CNC milling services for electronic components have to tackle one of the most important aspects of their work which is the balance between achieving high precision and speeding up the processes. Requirements that are as extreme as manufacturing heat sink fins of 0.5mm±0.05mm thickness and having the tolerances for RF connector holes at 0.01mm are so demanding that they drastically reduce both the yield rates and the productivity of the operations. As a result, it becomes necessary to spend more time to produce high-precision tooling such as PCB fixtures, which in turn delays the time-to-market.

Through our CNC milling services, we deliver a specialized solution for micro-feature machining. This solution was born out of a decade of manufacture industry experience. By carrying out a proprietary database, we follow the four, pillar system for fine machining, rapid changeover, in-process inspection, and urgent-order channels. This method results in a precision compliance rate of 99.2% and a lowering of the lead time to 48 hours.

CNC Milling Services For Electronics: Precision & Speed Solutions – Quick Reference

| Category | Key Information |

| Core Service | We offer precise-small to medium batch CNC milling with a focus on manufacturing intricate components for the electronics sector such as enclosures, heat sinks, connectors, and fixtures. |

| Material Expertise | We accurately machine diverse materials essential for electronics such as aluminum, copper, engineering plastics (e.g., PEEK), and pre-machined PCB panels. |

| Precision Solutions | We meet precision requirements by Swiss-style milling, state-of-the-art tooling, and real, time monitoring, allowing us to hold very tight tolerances (down to ±0.01mm) on fine details. |

| Speed & Turnaround | We leverage high-speed CNC milling, proficient CAM programming, and an optimized workflow to accelerate prototyping and production cycles. |

| Quality & Consistency | Besides that, we achieve reliability through stringent QA processes, including automated coordinate measuring machine (CMM) inspection, not only to ensure the parts are meeting exact specifications but also to maintain batch-to-batch consistency. |

| Design for Manufacturability (DFM) | During the prototyping stage, we provide professional DFM advice to align part design with the lowest possible cost-ease of manufacturing, and the highest performance in the end, use product. |

We address the major issues of precision, speed, and reliability in electronics CNC milling manufacturing. Our services guarantee that complex parts are manufactured to the exact micron-level tolerances for perfect fit and function. We shorten development cycles from prototype to production while maintaining quality. Ultimately, we give you the assurance that the parts we deliver are mechanically flawless and consistent, thus improving your product's performance, durability, and time-to-market.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Many articles have been written about CNC milling, but this one comes from the factory floor. We are not discussing theoretically, but we are doing it. For over 10 years, our members have been fighting the real world wars in the electronics manufacturing industry: machining delicate, high-tolerance enclosures, heat dissipation in compact heatsinks, and perfect fitting connectors. Each of the solutions offered in this article is tested under production schedule pressures and strict quality checks, thus exceeding textbook theory.

We can measure our precision with various standards. While milling thin-walled electronic housings or first, rate RF components, we follow a set of best practices that are based on a study by TWI Global for preserving the material and ensuring reliable joints. When it comes to working with special alloys or sintered materials, our methods are in line with the Metal Powder Industry Federation (MPIF) standards, which is the basis for obtaining parts with consistent metallurgical properties and working characteristics.

The knowledge we share is what we have learned from direct experiences. We have figured out the toolpaths that keep the aluminum frames free from chatter, how to set the feed rates for brittle plastics, and how to get the speed and surface finish right for prototype runs. These are not theoretical ideas but real, life solutions that have been tested by the chips, coolant, and the successful delivery of thousands of parts. We share with you the hands, on insights that we rely on every day to solve problems of precision and speed, which are your biggest challenges.

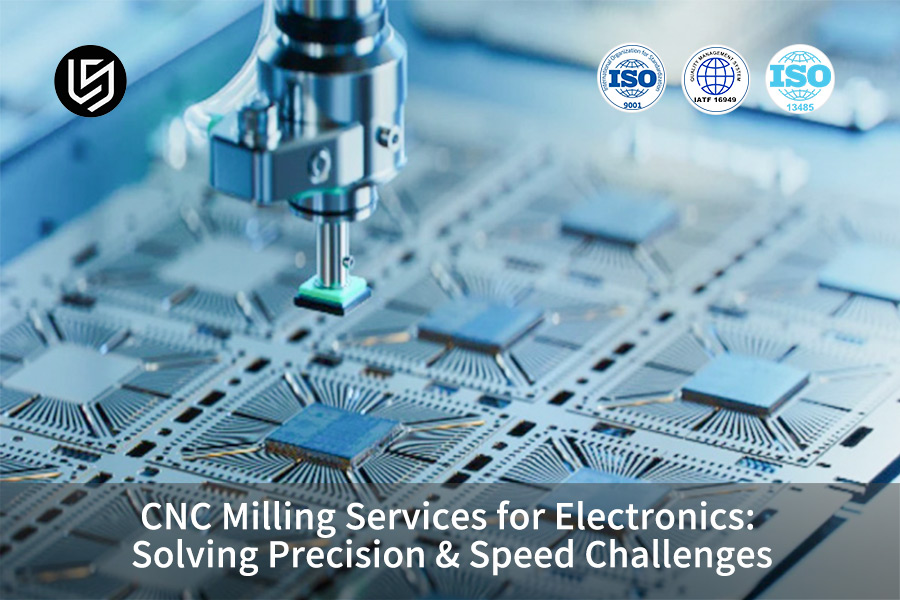

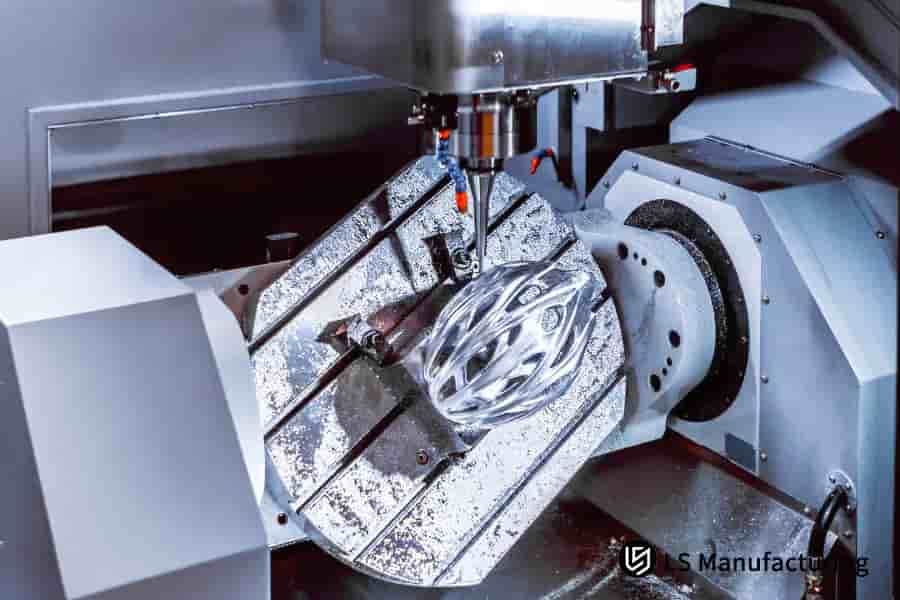

Figure 1: Live CNC milling precision aluminum alloy for quick-turn electronics enclosure manufacturing and quote analysis.

What Specific Precision Requirements Must Be Met For CNC Milling Of Electronic Components?

The miniaturization and high-frequency performance of modern electronics require extremely precision CNC milling that almost go beyond the capacity of traditional machining. This whitepaper unfolds the targeted approach of our company to tackle these challenges, thus ensuring the reliability of mission, critical applications:

Conquering Sub-Micron Tolerances for Critical Features

We get to a plus or minus ±0.005mm tolerance for things like PCB guide pins by first of all incorporating next, generation thermal compensation and vibration, damping systems right into our CNC milling operations. Such a stable platform enables micro-tools to operate in a very consistent manner thereby the strict tolerances for electronic components are directly achieved for the ideal fit and function in tight assemblies.

Ensuring Uniformity in Delicate Thin-Wall Structures

Keeping a uniform sub-0.02mm thickness for heatsink fins is not speculation but a fact that we have established while working with sharp tools. We use dynamic, toolpath-embedded feed rate adjustments that react to real-time spindle load of the tool. This smart machining technique that we use prevents deflection and chatter, thus maintaining the structural integrity and performance in terms of heat dissipation of the precision electronic components.

Integrating In-Process Verification for Zero-Defect Goals

In order to reach 99.5% first-pass yield, we take advantage of on, machine probing cycles that measure critical dimensions right after milling. If the measured dimensions are outside of the tolerance, then an automated tool compensation or process halt is initiated. This closed-loop system, which is in line with TWI Global standards, plays an indispensable role in the case of high-value parts where failures after the process are not an option.

Optimizing Surface Integrity for Functional Performance

A perfectly smooth Ra 0.4µm surface finish is a must for both conductivity and sealing purposes. We bring together ultra, high-spindle-speed finishing passes and tools with special geometries, a technique that we learned from the Metal Powder Industry Federation (MPIF). By controlling it this way, we are sure that the surface properties will be just right for both conductive and insulating electronics CNC milling applications.

This protocol reflects our solutions-oriented CNC milling services, which take deep technical knowledge and turn it into manufacturing results that are dependable and repeatable. We are not merely presenting specifications, but a tried and tested, detail-oriented process that directly addresses precision limitations keeping from advancement of high technology electronics manufacturing.

How To Achieve Efficient And High-Precision Machining Of Thin-Walled Electronic Enclosures?

When precision machining thin-walled structures, a very crucial problem is how to keep the working speed without the risk of vibration and distortion. Our method defeats this problem by using the combination of advanced simulation and dynamic process control for manufacturing aluminum electronics enclosure.

Strategic Toolpath Programming & Cutting Mechanics

- Adopt Trochoidal Milling: We use circular toolpaths which enable to significantly reduce radial engagement thus cutting forces and heat generation on thin walls are drastically lowered.

- Implement Axial Staggering: The cutting depth is varied in a non-repeating manner for each pass, which helps to dissipate heat evenly and avoid harmonic vibration.

- Utilize Dynamic Feeds: Feed rates are automatically adjusted in real-time guided by spindle load feedback, thus chip load and tool pressure are kept constant.

Rigorous Fixturing & Distortion Mitigation

- Conduct FEA-Based Fixturing Simulation: We use simulation technology to do a virtual test of clamping forces and machining stresses before starting production to make sure that the fixtures which hold the parts do not aggravate the stress.

- Employ Multi-Stage Stress-Relief Machining: This method uses separate operations for roughing, semi-finishing, and final finishing, so residual stress can redistribute between stages.

- Apply On-Machine Probing: After each major machining stage, critical dimensional features are checked and mid-process corrections can be made to compensate for any slight deflection.

Process Integration for Speed and Accuracy

- Leverage High-Speed Spindles: Operating 24, 000+ rpm spindles enable higher feed rates without sacrificing surface finishes at a micrometer level, which is indispensable for precision machining.

- Integrate Adaptive Control: The appliance supervises the tool's state and modifies the parameters so that quality can be maintained from the first to the last item in a batch.

- Streamline with Proven Protocols: Our established CNC milling services workflow, from the simulation stage to the final inspection, guarantees a dependable 3-day turnaround for prototype enclosures without lowering the sub-0.03mm distortion tolerance.

This complete procedure converts the usually tricky thin-wall machining issue into a dependable, quick-turn service offering. We deliver not only a machining quote but also a fully engineered CNC milling process which ensures dimensional stability and a high-end surface finish for your most challenging aluminum electronics enclosure applications.

Figure 2: CNC milling services precision aluminum alloy for real-time electronics enclosure machining and quotation analysis.

What Are The Fundamental Differences Between PCB Milling And Metal Machining?

In order to get the most out of electronics manufacturing services, it's essential to realize how completely different in nature PCB milling and metal machining really are. Although both are subtractive CNC milling processes, the material science and functional objectives call for completely different technical approaches, parameters, and contamination controls. This paper identifies these core differences and our customized solutions:

| Aspect | PCB Milling (FR4/Composite) | CNC Metal Machining (e.g., Aluminum) |

| Primary Goal | Electrical isolation with high accuracy and sharp feature definition while not causing any damage to the copper layers or the substrate. | Removal of material for making 3D mechanical parts with designed strength, tolerance, and surface finish. |

| Tool Geometry | PCB milling with specialized bits that have very sharp, low-angle (i.e. 15°-30°) cutting edges to shear copper and glass fiber successfully, along with the use of raw wood chips for insulation. | Making use of sturdy end mills with higher helix angles and variable pitch which are capable of continuous chip formation and heat generation control. |

| Cutting Parameters | Running at extremely high spindle speeds (≥30, 000 rpm) and feed rates (≥2, 000 mm/min) in order to reduce heat build, up and prevent copper lifting. | Making use of balanced speeds/feeds (e.g., 18, 000 rpm / 1, 200 mm/min) which are optimized for the rate of material removal and tool life. |

| Contamination Control | Requirement of integrated high-vacuum dust extraction (>90% efficiency) in order to remove abrasive, conductive glass fiber dust thereby protecting the machine and the board. | Mainly handling of the management and the use of coolant to dissipate heat, with less attention given to the extraction of the fine particles. |

| Tolerance & Quality Focus | Precision targeting isolation width and feature dimensions (±0.02mm) with surface quality being evaluated by the appearance of clean copper edges that are free of burrs. | Emphasizes on dimensional tolerance (e.g., ±0.01mm) and surface finish (e.g., Ra 0.4µm) for proper mechanical function and fitting. |

This study addresses your technical challenges by implementing process-specific protocolsfrom the choice of the tool to contamination controlthat guarantee accuracy and reliability. Our method produces consistent results where general CNC milling services fail, thus giving the required technical authority to competitive PCB prototyping vs CNC milling projects.

Figure 3: CNC milling precision aluminum alloy for electronic component enclosure manufacturing services.

How Does The Rapid Response Mechanism Meet The Urgent Needs Of The Electronics Industry?

The electronics industry is so fast that it demands not only the willingness but also a perfectly engineered system to shorten the lead time without compromising the quality. Our rapid response mechanism is the answer to the main problem of delivering the most complex high-accuracy parts in days instead of weeks by means of integrated process optimization and resource dedication. This approach relies on 3 main elements:

Modular Programming & Digital Pre-Validation

To avoid the traditional obstacle of CNC programming, we make use of a library of pre-engineered, modular toolpath strategies for typical quick-turn electronics machining features. For example, for a new RF enclosure design, this system automatically applies proven parameters for pocketing and thin, wall finishing thus drastically reducing the programming time from hours to less than half an hour. Taking a digital, first stance, this method not only gets the first piece right but also has no expensive trial runs.

Agile Material Logistics & Pre-Certified Stock

Immediate machining essentially means having the materials available for use right away. To avoid delays, we have our own stock of pre-certified raw materials thus we don't need to wait for external verification. Among them are specific grades of aluminum and copper alloys which are the main materials for electronics CNC milling, in addition to the availability of FR4 blanks. We can start production within a couple of hours after receiving confirmation of the order without going through the long lead time stages of other material procurement and verification.

Dedicated "Fast-Track" Production Cells

We do not just put the urgent projects into the same line as the other standard ones. High-speed machining cells with dedicated capacity are the only places where their work is being done. These cells utilize the most efficient CNC milling cycles allowed by running tooling and fixtures in a state of readiness thereby machine setup time is kept to minimum. The physical separation of the different areas make sure that urgent jobs can flow without any obstruction hence fast delivery is assured for even the most complex geometries.

Such a complete procedure from one end to another makes the no time to lose request of yours turn into a consistent, reliable result. We are addressing the main problem of shortened schedule by combining digital efficiency, ready logistics, and dedicated hardware, which gives not only a promise but a verified CNC machining quote coming with 99% past performance of on-time delivery of the critical electronics components.

How To Control The Effects Of Thermal Deformation During Electronic Component Manufacturing?

Machining thermal expansion can become a serious problem that can affect the dimensional accuracy of precision electronic components. This article presents a methodical, data-driven approach to the thermal deformation control problem. It starts with the traditional cooling, then goes predictive compensation and real-time monitoring, thus maintaining an accuracy level of less than-0.01 mm.

| Control Strategy | Technical Implementation & Measurable Outcome |

| 1. Proactive Heat Source Management | We use localized cryogenic cooling (e.g., LN₂ mist) at the cutting interface to keep the workpiece temperature below 40°C, thus directly eliminating the main source of thermal expansion during aggressive CNC milling. |

| 2. Predictive Thermal Error Compensation | Individual machine thermal drift is characterized beforehand and compensated through CNC macro programs, thus toolpath coordinates are corrected proactively to reduce thermally induced error from 0.05mm to less than 0.005mm. |

| 3. Real-Time Thermal Process | Monitoring In situ infrared thermography maps the temperature field of the workpiece, thus the data serve both as a proof of stability and as a trigger to adjust the process if the preset thresholds are violated, thus ensuring real-time quality assurance. |

| 4. Optimized Machining Sequence & Parameters | CNC machining process is planned such that heat is evenly distributed through the use of trochoidal toolpaths and staggered axial depths of cut, therefore preventing the formation of localized hotspots which lead to distortion of thin-walled features. |

This integrated protocol actively manages, predicts, and compensates for heat to fix the root-cause issue of thermal distortion. We assure batch consistency of your precision electronic components by developing a closed-loop system of cooling, compensation, and verification which is a crucial advantage in high-tolerance precision milling applications.

Figure 4: Precision CNC milling FR4 PCB substrates and aluminum alloy for quick-turn electronics manufacturing services.

How Can Tool Optimization Improve The Processing Quality Of Electronic Components?

In high-precision electronics manufacturing, the choice of tools decides the final functionality of the parts, such as electrical performance, or thermal management. Systematic tooling optimization directly addresses the main problems of burr formation, surface integrity degradation, and premature tool failure which result in unreliable components. With the help of our approach, we turn tooling from a consumable into a precision-engineered system variable:

Material-Specific Tool Selection

- Coating-Substrate Synergy: We match the hardness of the CNC milling tool substrate with the help of a tailor, made coating (e.g., diamond-like carbon for aluminum) in order to decrease adhesion and increase tool life in abrasive composites by three times.

- Micro-Tool Protocols: Ultra, fine grain carbide tools for sub-1mm features are used with runout control (<0.003mm) to achieve high accuracy and avoid breakage.

Geometry for Feature-Specific Results

- Burr Minimization: Tools with high helix and variable pitch geometries produce cleaner shear thus, reducing the burr height on delicate fins to less than 0.005mm.

- Chip Evacuation Design: Optimized flute geometry and coolant paths efficiently remove chips from deep pockets, thus the surface quality is protected.

Data-Driven Process Management

- Proprietary Tooling Database: Our system suggests the best tool and parameters by comparing material, feature, and machine dynamics to provide repeatable CNC milling services.

- Predictive Tool Monitoring: Real-time vibration analysis predicts wear, thus changes are scheduled proactively before a quality drop.

This integrated tooling protocol addresses the root causes of poor finish and dimensional drift by implementing a scientific selection process, precise geometry control, and vigilant lifecycle management. We guarantee the functional performance and durability of your precision electronic components thus, giving you the consistent, high-grade results necessary for securing a competitive edge in the field of advanced electronics CNC milling.

LS Manufacturing Communication Equipment Industry: Precision Milling Project For 5G Base Station Heat Sinks

This precision machining case study illustrates how LS Manufacturing eliminated a critical production bottleneck for a 5G equipment provider that was struggling with quality issues of complex aluminum heatsinks. Our solution serves as an example of a systematic approach to electronics manufacturing services for mission-critical 5G components:

Client Challenge

A leading 5G OEM was working on 6061-T6 aluminum heatsinks, featuring 0.8mm thick, 15mm high cooling fins and a critical mounting surface flatness tolerance as tight as 0.02mm. The supplier they were using before had been overheating the products and overpressure with the result that the yield rate was only 70%, and a two-week delay in the project that was critical for the launch of the product almost happened. On top of that, the per-unit costs go up.

LS Manufacturing Solution

In order to get rid of distortion, we have come up with a multi-stage precision milling protocol. The part was held in place by using a custom vacuum fixture which helped to evenly distribute the clamping pressure. The selective CNC machining process involved high-speed CNC milling at 20, 000 rpm with staggered axial depth cuts, and then a controlled stress-relief aging cycle. The finishing took place with the help of on-machine probing for real, time thermal compensation, thus, the output was fast, reliable.

Results and Value

The final pieces had a flatness of 0.015mm, which is 25% better than the standard. The first-pass yield rate was 98.5% and the overall production time was shortened to only two days. The rework was eliminated by this high-speed milling solution, the client was able to accelerate the rollout schedule by two weeks and achieve an annual quality cost saving of more than $70, 000, thus the value of a consistent, high-precision partnership is demonstrated.

This case illustrates how we can breakdown complex thermo-mechanical problems into simple, actionable, data-driven steps. Our CNC milling products are not merely components but are backed with fully certified, turnkey manufacturing stability allowing our clients to have a significant advantage especially in areas that precision, reliability, and speed are paramount in the advanced electronics markets.

What Are The Quality Inspection Standards For CNC Machining Of Electronic Components?

Reliability of machined electronic components can only be ensured through a rigorous and multi-faceted inspection system that incorporates more than just dimensional checks. For precision CNC milling operation, we use a closed-loop quality system which constantly checks and assures compliance all through the process from raw material to finished part thereby meeting the critical inspection requirements for fit, function, and longevity:

Comprehensive Dimensional & Geometric Verification

We conduct 100% inline dimensional inspection for critical features using high-accuracy CMMs (±0.001mm) and automated optical systems. This precision machining process validates not just basic lengths and diameters, but also complex geometric tolerances like flatness, parallelism, and true position of mounting holes, ensuring every part meets the strict quality standards for assembly interoperability in dense electronics.

Surface Integrity & Finish Assessment

Surface quality is very essential for electrical contact and thermal transfer. We statistically sample (≥30%) with white-light interferometers to quantitatively measure surface roughness (Ra, Rz) against specified limits. Our data-driven approach ensures that CNC milling services create finish functionalities of RF components, signal loss, and heat removal in the case of enclosures.

Material & Process Compliance Certification

We handle traceability of materials by checking the certificates of materials for each batch and carrying out periodic spectroscopic analysis. Besides, our CNC machining process is regularly checked and meets the standards of IPC and ISO to give clients a certified guarantee that components are made to quality standards of the performance and reliability industry.

This comprehensive inspection system resolves the main hurdle in quality assurance, which is the reliance on subjective judgments, by turning these checks into objective, data-backed metrics. We provide certified precision and guaranteed reliability by checking in advance every critical feature of the product, thus making sure that your printed circuit boards will be working as intended not only in prototype but also in mass production.

How To Obtain An Accurate CNC Machining Quote For Electronic Components?

Giving a reliable CNC machining quote for precision components is not just a matter of calculating based on volume. Our system is able to come up with an accurate electronic parts pricing by dissecting the technical complexity, material behavior, and production logistics through a well, structured parametric model. Here is how we accomplish cost transparency:

Parametric Analysis for Technical Complexity

- Material Machinability Coefficients: We use a set of experimentally determined factors (e.g., Aluminum: 1.0, Copper: 1.8, FR4: 2.2) that we multiply by baseline costs, thus reflecting the actual tool wear and machine time.

- Tolerance-Based Complexity Scaling: The sharper the specifications are, the more the cost rises exponentially; the factor for IT6-grade tolerances is 1.5 times, whereas for IT7-grade it is 1.2 times the cost of the same feature.

- Geometric Feature Assessment: Our system is capable of checking the undercuts, thin walls, and deep cavities so that it figures out the time for specialized tooling and multi-axis precision CNC milling strategies.

Integrated Technical & Logistical Evaluation

- Process Engineering Review: Each manufacturing quote is virtually run through a design for manufacturing (DFM) software which helps to determine the optimal CNC milling order thus reducing the number of setups and secondary operations.

- Urgency Factor Calibration: Changing our delivery to a quicker one not only affects the logistics and scheduling premium which dynamically change 1.3x but also real lead times are ensured.

- Supply Chain Cost Integration: Direct real-time material vendor data integration into the model, thus mirroring the current market conditions for the raw stock.

Automated Output with Human Verification

- Algorithmic Quotation Generation: The system integrates all parameters and outputs a preliminary itemized cost estimation within minutes.

- Engineer Validation Gate: A senior process engineer cross, checks every automated quote with the historical project data, final accuracy calibration, thus ensuring a ≥95% confidence rate.

This method makes quotation a predictable engineering result rather than a guess. We eliminate your budgeting doubt by giving you technically-grounded, transparent CNC machining quotes which reflect real manufacturing complexity thus your project planning of critical electronic components becomes a confident one.

FAQs

1. What is the highest precision achievable in electronic component machining?

The highest precision is ±0.005mm, with a surface roughness of Ra0.2μm, which is good for precision connectors, RF devices, and other similar applications.

2. What is the fastest lead time for urgent orders?

Simple parts can be done within 24 hours, while complicated parts may take 48-72 hours. LS Manufacturing offers a fast-track service for urgent requirements.

3. How do you ensure consistency in mass production?

We maintain CPK≥1.67 and dimensional fluctuations ≤0.01mm by using SPC process control, first-piece inspection, and online measurement.

4. Do you support micro-structure machining?

We can do features as small as 0.1mm and holes with a diameter of 0.3mm at the minimum, and we have micro-milling to satisfy the demands of electronic components.

5. How do you control electrostatic discharge (ESD) during the machining process?

Our workshop is ESD compliant at 1×10^9Ω, and our people are fully equipped to handle safe processing of electronic components.

6. Do you provide surface treatment services?

We are offering a range of surface treatment services including anodizing, conductive oxidation, and nickel plating, to comply with the specifications of the electronics industry.

7. How do I choose the most suitable electronic material?

We advise on material selection based on factors such as conductivity, heat dissipation, and strength requirements, and we also offer free material selection consultancy.

8. Do you support small-batch prototyping?

We accommodate orders commencing from just 1 piece, and we also offer expedited prototyping services whereby you can get your prototype within 3-5 days.

Summary

CNC milling for the electronics industry is not only about matching the super high precision needs, but also about doing it within the set deadlines. We bring about the perfect harmony of precision and speed by professional process optimization, rapid response mechanisms, and stringent quality control. LS Manufacturing's professional electronic component processing system takes your project from design support all the way to rapid manufacturing with a full, process solution.

Send in your electronic component drawings now and our engineers will offer you a thorough technical analysis, delivery commitment, and precise quotation all within 4 hours. Get in touch with us now to be able to use our fast production channel and thus secure the quick progress of your project.

Solve your electronic precision and speed challenges with our specialized CNC milling services for reliable performance.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.