacturing, we have been dealing with tough alloys for more than 15 years in relation to tapping and milling. What our technical staff knows is more than simply the differences; our technical staff uses this knowledge to make sure that what leaves here for a critical component is reliable.

The years of experience in the fulfillment of over 50,000 custom parts with accurate threading have provided an indication of those things that work. Whether optimizing a tapping cycle on a titanium part or suggesting milling cutters to be used in mass production milling, states the author, we have experience with what works relative to the aerospace quality that is perceptively tied to the strict specifications of the International Aerospace Quality Group (IAQG), also known as SAE International.

These lessons learned here are not of academic origin. It's battle-tested approaches developed while facing real world challenges in the aerospace, medical, and automotive industries-thread quality cannot be compromised in any way. It is within this spirit that all this hard-earned expertise is shared with you so you can learn from these mistakes and find the right balance of quality, efficiency, and price.

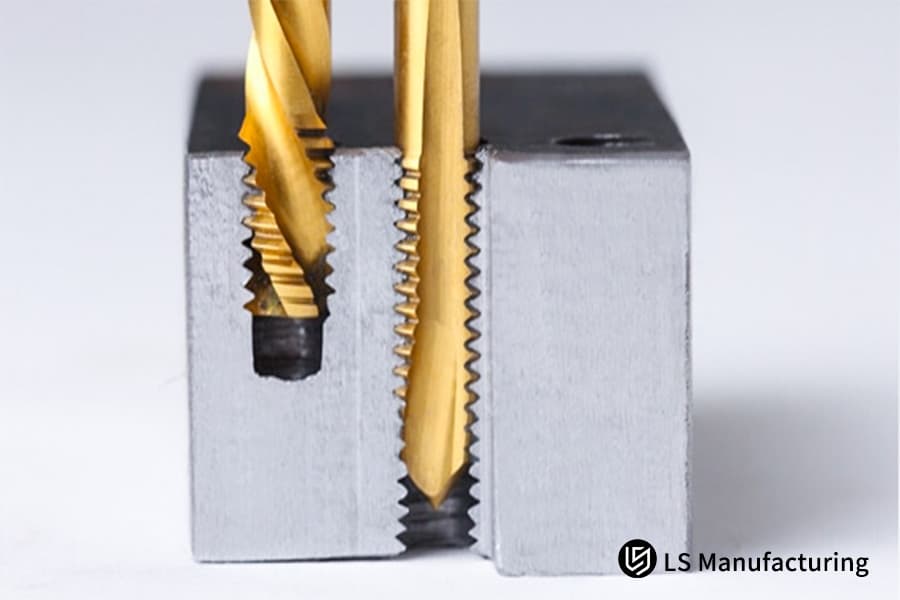

Figure 1: CNC manufacturing process highlighting thread tapping close-up view by LS Manufacturing

What Are The Fundamental Differences Between Tapping And Milling In Thread Machining?

The best method of tapping vs milling is dependent on a number of factors some of which include batch size, level of thread processing, materials, and levels of accuracy. The technique used by LS Manufacturing for process comparisons allows its clients to decide on the process that best suits, depending on factors such as thread detail and the hardness of the materials in question, thereby allowing an average efficiency improvement of 35% overall in thread processes.

| Feature | Tapping | Milling |

| Process | Type Forming/cutting thread directly with tap | Cutting via programmed toolpath |

| Tool Cost | Low (per size) | High (versatile end mill) |

| Setup Time | Fast | Slow (programming required) |

| CycleTime | Fast | Slow |

| Flexibility | Low (fixed size per tool) | High (one tool for multiple sizes) |

| Material Suitability | Ductile materials | All materials |

| Blind Holes | Excellent | Good (requires chip evacuation) |

| Thread Quality | Good (consistent) | Excellent (high precision) |

| Tool Breakage Risk | High | Low |

| Best Application | High-volume, simple threads | Low-volume, complex threads |

It is an amalgamation of tapping vs milling, entirely dependent on various factors. To completely tackle this problem, LS Manufacturing has devised a completely new way of process comparison that shall enable the customer to reach the completely optimal solution based on various parameters such as thread specifications and material hardness. All these have completely increased the efficiency of thread milling processing by an average of 35%.

How To Choose Between Tapping And Milling Processes Based On Product Characteristics?

The decision of how to choose tapping or milling is a significant concern for manufacturers, as this process selection affects the product characteristics as well as costs. To make this choice, one needs to evaluate a set of parameters related to products. The choice does not stand generalized based upon applications.

- Batch size-production volume: In production runs, tapping generally offers better economical advantages based on its shorter cycle times despite relatively high investment in tools. However, thread milling is flexible for small-size productions and prototyping since different thread sizes can be cut with just a single tool, with less investment in setup tools.

- Material Properties and Hardness: The class of materials used for this process includes ductile materials such as aluminum and mild steel. The hard materials include titanium and steel, where thread milling is used. For preventing the breaking of materials and the production of good quality threads, thread milling is considered essential. The machinability of materials, as well as the class of the formed chip, help determine the class of manufacturing processes.

- Thread Specifications and Complexity: For simple geometric features, tapping has a lot to offer in terms of speed of execution. When it comes to more complex geometry or larger diameter threads or pitches that are not standard, thread milling is more flexible in terms of programming.

LS Manufacturing has developed an intelligent selection tool for assessing these factors in order to make an optimal process selection between tapping or milling. With some factors dependent on the product characteristics, manufacturers are in a position to make 20-30% optimizations in terms of cost while maintaining high quality standards in order to make the optimal decision of the respective processes.

How Can Cost-Effectiveness Be Maximized In Economical Tapping And Milling Solutions?

To achieve cost-effective tapping milling process, the key, therefore, lies in identifying the optimal balance point between the cost of investment and the potential for optimization in the tapping and milling process as well. It all lies in the potential of the tapping speed while also considering the resulting flexibilities in the cost optimization through the use of the economic solution.

Value Engineering Analysis for Process Selection

In the scenario of LS Manufacturing, value engineering is intensely used to determine production cost. It has been observed that in mass production of generic threads, tapping is proved to be more cost-effective compared to other processes because of smaller production cycles. But in production of complex shapes or in low production volumes, due to versatility in thread milling processes, cost-effectiveness is observed despite high production costs.

Hybrid Approach for Mixed Production

Most of the manufacturing companies use the usefulness of a combination of the two processes. The thread tapping is applied to the standard volume components, while the complex components are produced by thread milling. It helps to cost optimization of production for all the components in determining which components are to be produced in which process.

Tool Life Management and Process Optimization

It is important to maximize tool life using proper tool parameters, use of coolants, as well as maintenance. In the LS Manufacturing, the process monitoring systems that are used can be useful for monitoring tool conditions. This reduces downtime and tool replacement costs, contributing significantly to overall cost optimization.

In order to have cost-effective tapping milling, it is required that one should have a data-driven approach in consideration of the overall manufacturing process. By utilizing the process of value engineering and combinations along with optimized tools for life management, LS Manufacturing helps their customers in achieving savings of over 25% in the cost of manufacturing.

Figure 2: CNC threading cutter machining blue material with an iridescent surface by LS Manufacturing

What Are The Differences Between Tapping And Milling In Accuracy And Efficiency?

Tapping and milling are two fundamental machining processes with distinct characteristics in accuracy efficiency and process performance. Tapping can be considered the best for high-speed machining of internal threads. But there are certain limitations regarding accuracy in tapping. But in thread milling, high accuracy can be attained with complex programming. Based on material and volume of production, there can be a choice between machining processes.

| Aspect | Tapping | Milling |

| Accuracy | Limited (±0.05mm) | High (±0.01mm) |

| Efficiency | Fast (single pass) | Slower (multiple passes) |

| Tool Life | Shorter | Longer |

| Flexibility | Low (fixed pitch) | High (variable pitch) |

| Programming | Simple | Complex |

Tapping and milling difference lie in the trade-offs they present to the users. Although the tapping speed may be fast and the volumes may be high, the accuracy of the process involved in milling is better due to the preferred wear of the tools compared to tapping. Hard materials are also considered to be among the factors that determine the process of milling over tapping.

How To Make The Optimal Process Choice Between Tapping And Milling?

There is a requirement for a decision framework model that considers a large number of factors in order to choose between tapping and milling. It is a combination of production and resource factors that must determine the optimal selection out of the two that consider the variability in benefits to be leveraged. It is a structured method for decision-making that holds the solution to decision-making in cases like LS Manufacturing.

- Production Volume and Batch Size: Due to the shorter cycletime needed for tapping, tapping is more ideally preferred for production in high volume, while programming is relatively simpler. The flexibility in production by batches as well as for prototype production for special products can also be met by milling operation. The break even point for material-thread specs is different for both processes.

- Thread Accuracy and Quality Requirements: Milling can ensure a very high degree of accuracy and surface finish if a tolerance level of + or – 0.01 mm or higher accuracy is required. On the contrary, tapping can function properly in the process of thread cutting if an accuracy of + or – 0.05 mm can be tolerated.

- Material Properties and Machinability: Hard materials (HRC > 45), and other alloys that are difficult to machine require milling. The reason for this is to avoid breaking that may occur during the time of tap. Moreover, it assists in the process of obtaining high-quality threads. The process of tapping is ideal for materials such as soft materials and materials made of non-ferrous materials. The hardness of materials is related to the life of tools.

- Equipment Capability and Setup Time: Tapping requires tapping skills for tapping performance, tapping synchronism, and spindle synchronism. Milling operation requirements include requirements for CNC systems that involve helical interpolation capability, other than rigidity. The specifications influence process capabilities.

- Cost Considerations and Tooling Investment: The tapping tool is more expensive. However, the life span of the tapping tool is longer when it comes to processing difficult materials. The life span of the milling cutter is longer than that of the tapping tool. This is aside from having multi-size threading advantages. All the component production costs take into consideration tool costs, programming costs, as well as machining costs.

A holistic approach needs to be implemented while making optimal selection between tapping and milling processes. This is because a generic solution for each problem is not available because each problem needs to be analyzed separately in order to make a decision framework the most feasible course of action. These operations also need to be implemented with the help of specially designed machines.

What Are The Technical Advantages Of Thread Milling Compared To Traditional Tapping?

Process of thread milling vs tapping can be identified as a significant technological advanced process with a technical advantages to make it a cutting-edge machining process. Although tapping is a conventional machining process for the past several decades, thread milling has a technical superiority.

Superior Accuracy and Surface Finish

The dimensional accuracy attainable within the tolerance limit of ±0.01mm by the thread milling process cannot be achieved solely by the tapping process, whose accuracy lies in the range of ±0.05mm. By means of helical interpolation, it is feasible to exercise a higher degree of control over the form and the pitch of the threads in order to compensate for the deficiency of the tapping process.

Enhanced Flexibility and Versatility

The single thread milling cutter can perform multiple types of threads along with their respective pitches for diameters that are possible depending on the cutting tool available. This process can be used for right-handed threads as well as for left-handed threads in an equal manner. For inner threads as well as for outer threads in an equal manner. In certain instances, it can also be used for tapered threads. There is no specific tap required for cutting threads for certain specifications.

Extended Tool Life and Cost Efficiency

Thread milling cutters would prove to be longer lasting compared to the taps. This is by a factor of 3 to 5 times if the material is similar. Sometimes, there could be improvements by a factor of 10 times. While the initial tool cost is higher, the extended tool life and reduced downtime result in lower cost per part over the production run.

Improved Process Reliability

Thread milling eliminates the risk of tap breakage in the workpiece, which can scrap expensive components. The process can be easily adjusted for size compensation and tool wear, maintaining consistent quality throughout the tool's life. In blind holes, thread milling provides better chip control and eliminates the need for peck tapping cycles, reducing cycle times and improving process stability.

Better Performance in Difficult Materials

Hard materials - HRC > 45, stainless steel, and so on are materials causing rapid wear to taps resulting in frequent breakage. These can also be effectively handled by thread milling. Cutting force and torque are lower in thread milling; as a result of which, it is preferred for thin-walled parts prone to breakages/distortion when tapping is done. Interrupted cuts and cross holes can also be effectively handled compared to tapping.

Thread milling vs tapping clearly demonstrates the technical advantages of this advanced process across multiple dimensions. It can be the accuracy of the process, the surface finish, or even the life of the cutting tools, thread milling performs better in one way or more; thus, it is the best process for doing the task, even though the initial expense of the process is high, its advantage is more preferable.

Figure 3: CNC tapping process employing a rainbow-hued helical flute tool by LS Manufacturing

How Do The Key Parameters Of The CNC Tapping Process Affect Machining Quality?

CNC tapping process success depends on precise control of key parameters that directly influence thread quality impact and tool performance. It has become clear from the experience gained by LS Manufacturing that the best possible control of critical parameters relies vastly on materials and specifications employed for the threading process.

Spindle Speed and Synchronization

The spindle speed needs to be properly synchronized with the rate of the feed. It needs to be ensured that there exists a proper relation between the speeds (Feed= Pitch×RPM). It means that if it exceeds to a higher speed, it would cause the tool to heat up. Thus, there would be wear and tear of the tool. In case it runs at a slower rate, it would give an undesirable shape to the chip. As such, there would be an increase in the cutting force. The range of the speed of the spindle could be from 50 to 500 RPM.

Feed Rate and Pitch Accuracy

Feed rate basically serves to control the accuracy of the thread pitch and therefore must have a value matching exactly the lead of the tap. Too much feed causes thread or tap breakage by stripping, while too little feed produces oversize threads with poor surface quality. For rigid tapping, the formula to determine the feed rate is pitch × RPM. For no error in the pitch due to misalignment, perfect synchronisation needs to be done between the two axes.

Coolant Application and Chip Evacuation

Cooling distribution is very important in heat dissipation, lubrication, and chip elimination. In this regard, high-pressure flood coolant (10-15 bar) applies for through holes while misting or lubricant coolants apply for blind holes. Inadequate cooling increases the chances of built-up edge formation, work hardening, and tool breakage, especially for stainless steel materials and their heat-resistant alloys.

Depth Control and Thread Engagement

The depth of a thread shall, however, consider tap chamfer length in addition to thread engagement. In cases of blind holes, the programmed tap depth will have to include the chamfer length in addition to an added depth of 1-2 pitches of full thread creation. An inadequate depth will lead to incomplete thread, while a depth that is too deep will cause tap breakage. A chamfer length in use will give a depth of 3-5 threads to smoothen thread engagement.

Tool Geometry and Coating Selection

Its geometric type, for example spiral point, spiral flute, or straight flute, should correspond to the particular job requirements. In the spiral point taps, chips pushed ahead in through holes and in spiral flute chips pulled out in blind holes. Coated tools with TiN, TiCN, or TiAlN good wear-resistant properties & friction-resistant qualities; hence, the life of the tools may increase 2-3 times.

A suitable optimization of parameters would have to be done for CNC tapping process so that quality impact effect is achieved. Key parameters related to cutting speed, cutting fluid, depth of cut, and a lot more would require a combination concerning the material to which it is working. Suitable combination parameters would result in the production of quality impact, improving the life of the cutter tool and bringing down the cost of production.

What Are The Specific Differences Between Tapping And Milling In Terms Of Processing Costs?

While calculating the milling vs tapping cost, it is to be noted that the cost curve for tapping and milling is not equal in nature. It should be noted that cost analysis is not a cost analysis on cost analysis. It is seen that the cost analysis for tapping and milling reveals that the cost curve is a function of the quantity.

- Initial Tooling Investment: The tapping tools costbetween $20 and $100 per piece, but thread cutting milling cutters costbetween $200 and $800. Nonetheless, by applying thread milling cutters, it is possible to produce more than one size of threads.

- Tool Life and Replacement: This is the life of the taps drilling hard materials. The life is 100 to 500 holes. However, this will require replacement. The thread milling cutters drill 1,000 to 5,000 holes before it is necessary to regrind. The longer life of the milling process will offset the work of drilling.

- Cycle Time and Efficiency: Tapping offers faster cycle times for single pass processing, and it is applicable where high production volumes are involved. There is a requirement for multi-pass processing and slower feed rates for thread milling. Milling can prevent other processing operations like deburring.

- Setup and Programming: G-code commands alone are enough to produce an optimal solution to the tapping process with very little programming. Thread milling requires complicated helical interpolations to be programmed. Small series production is far more economical with the tapping process due to its high setup costs when compared to thread milling. The tapping process cycle time is very long.

- Quality and Scrap Costs: In thread milling, the threads formed are very accurate and of good quality. There is cost saving due to the saving on inspection time. Tapping may be considered as a sensitive process because, in some cases, breakage may occur. While tapping tough materials, there may be some errors with respect to threads.

While performing a milling vs tapping cost of threads, it has been revealed that tapping is outstanding in producing standard threads in mass production; nonetheless, thread milling turns out to be more economical in mid-range production as well as in difficult materials processing. A thorough cost analysis considering all direct and indirect expenses is essential for the optimal economic comparison.

Figure 4: CNC threading instrument producing internal threads in metallic material by LS Manufacturing

LS Manufacturing Automotive Parts Industry: Optimization Of Engine Cylinder Head Thread Machining Process

LS Manufacturing was facing a tough situation in the car components manufacturing sector, but they were able to transform it through innovative process improvement. In the present case study, the definition for the strategic process improvement is identified as realizing substantial cost-saving initiatives along with quality enhancements for a high volume production process.

Customer Challenge

The problem that was facing the prime market in the context of the automotive spare parts industry was aluminum engine cylinder heads production and machining of threads. It may be noted that a level of tool wear and actual rejection rate of 8%, along with a cost of quality above 50,000 RMB, were some of these.

LS Manufacturing Solution

Full thread milling has been analyzed in the engineering process based on the intention of substituting tapping in these operations. This is achievable based on the selection criteria of the design of thread cutters capable of performing operations in relation to use in aluminum alloys, creating helical paths for interpolation, and levels of cutting factors. This process has the capabilities of producing full threads without necessarily adopting several setups in relation to eliminating levels of 6H threads.

Results and Value

This led to unexpected savings on various parameters. A tool life has increased by an astonishing 300%; hence, tools expenditure is now negligible at existing levels. The scraps per unit were decreased from 8% to an astonishing 0.5%; this affected the first past yield tremendously. The most astonishing fact is that this resulted in a cost saving contribution of nothing less than 600,000 RMB per year; due to this, the spending on this particular process is justified. This resulted in the formation of a strategic partnership amongst these two groups

LS Manufacturing is an example that demonstrates the level of efficiency of the process optimization technique in regard to specific issues in manufacturing and the general implications for a business. The thread milling method; which was clearly a very advanced technique in place of traditional tapping, provided the solution to a specific problem in a manner that considered a competitive advantage in regard to the implications of cost-effectiveness

Do you still find yourself torn between the tapping and milling processes? Well, we are here to assist in finding a suitable process for you.

How To Establish A Scientific Thread Machining Process Management System?

Process management for the threading process execution requires an organizational approach for efficiency and quality. Implementation of a quality system with standardized operation procedures for the operation of the process is essential in achieving efficiency in high volume processes. Such systems involve an organizational approach in the management of tools or parameters for the implementation of improvements in the process.

Standardized Operating Procedures

In this aspect, it is important to consider the relevance of process instructions in relation to thread processing. There should be an assurance that every process parameter related to threads in terms of spindle speed, machining speed, coolant use, and depth of control is considered in standardization for the benefit of employees within an organization.

Tool Management and Maintenance

There should be an organizational management system for the tools in order to track the usage life, as well as the replacement time of the tools. There should also be some set of standards that can aid in detecting whether it is appropriate for the tools to have an inspection, re-grinding, or even have to be replaced. The efficient management of tools can also aid in preventing unexpected breakage of tools and improving the usage rate of tools.

Quality Control and Inspection

There shall be the integration of the quality checks within the production process, starting from the inspection of the first piece to the final inspection. Thread plug gauges, ring gauges, and optical comparators are examples of gauges that can be applied. The process control can be used for recording the quality checks within the production process, and capability check can be done.

Effective process management requires a holistic approach that combines standardized operation procedures with robust quality system controls. By implementing systematic tool management, regular quality checks, and continuous improvement, manufacturers can achieve consistent thread quality, reduce costs, and improve overall production efficiency. This structured approach ensures that threading processes remain stable and capable of meeting quality requirements in high-volume production environments.

FAQs

1. In which process, tapping or milling, you remove a less amount of material?

Thread milling is also applicable in the case of small batch production. This is mainly owing to the fact that thread milling is done without a change in tools and also due to flexibility in programming.

2. Would it be better to tap or mill in the case of stainless steel material?

Thread milling would is also advised to be employed during the machining of stainless steel, given that it prevents work hardening, which can occur during the process of tapping.

3. What formula might I use to calculate economic cost savings for process conversion?

Free process evaluation through cost-benefit analysis to find the return on investment value for the conversion process.

4. Which of the two processes is more accurate in deep hole threading?

CNC milling is the preferred method to threading in deep holes for the improvement it offers in chip removal, accuracy, and resistance to tap breakage.

5. How to balance the processing accuracy with cost?

In this way, value engineering analysis leads us to a balance between the cost and precision for the given product. While in case of a normal connecting thread, tapping can be done, but for a critical component, milling is advocated.

6. Whether you can offer process testing and sample production service?

Free process testing and sample manufacture: to assist customers in verifying actual processing and selecting the best process solution.

7. What technical support is needed for the introduction of the new process?

In a bid to ensure that the new process functions properly, we shall offer technical support for the entire process.

8. How does a certain thread technique support quality control?

By adopting online inspection and SPC control, we established a full-scale quality monitoring system to ensure stable and reliable threading quality.

Summary

By the execution of scientific process selection methods and the processing management system, the quality and efficiency of the threading process can be significantly enhanced. With the vast amount of experience and the relevant expertise that they have, LS Manufacturing is capable of delivering effective process solutions to their clients.

Please contact our experts to schedule a no-cost thorough evaluation of your existing threading process because we will evaluate your needs specifically, and in particular with a point of view that considers these concerns in order to give you expert advice that meets your needs in regard to your requirements for efficiency as well as your sought-after quality.

GGet a free thread machining solution assessment today, optimize your tapping vs milling choices, and save up to 30% on costs!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.