Custom CNC milling services are a relatively effective means of escaping the present burning issues within the manufacturing industry. This may be due to the fact that the organizations within the industries are faced with the challenges of prototyping and scaling up issues, the use of a certain level of quality that means delayed product launches and loss of costs-competitiveness in the market.

In general, failure would have to be attributed to the unrelated chain. Traditional service companies would handle only a reaction or a portion of the chain but not the entire chain because there would not be any integration that is expected to be felt throughout design production to mass production. One of the main discussions in this article is service beyond a reaction.

Custom CNC Milling Services Quick Reference Table

| Category | Key Information |

| Process | Computer-controlled subtractive fabrication with rotating cutting tools to remove material on workpiece. Capable of producing high precision work (±0.001 inches) with complex geometry. |

| Benefits | High precision & accuracy, fast production, up to 70% faster when compared to manual, complicated shapes could be made out. Excellent repeatability can be achieved, flexibility in multi-axis, versatility in materials used and less labor intensity. |

| Machine | Types 3-axis VMC - Light Cutting, 4-axis HMC - Profound Material Removal, 5-axis - Intricate Geometries, Gantry mills - Oversized Parts. |

| Materials | Metals-aluminum, steel, stainless steel, brass, and copper; Plastics-PVC, PEEK, Teflon; Composites-carbon fiber, fiberglass; Wood. |

| Applications | Aerospace components, car parts, medical devices, industrial machineries, consumer electronics, robotics, mold making. |

| Process | Steps from CAD design, followed by CAM programming, machine setup, simulation, machining, inspection, to finishing at test: deburring, polishing, coating. |

| Cost Factors | Type of CNC milling material, size of the part, geometry complexity, machine hours, surface finish requirement, volume of production, tolerances. |

The CNC milling service has been a complete manufacturing solution, thereby filling a gap between prototyping and production. The services will allow for a complete supply chain solution with integration from design, through production, finally aiming at realizing speed-to-market with enhanced quality. The CNC technology has ceased being a secondary important element in modern manufacturing processes but has also become important for manufacturers.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are many articles available on the Internet which discuss topics related to CNC milling. But this is different. The origin of this information comes from the world of application, where our floor lab functions as a live testing ground where we are presently working on machining complex models and hard materials. For us, knowledge comes with performance and the success of every shipped part.

The core of our team's experience is steeped in results. We've completed thousands of projects over the years where strict tolerances had to be accomplished. Quality is not only our guiding principle but it is also shaped by industry standards through powerful bodies such as the National Association for Surface Finishing (NASF) and Metal Powder Industry Federation (MPIF) that ensure high benchmarks in our processes.

Every one of the recommendations in this guide is forged from that real-world execution. We share hard-won strategies for material selection, toolpath optimization, and quality control - the very methods we use to ensure part integrity for critical applications. This is knowledge refined through action, provided to help you achieve reliable outcomes.

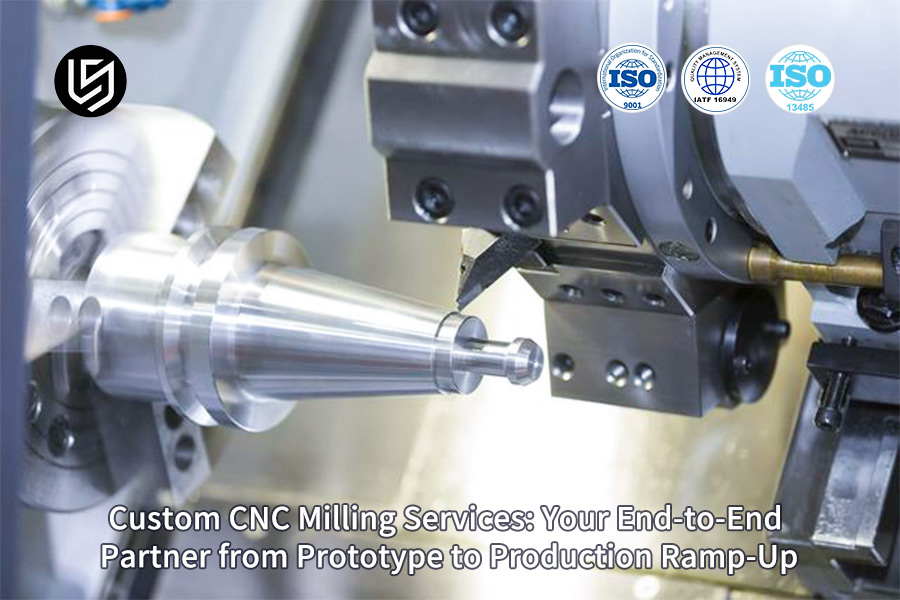

Figure 1: Expert CNC milling collaborator presenting machined parts by LS Manufacturing

How Can Customized CNC Milling Services Help Companies Achieve Rapid Product Iteration?

It should be remembered that the significance of custom CNC milling service in today’s product development process is still important, as it is capable of supporting the quick verification and optimization of design for a product. It has to do with flexibility, as well as adaptability, when it comes to meeting the demands for change from technological advancement in the market. It is also pertinent that the significance for rapid prototyping will be reasoned out in this review.

Rapid Prototyping and Design Validation

With our custom CNC milling services, we offer expertise in the development of functional prototypes characteristic of final production. This will help the designer and engineer validate the shape, size, and performance characteristics of the final product at an early stage in the development life cycle of the product. Validation of potential discrepancies in the design and performance capabilities of the product before embarking on mass production will significantly accelerate the overall product iteration process.

Small-Batch Production and Market Testing

The flexibility that the services offer to the manufacturer allows for the small batch production of the product to be used for market testing of the product. As such, the manufacturer will not be open to the risk that comes with large batch orders. Essentially, it allows the manufacturer to test how well the product is accepted in the market.

Improvements in Technology and in Process

The custom CNC milling process now used is based on multi-axis machining centers, high speed spindles, and computer software via CAD/CAM. That’s a high bar to clear. Additionally, it may be possible through process improvements that a rapid prototyping technology can deliver faster, based on design to completed prototypes.

Custom CNC milling services are a vital piece of the puzzle. It is now possible to deliver the speed, flexibility and accuracy that is required to confirm the real world feasibility of rapid prototyping and continuous product iteration. The custom solutions are a key enabler to quickly validate and bring new products to market that will guarantee competitive advantage. It will enable the company to respond to the feedback obtained from rapid validation.

How Can End-To-End CNC Milling Partners Improve Overall Project Efficiency?

The end-to-end CNC milling partner will handle all tasks which are linked to the key area project management. So all the value adding activities are concentrated on one single point of contact. Consequently, all the disadvantages which might occur because of the management of a multitude of suppliers as well as the key area process efficiency can be avoided.

| Service Phase | Key Activities | Efficiency Impact |

| Design | DFM analysis, prototyping | Prevents late-stage changes |

| Planning | CAM programming, scheduling | Optimizes production flow |

| Production | Machining, in-process QC | Maximizes machine uptime |

| Post-Processing | Finishing, assembly | Delivers ready-to-use parts |

| Delivery | Logistics, documentation | Ensures timely completion |

The potential for this efficiency stems primarily from a digital management system that ensures comprehensive process transparency and alignment. By partnering with an end-to-end CNC milling partner, the company eliminates the inefficiencies and additional costs typically associated with coordinating multiple parties. This integrated approach streamlines production, enhances control, and maintains consistency throughout the entire manufacturing workflow.

What Are The Key Technical Points To Pay Attention To In CNC Milling Prototype Making?

When it comes to CNC milling prototyping, material selection, tolerances and surface roughness of the prototype parts need to be taken into consideration in order to accurately simulate the proposed design. Our qualified engineering team can provide free DFM analysis to review the design features and technical specifications.

| Key Aspect | Technical Focus | Importance |

| Material Selection | Material properties, machinability | Critical for functional testing |

| Machining Precision | Tolerance control, geometric accuracy | Ensures design integrity |

| Surface Finishing | Ra value, post-processing | Affects aesthetics and function |

| Design Optimization | DFM analysis, feature simplification | Reduces cost and lead time |

| Toolpath Strategy | Cutting parameters, tool selection | Maximizes efficiency and quality |

To create a truly effective CNC milling prototyping, material, manufacturing considerations, and design optimization must all be taken into account. Taking these technical specifications in the initial stages of production will result in a prototype that is not only cosmetically accurate but also ensures that the item functions as intended, reducing the risk of error in production and saving time and money.

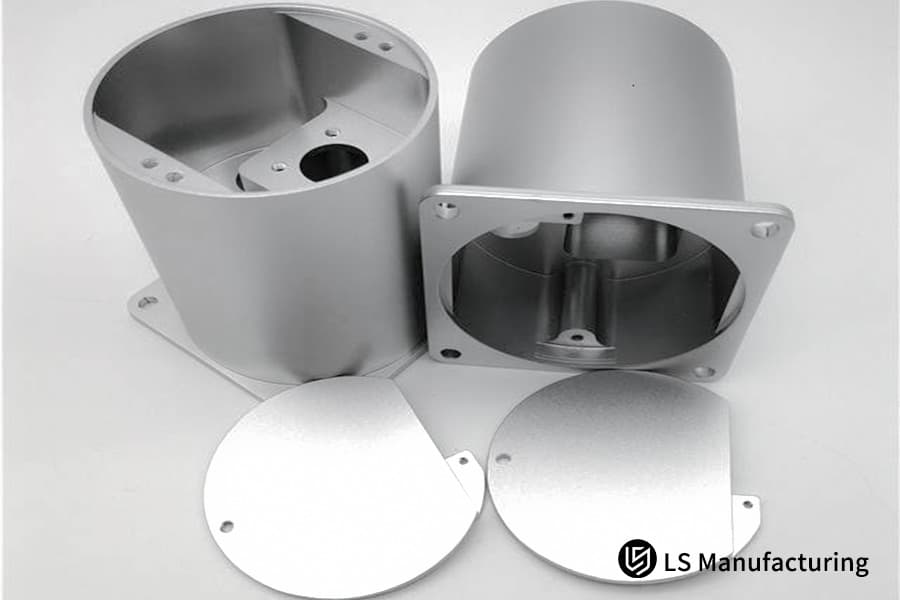

Figure 2: Accurate aluminum prototype parts from CNC machining by LS Manufacturing

How To Ensure The Stability Of CNC Milling Quality During The Production Scaling-Up Phase?

Production ramp-up machining has its own set of challenges in the pursuit of manufacturing perfection. Attaining quality consistency during ramp-up requires a rigorous and multi-faceted strategy involving statistical tools, process control and SPC control for process improvement that guarantees that each and every part will be built to spec, regardless of the production quantity.

Statistical Process Control Implementation

Robust SPC control is critical to the success of production ramp-up machining. Measuring real time data from parts that include critical dimensions and surface finishes, as well as data related to the processes themselves, can allow manufacturers to predict when part variation might lead to a defect. This means that adjustments can be made in real time to maintain quality consistency throughout the thousands of parts required for high volume manufacturing. Reduction in scrap or rework during high volume production significantly improves part quality and reduces the production costs.

Process Capability and Equipment Validation

Validating process capability for production ramp-up machining is the process of determining that a given process is capable of delivering parts that meet specifications consistently. Manufacturers should perform capability studies (Cp/Cpk analysis) to determine whether or not a process is capable of producing a part that fits within established tolerance limits.

Automated Inspection and Data Integration

In modern production ramp-up machining, reliance is solely placed on fully-automated systems providing data through measures presented in a feedback form. In-process gage vision or CMMs provide data directly to the control software of the SPC control system. As such, immediate correction to any variance in the data is possible to provide an assurance of quality consistency generated.

Standardized Procedures and Operator Training

Maintaining quality consistency during production ramp-up machining requires standardized work instructions and well-trained operators. Recording processes for machine setups, changes, and quality checks can guarantee all products alike are produced. Operator training and certification processes can solidify the best practices in the company and make SPC control a part of the production processes.

To sum up in the end, it could be safely drawn as a conclusion that once the production ramp-up machining is performed under a quality management system where the SPC control on the continuous production is available, it is feasible to keep the quality at a stable level with a constant stability, even though the quantity of production increases.

What Are The Main Factors Affecting The Cost Of CNC Milling?

An understanding and control of the CNC milling cost process cannot be guaranteed without a strategic analysis of the cost factors. A strategic analysis involves the determination of the dominant factors of the overall cost and the employment of the appropriate tools in an open cost structure.

- Material Selection and Utilization: Another way to reduce the CNC milling cost is by optimizing the material usage. The cost of a raw material depends on its grade, cost, availability, machinability, and its scrap rate. Efficient nesting and scrap minimization can reduce the material usage by 15-25%. This reduction can lead to substantial saving in the CNC milling cost without compromising on the quality of the part.

- Machining Time and Complexity: Machining time can affect the CNC milling cost in multiple ways. The increase in time due to cutting complex parts, with smaller tolerances and pockets, will obviously increase the machining time. But it is possible to reduce the time by 20 to 30 percent based on optimizing the machining cycles, cut tools, and machine speed and accuracy.

- Tooling and Equipment Costs: The total cost of tool ownership is another cost factor that can be commonly missed. This includes the initial tool purchase price, frequency of regrind, tool life, and tool change over time. We use a transparent pricing model that calculates all of these costs into the CNC milling cost so the customer can understand the value of choosing one tool over another.

- Setup and Programming Overhead: Another cost driver could be the non-producible time that may occur while setting up, programming, and developing work holding and modular fixturing. Modular fixture development and parametric programming template development can reduce set-up time by 40-60%. This transparent pricing model ensures our customers only pay for the time the part is being machined.

- Quality Control and Rework: With process level inspections, rework can be eliminated through Statistical process control or first article verification. The hidden cost factors for scrap materials, rework materials and inspections can be removed from the CNC milling cost calculation. With a transparent pricing with quality assurance, the customer would be in a position to judge the quality of the parts.

To sum up, to achieve CNC milling cost saving, all the above-mentioned cost factors are to be considered and a transparent pricing needs to be provided. Savings can be achieved in the CNC milling cost by saving on the material cost, reducing the machining cost, optimizing tooling cost, saving on the setup cost and saving on the inspection cost, and providing a quality part that meets the client requirements within the budget.

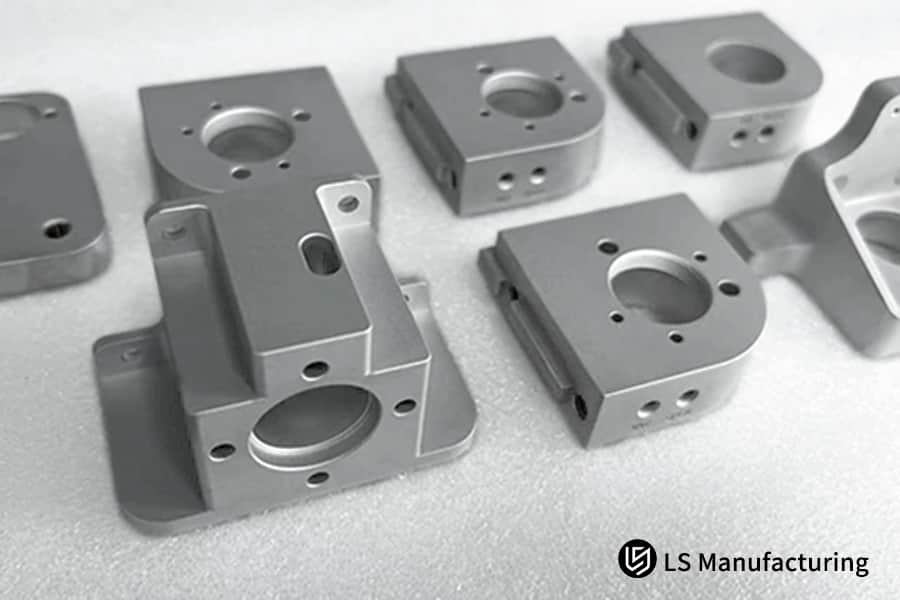

Figure 3: Exhibiting CNC machined aluminum parts with precision by LS Manufacturing

How Can Precision CNC Milling Services Fulfill The High-Precision Requirement?

If you sell a product, there’s a good chance that it contains parts and components that were made with precision CNC milling services because of their tight tolerances and complex geometries. High-precision machining services can be used to make parts and components for your products to satisfy any industry’s requirements. In this article, we will discuss how we can achieve the desired level of precision for parts and components using high-precision machining.

- Advanced Equipment and Technology: Precision CNC milling services are machined on brand-new, state-of-the-art multi-axis milling and turning machines that have high speed spindles and precision tooling. The linear scales, thermal compensation, and anti-vibration systems ensure precision and repeatability even on the longest of runs. CAD/CAM software ensures accurate tool path generation and greatly limits human error in programming.

- Rigorous Process Control and Quality Assurance: When high-precision machining is required, there are many checks and balances involved. FAI, in process inspection, final dimensional inspection on CMMs, and more are all part of the quality control process. SPC is used to monitor process capability and alert for any deviation before it affects the quality of your parts.

- Material Expertise and Tooling Management: Tooling and material knowledge are also critical in high-precision machining. Whether it is specific tool coatings and geometries for aluminum, stainless steel and exotics, or tooling life management systems and maintenance, there are quality checks every step of the way.

Incorporating precision CNC milling services ensures the greatest degree of accuracy. That is because the equipment used is very accurate, there is also very good control of the process and high knowledge about the material. For those that follow the quality standards, tolerances of ±0.01mm can be achieved, which is often necessary for the aerospace and medical sectors.

How To Choose A Reliable CNC Milling Service Partner?

The selection of a suitable CNC milling service partner can affect the quality of the final product and the overall success of a company. Performing a productive supplier evaluation allows companies to find a supplier that can serve their long-term needs and requirements. In this post, we have listed the key points that need to be considered in this process.

Technical Capabilities and Equipment

Assess the equipment in the supplier’s fleet (e.g., CNC mills, 5-axis machines), as well as the capacity of the equipment (e.g., maximum part size, tolerances, surface finishes). Make sure the supplier can handle your materials and geometries. This may involve an on-site equipment inspection and a technical evaluation of the partner’s capabilities.

Quality Management System

If the prospective contract manufacturer is ISO 9001 certified and adheres to other quality standards, that’s a positive indicator. A quality control process that includes a written quality control manual and a regular quality audit schedule indicates a company that is committed to delivering defect-free parts. Request the quality manual and review samples of parts that the company produces to confirm they regularly adhere to their standards.

Experience and Track Record

Ensure they have experience within the industry and that they have worked on similar projects before. They should be able to supply case studies, customer testimonials and references to prove they have successfully navigated complex manufacturing challenges. This proves they have a history of making good on their claims and that they care about maintaining long-term relationships.

Finally, it is crucial you find a good compromise of capability, quality and experience in finding the ideal fit with your CNC milling service partner. Carrying out a due diligence and reliability assessment in your supplier selection process guarantees that you will end up with a supplier that will continuously deliver and provide a long-term partnership.

What Are The Key Criteria For Selecting A CNC Milling Partner?

How to choose CNC milling partner is one of the most important business decisions a company can make and is also one of the most significant variables that affect the quality of the end product. A business must consider a wide variety of items to determine whether a potential partner is a trustworthy long-term partner. This evaluation guide will list the key selection criteria needed to make a sound decision.

- Technical Capabilities and Equipment: The first part of your requirements list would need to detail the type of equipment they use, how many axes they have, and the level of accuracy they provide. You would need to figure out their material and geometric limitations as well. A request list may also include an on-site inspection of equipment and technical capability.

- Quality Management and Certifications: Make ISO 9001 and any other quality certifications relevant to your parts your selection criteria. A quality management system with documented policies and procedures, and periodic reviews or audits, demonstrates a commitment to delivering defect-free parts. Request access to their quality manual, inspection records and part samples to confirm the quality of their parts and their processes.

- Experience and Track Record: Number of years in business and past performance on similar projects should be your selection criteria. Request case studies and testimonials and check references to ensure that your vendor can handle complex parts. A evaluation guide on selecting a vendor includes conducting reference checks and site visits to confirm the vendor’s experience and to gauge their problem-solving abilities.

An overview of how to choose CNC milling partner begins with a discussion of technical expertise, quality standards, and demonstrable past performance. The proper evaluation guide combined with a selection criteria can help determine the right vendor for your needs, and provide the foundation for a stable partnership that continues to serve your business well over time.

Figure 4: Custom prototype and production via dedicated CNC milling by LS Manufacturing

LS Manufacturing Medical Device Industry: Customized Manufacturing Of Precision Components For Surgical Navigation Systems

Here’s a new case study where we assisted a medical device company in the production of their new surgical navigation system. With medical devices, no compromises can be made in terms of quality and accuracy. Please read below to see how we provided value to the customer in order to expedite the adoption of this game-changing technology.

Customer Challenge

Medical parts needed for a surgical navigation application required both: micron level tolerances and medical grade biocompatibility certifications. The existing vendor was unable to consistently machine the parts to meet the project schedule or the certifications requirements.

LS Manufacturing Solution

We supported the client by utilizing one of our 5-axis CNC machining centers that was appropriate for the med device project. Cutting conditions and tool paths were developed to consistently machine the parts to the micron level tolerances. All work was performed in a controlled (cleanroom) environment that supported the medical grade biocompatibility and certification requirements.

Results and Value

The client enjoyed significant benefits as a result of the partnership. They saw a consistent 99.9% quality rate on the component, completely removing the issue of scrap and rework. They also saw a 40% reduction in total lead time, which allowed them to complete product registration three months in advance. Ultimately, the two companies were able to develop a long-term, trust-worthy manufacturing partnership.

This case study showcases how LS Manufacturing’s ability to precision machine for the medical device industry has tangible results on customer success. With extensive knowledge of complex medical parts and medical-grade biocompatibility standards, LS Manufacturing offers customers so much more than just parts. They offer an edge of accuracy, safety, and speed to market.

Facing micron-level tolerance and biocompatibility challenges? Our CNC milling expertise solves them fast.

Innovative Applications Of Advanced CNC Milling Technology In Mass Production

Advanced machining technology is a proven method to enhance the accuracy, productivity, and reliability of your volume production. With this innovative take on CNC milling, you can lower your costs, compress your lead times, and strengthen your competitive offering. The following aspects highlight how this innovation is reshaping high-volume manufacturing environments.

Digital Integration and Smart Manufacturing

One of the hallmarks of today’s advanced machining technology is digital connectivity. This includes real time monitoring, preventative tool maintenance, and process optimization. This translates to fewer unexpected stoppages, longer tool life, and superior part quality — all driving production efficiency.

High-Speed and Multi-Axis Machining

One of the biggest improvements in the production of complicated parts has been the adoption of 5-axis and multi-tasking machining centers. These machines enable the fabrication of complex parts to be completed in a single set-up. This has the advantages of greatly reducing cycle time, eliminating any part alignment mistakes, and the ability to machine complex geometries which may have not been possible in the past or require multiple operations.

Automation and Lights-Out Production

The use of robotic part handling, pallet changers, and tool load/unload systems is a big part of volume production. This level of automation facilitates the ability of near-continuous or lights-out production which drastically increases production capacity. It frees up skilled employees to perform operations of programming and inspection rather than manual tasks, improving production efficiency.

Data-Driven Process Optimization

Modern CNC’s can generate so much data and this will be the source of the next technological leap in process control. we can monitor all the variables, we can determine the ideal settings (spindle speed, feed rate, etc) for every tool, in every material. Optimisation gives us reduced cycle times, better surface finishes, longer tool life and most importantly, increased productivity and reduced costs.

You have to understand that when we talk about advanced machining technology, we are not just talking about cutting. We are talking about a system that involves data analytics, automation and a lot more. When you leverage that technology, you can improve productivity, quality and responsiveness in such a way that it gives you a major competitive advantage.

FAQs

1. What is the minimum order quantity of custom CNC milling?

Small batch (1 piece) to ten thousands of quantity, customized parts, depending on the scale of customers’ requirement.

2. How long does it take to scale up production from a prototype to mass production?

4-6 weeks as normal procedure. There is fast track procedure to shorten lead time to 2 weeks.

3. How do you ensure product consistency in mass production?

Through a comprehensive quality control system and automated testing, we ensure that the quality stability of mass production reaches over 99.5%.

4. How do design changes affect project schedule and cost?

We have a very flexible change management process. We estimate the change within 2 hours in order to not delay the project.

5. Do you provide material certifications and testing reports?

Yes, we can. We provide all material certificates and inspection reports for traceability.

6. How do you handle urgent orders?

We have an express channel for urgency. We will arrange the resource for the urgent order.

7. How do you protect your clients' design intellectual property?

We sign the NDA and use a very reliable documentation system. We have never had any information leak in 20 years.

8. Can I have on-site visit and trial machining?

Yes, we welcome you to visit us. We offer free trial machining for you to feel our machining by yourself.

Summary

The one-stop CNC milling solution can help companies improve the efficiency of product development and mass production. LS Manufacturing, a company with a complete technology system and service experience, is a guarantee for customers’ manufacturing.

Get professional CNC milling services now and efficiently achieve precise manufacturing from design to finished product.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.