Do you still worry about taper breakage, thread wear, and poor chip evacuation in tapping? Does a single mistake in machining a critical threaded hole risk a whole expensive workpiece being scrapped? These inherent pain points in traditional tapping processes, such as low tool life, reduced toughness, and high latent potential hazards on valuable parts, are mercilessly draining your manufacturing profitability and efficiency.

To disentangle this dilemma, LS Manufacturing strongly recommends thread milling, a superior choice for modern CNC machining. This is more than just a process substitution; it is a revolution in manufacturing philosophy. With clean chip breaking, chip-free tapping, the amazing versatility of producing a wide range of thread sizes with one tool, and increased precision and surface finishing, thread milling is liberating tens of thousands of manufacturers from the bondage of tapping. To save you time, here’s a quick overview of the core conclusions.

Thread Milling Core Adavantages Quick Reference

| Dimension | Key Points | Summary |

| Core Adavantages | Process Innovation, Flexible Manufacturing. | Thread formation is achieved by controlling tool motion through CNC programming, removing the restrictions of traditional taps and achieving very flexible processing. |

| Cost-Effective | Reduce cost, improve efficiency, and preserve safety. | A single tool can thread various sizes of thread, reducing tool inventory and tool changing time, and essentially eliminating workpiece scrap due to taper breakage. |

| Technical Advantages | Exceptional Ability and Even Chip Flow. | Particularly well suited to cutting high-hardness hard-to-cut materials and large-diameter threads; lateral chip removal perfectly overcomes the problem of blind hole machining, resulting in excellent machining accuracy and surface finishing. |

| Application Decision-Making | Proper Tool Selection and Evaluation. | Such critical parameters as tool material, cutting teeth number, and thread pitch are considered. It is suitable in production conditions with high product variety, small lots, high-value workpieces, and difficult-to-machine materials. |

Thread milling is not process substitution but an investment for the future. Its ability to perform multiple tasks with a single tool, its reliability in ensuring safety without taper breakage, and its amazing ability to treat hard-to-treat material, enhances the competitiveness of businesses overall in terms of tool management, production efficiency, and cost of quality, and therefore it is an imperative to achieve smart and efficient manufacturing.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The brains behind this guide are derived from over a decade of detailed experience and knowledge in CNC machining, thread milling, of the LS Manufacturing engineering department. We are not theoretical consultants; we are partners going through the same manufacturing challenges as you.

LS Manufacturing's master engineers have had years of full immersion in the aerospace, high-end energy equipment, and precision medical device industries with direct personal experience overcoming thousands of thread machining problems in hard-to-machine materials such as high-temperature alloys and titanium.

LS Manufacturing helped one customer to resolve the removal of chips of deep blind holes over M36 due to traditional tapping. LS Manufacturing also successfully enhanced the pass rate of thread machining on a high-temperature alloy turbine disc component from 78% to over 99.9% with a custom thread milling solution.

This guide, condensed from LS Manufacturing's direct experience, distilled from thousands of failures and successes, is meant to provide a brief, reliable, and efficient machining path.

Why Is Thread Milling An Alternative To Tapping?

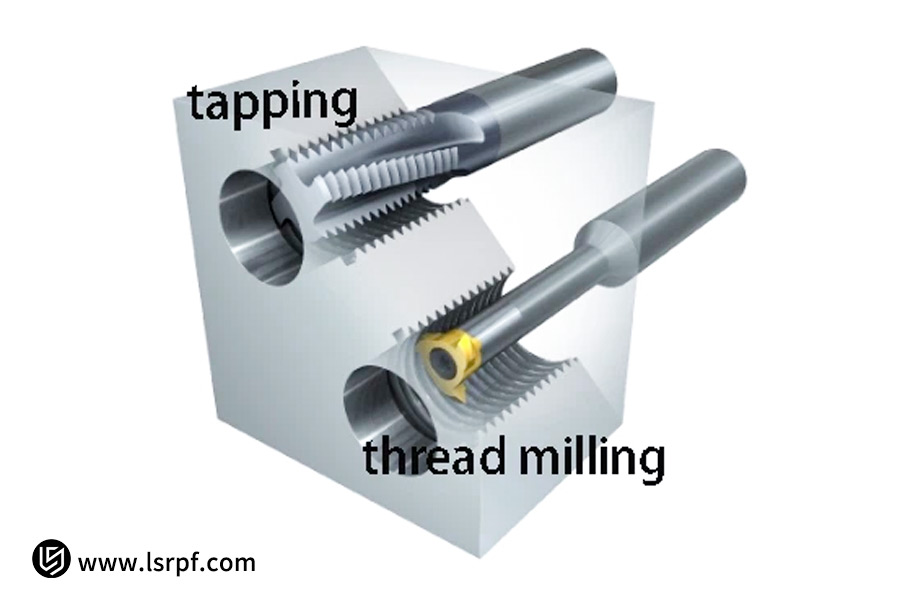

Traditional tapping, such as that of a fixed key opening a lock, is severely limited and implies extensive danger. Thread milling, instead of tapping, is akin to a universal key. Using CNC technology, it embodies the transition from "rigid" machining to "flexible" machining, thus addressing the underlying bottlenecks of tapping. The most basic differences between the two are compared below:

| Features | Traditional tapping | Thread milling |

| Processing principle | Spindle axial feed and thread pitch must be accurately synchronized. | A three-axis CNC machine utilizes machine tool interpolation to achieve a spiral tool path. |

| Tool flexibility | One thread specification can be produced by a tap alone. | One tool can produce multiple threads of the same pitch but different diameters. |

| Precision control | Determined by the tap diameter and fixed. | Tool radius compensation gives the potential to make flexible adjustments in the program, and the pitch diameter can be easily controlled. |

Specifically, its technological advancements are realized in:

1. Revolutionary machining principle:

Thread milling employs a three-axis CNC machine with helical interpolation commands to control the tool motion in three axes to "cut" the thread. Not only does this eliminate the restrictions of a close spindle feed-tap pitch relationship, but also effectively eliminates the risks of tap failure and thread damage because of excessive axial force.

2. Unparalleled Flexibility:

One thread milling cutter can mill threaded holes of various diameters at one pitch (e.g., M10×1.5 and M12×1.5), and even right-hand and left-hand threads. That "one tool, multiple applications" factor considerably reduces the amount and variety of tool inventory, cutting tool management costs directly.

3. Precise and Controllable Accuracy:

During machining, the accuracy of machining and pitch diameter of the thread can be simply controlled by adjusting the tool radius compensation value in the program without having to change tools. It allows for easy dimensional adjustment and control of tolerance, essential when working on high-precision parts.

These technological advantages make thread milling not just a process choice but also a strategic breakthrough for manufacturing efficiency and reliability.

How Can Thread Milling Reduce Unit Costs For Companies?

The majority of companies, considering the unit cost of a tool at first instance, feel that thread milling cutters would be more expensive than taps. But a deeper analysis with a view of total cost of ownership and long-term savings shows that thread milling is by far more cost-saving than traditional tapping and thus a wise choice for reducing unit costs. Its economic value is realized essentially in the following three facets:

1. Ultra-long tool life, reducing downtime and procurement:

The life of one top-quality thread milling cutter is typically 10 or even dozens of times the life of a tap. This greatly reduces downtime associated with tool changes and tool set-ups in lot production, ensuring continuity of production and directly reducing the frequency and overall expense of long-term tool procurement.

2. "One tool for multiple uses," reducing inventory and management costs:

A single mill thread tool can cut threads of varying diameter and same pitch as well as different materials. Such excellent manufacturing versatility significantly reduces the quantity and the specifications of tools a company needs to keep in inventory, resulting in fundamental cost savings, simpler tool management, and free hidden scrap losses.

3. Improved yield rate, eliminating hidden scrap losses:

Thread milling basically eliminates the potential for workpiece scrap from damaged taps. Based on a case study of one of the customers of LS Manufacturing, following the introduction of thread milling in its mass production of stainless steel valve bodies, the thread quality scrap has dropped to almost zero. Based on tool, labor, and scrap costs, cost per piece has been reduced by over 30%.

The key to cost reduction by means of thread milling, therefore, is to trade a larger initial investment for new manufacturing efficiency, flexibility, and yield technologies, and to reduce overall manufacturing cost by hundreds of percent.

What Are The Unique Advantages Of Thread Milling When Machining High-Hardness Materials?

In cutting hard materials such as titanium alloys, hardened steels above HRC58, and nickel-based superalloy threads used extensively in the aerospace industry, traditional tapping not only uses a great deal of time but also often leads to failure due to the absence of tool strength. Thread milling technology exemplifies its sole and irreplaceable advantages in this regard. Its better performance owes primarily to the following:

1. Efficient cutting method and superior tool material:

Carbide thread milling cutters have a high-strength body and can withstand more intense cutting forces. It employs side milling, with intensive tool rotational speed and three-axis linkage to achieve cutting speeds of 80-200 m/min, significantly higher than tapping. The high-efficient cutting not only enhances efficiency but also easy evacuation of chips due to the fragmented fine chips, preventing tool damage caused by chip blockage.

2. Extremely Low Radial Cutting Force and Excellent Chip Breaking:

Contrary to tapping, thread milling is characterized by extremely low axial force, effectively eliminating the source of tap breakage and chipping during cutting of high-hardness materials. Besides this, stable chip breaking enables smooth, safe cutting process, protecting tool and workpiece.

3. Stable Processing Environment and Process Assurance:

Good-quality thread forming in hard-to-cut materials like high-temperature alloys is not a result of merely owning a sharp cutting tool. LS Manufacturing's extremely rigid spindle and high-pressure coolant system internally provide an stable cutting environment for carbide thread milling cutters. The internal coolant system dramatically quenches excessive temperatures in the cutting zone and assists chip evacuation to provide high reliability and consistency throughout the entire process.

Faced with the difficulty of machining high-hardness and high-strength materials, thread milling, due to its inherent advantage in tools and processes, provides a safe, efficient, and high-quality thread processing process, and thus becomes a favorite solution for overcoming technical barriers.

How To Maximize Thread Milling Efficiency Through CNC Programming?

Its technological advantages rely on accurate thread milling programming. It is neither operator dexterity- and intuition-dependent, nor does it standardize and optimize the machining process by being dependent on the operator's skills and experience, but by using the exact, reusable G-code programs, it achieves unprecedented degrees of efficiency at assured quality. Maximization of efficiency is primarily a function of the following three factors:

1. Mastering core commands lays the foundation for efficiency:

The fundamental nature of thread milling relies on G02/G03 helical interpolation commands in G-code. They control circular tool motion in the X and Y axes with linear Z axis feed, thereby accurately "shaping" the thread groove. The program trace, being short and effective, is the secret to avoiding idle travel and high-speed cutting.

2. Leverage system functions for one-click code generation:

In order to simplify the operating barrier, top-rated CNC systems have made provision for heavy-duty parametric programming modules. The operators just enter thread parameters (diameter, pitch, and depth) on the console, and the machine will generate the whole set of proper and safe G-code automatically. The programming and preparation time is significantly reduced and nearly eliminates manual-programming errors.

3. Fine-tune tool compensation values to ensure quality and flexibility:

During machining, adjust tool radius compensation value merely set thread pitch diameter and precision fine-tune conveniently without changing the program. This enables a single program to fit normal tool wear or machine identical threads but different tolerances, which enhances programming effectiveness as well as machining flexibility.

Through the control of elementary G-code, utilization of all aspects of CNC system optimized automation capabilities, and the application of adaptable tool compensation, businesses can achieve the entire advantage of thread milling while reducing programming efficiency and making possible stable and efficient machining.

Case Study: LS Manufacturing Solves The Challenge Of Thread Machining In High-Temperature Alloys Through Thread Milling

In the high-end manufacturing industry, a real-world application of LS Manufacturing completely illustrates the significance of high-end thread milling technology. An aerospace customer was confronted with an apparently insurmountable challenge during production of critical engine components: they needed to thread mill a series of deep-hole threads in the highly hardened Inconel 718 high-temperature alloy.

1. Customer Pain Point:

Previously, conventional tapping methods were adhered to, but tool breakdown in high-temperature alloys was appalling with a tool breakdown rate as high as 30%. Continuous taper breakage not only led to a tenfold rise in tooling cost but also compromised seriously the yield rate of expensive workpieces, resulting in poor machining efficiency and impacting heavily the delivery schedule of critical projects.

2. LS Manufacturing Solution:

After conducting an on-site inspection, the LS Manufacturing staff assuredly recommended and executed an economical thread milling operation. We selected a carbide thread milling cutter specifically designed to machine heat-resistant alloys and, from our process database, developed a precise G-code program with optimized cutting parameters and high-pressure coolant techniques so that there was a stable and controllable machining operation.

3. Achievements and Value:

- Zero tool breakage rate: This effectively eliminates the risk of workpiece scrapping from taper breakage.

- Both efficiency and quality are improved: Tool life is improved by more than five times compared to traditional tapping; single-hole machining time is reduced by some 40%, and all threads achieve 100% qualified quality.

This successful instance of LS Manufacturing not only assures the client delivery cycle and quality of vital components, but also increases its thread processing abilities to industry-leading levels.

How Can Thread Milling Cutters Achieve Flexible Production With "One Tool For Multiple Uses"?

In the present high-mix, low-volume production trend, rapid responsiveness throughout the production process is critical. Perhaps one of the most appealing features of thread milling technology is the high level of flexibility, actually permitting "one tool for multiple applications," basically rendering the old tapping philosophy of "one tap for one thread" obsolete. Its high versatility among thread milling cutters is based primarily on the following two principles:

1. Program-controlled Dimensions:

The final thread size (e.g., nominal diameter) is determined by the cutter motion path included in the NC program, not by the fixed dimensions of the cutter:

- By simply modifying tool radius compensation value and helical interpolation diameter in the code, the same thread milling cutter can easily produce threads of varying diameters (e.g., a cutter with a wide enough base edge can mill all threads of the same pitch, M6 to M12).

- Simply changing the helical interpolation direction in G-code (G02 or G03) allows for left-hand and right-hand thread machining in a single program.

2. Matching Tool Structure to Thread Pitch:

The cutting edge of a thread milling cutter is generally organized to cut a specific range of pitches. As long as the pitch of the workpiece thread falls within the intended range of the tool, the same tool can be used to cut the thread. This "pitch-independent, diameter-independent" property is the physical basis for thread milling cutters' versatility.

This multifaceted model of processing significantly reduces manufacturing reliance on accurate tap specifications, significantly reduces tool inventory cost, and minimizes changeover time while switching among thread orders of varying specifications, allowing companies to experience never-before-seen responsiveness to complex and ever-evolving production challenges.

What Efficiency Breakthroughs Have Been Achieved In Thread Milling For Large-Diameter Threads?

Traditional tapping is faced with significant issues in machining big-diameter threads: extremely high torque machines must be used, tooling is weighty and expensive, and cutting forces are extremely high and susceptible to workpiece distortion or tool breakage. Thread milling technology, by contrast, offers a paradigm-breaking solution to the problem, bringing revolutionary leaps in efficiency and reliability. Breakthrough in efficiency is attributed primarily to the following two innovations:

1. Tool Innovation:

For coarse threads above M60, machine-clamped thread milling cutters are the standard. These consist of a heavy-duty cutter body with replaceable and indexable carbide inserts. The cost per insert is significantly lower than for a solid tap, and reused inserts do not require resharpening; they can simply be indexed or replaced, reducing tool cost as well as tool replacement downtime significantly.

2. Process Optimization:

Machine-clamping thread milling cutters are able to produce threads through disc milling or layered cutting. Instead of cutting the entire stock all at once, the tool completes the cutting in layers, multiple revolutions, along the thread groove, as defined by the CNC program. This method divides the heavy cutting load into numerous, light cutting steps, protecting the machine tool spindle while greatly improving cutting stability and tool life, achieving true high-efficiency cutting.

Through collaborative innovation in processing and tooling, thread milling has also transformed large-diameter threading from a process of high risk and high load to a controllable, efficient, and economic process.

Compared with traditional tapping, thread milling can potentially enhance process efficiency more than threefold while virtually ensuring process quality and safety.

How Does Thread Milling Solve The Challenges Of Chip Evacuation And Precision In Blind Hole Machining?

Blind hole threading has always been a nuisance in traditional tapping. Tap breakage, thread burring, and even workpiece failure are usually induced by chip blockage. Blind hole thread milling technology, with its proprietary cutting mechanism, eliminates these threats at their origin to a large degree by achieving optimized chip evacuation and precise thread depth control. The advantages of this technology are specifically realized in the following two aspects:

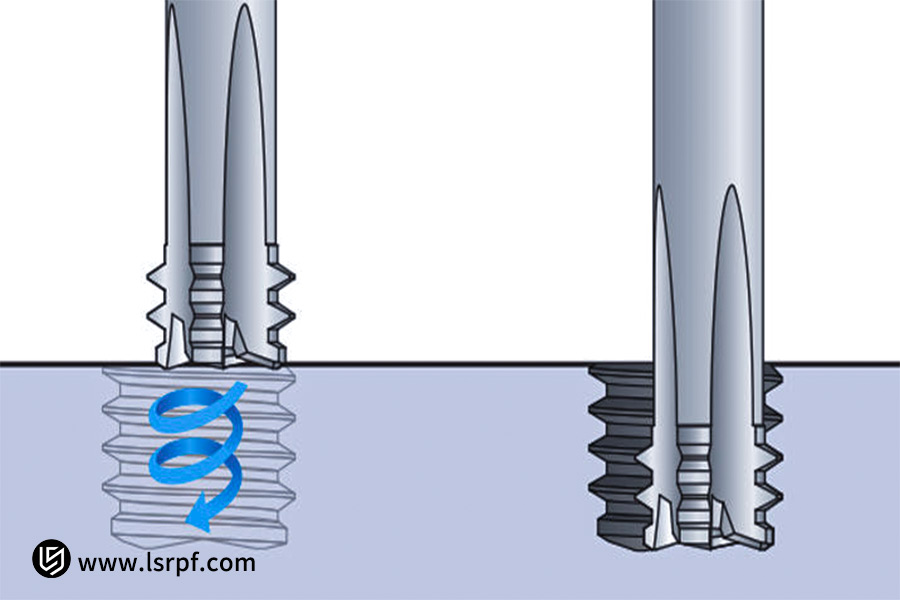

1. Smooth chip breaking for thoroughly optimized chip evacuation:

Unlike continuous ribbon-like chips produced by tapping, thread milling is an interrupted cutting operation producing interrupted, broken chips. The interrupted chips won't bind the toolholder and are easily and efficiently flushed out of the close-bottom blind hole by the machining center's internal coolant. This completely eliminates the risk of tool strain, chipping, or even tool breakage due to poor chip evacuation.

2. Program control ensures precise thread depth control:

The final thread depth is controlled directly by the CNC program for blind hole thread milling. The tool can reliably mill right up to the bottom of the hole and, through program control, perfectly develop a complete, clean thread finish. This actually eliminates precision issues with tapping, such as insufficient or incomplete thread depth, resulting from chip resistance or elastic deformation of the tool.

By dividing chip evacuation problems into manageable, small chips and taking advantage of CNC machining systems to economically control chip depth, blind hole thread milling offers a highly reliable, high-yield blind hole threading process that significantly increases process safety and quality consistency.

What Are The Key Parameters To Consider When Selecting A Thread Milling Cutter?

The selection of the right thread milling cutter is the essence of successful thread milling. Faced with a multitude of options, narrowing down your selection to a few critical parameters makes you capable of making the correct choice and achieving maximum material compatibility and productivity. To select a tool, note the following three critical parameters:

1. Tool Type:

- Solid carbide milling cutters: Offer high stiffness and precision, suitable for small and medium diameters (e.g., up to M20) and high-precision threading.

- Clip-on milling cutters: Offer better economic performance, feature replaceable inserts, and are particularly suited for large diameters, deep holes, and roughing operations. They offer long life tools and low maintenance.

2. Tool Coating and Grade:

Tool coatings are necessary to improve performance. Standard TiN (titanium nitride) coatings are highly adaptable and can be used with steel. AlTiN (aluminum titanium nitride) coatings possess higher hot hardness and are highly adapted for machining hard-to-machine materials such as stainless steel, cast iron, and high-temperature alloys, which significantly improve tool life and material compatibility.

3. Pitch Compatibility:

It is necessary that the tooth geometry of the thread milling cutter precisely matches the required pitch of the workpiece. A tool with a specific range of pitches should be used so that the desired thread profile, smooth surface finishing, and lack of chatter marks can be assured.

Successful thread milling cutter choice requires careful consideration of workpiece material, machining hole diameter, and thread specifications. The proper selection maximizes thread milling efficiency, cost advantages, and flexibility for secure production.

Is Thread Milling Suitable For My Factory?

Are you considering whether thread milling will be useful to implement in your factory? To determine its feasibility, no complex calculations are needed; simply study the following important scenarios. In case any of these situations apply to your factory, thread milling advantages will yield worthy gains. Please conduct a self-evaluation based on the following scenarios:

- Equipment and Material Foundation: Your workshop already has a three-axis or higher CNC machining center; or you are frequently machining threads in difficult-to-machine materials such as stainless steel, titanium alloy, and hardened steel, where the conventional tapping does not work.

- Production Model and Quality Requirements: Your applications include high-variety, low-volume production, a great variety of thread specs, and frequent thread changeovers. Or, you have strict thread quality demands (e.g., accuracy and consistency) and can't tolerate the risk of workpiece scrap because of taper breakage.

- Current Pain Points: You are progressively plagued by low tapping efficiency, excessive tool wear, inadequate evacuation of chips, or irregular thread quality.

If the above situations are most apt to describe your current position, taking advantage of thread milling and incorporating it into your production line will be a valuable investment. It is the answer to addressing these very basic pain points and increasing your overall competitiveness.

LS Manufacturing can provide you with a free, professional assessment to help you take the first step in your process upgrade.

FAQs

1. Is thread milling really more efficient than tapping?

For conventional thread machining, total efficiency of thread milling and tapping may be equivalent. However, for large diameters, deep holes, or difficult-to-machine materials (such as stainless steel), thread milling offers significant overall efficiency advantages. By reducing tool shifts, avoiding downtime due to broken taps, and providing greater cutting rates, thread milling can reduce single-part processing time as much as 40%, significantly improving equipment utilization and productivity.

2. Is thread milling programming complex?

Not at all. With advancements in modern CAM software and CNC technology, programming has been greatly simplified. LS Manufacturing's sophisticated process library involves best-practice parameters for a wide variety of materials and creates easy-to-run code automatically. We also provide tried-and-tested, standardized program templates and professional training so you can learn quickly and master the process with ease.

3. Is thread milling economical for small-batch production?

Yes, it is. The greatest advantage of thread milling lies in its very high level of processing flexibility: a single universal thread milling cutter can replace many or even dozens of taps with different specifications. Not only does this reduce the initial capital investment in tooling significantly, but also makes management and inventory easier and allows for easy transitioning between small-batch, many-variety orders to become faster and less expensive.

4. Does LS Manufacturing provide thread milling contract manufacturing services?

Indeed. LS Manufacturing possesses advanced CNC machine tools and thread milling cutters, and specializes in threading operations on challenging materials of a variety. Whether your machining issues involve high-temperature alloys, blind holes, or massive threads, we welcome your inquiry and will provide on-time, reliable, and precision contract manufacturing.

Summary

Thread milling is not another machining option; it is a paradigm shift and direction for the future of thread machining technology, from "experience-controlled" to "digitally controlled." Transformation from traditional tapping to new thread milling is a strategic step for companies to achieve cost savings, efficiency, product quality, and more production flexibility.

Whether you're working with difficult-to-machine materials and complex workpiece geometries, or for maximum production stability and reduced total cost, thread milling is vastly superior to tapping. Choosing LS Manufacturing is choosing not only a technology but a technology partner dedicated to bringing value to you.

Contact LS Manufacturing today! We would be delighted to extend a sincere invitation to send your part drawings. Our process experts will conduct a comprehensive, one-to-one evaluation and provide a customized thread milling process solution and detailed cost-saving analysis report at no charge.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.