A bolt's tap dream

Late at night, you need a tap of a specific size, but you can't find it in your toolbox, and the hardware store is closed. At this time, you look at a bolt of similar size at hand, and a thought flashes through your mind: "Can I turn it into a tap?"

The answer is: In theory, yes!Grinding the bolt into cutting edges and chip grooves to give it the function of tapping - this sounds like the charm of homemade tools: turning the ordinary into magic.

But the reality is often much more bleak.Precise "grooving", "grinding" and "quenching" under simple conditions are full of challenges. The final "homemade tap" may barely complete the task, or it may easilybreak the edge, curl the edge, or even destroythe workpiece, bringing deeper frustration than the original problem.

Welcome to the fascinating world of homemade tools - a field where creativity and risk coexist, and dreams and reality collide fiercely. Next, let's uncover the secrets ofturning bolts into tapsand face the challenges and possibilities.

Summary of thread manufacturing method comparison

| Method | Applicable materials | Required process | Reliability/results | Applicable scenarios |

|---|---|---|---|---|

| DIY (simple modification) | Soft metal (aluminum), plastic | Angle grinder cutting, simple quenching (such as flame) | Very low: poor thread quality, easy to break, short life | Only for extreme emergencies |

| Professional manufacturing | Tool steel (HSS, cobalt alloy, etc.) | Precision turning/milling, professional heat treatment, grinding | Very high: dimensional accuracy, high hardness, long life |

Applications requiring reliability and performance |

This guide will first teach you how to make a simple tap from a bolt in an emergency. Then, we will reveal howprofessional tapping toolsare made. Finally, a real case will show you why a professional solution is the only choice when faced with high-value laser cut parts.

Here’s What You’ll Learn

- A simple but dangerous survival guide:How to transform ordinary bolts into makeshift taps in extreme emergencies.

- The Art of Precision Manufacturing:Revealing the material science,CNC precision machiningand the core soul behind a $15 tap - multi-stage controlled heat treatment technology.

- Expensive lessons learned in practice:In-depth analysis of a real case - why the local hardened zone (HAZ) on laser-cut stainless steel plates causes standard taps to break instantly, and how to perfectly solve it with special spiral groove cobalt-containing taps and strict process parameters.

- Essential Knowledge Base for Tapping (FAQ):Clear answers to key practical questions:how to properly tap(bottom hole, verticality, chip breaking skills), tap core materials (HSS vs HSS-Co vs carbide), and the essential differences between taps, dies, and thread milling cutters.

- Key inspiration:Deeply understand the limitations of homemade solutions and recognize the criticality ofchoosing a partner (such as LS)with both precision manufacturing and full engineering wisdom for the success of high-value parts.

Now, let’s dive into the mysteries of thread manufacturing, from emergency tricks to industrial-grade precision processes.

Why should you trust this guide? Insights from LS’s manufacturing frontline

Hi, I'm Gloria, an engineer at LS. In our workshop, tapping is by no means a simple process. Watching hundreds of parts flow every day, I know better than anyone that the value of a part often depends on seemingly tiny details like threads. Wehave seen with our own eyesthat expensive custom parts were completely scrapped just because a low-quality tap broke in the hole, causing the entire carefully cut material to be completely scrapped. The heartache and loss are real lessons.

This pain also drives us to become more proactive problem solvers. We don't just cut metal. Wedeeply understandthe changes in the physical properties of the edge of the material after laser processing - those tiny hardened areas are real challenges for subsequenttapping operations. In the face of specialthread requirementsproposed by customers,we have even designed and manufactured special tools to ensure success.

Every suggestion in this guide comes from our real collisions every day at the design table, next to the machine tool, and on the assembly line.It is not a collection of theories on paper, but the full-link experience that has been accumulated after we have handled countless materials and dealt with various tricky thread requirements. We know where the pitfalls are and how to navigate them safely and efficiently. That’s why I believe this guide can really help you.

Emergency Manual: How to turn an ordinary bolt into a simple tap?

Before you begin, remember: This is a destructive, emergency-only method. Wear eye protection, and only try this on soft materials.

Steps Overview:

| Step No. | Core Operation | Key Points/Notes |

|---|---|---|

| 1 | Select the "sacrificial" bolt | Made of steel, as hard as possible (8.8 or higher), with a diameter slightly larger than the target thread |

| 2 | Create a "chip groove" | Cut 3-4 shallow grooves along the bolt axis (angle grinder/Dremel) |

| 3 | Create a "cutting edge" | Grind the front angle (Taper) at the front end of each groove to form a cutting bevel |

| 4 | (Optional) Simple heat treatment | Heat the front end of the bolt to cherry red, and quickly quench it in water or engine oil (increases hardness but becomes brittle!) |

| 5 | Use with caution | Only on soft materials, use a large amount of cutting oil, and remove chips at a low speed, gently, and repeatedly |

Step 1: Choose the correct "sacrificial" bolt

1.Purpose:Acquire a "raw material" barely suitable to serve as a tap.

2.Operation:

Choose a steel bolt as hard as possible. Preferably, the bolt grade should be 8.8 or higher (often marked on the bolt head). The higher the grade, the harder it can be after quenching (but also more prone to breaking).

The bolt must be slightly larger than the desired target diameter of the threaded hole you are attempting to tap. Because it has to form threads by compressing and shearing material, rather than precisely cutting away and removing material like a standard tap.

The bolt must be long enough to work, and thethreaded partmust be largely intact.

3.Must-know facts:Don't forget, this is a "sacrificial" bolt, and it more or less turns into scrap after this emergency.

Step 2: Open the "chip groove"

1.Purpose:To provide space and clear channels for the "cut" metal chips to prevent the chips from jamming up and causing the "tap" to jam or break.

2.Procedure:

- Use an angle grinder or a handheld rotary tool (e.g., Dremel) with a cutting disc or grinding head.

- Cut 3 to 4 grooves shallowly evenly on the threaded part of the bolt in the bolt's axial direction (i.e. parallel to the bolt rod direction).

- Groove depth must cut to the bottom of the thread teeth but should not be too deep so that the bolt strength will be weakened unnecessarily.

- The groove length must cover thetapping depth.

3. Key considerations:Depth and frequency of grooves are critical. Too little or too few grooves will clog easily; too deep will greatly reduce the strength of the bolt. Tighten bolts in use to prevent slipping and injury.

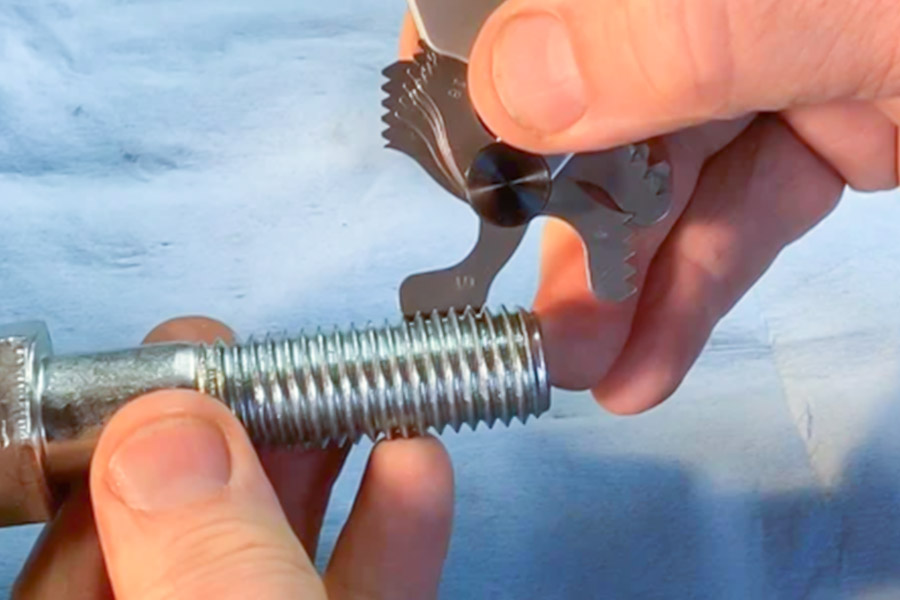

Step 3: Create the "cutting edge"

1. Purpose:To allow this "earth tap" to start cutting into the material, rather than relying on the thread alone to jam it in (most likely to be stuck).

2. How to Use:

- Use a grinding head on a grinder, file, or rotary tool.

- Grind with care a taper at the leading end of each chip groove (i.e., the end where the tap first enters the workpiece).

- This bevel is directly equivalent to a plain front angle, the effect of which is to make the cutting end of the thread teeth slightly "sharper" and form a slope to divert the cutting.

3. Key points to remember:The grind should be minimal, the goal is to form a leading taper, not to remove too much of the thread. Make it even. This step decides whether it can "bite" into material.

Step 4: (Optional but significant) Plain heat treatment

1. Purpose:To lightly harden the front of the bolt temporarily so that it can just "cut" in soft metal without weakening and deforming too quickly.

2. Operation:

- Use a propane torch or oxyacetylene flame (careful operation).

- Concentrate the heat on the front end of the bolt (including the cutting edge) to "cherry red" (about 750-850°C). Pay attention to the color change to avoid overheating and melting.

- After heating evenly, quickly immerse the heated part vertically in cold water or engine oil to quench. You will hear a "hissing" sound.

Remove and wipe dry.

3. Serious warning:

Become brittle! This simple quenching will greatly increase the brittleness of the bolt, making it extremely easy to break when subjected to force (especially torsion). Broken fragments may fly out at high speed and injure people!

Uncontrollable: Temperature, time, and cooling rate cannot be accurately controlled, and the effect is unstable. It may not be hardened or it may be too brittle.

Only process the front end: Only the part that needs to be "cut" is quenched to retain a certain toughness of the bolt shank.

Very high risk: This step is the main source of the risk of breakage! It is not necessary and can be skipped. If skipped, the "tap" will be softer and wear faster, but the risk of breakage will be slightly lower.

Step 5: Use your "emergency tap" with caution

1. Operation:

Only for soft materials! Again:soft aluminum, soft brass, low carbon steel (A3/Q235, etc.), wood, plastic. Hard materials will cause immediate jamming or breaking.

Use cutting oil or lubricant liberally! This reduces friction, cools, and helps with chip removal. Soapy water, motor oil, or even lard is better than nothing in an emergency.

Pre-drill the base hole! The base hole diameter should be close to the minor diameter of the target thread. A base hole that is too small will easily jam.

Slow and gentle! Clamp the bolt to a wrench or pliers (make sure it is secure) and cut in very slowly and gently in a clockwise direction. Stop immediately when you feel extreme resistance!

Frequently reverse and exit to clear chips! After every 1/4 to 1/2 turn, reverse and exit more than one turn, using the chip groove to remove the chips. This is the key to preventing jamming!

Pay attention at all times: Listen to the sound (whether there is abnormal friction or gnawing sound), feel the change of resistance (whether it suddenly increases). If there is something wrong, stop immediately.

2. Key points:The whole process requires great patience and caution. Be prepared to accept failure (the bolt breaks in the hole or cannot form an effective thread).

This method is truly a "last resort". It violates the principles of proper tool design and material science, is ineffective and dangerous. It is strongly recommended that you use a proper tap and tap wrench whenever possible. Only attempt this method in extreme emergencies, when there is no alternative, when you are willing to risk damage to the tool and workpiece, and only on soft materials. Safety first! Pay full attention, wear protection (especially eye protection), and be mentally and physically prepared to fail at any time.

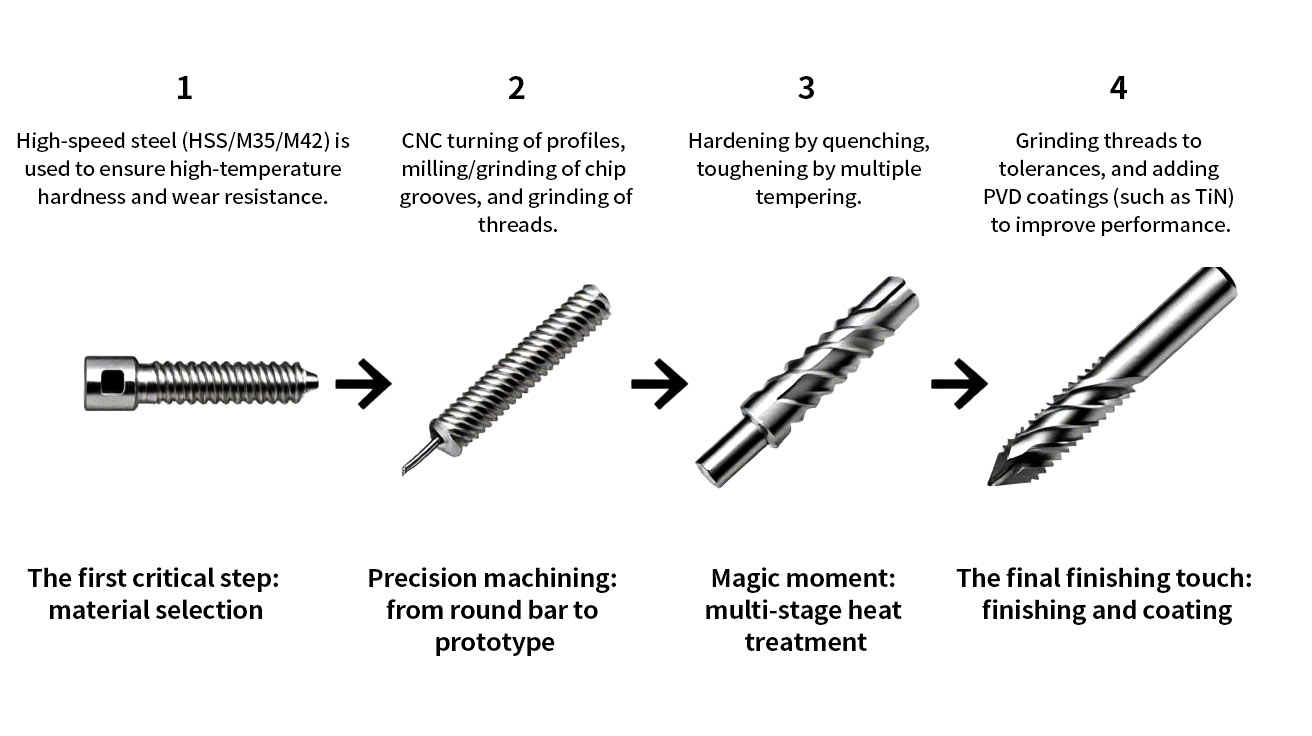

Professional choice: The birth of a high-quality tap

"Now, let's get into the real engineering world and see how much precision technology and engineering wisdom are behind aprofessional tapthat you buy for $15." This is no ordinary cutting tool. Its birth is a superb journey that combines material science,precision machiningand heat treatment.

Overview of the entire tap manufacturing process:

| Manufacturing stage | Core process | Key equipment/technology | Main purpose |

|---|---|---|---|

| 1. Material selection | Select specific tool steel | - | Lay the foundation for hardness, toughness and wear resistance |

| 2. Precision machining | CNC turning shape | CNC lathe | Form the basic contour of the tap |

| CNC milling/grinding chip groove | Special CNC milling machine/grinder | Form the chip removal channel (straight groove/spiral groove) | |

| Thread grinding (primary grinding) | High-precision thread grinder | Grind out precise thread geometry | |

| 3. Heat treatment | Quenching | Vacuum furnace/controlled atmosphere furnace | Obtain extremely high hardness (martensitic transformation) |

| Multi-stage tempering | Tempering furnace | Eliminate stress and improve toughness | |

| 4. Finishing and coating | Fine grinding | High-precision grinder | Ensure final size and geometric accuracy |

| Coating (optional) | PVD (physical vapor deposition) equipment | Reduce friction and significantly improve wear resistance |

1. Step one: material selection

A pro tap's performance begins with the material. Not low-carbon steel that constitutes a plain bolt. Tool steel is the raw material of pro taps, and the most common type of tool steel is high-speed steel (HSS). Its greatest feature is the red hardness - even for the high temperature generated by cutting (about 600°C), it can be maintained with sufficient hardness and sharpness so that it does not soften rapidly and fail. For cutting more difficult materials, such as stainless steel,high-strength alloy steelor high-temperature alloy, more cobalt-containing high-speed steel (such as M35 (5% cobalt) or M42 (8% cobalt)) must be employed. The addition of cobalt significantly improves the high-temperature hardness, wear resistance and thermal stability of the high-speed steel to make it suitable for more demanding tapping operations.

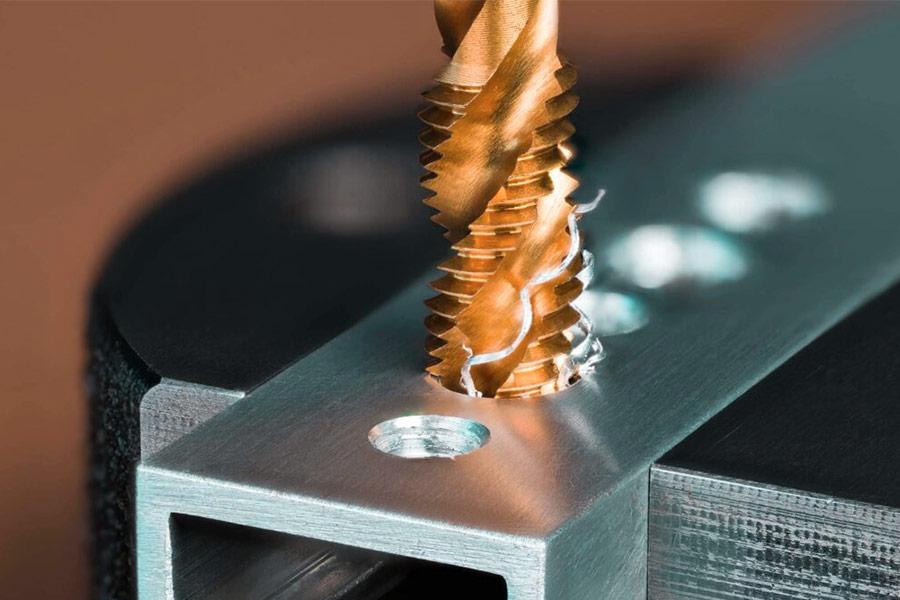

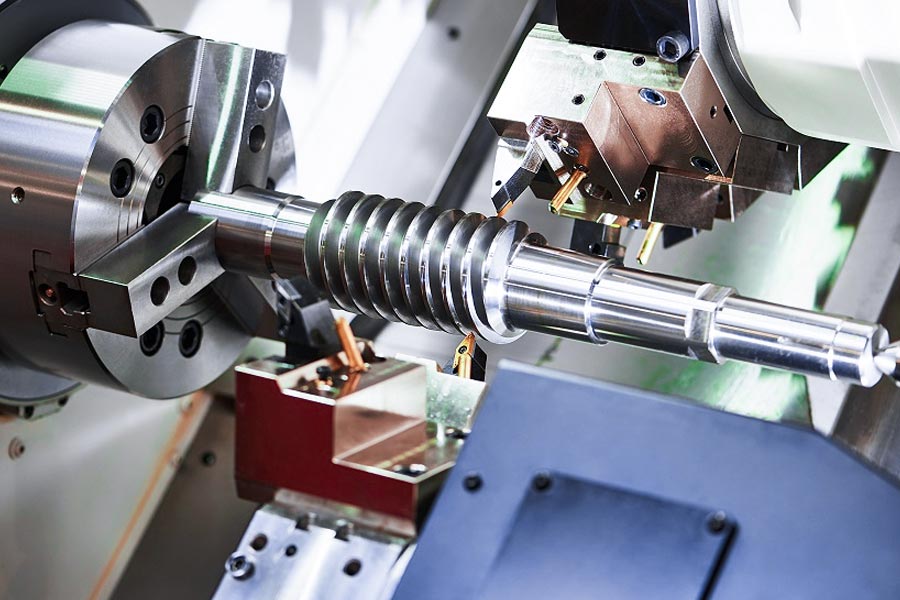

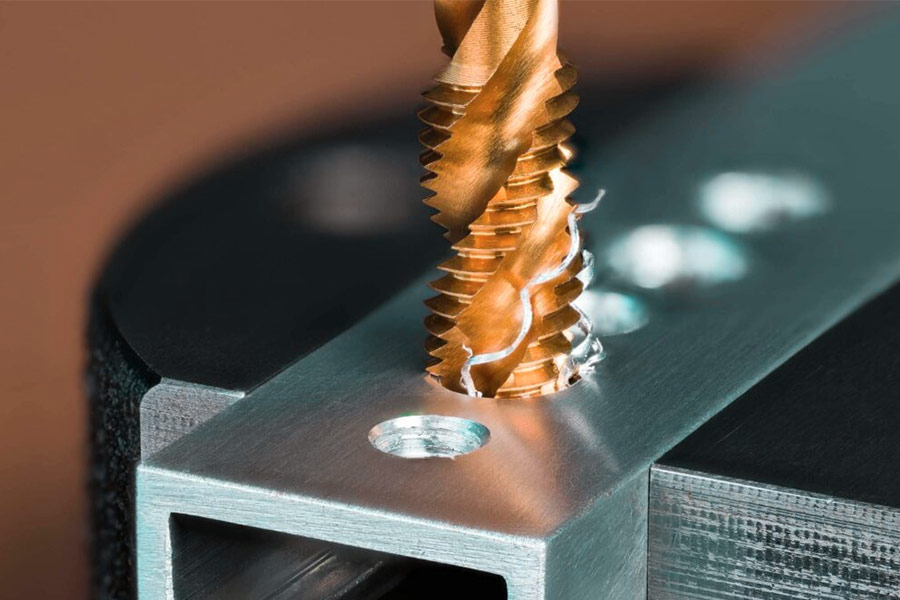

2. Precision machining: round bar to prototype

The selected high-grade tool steel bar will undergo a series of precise cold working and forming:

(1)CNC turning:Cylindrical tool steel bar is turned into the primary shape of the tap, e.g., the primary diameter of the shank, neck and working portion, onCNC lathe.

(2)CNC milling/grinding - machining chip grooves:This is a significant operation to form the cutting edge and chip removal channel of the tap. Use a specialCNC milling machineor grinder to accurately machine the chip grooves on the working section of the tap. The groove type chosen is vital:

- Straight groove:It has good versatility and is especially well adapted for through-hole tapping. The chips are pushed in straight downward direction.

- Spiral groove:It is also divided into right-hand spiral groove (normal) and left-hand spiral groove (special) according to the rotational direction, according to the used material for instance stainless steel. The structure of the spiral groove has more effective elimination of the chips upwards from the hole, greatly reducing the risk of chip blocking, and is the optimum one for blind tapping. All the shape, angle and helix angle of the groove are precisely calculated and machined.

(3)Thread grinding (primary grinding):

Before heat treatment of the last heat (quenching), a precise thread grinder is utilized to grind the tap's precise thread profile (e.g., tooth angle, pitch, major diameter, medium diameter, and minor diameter) to precise thread standards and tolerance specifications. This grinding process is the foundation for later fine grinding after heat treatment and ensures finalthread precision.

3. Magic moment: multi-stage heat treatment

Heat treatment is the process of transferring the "soul" of a precision-shaped piece of tool steel into a tap with greater cutting capability. It is a deciding factor in the final hardness, toughness, wear resistance and life:

(1) Quenching:The tap is placed in a strictly controlled atmosphere (usually a vacuum furnace or a controlled atmosphere protection furnace) and heated to the austenitization temperature of the material (usually over 1200°C in the case of high-speed steel). Once the target temperature has been attained and the temperature kept uniform, the tap is quenched abruptly (the quenching medium being usually oil or high-pressure gas). This operation alters the internal microstructure of the material (austenite to martensite) and develops very high hardness (up to HRC 64-67 or even higher). Vacuum or protective atmosphere is extremely crucial in avoiding surface decarburization and oxidation and ensuring material performance.

(2) Multi-stage tempering:Although the quenched tap is extremely hard, it is as fragile as glass and has huge internal stress. It is very susceptible to being fractured when used on a straight basis. Tempering is to treat this problem. The tap is heated to a comparatively low temperature (e.g. 540°C - 570°C, depending on the steel type and performance requirements) and held at this temperature for several hours. This process would usually be done 2-3 times. The purpose of tempering is to:

Remove quenching internal stress: Reduce brittleness.

Modify hardness-toughness balance: Maintain sufficient hardness while significantly increasing toughness to render the tap non-easily breakable under torsional loading in tapping.

Stabilize the company: Ensure guaranteed performance.

4. The last finishing touch: Finishing and coating

The tap has attained its primary performance through heat treatment, but yet needs the last fine processing to remain in its best state:

(1) Fine grinding:Thermal treatment will inevitably cause slight dimensional changes and possible deformation. Finish fine grinding is thus required. With extremely high-precision grinders, the principal parts of the tap, especially the thread profile and cutting edge, are ground meticulously. This ensures that the tap will possess micron-level dimensional tolerances, optimal geometry (e.g., coaxiality, tooth profile accuracy) and keen cutting edges, the key to making high-quality threaded holes.

(2) Coating (optional but standard):In order to further enhance the performance of the tap, especially wear resistance, lubricity (reducing friction and torque) and anti-sticking (ensuring that material does not stick to the cutting edge), high-grade taps are generally coated with a super-hard coating. The most standard coating is TiN (titanium nitride), which appears with a golden color. TiN coating has very high hardness (circa HV 2300) and can extend the tap's life to a considerable level, especially during machining hard-to-machine materials. The coating is typically deposited by a PVD (physical vapor deposition) process, which is done at a lower temperature and does not affect the heat treatment properties of the tap's substrate. Higher-end coatings such as TiAlN (titanium aluminum nitride), TiCN(titanium carbonitride), etc. are also used for more demanding working conditions.

$15 Value Decomposition

When this tap is in your hand, it possesses:

- 52 processes:from raw material selection to coating, encompassing 5 broad technical categories

- Micron-level precision:cumulative error of the entire process <0.02mm

- 300% life premium:TiN-coated taps can drill 3 times as many holes as standard taps

"It is not just metal, but also a work of art of quenching and grinding - this is the micro-epic of the industrial civilisation."

Actual combat case: Overcoming the "hard bone" thread problem of laser cutting parts

Where theory is useful, examples in practice are the best way to show the level of our engineering support. This case perfectly demonstrates the processing problems that may occur on laser cutting, and how experience and knowledge can overcome barriers.

Customer Pain Point: Thread "Dead Knot" on Artistic Steel Plate

Project Background: A high-end motorcycle modification center made an ornamental protection plate on the engine side. This artwork-like steel plate is made from 5mm stainless steel, and our online laser cutting facility beautifully replicates the detailed flame pattern profile. They need us to machine an M10 threaded hole in a specific location to accommodate a customized chrome-plated footrest.

Challenges encountered: The customer's tech tried tapping with a standard high-speed steel (HSS) tap, but the tap screaked terribly and jammed after one and a half turns. Forcing it out caused the tap to break and jam straight into the precious custom component, on the verge of scrapping!

LS's diagnostic analysis and solution

During inspection, we discovered three basic reasons:

- "Hard edge" effect:The focused cutting energy of the laser beam will produce a very thin but abnormally hard zone (heat-affected zone) on the edge of the cut, far beyond the parent material's hardness, and normal taps can't even cut through it.

- "Wrong weapon":GeneralHSS tapsare not hard and tough enough to withstand this local hardening, and forcing them into battle will ultimately lead to "failure."

- "Bad slag removal":The straight groove taps the technicians use are of bad chip removal effect, and the chips jam in the narrow channel, resulting in blockage and jamming at once, and finally breakage.

Emergency "mine clearance":First, guide customers to safely remove the broken taps, and recommend the use of electric spark (EDM) or super-hard carbide drills, carefully avoiding damage to the part body.

Recommended "weapon":We did not hesitate and directly recommended the cobalt spiral groove tap (Co HSS Spiral Flute Tap) designed for stainless steel. The spiral groove design can effectively discharge chips like a "screw conveyor", and the cobalt-containing material provides "armor" to resist hardening. At the same time, it emphasizes that high-quality sulfur-containing cutting oil must be used for adequate lubrication and cooling.

Imparting "heart method":Provides clear process parameters: "Always use a rigid tapping chuck (to avoid shaking the folding knife), reduce the speed by about 1/3, and ensure that the cutting oil is continuously and adequately poured on thecutting edge of the tap."

Results: From scrap edge to perfect assembly

The customer strictly followed our plan and successfully completed the processing of M10 threaded holes on the newly cut parts. The threads are smooth, regular, and high-precision, perfectly matching the chrome-plated footrest.

Value: Our professional intervention prevented the customer from losing high-end customized parts worth hundreds of dollars again and saved a lot of rework time. The customer deeply realized that choosingLS's laser cutting serviceis not only buying precision cutting parts, but also getting an engineering partner who understands materials, processes, and the entire assembly process. The value we provide runs through the entire manufacturing chain from design to implementation.

Core revelation:

Manufacturing is not an isolated link, but a closely connected chain.Choosing a supplierwho only knows cutting and choosing an engineering partner who understands cutting, material properties and subsequent processing and assembly challenges will ultimately lead to a world of difference in product quality, production efficiency and project success rate.LS is committed to becoming your reliable engineering partner.

FAQ- All your tapping questions

1. How to use a tap to tap correctly?

The key steps to correct tapping include: First, drill a bottom hole of the exact size according to the thread specification (too large or too small will result in failure). Second, be sure to use a guide or visual inspection to ensure that the tap is absolutely perpendicular to the workpiece surface. When operating, use the tap wrench to turn half a turn to a full turn clockwise, and then turn it counterclockwise about 1/4 turn to break the chips to prevent jamming. Use a suitable cutting fluid (such as engine oil, emulsion or special tapping oil) for lubrication and cooling throughout the process. For holes deeper than the tap diameter, it is necessary to completely withdraw the tap regularly to clean the accumulated chips in the hole before continuing to tap.

2. What material are tapping taps made of?

Most taps are made of high-speed steel (HSS, High-Speed Steel), because it has good hardness, toughness and wear resistance, and is cost-effective. When processing materials with high hardness, high toughness or easy to stick to the tool (such as stainless steel, titanium alloy, high temperature alloy), cobalt high-speed steel (HSS-Co) with better performance is often used. It improves red hardness and wear resistance by adding cobalt elements. For mass production or extremely difficult to process materials, more expensive but longer-lasting and more efficient solid carbide taps are used.

3. What is the difference between taps, dies and thread milling cutters?

All three are thread processing tools, but their uses and principles are different: Taps (Tap) are specifically used to cut internal threads in pre-drilled holes, and are cut and formed by rotation and extrusion. Dies (Die) are used to cut external threads on the outer surface of cylindrical bars or pipes, and are usually installed in die wrenches for use. A thread mill is a multi-tooth CNC machining tool that can process both internal and external threads by milling through the spiral interpolation motion of the machine tool. It is highly flexible and is especially suitable for large threads, blind holes, non-standard threads or hard materials, but the equipment and programming costs are relatively high.

Summary

Making your own tapsis undoubtedly a valuable practice to gain a deeper understanding of the principles of tools, but it also vividly demonstrates the excellentvalue ofprofessional manufacturing. For any project that pursues precision, precise geometric design, strict material selection and accurate heat treatment processes are indispensable elements - these are the professional heights that are difficult to achieve in the DIY field.

Don't let a small thread problem become a stumbling block for your high-value, sophisticated design!At LS, we not only provide industry-leading online laser cutting services and highly competitive prices, but also give you engineering wisdom throughout the entire process of "material selection - processing and manufacturing - final assembly". Upload your design file now, and let us work together to ensure that every detail of your work is perfect!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com