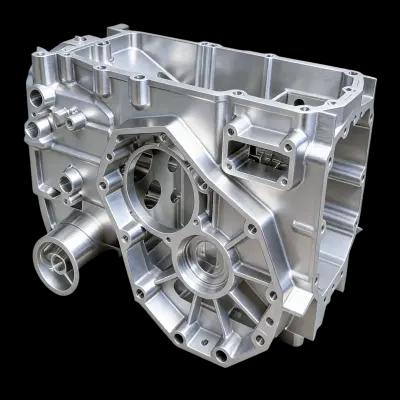

CNC Milling

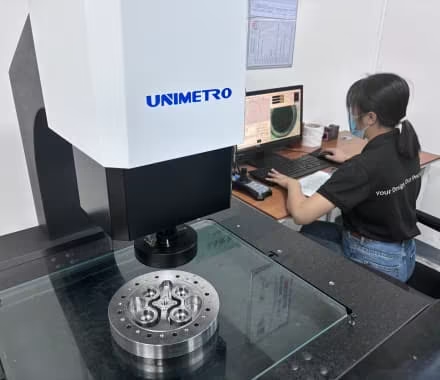

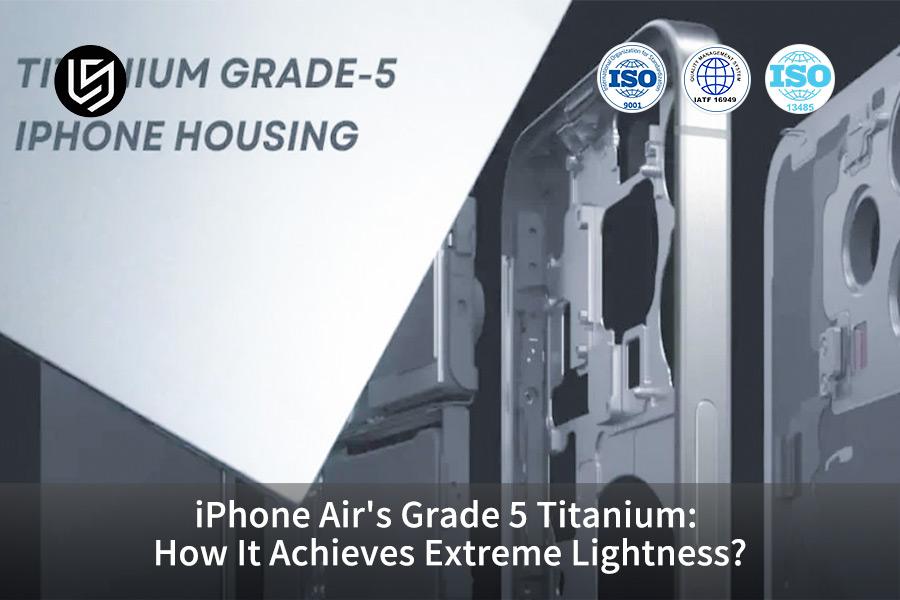

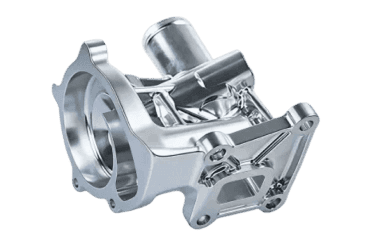

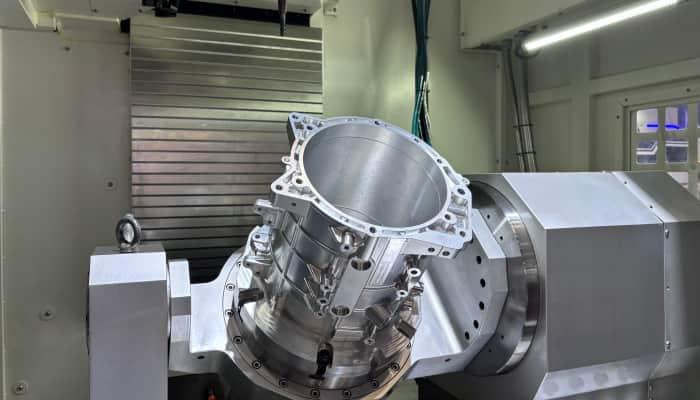

LS Manufacturing produces high-precision, tight-tolerance parts and complex geometries in metal or plastic using 3-axis to 5-axis CNC mills. We focus on minimizing delays and production risks, delivering reliable quality, consistent lead times, and precision components or molds for diverse industries.

CNC Milling Services

.e845ae5b.webp&w=2048&q=75)