In engineering and manufacture, material selection is most often a compromise of highest order on performance. Designers are often faced with a dilemma: the requirement for material that is indestructible but economically weightless; the requirement for crushing strength and the requirement for being economic. It is here that steel and titanium—the two titans of the metal world—are set against each other.

However, the actual question at hand is not the end decision. Titanium alloys are not universal, nor is high-strength steel outdated. Titanium is incredible with its spectacular strength-to-weight ratio and superior corrosion resistance, but steel prevails with its unparalleled absolute strength and affordability. Their utility is not for utility's sake but in their perfect fit within the ultimate application. This last comparison is intended to penetrate the misunderstanding for the most logical trade-offs among hardness, strength, and weight for specific applications. To save you time, here's a quick overview of the key takeaways.

Quick Reference: Choose Your Tap at a Glance

| Dimensions | Titanium (Ti-6Al-4V as an example) | Steel (4140 alloy steel as an example) |

| Hardness | High (~36 HRC) | Very high (~58 HRC after heat treatment) |

| Strength | Very high (tensile strength ~900 MPa) | Higher (tensile strength ~655 MPa, reaching ~1480 MPa after heat treatment) |

| Weight | Very light (density ~4.43 g/cm³) | Heavy (density ~7.85 g/cm³) |

| Corrosion resistance | Excellent | Poor (carbon steel)/Good (stainless steel) |

| Cost | Very high | Low (carbon steel)/High (stainless steel, alloy steel) |

The catch in selecting titanium or steel is in properly aligning the most important priorities of the application:

- If one desires maximum absolute strength, hardness, and lowest expense and the corrosion environment is manageable, steel is less expensive and the logical choice.

- If weight reduction, utmost corrosion resistance, and highest strength-to-weight are absolutely necessary, and expense matters not at all, titanium is the option that cannot be surpassed. No absolute better or worse, but best for a particular circumstance.

Why Trust This Guide? Real-World Experience From LS Experts

We've invested over a decade and a half at LS Precision delivering material science and engineering services. My area of expertise includes high-performance metal material choice, testing, and failure analysis. All comparison data and conclusions you come across in this guide aren't copy-pasted from textbooks; they've been stringently cross-checked by our team's lab tests and actual engineering applications.

LS Precision understand that even minute parameter fluctuations can make a whole project go haywire. Hence we always adhere to the philosophy of "data-driven, application-first" so that all recommendations we provide are firmly established. This is hard-won experience. LS Precision previously assisted a drone maker select material for the landing gears. Unfortunately, the customer initially requested us to utilize traditional alloy steel for maximum strength.

But through weight simulation and fatigue testing, we ultimately settled on a titanium alloy solution, which ultimately had so much more flying endurance without compromising on the strength needs. Experience has thus led us to believe that there is not an ideal material but the best under circumstances. This guide is full of practice wisdom.

Is Titanium Really Harder Than Steel? Uncover the Hidden Truth About Hardness

"Is steel harder than titanium?" This is one of the most common questions people have when choosing material. To solve this issue, we must first define the scientific definition of "hardness" and how to measure it. Hardness in engineering is conventionally defined as the ability of a material to resist local plastic deformation (e.g., scratching or indentation), and Rockwell hardness (HRC) and Vickers hardness (HV) are generally used as the quantification tools.

Based on measured figures, standard titanium alloys (e.g., Ti-6Al-4V) are roughly 30-36 HRC in Rockwell hardness, whereas medium-carbon alloy steels heat-treated (e.g., 40Cr) can be 50-60 HRC. Ultra-high-carbon tool steels are still greater than 60 HRC. That is, is titanium harder than steel? No—the raw hardness of most steels is much higher than that of titanium alloys. The following are comparative typical values:

| Material Type | Rockwell Hardness (HRC) | Vickers Hardness (HV) | Notes |

| Pure Titanium | 15-20 | 150-200 | Industrially Pure Titanium |

| Titanium Alloy Ti-6Al-4V | 30-36 | 300-350 | Aerospace-Grade Alloy |

| Mild Carbon Steel (Q235) | 10-15 | 120-150 | Unheat Treated |

| Alloy Steel (40Cr) | 50-54 | 500-550 | Quenched and Tempered |

| Tool Steel (Cr12MoV) | 58-62 | 700-800 | Quenched and Tempered |

So why is the myth that "titanium is harder than steel" created? The reason is misplaced context. People confuse "strength," "toughness," or "wear resistance" with hardness. The actual advantage of titanium alloys lies in their exceptionally high strength-to-weight ratio and better corrosion resistance compared to absolute hardness.

Strength Comparison: Titanium vs. Steel: Which Can Withstand Extreme Conditions Better?

Materialally speaking, the question "Is titanium stronger than steel?" can be replied to only in a multi-dimensional sense. Strength is not a single parameter; a thorough assessment of different parameters like tensile strength, yield strength, and fatigue strength is required. The performance under harsh conditions is particularly unmatched.

1. Yield strength and tensile strength

In sheer numbers, the high-strength steel is superior. For example, expensive titanium alloys (eg, Ti-6Al-4V) have a tensile strength of approximately 900-1000 MPa, while heat-treated alloy steel grades (say, 30CrMnSiA) can easily cross the 1500 MPa mark. Steel also has a higher yield point of strength, i.e., less permanent deformation under static loads of a very dispersed nature.

2. Dynamic and corrosive environments

But the answer to the question "Is titanium stronger than steel?" is reversed when it comes to dynamic and corrosive environments. Titanium alloys possess far better fatigue strength than steel, especially under cyclic loading conditions (such as in aerospace components), where they offer greater resistance to crack propagation.

Besides that, titanium possesses stable strength under high and low temperature and corrosive conditions (for example, seawater and acidic conditions), while steel requires surface treatment or alloying in order to mask the lack of corrosion resistance. It also embrittles under low temperatures and softens under high temperatures.

If it's all about maximum load-carrying capacity in a single direction, steel takes the cake; but where the issue of weight efficiency, fatigue life, and adjustment to advanced environments is a factor, then titanium alloys are the choice in extreme conditions.

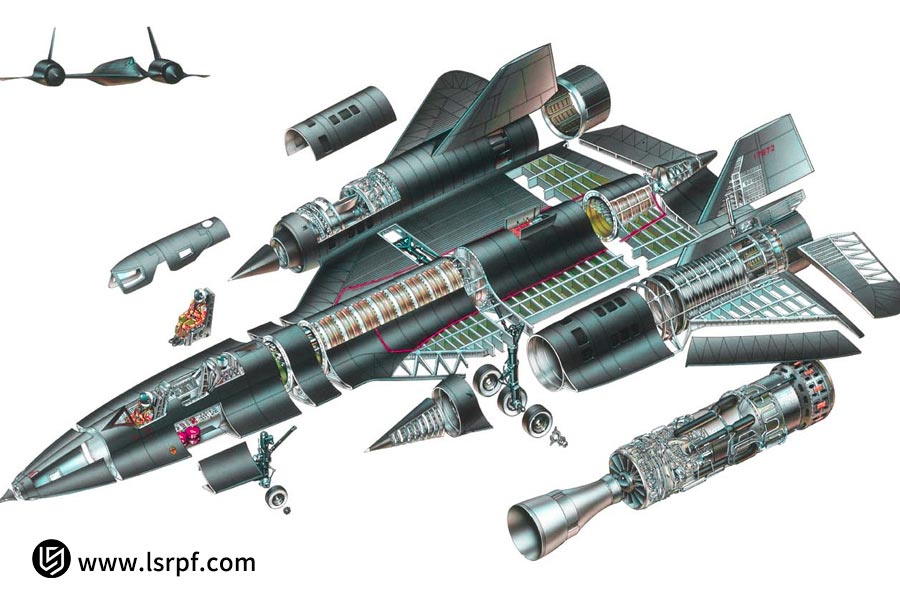

Weight Difference: Why Aerospace Prefers Titanium?

As a comparison between steel and titanium, the most significant difference is density. Titanium has a density of approximately 4.5 g/cm³, while the density of steel is 7.8 g/cm³—that is, for parts of identical volume, titanium is roughly 42% lighter than steel. This significant weight advantage has led to titanium being widely used in the aerospace industry.

Lightweighting is not enough, however; the key is "specific strength" (strength-to-density ratio). High-strength steel may be of higher absolute strength than titanium alloys, but titanium greatly exceeds steel in specific strength. For example, the widely used titanium alloy Ti-6Al-4V has a tensile strength of about 900 MPa and specific strength of 200 MPa/(g/cm³). 1500 MPa tensile strength high-strength steel has a specific strength of approximately 190 MPa/(g/cm³).

This means that titanium components can be light in weight while satisfying the same requirements for strength. Such weight efficiency is of paramount importance when it comes to aerospace applications. Every kilogram saved in weight translates to more payload, precious fuel efficiency, and better flight performance.

Although titanium is costly, the performance benefit that is obtained from the usage of titanium alloys in critical sections such as engine rotors, fuselage frames, and landing gear renders them a crucial strategic material. This is precisely the fundamental worth of titanium alloys in their unparalleled comparison with steel.

Corrosion Resistance Contest: Stainless Steel and Titanium: Which Lasts Longer?

Corrosion resistance is one of the primary considerations in a comparison of titanium vs. stainless steel. Though stainless steel is popularly, albeit erroneously, believed to be "corrosion-proof" due to its name, the manner in which it resists corrosive environments differs significantly from that of titanium.

1.Corrosion resistance mechanism:

In corrosion resistance mechanism, stainless steel relies on a passive chromium film to resist oxidation, while titanium is protected by a dense, self-healing titanium oxide layer on its surface. This inherent difference results in titanium showing greater overall resistance in a stainless steel vs. titanium comparison:

It is pitting and crevice corrosion resistant to chloride ions (common in seawater applications), whereas even good quality stainless steels like 316L can continue to experience localized corrosion after extended seawater immersion.

2. Chemical compatibility:

The implications of the stainless steel vs. titanium comparison are even more marked when it comes to chemical compatibility. Titanium performs well in oxidizing acids (for example, nitric acid), organic acids, and alkaline solutions, and its useful pH range is much wider than that for stainless steel.

Stainless steel is susceptible to stress corrosion cracking in acidic environments containing halogen ions, especially chloride ions. The only exception is in acid-reducing environments (i.e., dilute hydrochloric acid and sulfuric acid), where titanium will corrode rapidly, and stainless steel also fares poorly.

In a direct comparison between stainless steel and titanium, the choice depends on the application environment:

- For most everyday environments and most industrial applications, stainless steel provides a cost-effective corrosion protection solution;

- In aggressive environments such as marine engineering, chemical and medical, and aerospace, where reliability is paramount, titanium is undoubtedly the more durable option.

Cost Analysis: Why Are Titanium Products So Expensive?

The cost of titanium products is far above the cost of ordinary metal, and it is caused by several reasons. In the following, we will analyze the causes of the price difference in terms of raw material, difficulty in processing, and production cost.

Raw materials

In the aspect of raw materials, although titanium is abundant in the Earth's crust, its smelting is extremely complex and energy-intensive. The Kroll process of producing titanium sponge from titanium ore requires high-temperature vacuum conditions, which makes its production cost range from $10,000 to $15,000 per ton, while that of ordinary steel ingots is merely $500 to $800 per ton.

Processing difficulty

Processing difficulty is another important factor. Titanium has low thermal conductivity, which localized heat when machining, accelerating tool wear and requiring special tools and coolants. Furthermore, titanium is highly chemically active, requiring hot working in a protective atmosphere, with cold working requiring significant springback. All these factors require specialized processes and equipment, further adding to the cost of production.

Cost of production

As far as the cost of production is concerned, titanium is more expensive than steel in every stage of its production. Titanium smelting costs are 20-30 times higher than steel, and processing costs are 3-5 times the cost of the raw material. In the meantime, the yield rate is only 50-60%, far lower than the 85-95% of steel. With such a cost structure, the ultimate price of titanium products reaches 5-10 times, or even higher, that of steel.

Despite its costliness, the better strength-to-weight ratio and biocompatibility of titanium alloys make them a necessity in high-value applications such as aerospace and medical implants. These better properties ultimately offset their cost disadvantage.

Processing Performance Comparison: Which Material Is Easier To Manufacture?

In material selection, machinability is usually one of the determining factors for production efficiency and cost. This article impartially compares titanium and steel's machinability, weldability, and forming difficulty, offering practical advice for your manufacturing process selection.

Cutting performance

In terms of machinability, steel is more convenient to machine than titanium. Steel has favorable thermal conductivity and chip breaking properties in terms of machinability, which allows higher cutting speed and standard tools. Titanium alloys have low thermal conductivity, which has the effect of heat concentration at the tool edge during machining and results in lower tool life in addition to requiring special tools and lower cutting speeds, resulting in lower machining efficiency.

Welding performance

In weldability, steel again stands superior. The majority of steels are weldable using conventional techniques, while stainless steel requires only controlled heat input to yield consistent welds. However, titanium welding requires a completely inert atmosphere and imposes extremely high demands on the operating environment. Any minute trace of contamination can result in weld embrittlement.

Forming processing

Steel has excellent hot and cold working properties in forming and is easily adaptable to a variety of forming processes. Titanium exhibits high springback during forming at room temperature and typically must be hot formed. This not only increases equipment requirements but also greatly increases the cost of production. Steel exhibits superior manufacturability and cost in all three processing steps.

Overall, steel has greater manufacturability and cost-effectiveness for the three processing operations:

- Its higher machinability, established welding methods, and acceptable formability make it the first choice material for the majority of manufacturing applications.

- However, while titanium is more difficult to process, its unique performance advantages still remain unbeatable in certain high-end applications.

It is best to strive for an optimum trade-off between processing difficulty and material performance based on the end-use demands of the product, lot size of production, and cost allowance.

In What Way Does LS Identify The Most Suitable Material For Its Medical Device Clients?

1.Client Challenge:

A high-end medical device company was faced with a material selection dilemma of the highest significance in developing the next generation of minimally invasive surgical instruments. Traditional stainless steel instruments were unwieldy during long procedures, causing surgeon fatigue.

Furthermore, repetitive high-temperature and high-pressure sterilization cycles began to show evidence of surface corrosion, compromising the life and safety of the instrument. The client required a novel solution that would meet the most stringent hygiene standards for medical devices while enhancing the surgical experience.

2. Limitations of traditional solutions:

Traditional methods usually adopt a single-material approach: either utilize 316L stainless steel throughout to manage costs at the expense of weight and corrosion resistance, or utilize titanium alloy throughout, which is confronted with the predicaments of high cost and processing complications.

Such an either-or approach does not adequately address the various performance, safety, and economic demands of medical devices simultaneously, particularly when comparing the use of titanium versus stainless steel, where both have their respective advantages and limitations, thus precluding a straightforward trade-off.

3. LS Precision's innovative strategy:

LS R&D employed an innovative material combination strategy. They began by placing titanium and stainless steel side by side to compare the two materials' performance in specific medical applications. They conducted corrosion resistance testing (exposing the materials to 500 autoclave sterilization cycles), fatigue strength testing (exposing the materials to repetitive stresses that mimic actual use), and biocompatibility verification.

Based on test data, LS Precision innovatively proposed a "functional zoning" concept: titanium alloy was used in the joint mechanism and components in contact with the body of the instrument so as to be biocompatible and corrosion-resistant; specially treated stainless steel was used in outward structural components so as to ensure overall rigidity and reduce costs.

4. Final Results and Value:

Through this rigorous "titanium vs. stainless steel comparison" research and innovative use, LS Precison provided the customer with a best-of-all-worlds solution: 40% reduction in instrument weight and a three times longer service life, all within budget. Released to the market, this surgical instrument received lavish praise from surgeons and went on to set a standard in its class.

This success story not only demonstrates LS's expertise in material selection but also demonstrates the enormous value that can be realized through close knowledge of customer needs and technological innovation.

Application Guide: When to Use Titanium?

In choosing a structural material, titanium is not a universal solution, but it is a vital and perfect choice in some applications. Titanium should be a top choice when your application meets the following three most important requirements:

- Extreme lightweighting, especially when lightweighting is required with no sacrifice in strength;

- High corrosion resistance, especially when applications are exposed to aggressive environments for extended periods of time;

- High biocompatibility, perfect for medical applications with direct contact with humans.

Specifically, titanium excels in the following applications and industries:

- Aerospace (airframe components, engine components, and spacecraft skins), where its high strength-to-weight ratio significantly improves fuel efficiency and payload;

- Medical implants (artificial joints, bone screws, and surgical instruments), where its biocompatibility prevents rejection;

- High-performance sporting goods (racing bicycle frames, golf clubs, and mountain climbing equipment), where it provides an optimum balance between weight and performance;

- Chemical and marine engineering (heat exchangers, desalination plants, and diving equipment), where it resists long-term corrosion.

The basic principle for selecting titanium is this: when lightweighting, corrosion resistance, and biocompatibility are absolutely critical to the success of a project despite the higher initial cost, titanium's performance advantage justifies its selection based on lifecycle value by a wide margin over traditional materials.

Application Guide: When to Select Steel?

As the most fundamental and well-liked structural material, steel remains the invincible and top choice in the subsequent cases. Whenever a project requires the balancing of strength, cost, and processability, steel is generally the most reasonable choice.

Steel has the following fields of excellence:

- Construction and Infrastructure (steel bridges, high-rise building structures, reinforced concrete), where its high compressive strength and seismic resistance provide firm structural support;

- The automotive industry (body frames, engine components, chassis systems), where its high strength and impact resistance ensure safe driving;

- Heavy machinery (construction equipment, mining equipment, agricultural machinery), where steel's wear resistance and high load-carrying capacity meet the demands of severe operating conditions;

- Tool and mold making (cutting tools, stamping dies, injection molds), where heat treatment can achieve extremely high surface hardness and wear resistance;

- Consumer goods (kitchenware, furniture, household appliances), where steel meets mass market requirements with its excellent cost-effectiveness.

In instances where large-scale production, high load, or cost-intensive application is required, steel remains a time-tested and practical choice. Especially in instances of complex forming or welding application, the ease of fabrication of steel is second to none when compared to other materials.

FAQs

1. Can titanium alloys be heat-treated?

Yes. The titanium alloys are hardened through a unique heat treatment process consisting of two fundamental processes: solution treatment and aging. Solution treatment dissolves the alloying elements evenly and quenches them rapidly to form a supersaturated solid solution. The aging treatment precipitates the fine second-phase particles at low temperature, significantly hardening and strengthening the material.

2. Which material is better for biomedical applications?

Titanium alloys is better.Their favorable biocompatibility is due to the fact that they possess a stable surface film of titanium oxide, effectively preventing precipitation of metal ions and rejection by the body.They also have an elastic modulus comparable to bone and reduce stress shielding to a minimum. Nickel in stainless steel, however, has the potential to produce allergic responses, and cobalt-chromium alloys can elute metal ions.

3. Which material is better at high temperatures?

Specialty stainless steels are a good asset. Although titanium alloys are adequate even at temperatures of up to 300°C, their strength reduces enormously above 400°C, and they oxidize. Austenitic stainless steels like 316L are suitable up to 800°C, and ferritic heat-resistant steels can even reach 1000°C. Steels stabilize carbides through the addition of elements like chromium, molybdenum, and niobium and maintain high-temperature strength as well as oxidation resistance.

4.How do I select what material is appropriate for my project?

LS Precision offers free professional material selection consulting. Our engineers will carefully balance your application environment, performance, budget, and volume. We also contrast such options as stainless steels and titanium alloys according to material database and simulation analysis. LS Precision Manufacturing even organize sample production and performance testing to ensure that the suggested materials fully meet your project requirements, and you can select the most economical solution.

Summary

From this in-depth comparative examination, it is clear that both steel and titanium have their respective performance strengths. There is no "best material," but there is only the "most suitable option." Titanium alloys are at the forefront in terms of strength-to-weight ratio, biocompatibility, and corrosion resistance, while steel is at the forefront with regard to sheer strength, hardness, and cost. The final choice is contingent upon an unambiguous realization of the priority of the intended use.

If you are unsure what material to apply for your application, contact LS Precision Materials technical staff. We will provide a free, custom material selection consultation, specifying the optimum material solution and providing a competitive quote on your application, performance requirements, and budget. LS Precison will utilize our experience to act on your behalf and make the best decision. Contact our technical consultants for individualized service!

Upload your design drawings now and get an instant sheet metal fabrication quote (sheet metal fabrication price), let LS be your strong backing in pursuit of ultimate sheet metal fabrication precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com