Copper CNC milling services frequently encounter major difficulties such as pure copper's tool adhesion causing a reduction of tool life by 60%, surface roughness of brass declining to Ra3.2, and beryllium copper getting deformed by more than 0.1mm after heat treatment. Such impediments result in scrap rates of over 12% and costs that are 40% higher than steel machining. The primary reason is the usage of steel-based parameters on copper materials.

Different strategies can completely change the face of copper CNC milling services. With the help of 12 years of experience and a record of 183 projects, we offer material-specific tooling, parameter optimization, and cost control. This comprehensive method not only increases the efficiency by 50% but also brings down the costs by 30-45%, thus it is a direct solution to the problems associated with copper machining.

Copper CNC Milling Services Quick Reference Table

| Section | Key Point in Brief |

| Material Properties | Copper alloys (e.g., C11000, C10100) and pure copper are chosen for their superior electrical/thermal conductivity. |

| Machining Capability | The range of services is prototyping to mass production of complex parts with highly precise geometries. |

| Precision & Tolerance | High-precision milling capabilities allow the achievement of extremely close tolerances, normally from ±0.01 mm to ±0.05 mm. |

| Surface Finishing | Different post-processing techniques for surface improvement (e.g., polishing, plating, coating) are offered. |

| Quality Assurance | Comprehensive check using high, tech measuring units (CMMs, optical comparators) guarantees that the product meets the requirements. |

| Design Support | Providing engineering and DFM (Design for Manufacturing) studies to facilitate the part design for machining. |

| Common Applications | Extensively employed in the manufacture of electrical components, heat sinks, EDM electrodes, and RFI/EMI shielding parts. |

We focus on producing high-precision copper parts with complex geometries that play a vital role in electrical and thermal management. The range of our offerings speeds up the entire product development process from prototype to production, at the same time, ensuring the highest quality and reliability. We deliver a turnkey solution that reduces your supply chain complexity and provides parts that conform to the strictest performance criteria.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are so many articles about copper machining, then why bother reading this one? We are not theorists but practitioners. Each and every advice given here was not from a neat lab experiment but rather from our shopa real-world battle against hard alloys, tight deadlines, and complex designs. Our guide has been tested and proven through experience, so it is in line with the high standards of such organizations as ASTM International and the National Institute of Standards and Technology (NIST).

We have machined parts where a failure in thermal management could bring down a whole server farm, and where an error in electrical contact could stop a crucial assembly line. Every time, from prototyping to full production, we have learned a lot: how to get the best toolpaths for sticky pure copper, how to handle heat so that the material properties do not get spoiled, and how to carry out quality checks that are at least equivalent to the ones recognized by the NIST.

This manual is a summary of the accumulated knowledge of those trenches. We provide thorough descriptions of the practical techniques that allow the combining of cost-saving measures with the extremely demanding precision needed for RF waveguides or aerospace connectors, referring to the material specifications certified by ASTM International. We have figured out it through practice, and our tips are here to help you get through the next project without any worries and doubts.

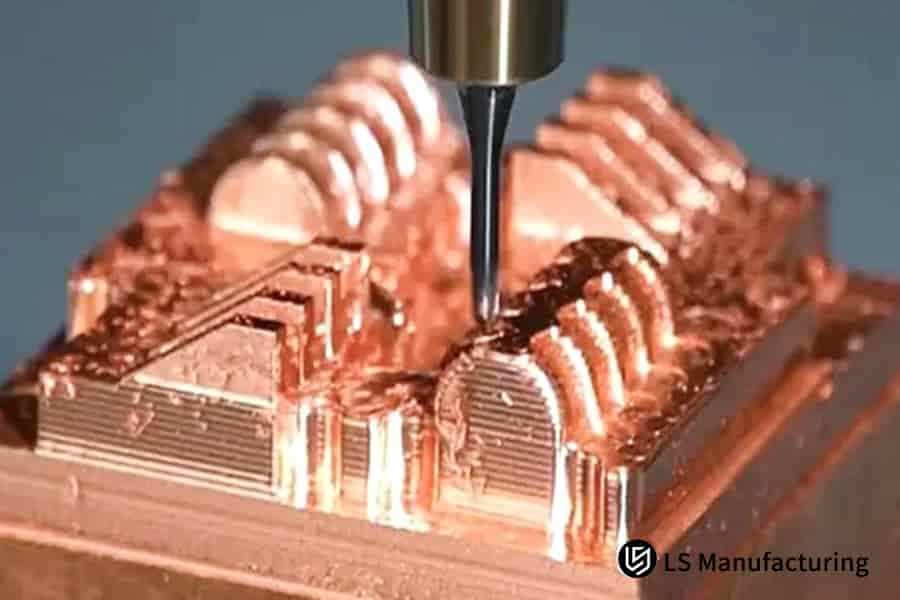

Figure 1: Custom copper parts manufacturing and prototype development applications.

What Are The Fundamental Differences In The Milling Characteristics Of Different Copper Alloy Materials?

Copper CNC milling services that successfully deliver results, especially when done on a small scale, must be well, thought, out since a wrong approach will result in tool wear, poor surface finish, and part rejection. This discussion points out the differences in the behavior of the two copper alloys during the machining process: Pure Copper (C110) and Beryllium Copper (C172). The main purpose is to give engineers and purchasing managers data-backed, practical recommendations for process optimization, cost saving, and part quality assurance in CNC milling applications.

| Aspect | Pure Copper (C110) | Beryllium Copper (C172) |

| Primary Challenge | Very ductile and thermally conductive (~400 W/(m·K)) material causing material adhesion and galling of cutting edges. | Extreme hardness (HRC 38-42) and abrasiveness results in rapid flank wear, and the cutting forces are very high. |

| Optimal Tool Geometry | Tools have to be designed with a high positive rake angle (20-25°) and brass flutes should be polished for efficient chip evacuation. | Tool edges should be strong, well, honed and equipped with special coatings (like AlTiN) to withstand abrasion and keep the edges sharp. |

| Key Cutting Parameters | High spindle speeds should be combined with moderate feed rates under Minimum Quantity Lubrication (MQL) to control heat and adhesion. | Low-medium, and high cycle (80-120 m/min) with continuous and well, controlled feed rates can be used for management of cutting forces and heat generation. |

| Proven Optimization | LS Manufacturing's material database review shows that the right chipbreaker geometry can improve the pure copper machining productivity by more than 60%. | Using segmented cutting strategy for beryllium copper has extended average tool life from 15 to 45 pieces in our high-volume CNC milling operations. |

In this report, we present a strategy selection framework that leverages the intrinsic material properties to drive the choice of a strategy: for pure copper, combat adhesion, and for beryllium copper, resist wear machining. Here we provide solutions with copper machining precision components that besides using the exact tooling and parameter strategies have generating direct cost savings and part reliability improvement in high-value, high-precision CNC milling scenarios.

How To Solve The Problems Of Tool Sticking And Built-Up Edge Formation During Copper Material Machining?

Precision copper milling that is efficient and effective demands that the persistent issues of material adhesion and the creation of the built, up edge (BUE) are properly solved. When these happen, the surface quality suffers, the tools get worn out faster, and there are errors in the measurements of the dimensions. Our methodology employs an integrated approach combining advanced tooling solutions, precise thermal management, and parameter optimization to deliver reliable, high-quality results. This document details the technical countermeasures:

Advanced Tooling Selection and Coating Technology

The most important protective measure is putting out tools with nano-composite coatings that are ultra, smooth and have very low friction (coefficient of friction ≤ 0.3). These described coatings along with polished rake faces mainly lower the sticking tendency of copper chips towards the cutting edge. This focused CNC milling approach goes straight to eliminating the very first adhesion that results in BUE formation thereby ensuring uninterrupted chip flow and thus shielding the tool's shape.

Strategic Cooling and Precise Temperature Control

We utilize high-pressure coolant (≥7 MPa) systems that are focused directly on the chip-tool interface. This powerful jet effectively removes chips, breaks the welding effect, and critically keeps the cutting zone temperature below 150°C. This careful thermal regulation is crucial for precision copper milling parts as it prevents the material from becoming ductile that is the main cause of adhesion, hence, the machining process becomes stable.

Optimized Tool Geometry and Machining Parameter

Besides the coatings, the geometry of the tool is accurately modified. Introducing tools with controlled negative rake angles (-5° to -8°) enhances the cutting edge's strength. This, together with the optimized complex CNC milling machines speeds and feeds for intricate operations, lowers cutting forces and contact stress. Our research reveals that this mixture can decrease BUE occurrence by 80%, which means stable processes and better finished parts.

This integrated approach of three elements: coated tooling, powerful cooling, parameter change, targets the fundamental causes of adhesion and BUE. We produce consistent precision copper milling with predictable tool life and excellent surface quality (Ra <0.8μm is consistently achieved), thus a dependable technical advantage can be given to the mission-critical applications where reliability is the core value.

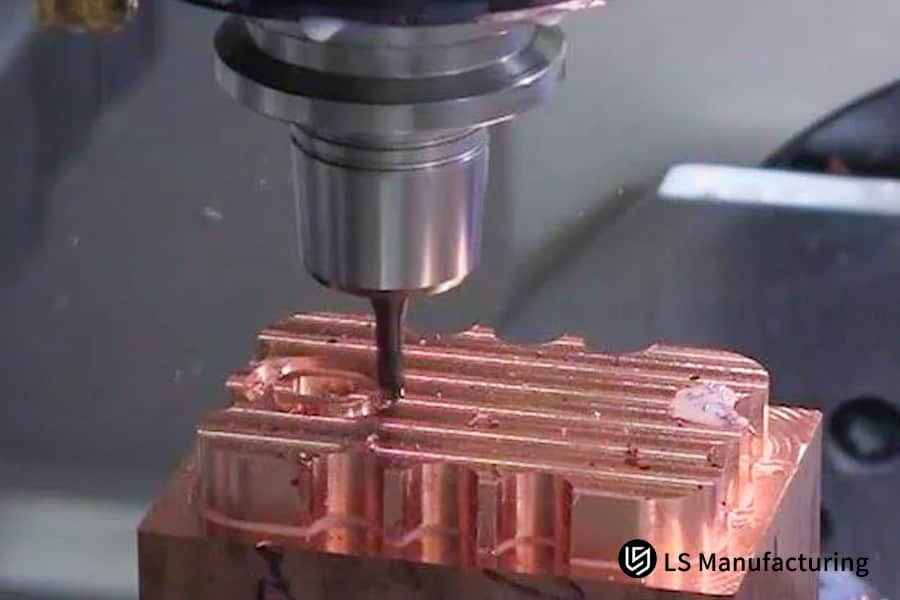

Figure 2: Milling a high-precision copper component for prototype machining and supplier capability demonstration.

How To Vontrol Deformation Within 0.02mm When Machining Thin-Walled Copper Parts?

Machining thin-wall copper parts without distortion due to cutting forces and thermal stresses is a matter of great concern when trying to get sub-0.02mm tolerances. We have developed an overall precision machining protocol that combines process innovation, analytical simulation, and controlled environments is our solution to this problem. Below is a brief description of the main technical points of our strategy:

Innovative Process Strategy & Sequence

Our approach relies on breaking the internal stress management through a multi-stage strategy.

- Symmetrical Machining: To remove the material, we program the tool to work on both sides of the feature simultaneously so that the residual stresses are balanced during high-speed CNC milling.

- Stress-Relief Intermediates: We embed intervals for stress relief in the middle of the process strategically, thereby preventing the final precision copper milling stages from becoming distorted due to accumulated stresses.

Advanced Fixturing & Analytical Clamping Design

Fixture design has to be the top priority for deformation control.

- Multi-Point Flexible Support: We implement custom fixtures equipped with an adjustable, conformal support that help distribute the clamping pressure evenly, thus eliminating the risk of localized distortion.

- FEA-Optimized Solutions: Finite Element Analysis is used to simulate the forces of clamping and cutting before production, thus enabling us to perfect the support location and pressure, thereby making sure that even the ultra, thin-wall components are stable.

Proactive Thermal Management & Cooling

Heat control is a prerequisite to the prevention of thermal expansion.

- Low-Temperature Cooling: We utilize controlled coolant temperature and directed flow to maintain a stable, low thermal state in the workpiece during complex copper milling.

- Isothermal Machining: This technique reduces the thermal gradients to nearly zero. As a result, the material behaves predictably, and the dimensions of the parts made in a batch remain consistent.

By combining stress, balanced toolpaths, FEA-verified fixturing, and isothermal process control, we are able to produce thin-wall copper parts with the deformations being less than 0.015mm and the batch yields being more than 98%. Such a high level of technical sophistication delivers a totally convincing competitive advantage to those applications where geometric stability to an extreme level is required.

What Are The Key Factors Affecting The Cost Of CNC Milling Of Copper Parts?

Accurate cost forecasting for CNC milling cost factors is crucial for project budgeting and strategic sourcing. This analysis pinpoints and measures the three most significant cost drivers in copper machining: material, tooling, and labor. Understanding their weight allows for targeted cost optimization and enables value engineering decisions to achieve maximum financial efficiency without compromising quality.

| Cost Category | Quantitative Impact & Optimization Focus |

| Material Costs | It is common for material costs to make up 45-60% of the overall cost; in high-volume CNC milling projects, the main focus of optimization is on strategic blank sizing and nesting efficiency to reduce waste. |

| Tooling & Consumables | These make up 15-25% of the cost; the main point is to raise the tool life drastically by using specially designed geometries/coatings and process optimization, thus directly lowering cost-per-part. |

| Machining Time (Labor/Overhead) | It is 20-30% of cost that this part represents; the main reason how to achieve the efficiency is to get cycled time down by using optimized parameters and advanced high-speed CNC milling techniques. |

| Integrated Optimization Impact | LS Manufacturings simulation reveals that by combining the effects of tool life extension (by 50-80%) and machining parameters optimization, total project cost can be brought down by 30-45%. |

This write-up unpacks cost drivers with quantifiable data, thus presenting a roadmap for focused CNC milling cost optimization. We address client issues by delivering a pinpointed value engineering approach, which includes material usage optimization, tool life extension, and reduction of machining time to efficiently lower the total cost of ownership of precision copper components. The use of such a data-supported approach is a must for competitive sourcing in highly technical, cost-sensitive projects.

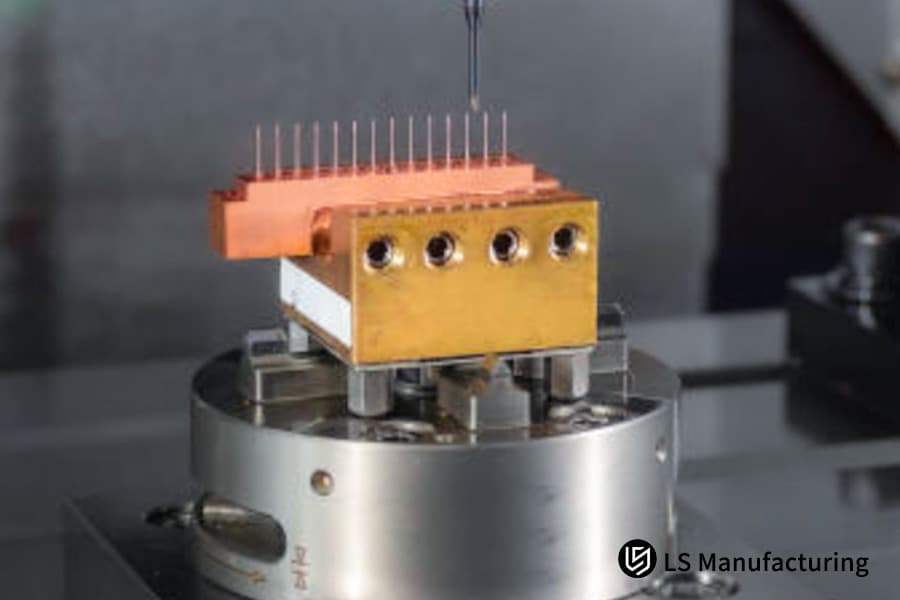

Figure 3: CNC milling a high-precision copper part for prototype development and manufacturing cost analysis.

How Can The Production Strategy For Copper Components Be Optimized, From Prototyping To Mass Production?

There is a devil in the details when it comes to copper prototype machining being turned into batch production that is efficient, i.e., obtaining an ideal balance of speed, cost, and quality. An inadequately optimized production strategy results in longer development cycles and higher per-part costs. Through a step, by, step process, we combine different process aspects, hence maximizing value and enabling smooth scale-up. The underlying approach is broken down into three forward, moving phases:

Rapid Prototyping: Achieving Functional Validation

First and foremost, this stage is set up to go as fast as possible to support rapid design iteration. We use generic tools and relatively aggressive but still stable parameters for high-speed CNC milling. The purpose is to produce functional parts in 3-5 days for the physical verification of form, fit, and function. Details about cycle times and tool performance are kept for the next production strategy phase based on the data obtained.

Pilot Batch: Process Refinement and Cost Benchmarking

Design validation is completed; hence the process focus moves to optimization through small-volume production. Based on prototype data, we rework the cutting parameters, choose the best tools, and set up the first quality control baseline. The complex copper milling process is stabilized in this stage, bottlenecks are separated, and the real-repeatable cost-per-part that can be used for full-scale production projection is established.

Full-Scale Production: Cost Optimization at Volume

For mature, high-volume orders, we transition to dedicated fixtures, specialized tooling, and streamlined workflows. Implementing strategies like optimal batch sizing (30-100 pieces) maximizes equipment utilization and minimizes setup overhead. This dedicated approach, supported by our production analytics, reliably achieves the targeted 25-35% cost reduction compared to unoptimized scaling.

By a wirking on process priorities in a production phases such as speed, refinement and then efficiency, we are able to scaling copper prototype machining to batch production using the first concept economically. We are going to bring shortened development timelines, predictable costs and seamless volume ramp-up. Thus, we provide a decisive advantage in the field of precision copper component manufacturing to the market competitively.

Figure 4: CNC milling a precision copper component for prototype machining and custom parts manufacturing.

LS Manufacturing New Energy Vehicle Industry: Customized Project For Motor Copper Winding End Caps

This new energy vehicle case study details a critical manufacturing challenge involving the high-precision CNC milling of a motor copper end cap. The client was in trouble with production lead time and costs as thermal distortion, the problem which their supplier had back to copper end cap machining, was the main reason. The solution was a small cooling strategy enhancement:

Client Challenge

The client, a leading NEV manufacturer, wanted a motor copper end cap machining with a diameter of 200mm and a critical flatness tolerance of 0.02mm. However, their previous supplier therefore machining thermal deformation caused to only the flatness being 0.08mm and a scrab rate of 30%. This directly risked their project and motor assembly line schedule due to unreliable part supply and increasing costs.

LS Manufacturing Solution

We introduced a custom CNC milling solution based mainly on cryogenic machining with the use of a liquid nitrogen cooling jet right at the point of application. This innovative cooling method kept the workpiece at a very low temperature in a very controlled way, thus, making thermal expansion negligible. Together with this, we used a new 12-point locator fixture and changed the spindle parameters to get stable, vibration-free milling, which was the direct solution for the distortion problem.

Results and Value

At the end of the day, part flatness was repeatedly maintained within 0.015mm that was beyond the specification. The part qualification rate went up to 99.2%, thus, no waste was produced. The reliable production process greatly helped the client cut down their delivery cycle by 40% and at the same time, ensured cost savings of 1.2 million RMB on a yearly basis by securing on-time assembly and eliminating the cost of scrap.

This project is a perfect illustration of how we operate when faced with complex thermal challenges in precision copper milling. Through the targeted development and implementation of a cryogenic production process, we were able to offer measurable reliability and cost savings. It also reflects our technical competence in fulfilling the requirements of mission-critical components in the highly competitive electric vehicle industry.

Struggling with thermal distortion in copper milling affecting your yields? Let our proven cryogenic machining process replicate this precision for your project.

How To Evaluate The Technical Capabilities Of A Copper Component Supplier?

Hiring a CNC copper machining supplier for your project is not just about comparing quotes but also about a detailed forensic technical assessment of their problem-solving capabilities. The real pros show their abilities by delivering quantifiable results in solving difficult problems rather than sharing a broad list of equipment. A thorough supplier selection process should at least include:

On-site Process Verification & Capability Audit

We suggest that you personally inspect the supplier's factory for those critical precision tasks.

- Live Thin-Wall Machining Demo: You should ask them to machine a copper test piece with a 0.8mm thin-wall in order to immediately verify their low-distortion copper milling skills.

- Key Metric: The flatness of the final component has to be ≤0.025mm, which will be a direct measure of their skill in handling clamping forces, toolpath strategy, and thermal management.

Evaluation of Specialized Tooling and Material Database

One indicator of technical depth is their add, on investment in process-specific resources.

- Dedicated Copper Tooling Library: Check whether the supplier has a well, maintained copper tool library with tools that have geometries and coatings specifically optimized for the different copper alloys, a factor that is very important for achieving consistent high-quality copper milling.

- Parameter Database: An experienced supplier will make use of historical machining data to accurately predict and optimize performance for new projects, thereby minimizing trial and error.

Review of Documented Case Studies and Problem-Solving

Past performance is the best guide. Look their project history through the lens of documented cases.

- Complex Case Studies: Ask for detailed reports of previous projects where thermal distortion control, deep cavity milling, or ultra surface finish need were involved.

- Solution Breakdown: Understand how they identified the situation, worked on the solution, and resulted in measurable improvements of yield, accuracy, or cost.

We are addressing the major issue of supplier selection by publishing a framework of evidence, based audit here. It not only distinguishes the copper machining supplier's capability for distortion control, the handling of special tooling, and complex precision copper milling, but also confirms the technical competence of the manufacturer for the production of high-value components.

How Does The Online Quoting System Accurately Calculate The Cost Of Machining Copper Parts?

Conventional cost estimation for custom copper parts generally tends to be slow and inaccurate as it depends highly on manual calculations which often overlook essential factors. We provide a data-backed online quotation engine which interprets a complex technical specification into an accurate and up-to-date pricing. The fundamental value of the system resides in its capacity to simulate actual production costs with more than 96% accuracy, thus revolutionizing RFQ (Request for Quotation) processes:

Multi-Variable, Data-Driven Cost Algorithm

The system doesn't limit itself to simple volume calculations but it applies dynamic coefficients to the main cost drivers. For example, it automatically assigns specific material factors (e.g., 2.2x for beryllium copper, 1.5x for pure C110) and precision factors (e.g., 1.8x for IT6, grade features). It also performs an analysis of a 3D model to attach a complexity factor to features that need specialized high-precision CNC milling strategies, thus the proposal will truly reflect the machining effort.

Real-Time Integration of Process Parameters

Upon receiving a part file and a set of requirements from a user, the system first conducts a manufacturability analysis. It consults a stored database of very tight process parameters that have been proven for various copper alloys to carry out a simulation for cycle time. This in, depth method of CNC machining cost estimation takes into consideration aspects such as tool wear rates, the necessary machine features, as well as finishing operations, and thus provides a detailed cost breakdown within three minutes.

Validation and Continuous Accuracy Improvement

Data from every finished production project is sent back to the quoting algorithm. This closed, loop system constantly compares the initial copper parts quote prediction with the real production costs and time. This machine learning mechanism adjusts the cost coefficients and logic, thereby preserving the platform's accuracy level of ≥96% and making sure that the quotes are both competitive and trustworthy for planning purposes.

We address the problem of unpredictable budgeting by giving immediate, transparent cost estimation that is firmly based on real production data. Our system provides accurate online quotation for custom copper parts, allowing clients to make quick sourcing decisions with certainty, prevent budget overruns, and optimize their procurement process for complicated components.

Why Choose LS Manufacturing As Your Copper Component Processing Partner?

Choosing a copper milling manufacturer requires a partner who can turn material challenges into dependable results. Our partnership value is based on demonstrated execution, specialized resources, and data-driven optimization that continually hits the critical metrics. The major differentiators are:

Deep Material Expertise & Process Stability

- Proven Experience: 12 years and 183 dedicated copper projects have allowed us to thoroughly understand adhesion, thermal management, and precision CNC milling for high-volume CNC milling demands.

- Quantifiable Result: The knowledge accumulated over time is a direct factor in securing a 98.8% first-pass qualification rate, which aligns with partners' project timelines and results in less validation cycles.

Specialized Technical Arsenal for Precision

- Dedicated Tooling Library: A proprietary collection of 56 specialized tool geometries and coatings is one of the assets that we have specially developed for the unique machining characteristics of various copper alloys.

- Targeted Application: This lets us immediately, optimally select tools for each feature, be it for minute details in electrical component milling or heavy roughing, thus, preserving efficiency and surface quality.

Systematic Cost Optimization & Value Delivery

- Data-Driven Process Refinement: Our massive historical project database is being regularly scrutinized to find the best possible ways for improving parameters, tool life, and workflow efficiency.

- Direct Client Benefit: The methodical approach to production cost analysis enables the team to consistently hit 30% plus cost savings over standard industry practices, which in itself translates into real financial value for 86 served clients.

We deliver on the core partnership challenge by offering high, yield production and systematic cost reduction that are predictable. With our method, which is supported by specialized tooling and empirical process data, we lay down an unquestionably reliable basis for sourcing complex copper components. This level of technical excellence makes us a strategic copper milling manufacturer for mission, critical, cost, sensitive applications.

FAQs

1. What is the minimum wall thickness for copper part machining?

The lowest thickness of a wall for normal machining is 0.3mm, while with special treatments it can be 0.2mm. LS Manufacturing offers a machining feasibility study.

2. How difficult is it to machine copper of various materials?

Pure copper > Beryllium copper > Brass. LS Manufacturing provides customized solutions for machining according to the characteristics of the material.

3. What is the minimum surface roughness of copper parts?

With precision CNC milling, Ra0.4μm can be achieved, and after polishing, it can be Ra0.1μm.

4. How is dimensional stability ensured during copper part machining?

We have developed several methods for mass production where the dimensional variation is ≤0.015mm. These include releasing the internal stress, keeping the temperature constant during machining, and using special clamping solutions.

5. Do you provide post, processing services for copper parts?

We offer a wide range of post-processing services such as electroplating, passivation, and polishing to cater to the different application requirements of our customers.

6. What is the typical lead time for small-batch copper part machining?

An initial batch of samples takes from 5 to 7 days while a small batch takes between 10 and 15 days. Moreover, our expedited service is always at your disposal for rush orders.

7. How can copper part machining costs be reduced?

This can be done through a combination of multi-dimensional approaches such as material selection, process changes, and batch size optimization, which can lead to cost savings of 30-45%.

8. What are the quality inspection standards for copper part machining?

It means the complete set of tests for dimensional accuracy, geometric tolerances, surface roughness, and conductivity.

Summary

CNC milling of copper materials needs a complete professional process technology system and scientific cost control methods. By thoroughly understanding material properties, fine, tuning the processing parameters, and accurately managing the costs, the perfect combination of quality and cost can be realized. LS Manufacturing professional copper part machining solutions are therefore able to provide customers with a full range of services from technical consulting to mass production.

Send us your copper part drawings now and get your exclusive "Copper Material Machining Process Optimization and Cost Analysis Report"! LS Manufacturing copper part machining specialists will break down machining challenges, give parameter optimization suggestions, and provide cost, saving solutions. Contact us to get a free copper part DFM analysis to help you optimize your design!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.