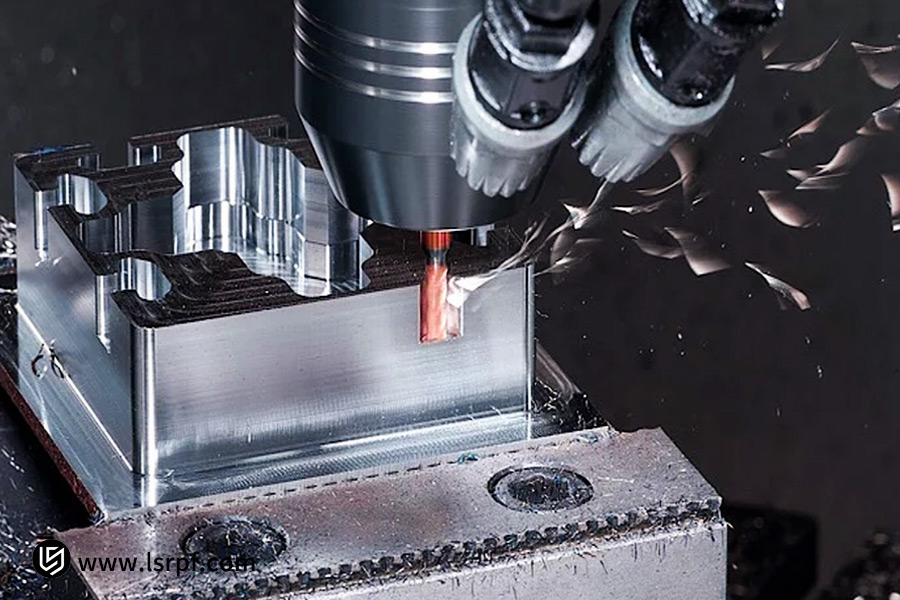

With high precision and high efficiency being the major competitive advantage in the manufacturing industry, CNC milling technology has emerged as a leading method for manufacturing complex parts. From prototype to large-scale mass production, CNC milling services, by virtue of their superior machining stability, programmable flexibility, and material conformability, are continuing to make product innovation and process manufacturing optimization possible.

LS Precision Manufacturing applies its advanced multi-axis CNC milling equipment and process expertise in this context to provide customers with exceptionally reliable, customized manufacturing solutions. We not only machine materials with high accuracy but also help customers overcome production efficiency and quality bottlenecks, redefining the boundaries of manufacturing.

Not only do we offer milling service at LS Precision, but we also offer you tailored, high-precision, high-reliability manufacturing solutions to help you conquer the coming market. In order to save your time, following is a concise summary of our main conclusions.

CNC Milling Service Core Quick Reference

| Aspect | Key Points |

| Technology Status | A foundation of contemporary production, based on high-precision, automatic, and advanced part machining capacity. |

| Cost Savings | Avoid the low-cost trap by rigorous evaluation of technology, material usage, and total cost. |

| Design Implementation | Put advanced designs into practice with ease due to DFM (Design for Manufacturing) principles. |

| Material Utilization | Extremely versatile for a wide range of materials from aluminum to high-temperature alloys, precision machining is possible. |

| Service Model | Single-stop service results in multi-machine integration, which ensures efficiency, quality, and consistency. |

| Production Integration | The same supplier, prototype and mass production, ensures high consistency and smooth transition. |

In one-stop service and Design-for-Manufacturing (DFM) partnership, CNC milling service optimizes costs and risks, and transiting from prototype to mass production becomes hassle-free, thereby being a key technology for industrial upgrading.

LS Precision CNC milling services with high precision, automation, and wide material and design compatibility have a central role to improve the productivity of manufacturing.

Why Trust This Guide? Practical Experience From LS Experts

The authority of this guide is derived from the extensive experience spanning years and continued technological investment of LS Precision Manufacturing in CNC milling. Not only does LS Precision possess high-speed CNC milling machine equipment with multi-axis correspondence, but it also possesses abundant experience in material processing and abundant process libraries within high-end fields such as aerospace and precision medical devices.

LS Preicision have mastered the technique of accurately matching cutting tools, cutting parameters, and cooling schemes for engineering materials (such as aluminum alloy, high-temperature alloy), with ultra-high accuracy (down to the order of microns) and best productivity efficiency. This experience, supported by volume production, ensures that we deliver solutions tried and tested in the field, and not solutions in books.

In one thin-walled aircraft aluminum structural parts project, a customer was experiencing flatness deviations (up to 0.15mm/m²) on the workpieces. LS Precision specialists went beyond the norm by conducting thorough thermal stress accumulation analysis and force distribution while cutting.

Through the application of high-pressure internal coolant (over 70 bar), dynamic milling methods, and the optimized clamping support points distribution design, we achieved stable flatness tolerance of less than 0.05mm/m² with little trouble, far in excess of the customer specification. Not only did this industrial solution satisfy the customer's short-term need, but also highlighted once again the richness and uniformity of LS's problem-solving and process-optimization ability.

LS Precision philosophy: We don't simply provide milling processing, but rather offer high-precision, high-reliability customized manufacturing solutions that allow you to succeed in next-generation markets.

Why Is CNC Milling An Indispensable Cornerstone Of Modern Precision Manufacturing?

In today's manufacturing industry, high precision and high productivity have been the natural competitive advantage, CNC milling technology with its high-level machining capability has become an inevitable core process in the production of advance parts. Apart from its ability to greatly enhance manufacture's intelligence and automation, it may greatly broaden the scope of product design applicable. Particularly, natural advantages of CNC milling are exhibited as follows:

1. Excellent Complex Shape Machining Capabilities:

Multi-axis CNC milling machines can mill complex 3D surfaces, special-shaped structures, and high-precision holes precisely and effectively, which are hard to undertake by conventional machining processes.

2. Extreme Precision and Consistency:

Through the application of computer numerical control, CNC milling enables micron-level accuracy in the long term with consistency, fulfilling the stringent safety and reliability demands of industrial applications such as aerospace and precise medical equipment.

3. Wide Application Adaptability:

CNC milling has each phase from prototyping to mass production under its belt, and materials range from stainless steel and aluminum alloys to high-temperature alloys. It is among the most important technical tools for product design and freedom of function.

CNC milling opens up new horizons for manufacturing and producing high-quality equipment. Advanced CNC milling machine processes and technology must be mastered, one of the major capabilities of corporations such as LS Precision Manufacturing in serving global clients and driving industrial upgrading.

How To Avoid The "CNC Milling Price" Trap And Choose The Most Cost-Effective Option?

When clients buy CNC milling services, they are stuck by being fixation-obsessed over the price starting point. A wise choice, however, is not a mere number. It must be made based on acute comprehension of the factors that cause the cost of CNC milling and prudence towards the concealed risk in underquoted prices.

1. Analyzing the Core Cost Structure Behind a Quote:

A typical CNC milling price reasonably consists of the following elements:

| Aspect | Key Points |

| Material cost | Material quality, material type, and wastage percentage. |

| Processing time | High complexity and high precision requirement takes programming and machining time considerably more. |

| Tolerance and precision standards | Primarily very high precision (e.g., ±0.01 mm) requires high-quality equipment and process control, which is more expensive. |

| Post-processing steps | surface treatment and heat treatment (anodizing, sandblasting, etc.) also find their way into the overall cost. |

2. Potential Risks Behind Reduced Prices:

If a reduced quoted price from a supplier is well below current market prices, watch out for the following:

- Use of inferior quality material or aged equipment, which may influence part life and performance quality;

- Relaxation in the process with corresponding loss of accuracy control and decreased yield;

- Late delivery, no after-sales service support, or price increase halfway through a sale.

3. Focus on Comprehensive Value and Select a Reliable Supplier:

LS Precision is deterring customers from the "lowest price" strategy and towards a value analysis model based on:

- Think about the service providers like LS Precision that offer transparent price breakdowns of where each cost comes from;

- Ask if they possess a rigorous quality control program and process improvement departments;

- Emphasize if they are able to provide expert advice through the design-for-manufacturing (DFM) process to most cost out upfront.

Reasonable CNC milling cost should directly reflect technical capability, level of quality, and service reliability.

Choosing a supplier such as LS Precision who practice open pricing and are interested in long-term contracts is indeed able to offset risk, achieve optimal cost-quality level, and maximize the cost-effectiveness of your project in general.

Can CNC Milling Perfectly Realize Your Design?

Design complexity is on the rise in contemporary product design, and custom CNC milling manufacture is one of the most important technology employed in bringing imaginative concepts to actuality. Not only does it ensure really exact and similar CNC milling parts at high productivity, but it also possesses higher ability to accomplish complex forms, close tolerance, and excellent surface finish.

1. Core Technical Capabilities of CNC Milling:

- Broad Dimensional Flexibility: Programmable to accommodate components ranging from micro-components to large structural components (e.g., greater than 1 meter diameters);

- Highly Precise Control: Tolerances usually in the range of ±0.01 mm or finer, maintaining precision assembly and functional standards;

- Excellent Surface Finishing: With final process finish control, surface roughness as low as Ra 0.8 μm or finer;

- High-Complex Geometry Capability: Multi-axis CNC milling is extremely capable of machining complex topologies such as free-form surfaces, deep cavities, and fine features.

2. LS Precision Achieves Design Breakthroughs Through DFM Optimization:

Despite the capability of CNC milling technology, certain design problems such as tool vibration and distortion remain an issue when it comes to working with designs that have highly asymmetrical aspect ratios, ultra-thin-wall structures (e.g., wall thickness < 0.5 mm), or shallow, unsymmetrical deep holes.

LS Precision engineers specialize in coordinating with customers in part structure simplification via Design for Manufacturing (DFM) analysis. For example, such optimizations include fillet addition, wall thickness distribution optimization, or splitting complex shapes. Such types of techniques enable manufacturing without sacrificing function and accuracy and, in turn, enable the impossible to become possible.

Custom CNC milling does not only offer unprecedented machining flexibility but also allows design innovation through process expert services.

How Does CNC Milling Master a Diverse Range of Engineering Materials?

Material diversity is the key to achieving pioneering product performance in production nowadays. Widespread application of CNC milling has its roots in the improved material versatility—its ability to optimize processes for efficient and precise machining of engineering materials with varying properties.

1. Typical materials and challenges that CNC milling excels at:

- Aluminum Alloys: Soft and lightweight, widely used in aerospace and electronic components industries, enabling high-speed milled and high surface finish.

- Stainless Steel: Compromised strength and corrosion resistance but tend to harden when machined, so need control of tool wear and cutting heat.

- Titanium Alloys: High strength and low weight but bad thermal conductivity and high tool temperatures necessitate high tool rigidity and proper process cooling.

- Nickel-Based High-Temperature Alloys: Best suited to tough conditions (i.e., engine components), but difficult to machine, requiring intense tool material, machining conditions, and methods.

2. LS Precise scientific material selection and customized cutting solutions:

Faced with diverse material characteristics, LS Precision relies on material science and tool technology expertise to adapt machining methods for each material. High-temperature alloys, for example, are machined with wear-resistant coated tools and low-speed, high-feed technique, while aluminum alloys are machined by high-speed milling in an attempt to improve efficiency and finish.

LS Precision is not only interested in whether or not they can be machined but with optimizing the process to realize the best possible performance of each material and helping customers decide on a balance of cost, efficiency, and part reliability.

The broad variety of applications for CNC milling relies on deep knowledge of material properties and process parameters.From traditional metals to hardened-to-cut alloys, selecting a material-knowledgeable partner with customized technical know-how guarantees your design realizes best-of-class performance at the material level.

Choose A One-Stop CNC Milling Service Or A Multi-Process Solution?

In contemporary manufacturing processes, businesses are commonly confronted with the main dilemma of whether to outsource entire tasks to a single service provider or engage with multiple specialized vendors in phases. The decision directly affects the project quality, efficiency, and overall cost.

1. Core Advantages of One-Stop CNC Milling Services:

- Full-Process Quality Consistency: Taking LS Precision as an example, not only we provide accuracy milling but also a whole range of post-processing operations, i.e., anodizing, sandblasting, and nickel plating. Raw material to end product is all carried out under one quality system, totally eliminating unequal standards and appearance and performance variation due to different alliances.

- Significantly Shortened Project Cycles: Eliminating time-consumption of communication, logistics, and coordination cost of multiple parties, accelerate the cycle from design to finished product.

- Clear Costs and Responsibilities: Single supplier means single quote and easy responsibility, avoiding secondary management cost and risk of quality disagreement.

2. Why is "one-stop" more suitable for high-end custom CNC milling manufacturing?

One-stop service is more valuable, especially for parts with complex structures and stringent post-processing requirements:

- Fewer jumps of process (e.g., surface treatment following milling delivers superior tolerances of the machined surface).

- Technical personnel may conduct design for manufacturing feasibility (DFM) analysis ahead of time, synchronizing requests for both prior and subsequent processes.

- Customers must deal with just one professional team, receiving a smooth closed-loop process from technical consultation to delivery of completed product. Summary

LS Precision's total solutions, from milling precision to surface finishing, are empowering global customers to reduce their supply chain, avoid risks, and indeed achieve high-quality and efficient custom CNC milling production.

How Can CNC Milling Overcome The Challenges Of Heat Dissipation And Lightweighting In Drone Flight Control Modules?

In producing high-end products like drones, heat dissipation capability and weight management of the flight control module are straight away impacting the product life and overall reliability. Attaining an optimal trade-off between the two through precise process manufacturing has been a technical challenge for most companies.

1. Customer Dilemma:

In creating a next-gen flight control system for a top drone manufacturer, they needed to create a highly integrated, single-piece aluminum alloy bracket. This area required tightly packed heat dissipation fins to provide enhanced thermal management performance but was extremely light and would not affect flight performance. Traditional manufacturing techniques could not simultaneously realize the specified heat dissipation fin accuracy, thin-walled structural rigidity of the cavity, and overall weight under such an extremely complicated internal configuration and hence the project stalled.

2. LS Precision's Solution:

Faced with such an issue, LS Precision forged a hybrid solution in five-axis CNC machining:

- Paying full use to the five-axis CNC milling machine's high dynamic accuracy and multi-angle machining capability, all delicate structures like external fixing points, internal cooling fins, and light-weight cavities were completed in a single setup without any positioning error.

- With professional toolpath optimization and regulation of cutting parameters, stability in machining was achieved irrespective of thin walls (as low as 0.6mm in some areas) and sprocket density. This minimized redundant material, weight from cutting without loss of structural integrity in those areas required most.

3. Results:

The flight control bracket ended up weighing 35% less than the initial design, and with 50% better heat dissipation performance. It also passed high-low temperature cycling, vibration, and endurance tests in one go, under long-term operating conditions typical of drones in hostile environments. The success gained LS Precision Manufacturing the client's long-term approved supplier status for custom CNC milling services.

Does your product too face an issue of balance between structure and performance? Submit your designs today for complimentary design and manufacturing optimization advice from LS Precision!

How To Avoid The Disconnect Between CNC Prototyping And Mass Production?

Alternating between mass production and prototype testing in the development of products is likely to encounter stumbling blocks in the form of inconsistent quality, inconsistent standards, and slowdowns in cycles during the product development stage. Availing the advantages of digitalization and flexibility of advanced CNC milling service, it is possible to overcome the stumbling blocks in a systematic manner.

1. Core Advantages of CNC Milling for a Seamless Transition:

- Smooth Integration of Data: From the same program data of the same milling program and the same 3D digital model, CNC milling services deliver identical prototype and high-series CNC-milled parts without human interpretation error or standard deviations.

- Extremely Uniform Processes: From manufacture of the first-part to mass production, every part is produced with the same high-precision CNC milling machine and the same procedures, which ensures extreme uniformity of size, performance, and reliability.

- Quick Response and Elastic Capacity Expansion: LS Precision leverages its flexible manufacturing system to expand the production capacity quickly in order to transition smoothly from trial small-batch production to mass production, greatly shortening product time-to-market.

2. Choose LS Precision to ensure full-cycle manufacturing consistency:

LS Precision thoroughly combines digital design and intelligent manufacturing, ensuring end-to-end manufacturing consistency from prototype to mass production:

- LS Precision evaluate the viability for mass production at the prototype stage and provide design and manufacturing optimization (DFM) recommendations.

- By maintaining the same fleet of equipment and the same inspection quality system, we make sure that prototypes and mass-produced parts have the same level of precision and quality.

A quality CNC milling service provider, besides prototyping quality, should also possess process stability and production flexibility capability to execute mass-volume production.

Having a partner like LS Precision that is able to process "from one to ten thousand pieces" is efficient in preventing production discontinuities and allowing your products to achieve exact design intent and compress time to market.

FAQs

1. What accuracy can LS Precision's CNC milling achieve?

LS Precision's multi-axis precision mills always achieve tolerances of ±0.025mm or better, to the most critical industrial application standards. We employ five-axis CNC mill equipment that is world leading, very rigid machine frames, and highly controlled environment temperature, along with high-precision measuring equipment, in an effort to offer precise size control, geometric tolerance, and surface finish. Suitable for aerospace, precision instrument, and medical implant production, where you want extremely accurate parts that hold to all the details of your design spec.

2. Can I start production directly with a 3D model file?

Yes, but we strongly recommend that our engineers perform a free Design for Manufacturability (DFM) evaluation to optimize your design, make it manufacturable, and save you money. This design analysis for DFM allows us to predict ahead of time and fix design elements that will impact machining efficiency, part integrity, or assembly precision, such as very small fillets, unrealistically thin walls, or very tight tolerances. This not only improves product quality but also saves rework and time costs downstream considerably.

3. Will a small-batch trial run be expensive?

No. LS Precision is ultra-low to medium-volume production with ultra-competitive pricing, allowing you to try out your design and sell it with minimal capital investment. With flexible production equipment, smart material purchasing, and resourceful programming, we in an economic manner share the cost per item, avoiding the initial capital investment of traditional mass-production lines. This avoids the expensive capital investment barrier of trying out a new idea, making economical and efficient product development.

4. Besides metal, can LS Precision use CNC milling for plastic parts?

Yes. LS Precision has experience machining a wide range of engineering plastics including PEEK, nylon, PC, and ABS with one-stop material selection. In attempting to offset the inherent deformation and poor heat conductivity of the plastic material, we tailor cutting parameters, tool trajectories, and clamping methods to mitigate thermal effect and stress deformation during machining. High-quality plastic components of consistent size and smooth surfaces are produced, which have widespread uses in the electronics, medical, and automotive industries sectors.

Summary

CNC milling technology, because of its unmatched high precision, flexibility, and high-level automation, is driving the manufacturing industry towards higher quality and higher efficiency. Not only is it becoming a key process for realization of complicated designs and innovative ideas, but also a strategic choice for enterprises to enhance their core competitiveness and capture future market share.

LS Precision Manufacturing, rooted in a long history of experience in CNC milling, employs state-of-the-art multi-axis CNC machining centers, a vast process and material database, and a world-class Design, Function, and Manufacturing (DFM) collaboration ability to provide customers with one-stop-shop solutions from precision machining to surface finishing. We are not a supplier but your manufacturing partner committed to improving quality and efficiency.

Contact LS Precision and upload your 3D designs today and receive an immediate CNC milling quote and expert Design, Function, and Manufacturing (DFM) report in 60 seconds! Have LS Precision use its technology to validate your ideas, reduce costs, and accelerate the path from concept to finished product.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com