CNC milling services are crucial for manufacturing complex parts, yet companies often struggle with precision variations of ±0.05mm, delayed deliveries, and costs exceeding budgets by over 30%. This situation affects product development cycles and ability to compete in the market, and is a major problem in outsourcing.

To solve this problem, we use 12 years of precision machining experience. With the data of 286 successful projects, our three-dimensional evaluation model guarantees that the machining accuracy is within ±0.01mm, the on-time delivery rate is 99%, and the overall cost is reduced by 25%, making CNC milling an important competitive advantage for us.

![CNC milling machine producing precision parts with sparks by LS Manufacturing].jpg](https://image.lsrpf.com/image/cnc-milling-machine-producing-precision-parts-with-sparks-by-ls-manufacturing.jpg)

CNC Milling Services: Full-Text Quick Reference Guide

| Module | Key Content in One Sentence |

| Current Challenges | Unrealistic tolerance differences over lead time. Excessive 30% extra cost of high mix low volume and high precision components outsourcing. |

| Core Problem | In fact, the root cause is due to the lack of scientific supplier evaluation methodology, and simply evaluating and selecting suppliers based on price or machine list. |

| Our Solution | We can help. We use a 3 dimension evaluation model (Technical Capability, Quality System, Service Support) which is summarized from 12 years and 286 projects of experience to select the right suppliers for your components. |

| Guaranteed Outcomes | We guarantee ±0.01mm machining accuracy, 99% on-time delivery and save up to 25% of your total cost after cooperating with us. |

| Technical Value Proposition | We specialise in 5-axis milling, enabling repeated manufacture of the high-precision complex shapes that underpin competitive new-product introduction. |

| Selection Methodology | Our business model enables objective, fact-based supplier selection, with proven process management and project management capability. |

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Why read this overview of CNC milling services instead of something else online? Because this overview isn’t theoretical, it’s practical. At our facility, we don’t study machining, we execute it every day. Whether it’s machining micron-level tolerances in aluminum or complex geometries in tough materials, every concept in this overview is tried, tested, and true, and will guide you in producing quality parts.

With expertise rooted in actual accuracy, we work within the standards of entities such as ASTM International and the Aluminium Association (AAC), and all of our recommendations align with industry standards. Our solutions have been proven to work and assure reliability and accuracy for your most critical projects.

The subsequent chapters offer you insider access to the techniques and strategies that have been proven to pay dividends – in terms of better surface finishes, assured component quality and improved productivity. These are the kinds of competitive differentiators that mean you can compete for complex milling work.

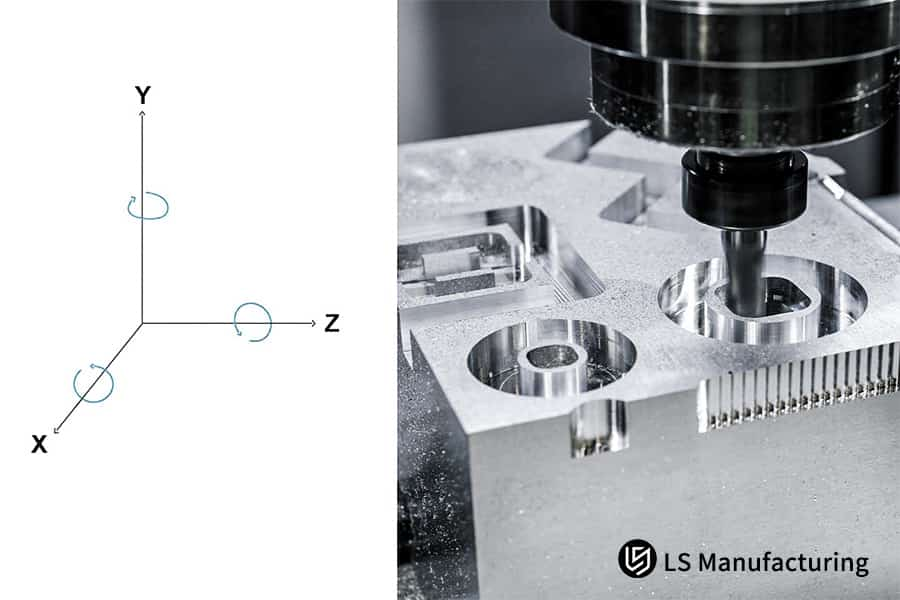

Figure 1: Detailed diagram of CNC milling axis motion on metal parts by LS Manufacturing

How Does 5-Axis Machining Create Core Technological Value For Complex Parts?

5-axis CNC machining is a game-changer because it finally tackles the central difficulty of complex parts milling — obtaining accurate cuts on all sides of the part in one go — head-on. That reduces stack up tolerancing, saves time and money, and removes design constraints. So it’s a good tool to deploy in the right circumstances, which is why it’s often used for:

Eliminating Cumulative Error through Single-Setup Machining

The biggest benefit is that we can do all the multi-face machining at one time. For example, for one aerospace turbine housing, the number of setups decreased from three conventional to one, and subsequently, decreased the datum transfer error. In the precision CNC milling process, tolerance stack-up reduced from 0.08mm to 0.015mm, ensuring part accuracy.

Optimizing Tool Paths to Overcome Physical Constraints

The capacity to maintain tool orientation is critical when it comes to reaching feature. We utilize the latest in CAM tools to plan tool axis vectors that will help to machine deep pockets and long grooves. This proactive approach to CNC milling services prevents the toolholder from hitting the wall of the part; a frequently encountered weakness that leads to failure before the first piece of production is completed.

Enhancing Efficiency and Reducing Indirect Costs

The most direct benefit is the reduction in machining time. For the project mentioned above, the cycle time was reduced by 40%. Apart from that, the customized fixture was avoided, which also saved the customer around 150,000 RMB in tooling cost and simplified the whole manufacturing process.

Ensuring Superior Surface Finish on Contours

Where intricate curves are involved, such as an airfoil or impeller, it’s important to keep the cutting conditions as constant as possible. Tangency in 5-axis machining lets the cutting tool stay tangential to the surface as the machine uses high-speed CNC milling methods. This yields better surface finishes, less need for secondary polishing, and enables achieving demanding aerodynamic or fluid dynamic specifications.

This document demonstrates our technical depth through concrete problem-solving—not just capability listing. Our approach focuses on de-risking the manufacture of your most challenging components by providing engineered CNC milling solutions that guarantee precision, reliability, and cost-effectiveness from the first part onward.

In Which Industries Are ±0.005mm Accuracy Requirements Mandatory?

In high-value manufacturing, ultra-tight tolerances are a matter of functional and safety need. Medical, optical and aerospace are all sectors where dimensional control down to a micron is the norm. This paper describes what applications require such tight tolerance milling and the integrated systems needed to routinely attain and verify it.

| Industry / Application | Mandatory Precision Requirement | Key Challenge & Consequence of Failure |

| Medical Implants & Instruments | ±0.008mm on bone interface and joint features. | Non-conforming implants may fail to integrate with the body properly and be rejected. |

| Optical Molds & Lens Masters | 0.002mm or better on light transmitting surfaces. | Non-conforming optics distort and scatter light and cannot perform their intended function. |

| Aerospace Fuel & Guidance Systems | Bore and sealing surface tolerances of ±0.005mm for fluid dynamics and alignment. | Critical for system integrity at high pressure and extreme temperatures. Any variation could result in leakage or failure to maintain required course. |

| Semiconductor & Electronics | Tooling Feature location and flatness of micron tolerances for wafer processing. | Critical for miniaturization of circuits and high-yield results. A mismatch can cause defective microchips. |

All of this requires a system to be able to consistently deliver precision CNC milling. The system consists of temperature control, metrology, and processing protocols. It is the foundation from which to choose a precision milling supplier for your 0.0001-inch tolerances and ability to verify function of your parts for first article success in mission critical applications.

Figure 2: Coolant sprays and sparks fly from milling metal on CNC by LS Manufacturing

How Can Rapid Prototyping Achieve 24 Hour Delivery While Guaranteeing Functionality?

Rapid CNC milling doesn’t just need to be fast — it needs to make functional, precision-milled parts. Our platform does it by combining a library of pre-engineered digital process plans, concurrent workflow, and inspection and analysis throughout the manufacturing process. Tight deadlines become exact, repeatable results for faster design iteration:

Engineered Process Foundation

- Digital Process Library: A treasure of pre, validated parameters for commonly used materials that help to completely eliminate programming trial and error.

- Automated CAM Planning: Smart templates through the use of artificial intelligence immediately reapply the best cutting paths, thus, guaranteeing zero, error machining and surface quality.

Parallelized Workflow Execution

- Dedicated Resources: Machines dedicated solely to prototype milling services thus allowing the immediate availability and hence no waiting.

- Concurrent Operations: All the preparation jobs are carried out simultaneously in order to shorten the overall lead time.

Integrated Functional Validation

- In-Process Verification: On-machine probing checks critical features mid-cycle, ensuring a 95% first-article success rate.

- Production Fidelity: Using the final materials and controlled conditions ensured that the prototypes gave correct functional test data.

This well, structured methodology indicates that dependable, fast-turn milling is achievable through systematic engineering. Our CNC machining services routine can produce parts that are representative of production within 24/48 hours, thus a shortened schedule is a proven competitive advantage for speeding up product development.

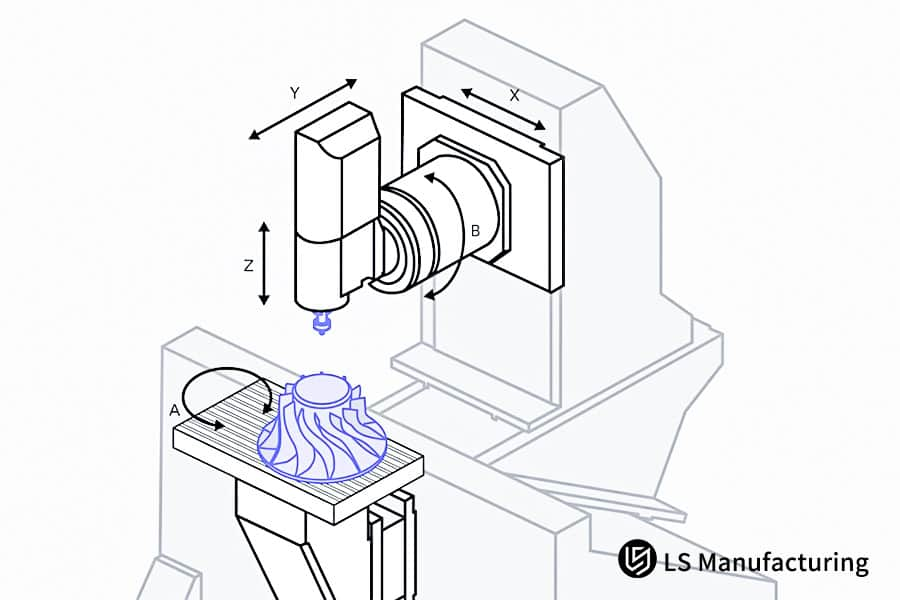

Figure 3: Multi-axis CNC milling with a detailed coordinate diagram by LS Manufacturing

How To Control Deformation And Ensure Stability During The Machining Of Thin-Walled Structures?

Complex parts milling of thin-wall structures requires overcoming inherent deformation from cutting forces and residual stress. Our method can ensure the flatness of the 600x400mm aluminum drone frame within 0.02mm, and the batch consistency can reach 99.8%. To realize this, three technical measures must be taken:

- High-Speed, Low-Depth Step-Milling: We use a high speed, low depth strategy - for example 0.2mm axial depths of cut - to reduce the instantaneous cutting force and thermal input, preventing the localized stress concentrations that lead to deformation. This is a core tight tolerance milling of thin features.

- Balanced, Symmetrical Toolpath Strategy: Rather than removing material from one side to completion, we design the toolpath to remove symmetrical halves on an alternating basis. This allows the forces imparted from clamping and cutting to be balanced and neutralized on the part, avoiding any deflection or warping over the course of the precision milling process.

- In-Process Metrology and Adaptive Compensation: On-machine probing allows us to take measurements mid-process to check for accuracy. Data from these measurements can be used to adjust the CNC program for final finishing operations. This closed-loop process accounts for material spring-back and guarantees a part’s final size.

- Engineered Workholding and Fixture Design: The fixture is made to offer the most support under thin walls without excessive overhang. In some instances, we have actually machined temporary support ribs that are removed in the last pass to keep the part stiff as long as possible in the custom CNC milling process.

This technique shows that thin wall machining can be performed stably with the use of adaptive process adjustments. Distortion can be controlled at the root cause, resulting in consistently precise, accurate parts that meet the highest standards for aerospace and advanced manufacturing applications.

What Are The Key Technological Breakthroughs In Milling Difficult-To-Machine Materials (Such As Inconel And Titanium Alloys)?

CNC milling of Inconel and Titanium alloys is notorious for excessive tool wear and poor thermal conductivity. For complex part milling to be viable, specific technological advancements are needed to maintain price and quality. In this whitepaper, we will outline evidence-based strategies that define the state of the art in precision CNC milling of these alloys.

| Technological Focus | Breakthrough & Implementation | Quantifiable Outcome |

| Targeted Thermal Control | Localized cryogenic cooling (e.g., -50C air) applied to the cutting zone for heat management. | Prolongs tool life by 300% (e.g., 30 min to 2 hours) and allows for consistent surface finish of Ra 0.8μm. |

| Optimized Cutting Dynamics | Trochoidal and adaptive toolpath strategies to maintain constant low radial engagement. | Reduces cutting forces by over 30%, allowing for high-speed milling of thin features. |

| Advanced Tooling Application | Specialized coated carbide tools with geometry designed for high temperature shearing. | Allows for higher sustained speeds and feeds, lowering cost per part in custom CNC milling projects. |

| Process Stability & Monitoring | In process sensor monitoring for tool wear detection and parameter adjustment for process consistency. | Prevents tool breakage and guarantees part-to-part consistency in critical production lots. |

The key to this is to integrate heat, motion and control in a systematic way. If you need to purchase CNC milling services on superalloys, look for a supplier who follows this integrated approach to turning a highly risky process into a controlled, optimized one that delivers consistent part quality at the lowest possible cost.

How Can A Scientific Pricing System Ensure Cost Transparency And Control?

Conventional quoting can leave you with unexpected costs and uncertainty, which can lead to project blowouts and sour relationships. Scientific, data-driven quoting eliminates this risk by making your costs transparent and predictable. By breaking down the total CNC milling quote into quantifiable constituent parts, you can keep your costs under control and build trust:

Data-Driven Cost Deconstruction

- Material Cost Analysis: Prices are based on current market data for raw material grades and dimensions, thus not being mere estimates. This eliminates one major variable.

- Machining Time Calculation: Cycle times are obtained from a proprietary database of validated parameters for different materials and operations, thus ensuring accuracy.

- Tooling & Consumables: Cost is determined through a predictive tool, life model based on material machinability. This is not just a simple markup and it accurately foresees wear.

Transparent Process Breakdown

- Programming & Setup: This should be listed as a separate and fixed engineering cost, rather than being a part of the per, part price.

- Quality Assurance: The inspection cost is, generally, defined by the inspection requirements of the statistical sampling plan (e.g. AQL levels) or by the scope of the First Article Inspection (FAI). It is not, thus, included in the price in an ambiguous way.

- Secondary Operations: Any post, processing (e.g., anodizing, heat treat) is being offered as a clear line item from the suppliers to whom the certified sub, tier is given.

Proactive Cost Optimization Analysis

- DFM Feedback: We provide a quote with specific and clear suggestions for Design for Manufacturability that can help to reduce processing time or material waste without sacrificing the product's function.

- Process Alternatives: We can offer different ways of CNC milling services (e.g., 3+2 vs. 5, axis simultaneous) along with the associated cost/benefit trade, offs for the client to make a decision.

- Volume-Based Scenarios: The quote is detailed in explaining the cost allowance at different production volumes, thereby demonstrating the effects of economies of scale.

This structured approach changes quoting from a mysterious process into a joint engineering and financial tool. As a precision milling supplier, we offer our clients a clear, workable cost model. Therefore, they can make their decisions based on information, be free of unexpected costs, and trust each other, which is essential for a long, term partnership, thus, resulting in a reduction of the total CNC milling procurement costs.

LS Manufacturing Aerospace Division: 5-Axis Precision Milling Project For Engine Casings

In order to machine complex titanium aerospace parts successfully, it takes not only equipment, but tooling and processes. Read this case study of how LS Manufacturing achieved a 5-axis precision CNC milling project, and reached the precision tolerances for a titanium engine casing:

Client Challenge

An Aerospace Tier 1 supplier was at a standstill due to their inability to machine a Ti, 6Al, 4V engine casing with deep cavities, thin ribs, and multi, angle bores. The main problems were that the part distortion was more than 0.1mm and the positional tolerance was out of 0.05mm using the process of the previous vendor. These failures resulted in a project delay of 3 months and the whole timeline for the new engine program assembly was at risk, thus outsourcing the complex parts milling was a very dangerous gamble.

LS Manufacturing Solution

We used a comprehensive approach focused on stability. A purpose-built, stress-engineered fixture — qualified by FEA analysis — was used to reduce clamping deflection. The part was machined using adaptive, high-speed CNC milling — with in-process cutting force monitoring — to adjust the feed rates and maintain a constant chip load. This emphasis on stable removal rates addressed the underlying issues driving distortion and tolerancing associated with this part’s difficult design.

Results and Value

Upon completion, validations of the finished parts verified ±0.015mm tolerance on the profile and ±0.025mm tolerance on position. A successful first article inspection was completed and 99.5% overall yield on production quantities was maintained. The project was completed 40% ahead of the initial compressed schedule. Savings for the customer consisted of 1.8 million RMB in direct project costs avoided, removal of a critical program hold up, and ensured on-time integration to the final engine assembly.

This is just one example of how we can provide dependable, highly accurate CNC milling even in situations with very tight technical constraints. To us, being a precision milling supplier means more than just doing the machining work. We figure out the engineering challenge that is behind the machining task and thus give our partners from the aerospace industry confidence to get their advanced manufacturing programs done successfully and on time.

Struggling with titanium aerospace parts? Our precision 5-axis CNC milling ensures complex profiles stay within strict tolerances.

Why Choose LS Manufacturing As Your Precision Milling Partner?

When it comes to choosing the right custom CNC milling provider, it is not enough to know what capabilities they have; you must also have confidence that they can minimize technical and commercial risk. At LS Manufacturing, we offer that confidence with our measurable, systematic approach to manufacturing, which makes even the most difficult technical and business challenges solvable. And here’s how we do it:

Validated Process Library for Predictable Outcomes

We have developed a comprehensive database of 286 projects that allows us to use pre-tested parameters for new projects. Therefore, we can predict the machining process, tool life and cycle times accurately right from the beginning. This minimizes the technical risks for our CNC milling services and helps you ensure a high level of first-time success and scheduling certainty.

Integrated Quality Systems for Guaranteed Precision

Precision is a system, not an event. We can deliver ±0.003mm tolerances only because of the 20±1°C temperature control, calibration of our equipment, measurement of parts on the machine during the CNC milling process and a measurement system that is approved by our AS9100 system. This controlled ecosystem is what defines a true precision milling supplier, guaranteeing part conformity and eliminating quality escapes.

Holistic Project Management for Cost and Schedule Control

We reduce the risks of programs by integrated project management. Proactive DFM analysis helps to optimize design for cost, effectiveness, at the same time, predictive tool, life models set the stages to prevent unplanned downtime. Real time progress dashboards give visibility. Such a systematic approach is the reason that we always have 99% on, time delivery and deliver an average of 25% total cost reduction to our clients.

We provide the solution to the 3rd-party manufacturing problem: uncertainty of quality, price, and lead time. Our process gives the engineering predictability required for high-quality manufacturing. With LS Manufacturing, you've chosen a reliable milling partner to ensure your toughest designs are converted into high-quality parts, delivered on time, and at budget.

Figure 4: CNC milling metal workpiece with visible chips and grooves by LS Manufacturing

How To Ensure Efficient Management And Quality In Small-Batch Multi-Product Manufacturing?

Low volume high mix manufacturing typically lacks efficiency and standardization, which can compromise the quality of the final products. Our approach to this issue is to provide a standardized process to achieve high quality while maintaining efficiency, hence reducing the cost and lead time. This approach involves a combination of digital tools, process engineering, and quality planning, and it makes the CNC machining services or any other low volume high mix service more predictable and standardized.

Engineered Production Agility

- Rapid Setup Protocols: Standardized work and modular tooling allow a complete machine changeover in less than 30 minutes.

- Dedicated Prototyping Resources: Rapid CNC milling is facilitated by segregated cells, hence quick, turn jobs can be made without interfering with scheduled production flows.

Systematic Process Control & Visibility

- MES-Driven Transparency: The manufacturing execution system in real, time traces every job, thus offering full visibility from order to delivery.

- SPC Quality Monitoring: Statistical Process Control is used during the production run allowing for immediate correction to maintain a Cpk level of at least 1.67.

Structured Quality Foundation

- Digital Work Instructions: At each station, visual, paperless instructions guide operators to correctly setup each unique part, thus significantly lowering errors.

- Comprehensive First-Article Inspection: A detailed first, part validation process ensures that the entire setup is checked and confirmed before any batch is allowed to proceed.

This methodical system embodies the fact that well, executed prototype milling services and small batch productions result from systematically designed operations rather than from sporadic efforts. We offer the controlled agility that makes it possible to handle complexities effectively, thus ensuring consistent quality and meeting timelines for every CNC milling project, no matter the volume.

FAQs

1. What is the minimum tolerance that LS Manufacturing can achieve with CNC milling?

Working in a temperature, controlled environment with five, axis machining and in, machine measurement technology, we are capable of producing parts with tolerances of 0.01mm for standard materials, and we can push the accuracy even further depending on the nature of the project and through process optimization.

2. How long does it usually take to get a quote after submitting drawings?

We normally give you a detailed quote within 4 working hours after you give us complete 3D models and drawings, and for complicated parts no more than 8 hours.

3. What engineering materials do you support for selection and processing?

We are capable of milling up to 50 different materials including aluminum alloys, stainless steel, and tool steel to titanium alloys, high, temperature alloys (such as Inconel), and engineering plastics (such as PEEK), and we offer material selection guidance.

4. How do you ensure the security of my design drawings and intellectual property?

We sign strict NDA agreements, all data is transmitted and stored on encrypted servers, and relevant files can be destroyed as agreed upon completion of production. IP protection is our lifeline.

5. Is there a significant price difference between small-batch prototype processing and large-volume production?

Differences basically stem from the amortization of molds/fixtures and the allotment of programming time. We implement stepped pricing; the more the batch size, the lower the unit cost. The quotation will list all the components.

6. Do you provide subsequent surface treatment and quality inspection reports?

We do provide one, stop post, processing services such as anodizing, sandblasting and passivation, etc., and at the same time issue comprehensive dimensional inspection reports and material certificates.

7. What are the common reasons for delivery delays? How does LS Manufacturing guarantee on-time delivery?

Delivery delays are usually caused by improper process planning or quality control problems. We keep track of the progress in real, time with a digital manufacturing execution system (MES), and we set aside a 10% buffer time which results in an on, time delivery rate of over 98%.

8. What happens if a part is found to be defective during inspection?

We guarantee 100% qualified products. In case of any non-conformity, we will immediately initiate quality tracing, analyze the cause, and prioritize equipment remanufacturing, with all costs borne by us.

Summary

Choosing a CNC milling provider mainly involves deciding the engineering and technical capabilities offered. The article uncovers the core technologies and systems that have been instrumental in achieving successful manufacturing of parts with geometric complexity and dimensional accuracy, as well as quick production. Through a combination of thorough expertise, methodical approaches, and an emphasis on customer needs, LS Manufacturing is able to help the major companies in resolving their difficult issues.

Your project warrants the most dependable manufacturing support. Forward your part drawings and specifications to us at LS Manufacturing, and our engineering staff will be more than happy to give you a complimentary and actionable DFM analysis report along with a transparent quote. Hit the quote button at the bottom to receive your tailor, made quote and make the first move towards accurate and efficient manufacturing.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.