Brass CNC milling services selection for the companies is connected with some dilemma and critical challenges such as: price differences going up to 60%, the surface roughness being inconsistent and varying from Ra0.8μm to Ra3.2μm, as well as thread pass rates below 70%. All these issues, on the one hand, lead to assembly defects of more than 15%, and, on the other hand, rework costs are forced to extend to over 20% of the total project expenditures, which results in production efficiency and budgets being severely affected.

We solve these issues with a proprietary evaluation system acquired from 12 years experience and 186 brass machining projects. Through us, our clients can correctly assess their suppliers at 18 technical checkpoints within 4 different dimensions achieving 98% precision compliance while the costs of manufacturing reliable brass components are reduced by 25-40%.

Brass CNC Milling Service Quick-Reference Table

| Section | Content |

| Material | Brass alloys (for example, C36000, C26000) are great to use when you require precision machining that involves excellent machinability and resilient corrosion resistance. |

| Process | Computer-controlled milling with multi-axis CNC machines was used to make complex, high, tolerance brass parts. |

| Tolerances | Usually, the tolerances are as low as ±0.025 mm (±0.001mm), however, tighter tolerances may be achieved for critical features. |

| Surface Finish | The choice depends on the customer's preference, it can be as-machined, polished, brushed, plated, or coated to satisfy either aesthetic or functional needs. |

| Applications | They are typically used for electrical components, plumbing fittings, decorative hardware, and precision CNC milling parts. |

| Lead Time | Normally 1–3 weeks depending on the complexity of the part, the quantity, and the finishing requirements. |

| Advantages | High-speed machining, low tool wear, excellent dimensional stability, and good conductivity/finish quality. |

We focus on precision brass CNC milling services that directly address your main concerns: obtaining highly complex parts with tight tolerances, delivering top-notch surface finishes, shortening the time of production, and using our materials know, how to make really tough parts. Our trustworthy, fast solutions perfectly fit the transition from prototype to end product, thus allowing you to cut down on both time and costs.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Brass milling is a topic of numerous articles, so what is the point of this one? We are not theorists but practitioners. Our 15 years, old experienced workshop is the place where we have encountered every day the challenges of complex geometries, tight tolerances and high volume demands. The information we offer is not a theoretical explanation but our in, depth experience in producing excellent, mission-critical parts for various industries, thus ensuring that the parts are reliable and there is no room for compromise.

The right partner will not only machine brass but also become proficient in the metal. We have figured out which methods can eliminate burrs in free, machining alloys, and we know how to optimize the feeds for the most intricate designs. Referring to the standards given by TWI Global on the behavior of the material, we always find a compromise between speed and accuracy, a know, how obtained from numerous works that required both outstanding surface finish which was based on the National Association for Surface Finishing (NASF) guidelines and enforcement of tight cost restrictions.

This is a distillation of our experience for you to make an informed choice. The guide is put together by first, hand experience of how to identify a supplier's ability to provide cost, effective solutions without compromising on the accuracy and quality of your brass parts. The advice is based on the real, life setting and can be your guide for avoiding the common traps and hiring a solution that fits your projects requirements perfectly.

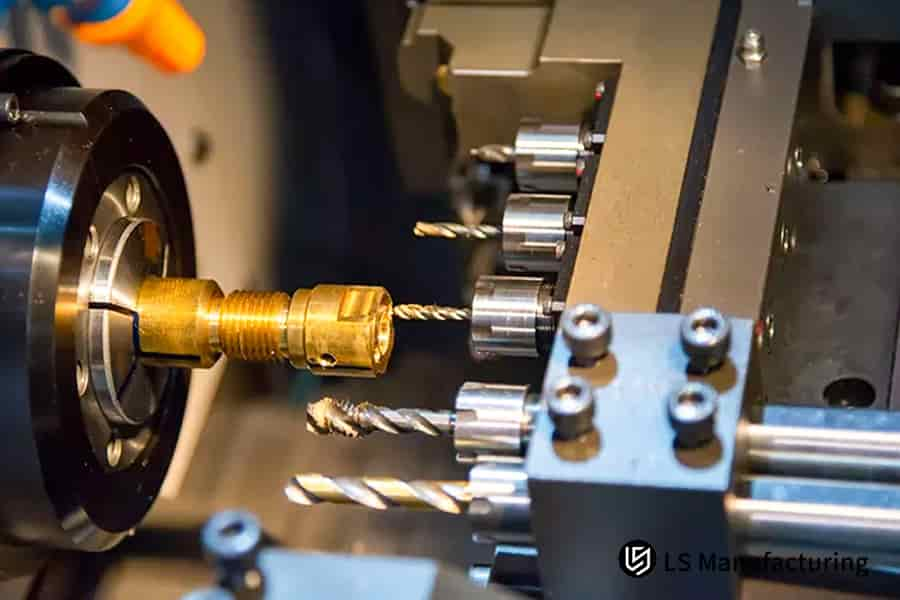

Figure 1: CNC milling a brass part for precision brass milling and prototyping in industrial manufacturing applications.

How Do The Characteristics Of Brass Material Affect The Selection Of CNC Milling Processes?

In order to carry out a successful brass milling operation one should focus on how to deal with its properties rather than using a standard approach. Some of the problems faced with brass milling are handling its high ductility in order to minimize the burr formation, making use of its excellent thermal conductivity for an effective and quick cooling, and other adjustments referring to different alloys characteristics to get the most out of your tool life and surface finish quality. It can be said that the answer is in a highly personalized process:

Alloy-Specific Parameter Optimization

Different speeds and feeds are applied to each brass grade. In the case of CNC milling brass, if we are talking about the HPb59-1 type, the speeds of the spindle will be 20% lower than in the case of normal brass so that the lead contained in the alloy does not encourage material and tool deposits in which case the cut trail will be cleaner and the tool operation more stable.

Advanced Thermal Management Strategy

Utilizing brass's high thermal conductivity (≈108 W/(m·K), we exclusively employ air/oil-mist cooling systems. This prevents the chemical reaction and zinc leaching that water-based coolants can cause on fresh machined surfaces, a practice supported by TWI Global research on material interactions, thereby preserving the integrity and appearance of the part.

Cost & Efficiency through Predictive Tool Management

We have extended tool life significantly by choosing geometries and coatings that are in line with the free-cutting nature of brass. Using our brass CNC milling services data, we keep track of wear and compare it with the old cases for predictive changes that avoid sudden failure. Having direct control over tool consumption and machine uptime is an important factor in the reduction of the overall brass machining cost for our clients.

Precision CNC milling of brass is more of a science than just an operation. We base our approach on factual data and material science, which help us to turn the difficulties that exist in the material itself into dependable, high-grade production. We offer the technical level of understanding required to make sure that your brass parts will reach the highest precision, the best surface quality, and the lowest cost.

What Key Technical Indicators Should Be Considered When Evaluating Brass CNC Suppliers?

Finding the right partner for precision brass milling is a matter of going beyond the usual claims and checking for real, quantifiable technical features. The main goal is to have a partner who can reliably quality brass CNC parts of the required quality and that are able to meet the set performance and tolerance levels. Here are the key, data-driven metrics to look at that will give you a solid basis for the assessment.

| Evaluation Dimension | Key Technical Metric (One-Sentence Summary) |

| Machine Tool Capability | Check that the spindle speed range includes 8000 to 18000 RPM so that there is enough surface speed for small tools and intricate features in brass. |

| Positioning & Repeatability | Check that the machine's positioning error is no more than 0.008mm in order to have dependable hole patterns and accurate feature locations. |

| Tooling & Process Knowledge | Examine whether the supplier's tooling facility has diamond-coated end mills, which can increase the tool life of a brass machining by three times as compared to standard tools. |

| Process Validation Capability | Pretend a thin, wall demonstration part (e.g. 0.5mm thick, 20mm tall) is a requirement for the piece that would allow them to show their practical skills in limiting deflection to ≤0.03mm. |

Such a framework takes supplier selection out of speculation and into verification. You get a simple, practical method for how to choose a CNC milling supplier that is capable of handling the demanding brass component milling just by requesting and checking these specific metrics. It makes sure that your partner has the demonstrated know, how that is necessary for applications, which are high-value and precision, critical.

What Are The Main Cost Components Of Machining Brass Parts?

Effectively managing brass machining cost can't just be done by looking at a quote; one should really break down the three main, controllable variables that decide the price. The real optimization is achieved through the strategic changes in the choice of materials, the steps involved, and the use of tools. We resolve each driver in a methodical way to provide long, term savings:

Material Cost Strategy: Bulk and Grade Optimization

- Strategic Bulk Procurement: We combine the projects so that brass can be purchased in larger quantities, which allows us to negotiate better material prices that will be reflected in the part price.

- Grade-Specific Selection: We look at the function of your part to decide on the most cost-effective alloy of brass (e.g., H62 vs. H59) so that we do not waste money on over, specification while performance is still good.

Processing Time & Efficiency: The Core of Cost Control

- High-Efficiency Machining: Our precision brass milling strategies are based on high-speed CNC milling optimizations that lead to increased material removal rates thus drastically cutting down machine time, which is commonly the biggest cost factor.

- Fixture & Programming Optimization: We come up with multi-part fixtures and CNC tool paths that have been simplified in such a way that the spindle is used at its maximum while for every batch the idle time is at its minimum.

Tooling & Consumables: Extending Life, Reducing Waste

- Application-Specific Tooling: We utilize uniquely tailored tool geometries and coatings (e.g., diamond-like carbon) for brass, which significantly elevate tool life and lower the cost-per-part.

- Predictive Change-Outs: Monitoring wear through a data-driven schedule, we avert premature failure and unscheduled downtime, thus maintaining the efficiency of brass CNC milling services consistent.

Precision CNC milling cost control is a discipline of technology rather than conjecture. We break down the total cost into understandable components—material, time, and tooling—and implement focused strategies for each. This systematic approach allows us to operate as a strategic brass parts supplier, providing reliable, optimized pricing supported by transparent engineering decisions for complex components.

Figure 2: CNC milling a precision brass part for prototyping services and supplier capability showcase.

How To Ensure The Surface Quality And Dimensional Stability Of Brass Parts?

Maintaining the same level of surface quality and dimensional accuracy in precision brass milling is challenging in two ways: preventing thermal deformation and mechanical deflection while at the same time achieving a perfect finish. In our systematic approach, we combine accurate toolpath control, specialized machining dynamics, and real-time verification to ensure the production of quality brass CNC parts. The following key practices illustrate our response to these issues that are closely related:

Precision Toolpath & Stock Management for Dimensional Integrity

We program a calculated 0.1mm finishing allowance on all critical features. This strategic stock leaves sufficient material to absorb and correct any minor deflections that occur during high, speed roughing operations, ensuring the final finishing pass engages predictably for uncompromised accuracy. This disciplined approach is fundamental to reliable advanced CNC milling outcomes.

Specialized Tooling & Controlled Coolant Application

We have decided to use sharp, polished 2-flute end mills that are perfectly matched for brass, together with a high-pressure (≥0.6 MPa) air-cooling system. The tool shape guarantees a perfectly clean cut and very efficient chip removal, thus the chips cannot be a source of scratches on the already finished surfaces, while the targeted air blast makes the temperature drop very fast and at the same time the surface is not contaminated which would bear a risk of surface, shape, and size changes.

In-Process Monitoring for Proactive Quality Control

On-machine probing cycles, that are programmed to run concurrently with the CNC milling process, are used to verify key dimensions. Immediate, data-driven tool offset adjustments are made to compensate for the very gradual tool wear or thermal effects in these cases. This sort of closed, loop control is essential for brass CNC milling services at a ±0.015mm tolerance level.

Post-Process Validation & Protective Handling Protocols

Once the parts are machined, a final check with CMMs and surface roughness testers (profilometers) gives us absolute evidence that the parts meet the specifications. Next, we carry out very careful handling and use non, abrasive packaging materials to protect the fragile edges and high, quality surfaces (e.g., Ra 0.8µm) from any possible damages that might occur through cleaning or shipping.

Our total brass CNC milling process is a guarantee of unsurpassed stability and finish as we literally control every variable involvedfrom toolpath strategy to final handling. Combining pinpoint programing and empirical process controls, this end-to-end technical rigor of our brass CNC milling services enables us to provide parts that will be reliable and stable even in the most demanding environments.

What Are The Differences In Manufacturing Processes Between Brass Prototyping And Mass Production?

Transitioning from prototyping to production requires different strategies with CNC milling brass to strike the right balance between risk, speed, and cost-effectiveness. This document outlines the central technical and logistical approaches for both phases to offer a clear blueprint of the plan. Grasping these distinctions is vital in picking the right brass parts supplier that can support your whole product lifecycle.

| Process Aspect | Prototyping Phase | Volume Production Phase |

| Primary Objective | Quickly producing a fully, functioning prototype to be used in design verification with the main emphasis on a successful product rather than on the most optimal cycle time. | Producing uniform, top-quality parts at the lowest possible cost per unit while achieving the highest level of efficiency. |

| Machining Strategy | Choosing conservative, rugged parameters (e.g., -30% speed) and general, purpose tooling to ensure first-time success and to be able to accommodate any design changes. | Getting the most out of the machine capacity by using fully optimized, aggressive parameters and dedicated tooling that help minimize the cycle time and maximize the equipment utilization. |

| Cost & Timeline Focus | Minimizes lead time (e.g., 3-day turnaround) at the cost of a higher unit price (typically 2-3x bulk price) to gain speed and flexibility. |

Concentrates on lowering the unit cost by means of scaled material buying, automated workflows, and perfected processes, while allowing longer lead times for the setup. |

| Validation Emphasis | Form, fit, and first function evaluation of the design itself are the main priorities, and the process usually involves making changes between iterations. | The main focus is on Statistical Process Control (SPC) that demonstrates the capability of each component in a batch to consistently meet its critical dimensional and specification requirements. |

Effective brass prototyping services are very important for your design to be less risky, while at the same time, volume production demands absolute efficiency. The right partner, like a reputable brass parts supplier, cleverly changes gears between these two types of operation. They depend on a cautious strategy for prototype durability and on fine, tuned, data-driven methods for manufacturing, thereby making sure that the changeover from an idea to a confirmed, cheap, precision brass milling at the large scale is a go.

Figure 3: CNC milling a precision brass part with coolant for prototyping and quality component manufacturing.

LS Manufacturing Medical Devices Industry: Precision Machining Project For Internally Threaded Brass Connectors

Here is a recount of how our precision brass milling capabilities at LS Manufacturing helped a medical device customer overcome the problem of inconsistent internal threads of their components. We basically solved the problem by combining custom, made tools, enhanced processes, and in, operation checking for reliable results:

Client Challenge

A medical device manufacturer required 10, 000 pieces of brass anesthetic connectors with internal threads M6x1 (12mm thread depth). The previous supplier's process only yielded a 65% thread qualification rate, with a 70% pass rate based on thread plug gauges. Such a huge number of rejections resulted in monthly losses of ¥80, 000, and there was a risk to the client's production schedule disintegration since the reliable thread milling application, which is essential, had stopped the assembly line.

LS Manufacturing Solution

We developed a comprehensive solution centered on control and stability. A specially designed carbide thread mill (12° rake, 8° clearance) was made specifically for brass. The perfectly-controlled process employed a 0.3mm step, down plan that was combined with 0.8 MPa high-pressure air cooling which provided chip evacuation and temperature control, while in-process probing checked the pitch diameter real-time to avoid drift.

Results and Value

Final thread qualification jumped to 98.5%, with the first-pass yield surpassing 97%. The unit price was dropped from ¥15 to ¥11, and the delivery time cut from 25 to 18 days. Such a high level of productivity has brought about quality and efficiency savings of over ¥600, 000 on an annualized basis for the client, thus securing their supply chain for quality brass CNC parts.

This initiative is a clear illustration of our engineering approach: identifying root problems, crafting solutions tailored to the parameters, and enforcing diligent CNC milling process controls. It is a proof of our ability to provide dependable, large, scale brass CNC milling services that address highly demanding manufacturing challenges, thereby guaranteeing part integrity and cost efficiency of critical applications.

Facing challenges with milling precision? Our professional machining services can help you improve your yield rate and achieve efficient cost reduction.

How To Prevent And Resolve Common Defects In Brass CNC Machining?

By proactive prevention of common defects is the best way to quality brass CNC parts and brass machining cost. Targeted strategies from us deeply touch material adhesion, dimensional inaccuracy, and poor surface finish, which drastically reduce scrap rates to significantly lower than the industry average through very exact CNC milling brass interventions:

Preventing Material Adhesion and Built-Up Edge

- Cutting Parameter Control: Keep speed at 100-130 m/min to reduce heat.

- Tooling Specification: Select high rake angle tools (≥15°) for shearing.

- Coolant Strategy: Use high-pressure air to keep the tool cutting surface clear.

Ensuring Dimensional Stability and Accuracy

- Workholding Protocol: Multi-point positioning with clamping force ≤0.5MPa.

- Thermal Management: Continuous air cooling to avoid heat distortion of workpiece.

- Process Sequencing: CNC milling material stabilization through a semi-finishing pass before final sizing.

Eliminating Burrs and Achieving Superior Finish

- Tool Path Strategy: Optimize final contour passes with minimal step-over.

- Tool Life Management: Implement a strict and predictive tool change schedule.

- Deburring Technique: Add edge break with spindle-speed specific routines.

Our defect, prevention framework is one of the main advantages of our brass CNC milling services. We achieve reliable manufacturing of precision parts, thus increasing the part quality and making costs more predictable, by applying these particular, tightly controlled protocols. This methodical approach, which is based on empirical data, offers clients the technical assurance that complex projects and an uninterrupted supply of precision brass parts require.

Figure 4: CNC milling a brass part with multiple tools for supplier capability demonstration and prototyping services.

Why Choose LS Manufacturing As Your Brass Machining Partner?

When picking a partner for precision brass milling, it is not enough to have general machining capability; you also need specialized knowledge that will allow you to consistently solve the problems such as material galling, thermal management, and holding tight tolerances. We are characterized by a systematic, data-driven approach to brass CNC milling services that ensure results you can count on, even for complex parts.

Application-Specific Equipment & Tooling Configuration

We use dedicated machining centers (20, 000 RPM spindles, ±0.006mm positioning) and a proprietary brass tooling library. A combination of the equipment and tooling is specifically tailored to the material characteristics in order to support high-speed, clean cutting without built-up edge and thereby provide excellent surface finishes that are indispensable for the high-volume CNC milling of brass parts.

Data-Driven Process Optimization for Alloy-Specific Results

Our process parameters are far from being generic. They are based on a proprietary database of 186 historical brass projects. For each alloy such as H59 or HPb59-1, we use a customized recipe, modifying speeds, feeds, and toolpaths, which has been experimentally demonstrated to manage cutting forces and heat, thus getting right to the main causes of dimensional variation and low surface quality.

Integrated Quality Assurance for Consistent Compliance

Obtaining a 98% Ra 0.8µm surface finish compliance rate necessitates validation during the process. We combine real, time SPC (Statistical Process Control) monitoring and post-process CMM verification against your critical dimensions. Quality is not only inspected but the machining process is also controlled to the extent that every batch is compliant with the highly demanding standards for quality brass CNC parts through this closed-loop system.

Choosing LS Manufacturing to be your brass parts supplier is essentially a decision to engage with a team that can turn its profound understanding of materials into a high-yield production that is dependable and predictable. We tackle the technical issues that are particular to brass by means of a dedicated infrastructure, taking advantage of empirical process knowledge, and strict control, thus we not only provide you with parts but also guaranteed precision and reliability for your most demanding applications.

How To Obtain Professional Brass Processing Solutions And Accurate Quotes?

Getting an exact quote for brass CNC milling services is more than just a geometry review, it requires a collaborative, data-driven analysis. We offer a transparent technical consultation to help find the optimization opportunities and thus making sure that your brass machining cost is in line with the most efficient manufacturing strategy. Below is our formalized method for preparing your CNC milling solution:

Comprehensive Initial Data Intake & Analysis

- Technical File Submission: We ask for the 3D model (STEP), material spec, and key tolerances to conduct a thorough initial assessment of your brass prototyping services or production needs.

- Rapid Engineering Review: A dedicated engineer reviews the data within 4 hours and determines primary machining challenges, fixturing strategies, and potential cost drivers.

Detailed Process Engineering & DFM Feedback

- Optimization Strategy Proposal: We send you a report highlighting potential design changes (e.g., fillet sizes, undercut simplification) and new CNC milling strategies, which could improve the product manufacturability and lower the cost.

- Transparent Process Breakdown: The report specifies the recommended tooling, the expected machining time, and the main quality control points, thus providing the ground for an accurate quotation.

Transparent Quotation and Collaborative Refinement

- Itemized Cost Breakdown: The quote breaks down the costs of materials, machine time, tooling, and finishing separately and visibly, thus making the price directly correspond to the process.

- Value-Engineering Dialogue: We review the report with you, showing that choosing us answers the question of how to choose a CNC milling supplier by technical understanding, not merely price

Our method is not only about the price. It's a step-by-step plan for making the product that is more detailed and more informative. By spending engineering analysis, we uncover efficiencies that can lower the final part cost, thus turning the quotation phase into a value-creation step that lays the groundwork for a successful and predictable partnership.

FAQs

1. What are the minimum hole diameter and depth-to-diameter ratio for brass CNC machining?

Minimum hole diameter are Φ0.3mm, depth, to, diameter ratio is 1:8. A special tool can make a ratio of 1:12. LS Manufacturing offers a free feasibility analysis for the process.

2. How large are the differences in machining performance of various brass grades?

Brass H62 cuts 15% better than H59. HPb59-1 is the best in machinability, however, its mechanical properties are downgraded by 10%, so the choice should be made based on the purpose.

3. What are the surface finish options available for brass parts?

Passivation treatment saves you the most cost-effective. Nickel plating is the right choice for corrosion resistance. LS Manufacturing can handle the entire surface treatment for you.

4. How do you make sure of consistency in the mass production of brass parts?

By SPC process control, a first-piece inspection, and online measurement, we guarantee CPK ≥1.67, and batch size variations ≤ ±0.015mm.

5. What is the maximum height, to, thickness ratio for thin-walled brass machining?

The usual processing height to thickness ratio is 40:1 and special techniques can get up to 60:1. A machining check has to be done depending on the shape of the piece.

6. What information is required for sample production?

Kindly share 3D drawings, material grade, and accuracy requirements. LS Manufacturing will take 3 business days for the completion of sample production.

7. How should dimensional tolerances be designed for brass parts in combination with other metals?

A tolerance of H7/g6 is recommended. LS Manufacturing engineers give tolerance optimization suggestions free of charge.

8. Do you offer material certification and traceability services?

We give 3.1 material certificates and set up a full traceability system where each batch of material can be traced back to its original furnace number.

Summary

Selecting a supplier for brass CNC milling should start with setting up a comprehensive technical evaluation system. One should take into account the nature of the materials, the processing that can be made, and the quality control standards. By choosing suppliers scientifically and optimizing the processes, one can decrease the costs by 25-40% while maintaining the quality of the processing, and thus, really achieving value optimization.

If you are seeking a specialized brass CNC milling partner, dont hesitate to contact the LS Manufacturing technical team right away. Send your brass part drawings and get a tailor, made process optimization plan! Our brass machining professionals will return to you with a complete technical analysis and an accurate quotation in 4 hours, thus assisting you in getting the best brass part machining solution.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.