Choosing A CNC Milling Partner: An OEM's Framework For Technical & Commercial Evaluation

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How To Quantitatively Assess The True Technical Capabilities Of CNC Milling Suppliers? 3.How Can A Quality Control System Be Implemented From "Certification" To "Parts Consistency"? 4.How Do Project Management And Communication Mechanisms Affect Delivery Success Rate? 5.How To Analyze A Price Quote To Identify The True "Total Cost Of Ownership"? 6.Can The Supply Chain Resilience And Capacity Guarantee Withstand Stress Tests? 7.What Agreements Must Be Signed For Intellectual Property Protection And Data Security? 8.LS Manufacturing Partners With A New Energy Battery Enclosure Supplier To Reach A Cooperation Agreement Through A Systematic Evaluation 9.Why Does LS Manufacturing Often Become The Final Choice For OEMs After Comprehensive Evaluation? 10.FAQs 11.Summary 12.Disclaimer 13.LS Manufacturing Team

Gloria

Gloria

CNC Milling Services For Electronics: Solving Precision & Speed Challenges

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Specific Precision Requirements Must Be Met For CNC Milling Of Electronic Components? 3.How To Achieve Efficient And High-Precision Machining Of Thin-Walled Electronic Enclosures? 4.What Are The Fundamental Differences Between PCB Milling And Metal Machining? 5.How Does The Rapid Response Mechanism Meet The Urgent Needs Of The Electronics Industry? 6.How To Control The Effects Of Thermal Deformation During Electronic Component Manufacturing? 7.How Can Tool Optimization Improve The Processing Quality Of Electronic Components? 8.LS Manufacturing Communication Equipment Industry: Precision Milling Project For 5G Base Station Heat Sinks 9.What Are The Quality Inspection Standards For CNC Machining Of Electronic Components? 10.How To Obtain An Accurate CNC Machining Quote For Electronic Components? 11.FAQs 12.Summary 13.Disclaimer 14.LS Manufacturing Team

Gloria

Gloria

CNC Milling Services: Milling Machines For Complex Parts, Tight Tolerances & Rapid Production

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How Does 5-Axis Machining Create Core Technological Value For Complex Parts? 3.In Which Industries Are ±0.005mm Accuracy Requirements Mandatory? 4.How Can Rapid Prototyping Achieve 24 Hour Delivery While Guaranteeing Functionality? 5.How To Control Deformation And Ensure Stability During The Machining Of Thin-Walled Structures? 6.What Are The Key Technological Breakthroughs In Milling Difficult-To-Machine Materials (Such As Inconel And Titanium Alloys)? 7.How Can A Scientific Pricing System Ensure Cost Transparency And Control? 8.LS Manufacturing Aerospace Division: 5-Axis Precision Milling Project For Engine Casings 9.Why Choose LS Manufacturing As Your Precision Milling Partner? 10.How To Ensure Efficient Management And Quality In Small-Batch Multi-Product Manufacturing? 11.FAQs 12.Summary 13.Disclaimer 14.LS Manufacturing Team

Gloria

Gloria

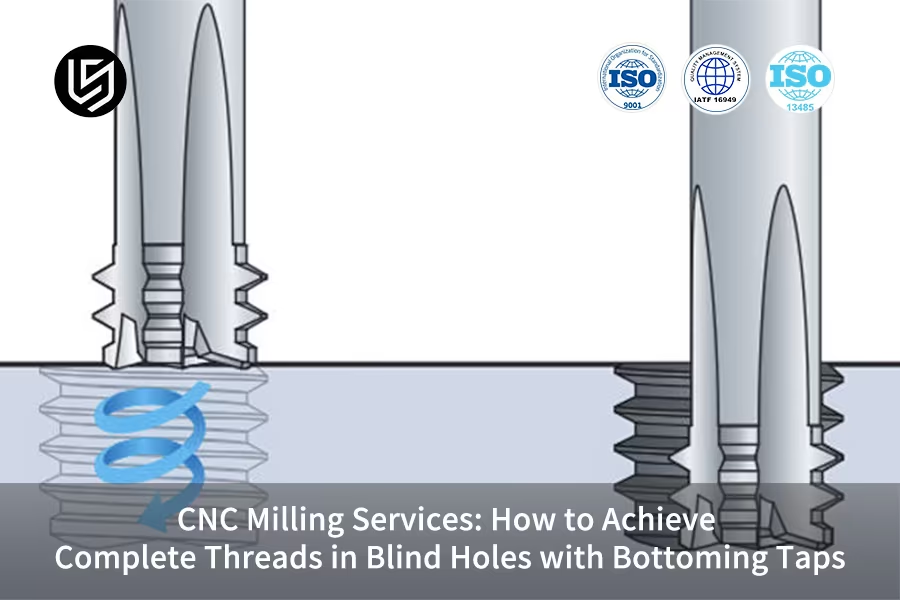

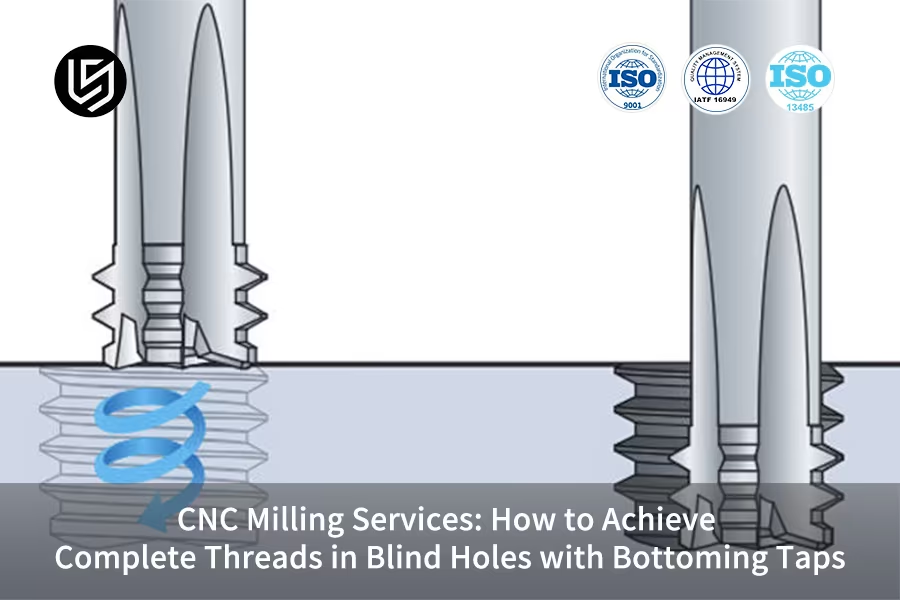

CNC Milling Services: How To Achieve Complete Threads In Blind Holes With Bottoming Taps

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.Why Can't Standard Taps Achieve Complete Threading At The Bottom Of A Blind Hole? 3.How To Select Bottom Tap Geometry Based On Material? 4.How To Optimize Cutting Parameters To Prevent Tap Breakage During Blind Hole Tapping? 5.How Does The Bottom Structure Design Of A Blind Hole Affect Tapping Quality And Tool Life? 6.How Does CNC Tapping Service Ensure Consistent Accuracy Of Blind Hole Threads? 7.What Are Key Result Differences Between Various Bottoming Taps? 8.How Can Coolant Optimization Improve The Quality Of Blind Hole Tapping And Extend Tool Life? 9.How To Establish Quality Control For Blind Hole Tapping In Mass Production? 10.LS Manufacturing Aerospace Division: Engine Mount Blind Hole Tapping Project 11.How To Evaluate The Overall Technical Capabilities Of A CNC Tapping Supplier? 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

CNC Milling Services: The Ultimate Guide To Selecting Thread Taps For Quality, Efficiency, And Cost

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How To Improve Thread Machining Quality And Efficiency Through Tool And Process Selection? 3.How To Select The Most Suitable Tap Type For Tapping Different Materials? 4.How Can Tapping Achieve Breakthroughs Through Optimization? 5.How Can Precision Thread Machining Ensure Dimensional Stability At The Micrometer Level? 6.How Can Tap Geometry Optimization Solve Tapping Challenges? 7.How Does CNC Tapping Service Ensure Consistent Quality In Large-Scale Production? 8.How To Evaluate The Cost-Effectiveness Of Different Tapping Solutions And Optimize Them? 9.What Core Threading Capabilities Should A High-Quality CNC Machining Supplier Possess? 10.LS Manufacturing Automotive Engine Cylinder Block Threaded Hole Machining Project 11.Future Development Trends And Innovation Directions In Thread Machining Technology 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

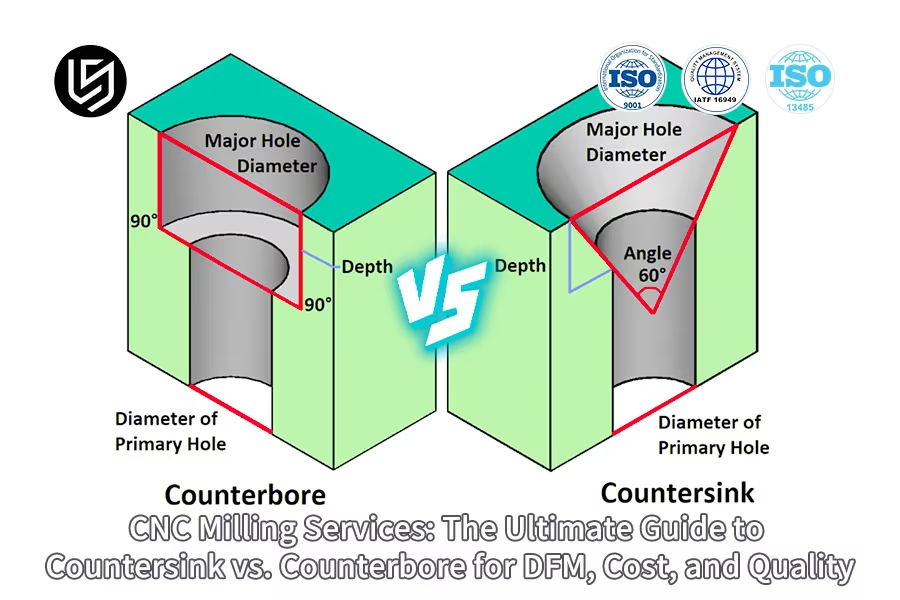

CNC Milling Services: The Ultimate Guide To Countersink VS. Counterbore For DFM, Cost, And Quality

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Are The Differences Between Countersunk And Counterbored Holes In Design And Application? 3.How Do CNC Milling Services Ensure Accuracy And Quality Of Countersunk Holes? 4.How To Select Between Countersunk And Counterbore Designs Based On Functional Requirements? 5.What Are The Key Parameters That Require Special Attention In Countersunk Hole Design? 6.In Which Application Scenarios Do Countersunk Holes Offer Irreplaceable Advantages? 7.How Can DFM Optimization Reduce The Machining Costs Of Countersunk Holes/Counterbores? 8.What Special Process Safeguards Are Required For High-Quality Countersunk Hole Machining? 9.How To Evaluate A CNC Milling Supplier's Capabilities In Countersinking/Counterboring? 10.LS Manufacturing: Countersunk Hole Machining For Wing Components 11.Analysis Of Future Trends In Countersinking And Counterboring Processes 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

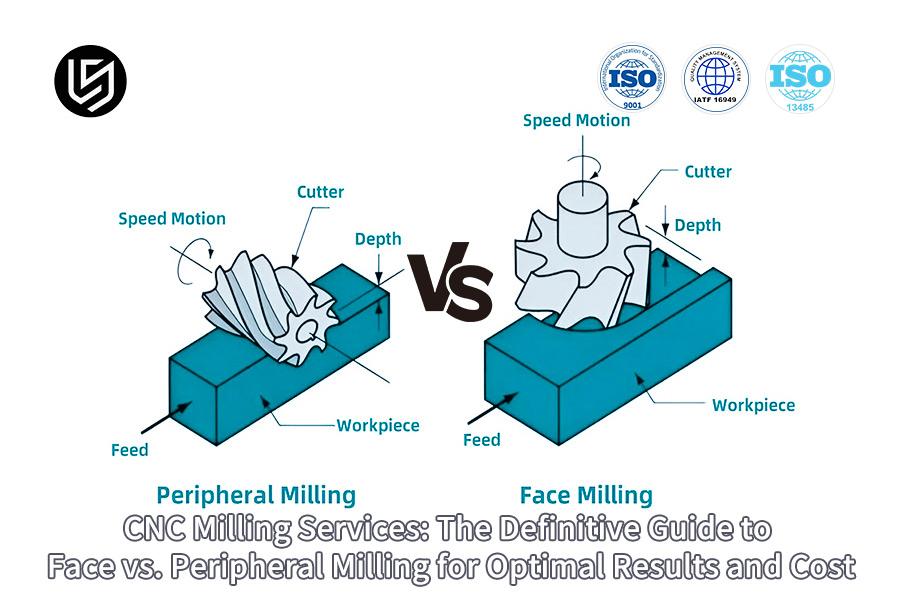

CNC Milling Services: The Definitive Guide To Face VS. Peripheral Milling For Optimal Results And Cost

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Are The Differences In MRR Between Face Milling And Peripheral Milling? 3.How To Scientifically Select A Milling Process Based On The Machining Objectives? 4.How Can Cost-Effective CNC Milling Reduce Costs Through Process Optimization? 5.How Does High-Precision Milling Technology Ensure Micron-Level Machining Quality? 6.What Key Technical Parameters Are Needed To Support Optimal Milling Performance? 7.What Special Milling Strategies Are Required For High-Quality Surface Finishing? 8.How Does High-Efficiency Milling Improve Production Efficiency Through Technological Innovation? 9.What Cost Elements Are Included In A Quote For CNC Milling Services? 10.LS Manufacturing Aerospace Division: High-Efficiency Milling Project For Engine Casings 11.How Can Comprehensive Optimization Of Milling Processes Be Achieved Through Process Innovation? 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria