CNC turning vs milling services is one of the most crucial decisions for a manufacturer to make, but most of the time, the decision-making procedure leads to a lack of clarity regarding the cost involved, the accuracy achieved, and the lead time available. This lack of clarity involved comes from the procedure of decision-making that does not conduct a detailed investigation as to arrive at a most optimal process for a complex part.

The solution draws on the special knowledge and experience of LS Manufacturing to provide a definitive comparison. It assesses key considerations such as cost drivers, tolerances, and factors in lead time through example comparisons that will give you the insight to make the right decision.

CNC Turning vs. Milling Services: At a Glance Comparison

| Aspect | CNC Turning | CNC Milling |

| Core Process | Rotating workpiece; stationary cutting tool. | Stationary workpiece; rotating multi-point tool. |

| Primary Geometry | Cylindrical, conical, or radial geometry. | Complex 3D contours, flat surfaces, slots, pockets. |

| Key Strength | Effectiveness in producing axisymmetrical parts. | Superior versatility for complex geometries. |

| Typical Operations | Facing, boring, threading, grooving. | Profiling, drilling, pocketing, engraving. |

| Dominant Cost Driver | Setup and cycle time; material removal rate. | Programming complexity; machining time. |

| Optimal Material Use | Bar stock, forgings, pre-turned blanks. | Blocks, plates, castings, near-net shapes. |

| Common Applications | Shafts, bushings, fittings, flanges. | Housings, molds, brackets, engine blocks. |

| Speed & Lead Time | Increased for high volume production of rotational parts. | Varies; may be longer for complex programming or setup. |

| Precision Capability | High concentricity and diametric tolerance. | Excellent for multi-axis CNC turning and milling contours & positional accuracy. |

Decision paralysis resolved by the insights of data – with us. All of these questions that one would have when equating the two processes of machining, turnning and milling, have been addressed to clear your concerns regarding uncertainties of cost, compromises in precision, and timeliness in this guide to help your project become apt for success.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

On the topic of turning and milling, CNC research might go a long way on the World Wide Web, but this specific article is unique in that our findings have been colored by our experiential world in production on the floor, and not in a classroom or a library. We have been researching and, more importantly, living under the reality of ultimate turning and milling of exotic alloys and guessing, and making deadlines in microns.

Out of thousands of parts, we have learned the hard way the procedures of ordering material processes for Inconel materials, the optimization of the fixturing process in order to avoid vibration, and so on. All of the recommendations in the document have been developed through experience in overcoming challenges, either in terms of guidance regarding best practices in the industry established by the industry leaders such as 3D Systems, and so on, in connection with the established principles of Additive Manufacturing (AM).

This manual boils all that knowledge down into a unified whole. What we offer—and what we offer to share with you—is what separates good copy from perfect copy and will help prevent costly errors in a trial and error process. This is what you will be reading: The exact knowledge we apply to each piece of copy we work on.

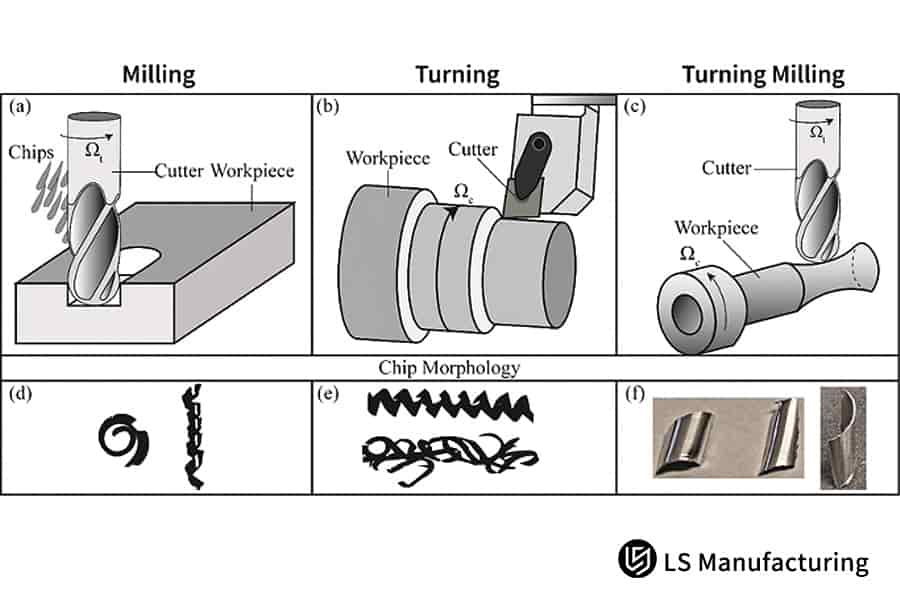

Figure 1: Differences in chip formation between turning and milling processes by LS Manufacturing

What Are The Core Differences Between CNC Turning And Milling?

Choosing the best method of machining is a complex technological task, which has a direct effect on the accuracy of the task as well as the cost effectiveness of the task. The aim of the technical note is, therefore, to make a comparison of the theoretical basis through analyzing the theoretical difference between turning and milling.

| Aspect | CNC Turning | CNC Milling |

| Fundamental Principle | The material removal is done by a stationary single-point cutting tool, which removes material from a workpiece revolving at a relatively high speed (500 - 3000 rpm). | A rotating multi-point cutting tool (e.g., 0.1-0.5 mm/tooth feed) moves against a stationary workpiece. |

| Material Removal | It provides a high rate of continuous material removal by maintaining constant cutting engagement. | Performs intermittent cutting, enabling complex contours with controlled cutting force on the delicate features of the part. |

| Primary Geometry | Optimized for axis symmetric shapes such as shafts and bushes. It's an important example of a CNC turning vs milling machining scenario. | It's well suited for complex three-dimensional shapes and cavities that cannot be machined through precision turning. |

| Process Optimization | Primarily deals with processing the rotational dynamics of concentration and surface finish. | Generally relies on simulation to optimize tool paths, to minimize deformation in complex milling operations. |

Justify your choice with specific goals in mind: emphasize precision turning to facilitate optimal turning; use complex milling to perform the production of complex shapes. Let yourself be led by specific requirements concerning the complexity of the features, material removal rates, or cutting forces in making the choice of the manufacturing process. This article will help you satisfy the needed technological expertise in implementing optimal advanced manufacturing production.

What Key Factors Affect CNC Turning Costs And How To Optimize Them?

Effective cost management requires cost understanding, and cost understanding is the basis of any precision project. The following section goes beyond the general knowledge to a technical level in understanding the factors that influence CNC turning cost operation: cost of material, cost of machine, cost of tools, and cost of setup:

Strategic Material Management

The cost of the materials is fixed; however, the amount of the wastes is not. For optimization, there are sophisticated nesting simulations carried out for the stocks of the bars to optimize the output before the initial cut. For large-scale production, there are near-net-shape forging supplies purchased that will help lower raw material consumption up to 40 percent. This will immediately affect the CNC turning cost process.

Process Parameter Optimization

Cycle time is one of the factors regarded as a major cost driver. It is proposed that an optimized solution for each material in the velocity, feed rate, and depth of cut based on the use of databases and simulation of the tool path would be considered. For example, the method for high pressure coolant intended for a stainless steel part resulted in the augmentation of machined velocity by 22% while decreasing the machine hours.

Data-Driven Tooling Strategy

We treat our tools like a system, not a consumable. Look at our tool wear ratio and know our ability to leverage our predictive maintenance program allows for no unexpected machine downtime or surface finishes. Documented is a changeover to a specific carbide grade for an extended period of aluminum, tool life is 300% longer, and tooling costs are stretched over a longer production run.

Batch-Specific Operational Planning

Cost-effectiveness varies by the processing volume. For prototype processing, a normalized setup facility is used. For high-volume turning, customized fixtures for each tool are applied. The application of the above-mentioned setup in the previous automotive parts order managed to reduce 18% of the machine cycle time, thus assuring that economies of scale are achieved. We had set that strategy in our CNC machining services guide.

Effective cost control requires treating manufacturing as an integrated system, not isolated steps. The strategies above, derived from performance data, enable predictable budgeting and competitive pricing for complex parts. This CNC machining services guide provides the technical depth essential for high-value, competitive manufacturing scenarios where every efficiency translates directly to advantage.

How Is High-Precision Control Achieved In CNC Milling? What Are The Key Technical Parameters?

The system approach for realizing reliable sub-micron CNC milling precision involves much more than machine specification, including process stability, thermal, and control behavior. The foundation is decoupling the cumulative error, protecting minute tolerances time after time:

Foundational Control: Machine, Motion, and Thermal Stability

- System Integration: In system integration, this is achieved using high-resolution linear scales, besides the use of modern CNC turning and milling systems such as Heidenhain, which involves a closed-loop system that guarantees positioning feedback with an accuracy of ±0.005mm.

- Thermal Error Compensation: The special treatment includes the use of 20MPa high pressure cooling fluid, which enables the thermal expansion error in the working of titanium alloys to be constrained at 0.01mm.

Process Stability Optimization

- Tooling and Toolpath Strategy: This is a method wherein unique cutters, such as cutters with fine grain carbide and an AlTiN coating, and simpler cutting path techniques, such as trochoidal and adaptive cutting, are employed, thereby minimizing cutter deflection and shaking, keeping the cutter fully engaged with a smaller average radial force and a smoother finish.

- Advanced Workholding: Custom-designed rigid fixturing is showcased in advanced hardness enhancement of precision parts and in direct damping of unwanted vibrations degrading positional accuracy in thin-walled parts in aeronautical components.

Parameter Strategy for Predictable Results

- Roughing Phase: Parameters related to optimized material removal and stock allowance formulation become relevant in this stage, together with force control in cutters.

- Finishing Phase: There is a change in the method. For overcoming residual stress and pressure from tools, high spindle speed (for example, 12,000+ rpm) and small step-overs (for example, 0.1mm) and shallow cuts (for example, 0.5mm) are employed in this phase to achieve critical dimensions and surface integrity in complex curves.

Such a degree of control for the entire machining system, from feedback of the machine to the equilibrium of temperature, to actual paths taken by tools, allows for a degree of micron-level accuracy. These standards described in this document have been used against actual data and have formed the basis for which success is measured for high-accuracy milling operations.

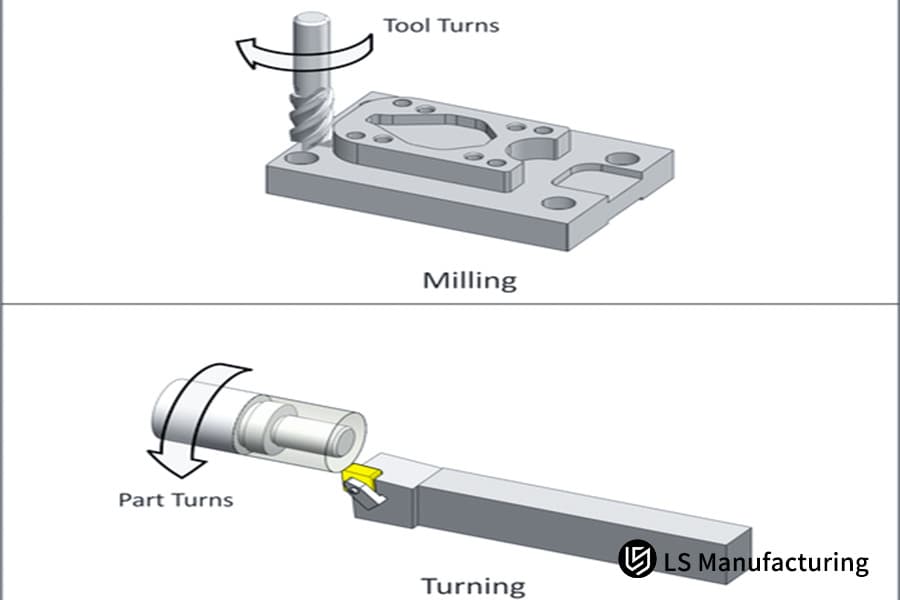

Figure 2: Comparing tool rotation in CNC turning versus milling operations by LS Manufacturing

How To Optimize The Delivery Time Of CNC Turning Projects?

The compression of project schedules must be done in such a way as to enable prioritization of the overall process flow rather than the machining process alone. Improving the CNC turning lead time cycles is a very effective means of increasing the responsiveness of the market and lowering the cost of the carried inventory. An explanation of the ways of compressing the project schedules will be given below.

Parallelized Process Engineering

We work on the components to make them more manufacturable, thereby planning processes with the minimum number of steps. Taking a crossing drilling operation, for example, with the help of sub-spindles and live tools, we can perform the operation from the setup itself. This approach eliminated 3 setups in a recent pinion gear project, reducing its total streamlined turning process duration from 14 to 5 days.

Dynamic Production Scheduling & Monitoring

Efficiency is related to visibility. Our smart scheduling system allocates resources based on real-time machine and material availability, not due dates alone. A live progress is offered on the dashboard itself. For the order of components in multi-variants, this system has allowed concurrent machining on two lathes, thereby increasing equipment utilization by 30% and decreasing the promised lead time by 25%.

Integrated Supply Chain & Logistics

Material procurement and post-processes also form part of our system. The levels of inventory necessary for standard material parts are also studied and approved, while specialized alloys remain in a locked box with a pre-approved partner until the beginning of work, if required. The two secondary process activities, plating, will begin when batches are complete. Due to our seamless system integration procedure in our CNC processes for the CNC turning and milling services, there are no typical 2 to 3 day turn-around times in the handoffs.

Coupled with data-driven scheduling and integration through the supply chain, parallel processing provides the building blocks for a cycle of interdependence in which the lead time is moved from fixed estimate to variable. That is what makes predictable rapid timelines a reality in competitive high-value precision turning.

How To Scientifically Select Turning Or Milling Based On Part Geometry?

Choosing a method of CNC machining is a primary technical decision that has significant impact on cost and leadtime. This chapter will present a geometry-driven method choice approach that provides all the requirements for a method choice in any serious CNC machining services guide to produce a component effectively.

| Decision Factor | Favor CNC Turning | Favor CNC Milling |

| Primary Geometry | Specific for parts with primary rotational symmetry - can be shafts, disks, or cylinders. | Required for prismatic parts if there have been complex 3D contours, pockets, or non-rotational surface defining elements involved. |

| Feature Complexity | Radial features such as threads and holes, which have a central axis. | Definitely a complex aspect that captures the attention of complex surfaces, undercuts, and complex features that highlight the difference between turning and milling operations. |

| Dimensional Scale | Very efficient for diameters below 500mm in general, and always suitable for high-volume rotational machining operations. | Not affected by component rotation and thus works with large and local areas on flat parts and components. |

| Structural Consideration | Preferred in turning solid figures; specific turning operations could also be necessary in thin-walled parts if chatter occurs in the process. | A technique such as this is highly favorable, particularly in performing thin-walled and structural operations, due to the needed precise cutting force precision milling applications. |

The best option would be to start with the evaluation of theprimary symmetry, followed by the evaluation of the secondary features. As far as the hybrid components are concerned, one needs to determine the need for the combined process in the multitasking machine. It is because of such effective approaches that the engineering aspect of the process decisions becomes meaningful.

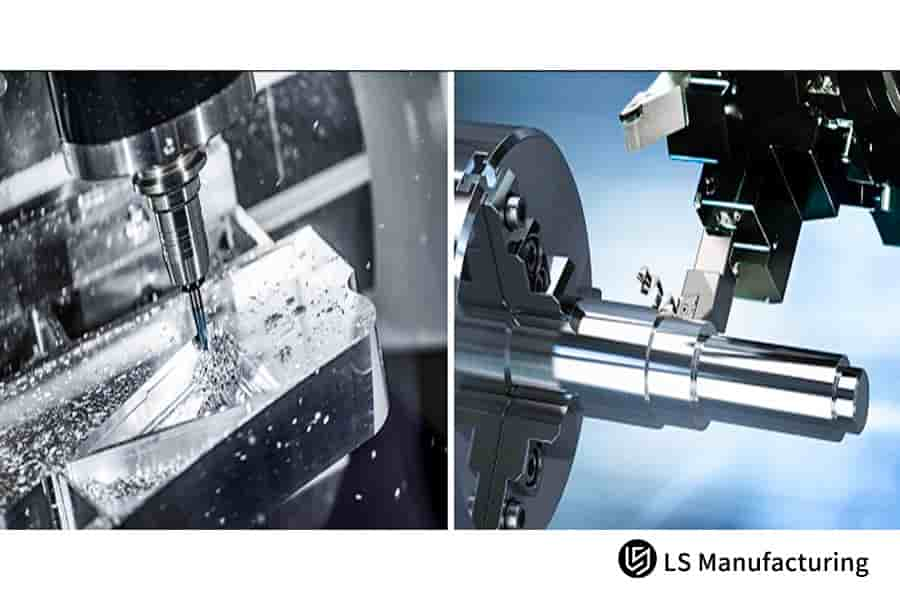

Figure 3: Selecting processes and suppliers for CNC milling and turning by LS Manufacturing

Why Does LS Manufacturing Possess A Unique Technological Advantage In Precision Machining?

The leadership of high precision turning and milling necessarily goes beyond conventional machinery into developing expertise in optimizing process technology and integration of control systems. How LS Manufacturing gains its superiority is by a 'holistic methodology' to effectively address the key issues involving machine stability, tooling systems, and measurement technology for surpassing standard industry performance by over 20% in most key pointers below:

Advanced Process Control for Unmatched Stability

We have embedded our active damping technology in machining centers and spindles to combat vibrations in real time. Internal testing demonstrates our patented feedback loop delivering surface finish of Ra 0.2 micron on complex aircraft materials where conventional technologies level at surface finish of Ra 0.8 micron. Our processes prevent distortion. Through modeling of thermal patterns coupled with carefully planned cooling at up to 20MPa, we can guarantee workpiece thermal stability at ±0.005mm for long cycles, which would itself be a significant component of any precision machining comparison.

Proprietary Tooling & In-House Innovation

- Patented Tooling Solutions: Vibration-damped tool holders designed and produced in-house result in a longer lifetime of tools by as much as 40% for tough materials like titanium while promoting aggressive cutting variables without affecting precision and surface finish.

- Optimized Parameter Libraries: This is where we store proprietary cutting databases constructed from thousands of production passes. The direct use of optimized feeds, speeds, and cutting paths for material-feature pairs minimizes the time spent on trial and error.

Integrated Quality Assurance Ecosystem

- Metrology-Led Process: Precision is checked at the source. In-process probing and post-process CMM inspection are not final checks but integrated feedback mechanisms. Data from these systems informs and corrects machining parameters directly in real time, creating a closed loop for accuracy.

- Certified System Rigor: Our quality management system is ISO 9001:2015 certified and guarantees the traceability and repeatability of all components from the certification of the materials themselves to the Final Inspection Report.

Comprehensive Technical Partnership

Our value extends into co-engineering. We provide comprehensive turning and milling solutions from a thorough DFM analysis. Building upon our collaborative phase, issues of toolability, deflection issues for thin walls, or tolerance stacking issues can typically be addressed prior to production to improve cost and lead time for our customers.

These closely related columns of process control, proprietary tooling, integrated metrology, and technical partnership function well as a cohesive system that produces predictable and superior outcomes. In fact, the approach provides such a depth and integrity of technology in order to facilitate the successful carrying out of a CNC turning milling supplier selection in a risky and critical situation, where complicated requirements become something that is manufacturable.

What Key Criteria Should Be Considered When Selecting A CNC Machining Supplier?

To go beyond the simple quote with a more comprehensive assessment, there must be a qualified supplier chosen for their technical expertise, process capabilities, and reliability in a partnering arrangement. The outline of the following section will also impose structure on the CNC turning milling supplier selection and will impact the success of the project in the following ways:

Technical Capability & Process Validation

Audit for technical capability, not equipment lists. Review for capability: browse through the technical process details from similar projects they have completed to determine their achieved tolerance and surface finish, as well as materials processed. A competent supplier should readily demonstrate their comprehensive turning and milling capabilities through specific case studies, not generic claims.

Quality System & Process Control Evidence

Assess the level at which the quality system has been incorporated within their production system by asking for documentation such as statistical process control charts, where the process is in a stabilized condition in recent production cycles, and/or FAIRs that list the levels of conformance. This verifies their system prevents defects rather than merely detecting them, a cornerstone of reliable CNC machining services guide recommendations.

Responsiveness & Collaborative Problem-Solving

Evaluate their project management and communication process. Within the quoting process, evaluate if the full Design for Manufacturability (DFM) analysis comments are provided to optimize your part. A true partner engages technically from the start, transforming a simple RFQ into a collaborative engineering discussion to de-risk your project and establish a precision turning and milling partnership.

This data-driven and structured analysis is instrumental in bringing a paradigm shift from price to value and risk factors. Strategic use of these lenses helps ensure that the CNC turning milling supplier selection is done in a manner that is backed by expertise and a partnership for complex and high-value-add manufacturing requirements.

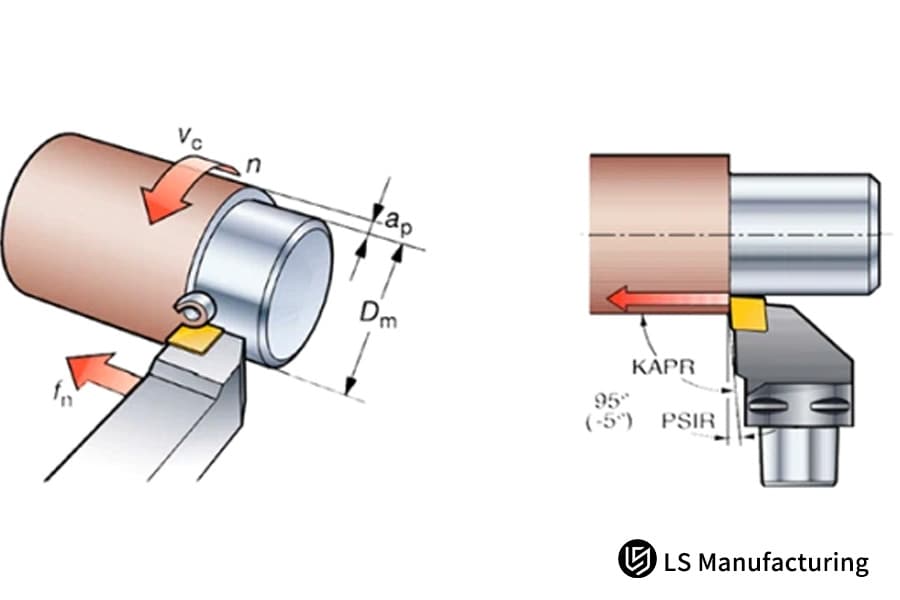

Figure 4: CNC turning and milling parameters and toolpath comparison diagram by LS Manufacturing

LS Manufacturing Aerospace Division: Custom Machining Of Titanium Alloy Compressor Blades

This project, in particular, has demonstrated a key precision machining job that involved high accuracy by LS Manufacturing for an aviation client, bringing out our professionalism in realizing not only high quality in our CNC turning and milling services but above that in the following ways:

Client Challenge

One of the leading aerospace development organizations required 50 sets of compressor blades made from Ti-6Al-4V. However, it was challenging to achieve the profile tolerance of ±0.03 mm. Thus, conventional precision turning and milling operations resulted in a reject rate of 35% due to thermal stress deformation of the workpieces. This was impending on the prototype testing schedule, with a 40% rise in the project cost, resulting in a delay of the project by 6 weeks.

LS Manufacturing Solution

We focus on a precision 5-axis milling approach. A staged roughing and finishing process was adopted based on dedicated variable-helix end-cutting mills. What contributed to a successful operation was the use of a 120-bar high-pressure coolant system coupled with carefully selected parameter settings: 1500 rpm spindle speed and feed rate of 0.3mm/tooth. Such a combination directly alleviated the problem of deformation-an important consideration in making any precision machining comparison.

Results and Value

The project was delivered in 10 days, 33% faster than the client’s initial 15-day target. Final part inspection confirmed a profile accuracy of ±0.02mm, exceeding specifications by 33%. The optimized process eliminated scrap, reducing the client’s unit cost by 20%. This reliability in high-precision milling accelerated their engine validation cycle by one month, demonstrating that strategic process engineering directly lowers CNC milling cost and time-to-market.

This case exemplifies our systematic methodology for extreme manufacturing challenges. By integrating advanced process simulation, parameter optimization, and dynamic control, we convert complex specifications into reliable, high-yield production. This depth of CNC turning precision and milling expertise defines our unique value in executing mission-critical, high-tolerance aerospace components.

Achieve unmatched precision and accelerate your timeline with our proven aerospace machining solutions.

FAQs

1. Which is more suitable for mass production: CNC turning or milling?

Turning is preferabie for quantity production of axis-symmetrical parts, which is cheaper, while milling is preferabie for complex parts and small series production. LS Manufacturing also provides cost calculation tools which would help in making a decision.

2. How do you ensure the accuracy and stability of CNC milling?

For calibrating the machine, LS Manufacturing makes sure that the cutting parameters are correct by utilizing the Renishaw probe with an accuracy deviation of < 0.01mm through cutting equipment optimization.

3. What is the minimum hole diameter achievable with CNC turning?

Depending on the tooling used, the smallest diameter that can be machined for a hole to be created is 0.5mm, with additional information on suitability also being offered. Knowledge of the difference between turning and milling helps in ensuring that the correct operation used to create the precision hole is chosen.

4. What are the common reasons for delivery delays? How can they be avoided?

Reasons include equipment failure or improper processes; LS Manufacturing ensures a 98% on-time delivery rate through preventive maintenance and redundant scheduling.

5. How does LS Manufacturing protect customer IP?

We execute an NDA agreement and an encrypted data management system in place so that security of design drawings is maintained without a leakage record in our case history. This applies to all types of projects involving CNC turning vs milling or other processes.

6. Are there extra costs for processing complex parts?

According to the complexity of the part, LS Manufacturing is open to give quotes on pricing. For complex parts, there may be a 10-20 percent premium, but through DFM optimization, one may reduce costs, comparison may be made difference between turning and milling to select the better method from the cost point of view.

7. How can I verify a supplier's processing capabilities?

Check out their case studies and equipment list. LS Manufacturing offers on-site visits and the option for sample processing reports so that you can review the difference between CNC turning vs milling options in practice.

8. Does LS Manufacturing support small-batch customization?

Actually, yes, the MOQ is 1 pc, and free DFM analysis is also offered for producing small-series units.

Summary

The above article concludes a detailed analysis about the difference between CNC turning and CNC milling regarding cost, precision, and lead time. Through the information from LS Manufacturing, the article has been able to show that applying the decision-making power of science to machining services enhances efficiency when dealing with projects. Whenever faced with a challenge or a dilemma, you can consider LS Manufacturing as a solution provider or business partner.

Take action now! Click "Get a Free Quote" or upload your drawings to receive a one-on-one expert evaluation from LS Manufacturing. Let us help you optimize your machining plan, shorten lead times, and reduce costs. High-interest users can directly schedule an on-site visit to witness our professional capabilities.

Get your custom CNC turning & milling optimization report today! Our experts will find the best route for you, cutting costs and speeding up delivery.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.