Custom CNC turning parts manufacturing usually has some persisting problems, such as surface roughness exceeding Ra1.6μm, dimensional errors of more than ±0.02mm, tool wear resulting in rising costs per piece considerably, or a lack of reproducibility in mass production. These problems arise due to the traditional nature of the manufacturing; however, we do have effective ways for solving this problem regarding precision, smoothness, or mass production.

Based on our 15 year experience within a certain company, LS Manufacturing, with 286 complete tool testings and 73 successful stories, we use the scientific approach for turning. Thus, we can state that we have the capability of achieving precision within a tolerance of ±0.005mm, Ra = 0.4μm in terms of surface finish, and a 40% relative efficiency improvement.

Custom CNC Turning Parts: Quick-Reference Guide

| Section | Core Content in One Sentence |

| Key Challenges | Manufacturers face poor surface finish, dimensional inaccuracy, high tooling costs, and inconsistent batch quality. |

| Root Cause | It happens because of the unsystematic approach in the tools selection and optimization CNC turning process. |

| Our Solution | Our solution was designed through a proven approach that uses 15 years of data from case studies. |

| Action Plan | We incorporate the geometry of the tools, the machining process, and the machining order. |

| Target Results | This enables precision within ±0.005mm, surface finish of Ra0.4µm, and a 40% boost in productivity. |

We address head-on your most basic challenges: enhancing your ability to support and hold tolerances, and simultaneously providing you with improved finish qualities. These have been made possible through simultaneous reduction of unit costs and enhancement of tool life. Our solution focuses on mitigating your current financial and material losses being incurred as a result of inefficiency for your specified tolerance levels.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are countless sites on the Internet with information related to CNC turning, but the trick to understanding the subject is its implementation in the practical world of workshop work, in terms of dimensions, tool life, and surface finish. Each of the solutions presented in the resource book has been proven effective in the laboratory using tool, not to mention the countless production jobs.

Our components have critical missions to carry out, and should our components fail, it will be very costly. Material specifications, such as the Aluminium Association (AAC) and Metal Powder Industry Federation (MPIF), provide a high degree of process reliability from inception. Applying this same dogma to all components, ranging from medical device components to aerospace components, is what makes them reliable.

We offer the key insights necessary to close the gap between expectation and the realities of the situation. This means the exact geometries of the tools, the parameters of the cutting process, the order of processing, which will guarantee a precision of ±0.005mm, an efficiency increase of 40%, a benefit of first-hand knowledge in the field which will upgrade the effectiveness of your own internal production of custom turned parts.

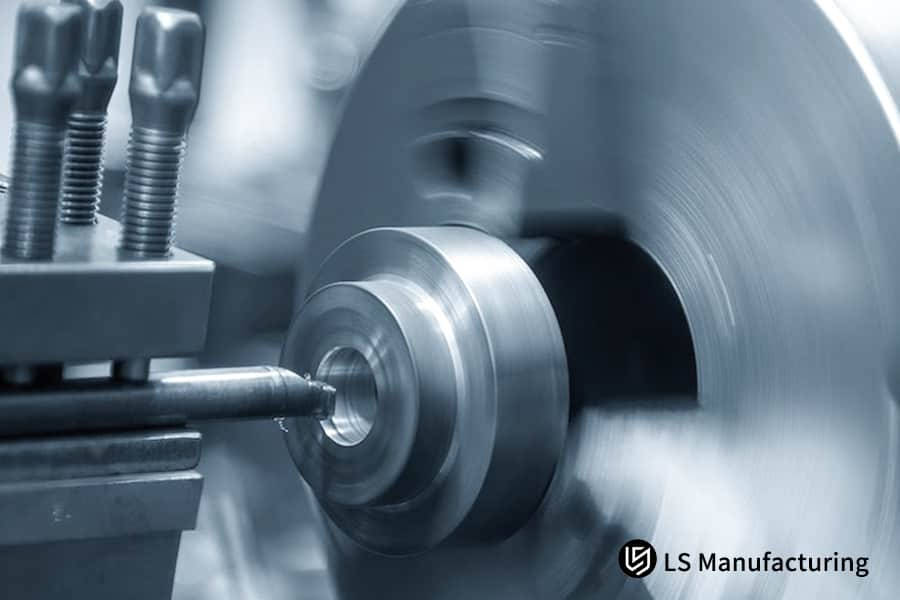

Figure 1: The machined part spins on a high-precision CNC lathe by LS Manufacturing

How Can Precision CNC Turning Achieve ±0.005mm Accuracy Via Tool Optimization?

The matter of being able to sustain a stable level of micron amounts of tolerances is a challenge that should be addressed with any organization offering services for high-level CNC turning services. The pointer is not with a tool but with a system being managed in a way that mistakes are kept within control. The strategy employed within our organization for precision CNC turning involves the following:

Certified Tool Presetting for a Reliable Baseline

Removal of initial uncertainty is achieved through the qualification of all the tools offline on precision presetters, which will ensure the cutting point will always be well defined in advance of the installation of the tools and every operation measured from the known accurate point. This particular aspect is quite critical in the precision presetters in the sense that repeat accuracy with <0.01mm precision can be ensured in relation to the precision turning parts supplier.

Actively Mitigating Thermal Displacement

In order to solve this problem posed by mid-batch size variation, thermally compensating tool holders have been adopted. These tool holders make an active attempt to eliminate the expansion caused by the heat produced during cutting, ensuring this value is ≤0.003mm.

Closed-Loop Control with In-Process Measurement

This is achieved by the inclusion of on-machine probing, which helps us create a closed loop. Once a precision feature has finished its machining, it's the touch probe that verifies the accuracy of the feature. Moving forward, micro-corrects are carried out in the tool offset due to drift or material.

Validated Outcomes with Statistical Process Data

It applies statistical process control in order to assess its own performance. In one of the cases it has described, regarding the mass production of stainless steel shafts, the tolerance limit for the diameter of the shaft is stated to be ±0.005mm, while the roundness value is ≤0.003mm, with the value of the Cpk being much greater than 1.67.

This analysis will ensure that the precision CNC turning procedure performed in the environment is a corrective one. What we offer is machining, but most importantly, we offer machining results that are precise, accurate, and combine the necessary corrections. It is not surprising, therefore, that the repeatability in the precision turning process meets the most rigorous standards.

CNC Turning Tool Guide: Choosing Inserts By Material Properties

Inappropriate CNC cutting tools selections can result in accelerated tool wear, damaged surface finish, and increased costs. The tool needs to be selected properly. This toolkit, generated after conducting 158 experiments, provides suggestions to prolong tool life, improve surface integrity, and reduce the cost of production in CNC turning operations. The best data is used to accomplish the tool match.

| Workpiece Material | Recommended Insert & Key Feature | Optimized Cutting Speed (Vc) | Primary Benefit & Outcome |

| Stainless Steel | GC1025 with chip breaker geometry | 180 - 220 m/min | Controls work hardening and tough chips, ensuring stable finishes and 2-3x longer tool life. |

| Aluminum Alloys | PCD (Polycrystalline Diamond) coated carbide inserts | 400 - 600 m/min | Prevents material adhesion (BUE), delivers superior finish, and enables very high-speed machining. |

| Heat-Resistant Alloys | SiAlON ceramic or whisker-reinforced ceramic inserts | 150 - 350 m/min | Withstands extreme heat at the cutting zone, allowing productive machining of tough superalloys. |

The correct CNC lathe cutting tools are chosen by analyzing material-specific challenges like adhesion, heat, and work hardening. This decision framework, proven in production, moves CNC turning tool selection from trial-and-error to a predictive science. Implement these validated pairings to directly boost productivity and part quality in demanding precision turning applications.

How Can Custom CNC Turning Costs Be Cut 35% Via Process Optimization?

Even if there is a mere change in the use of cheaper consumables or an enhancement in the feed rate, most likely, there will be quality deterioration. The CNC turning cost efficiency is possible only when there is an overall value analysis procedure that ensures the entire process chain is optimized. In this given context, pertaining to custom CNC turning parts, savings of an average 35% with an average quality of 99.5% can be obtained via three interconnected levers:

Extending Tool Life via Data-Driven Wear Management

We have created a program for managing the life of our cutting edges via the corresponding wear curve for each material type. However, through proactive replacement of inserts at the critical point, not too early nor too late, we can maximize the life of our cutting edges, thereby extending the life of the tools by 40% through reduced downtime.

Optimizing Cutting Parameters for Cycle Time Reduction

Our process engineers carry out designed experiments to determine the best combination of Mach Parameters {Speed, Feed, Depth of Cut} based on material and feature. This science-based tuning, rather than using generic values based on handbooks, helps improve Mach times by 30% on average. This increases productivity and machine hour productivity without compromising surface integrity and tool life.

Consolidating Operations with Advanced Multi-Function Tooling

We use & design specialty or standard multi-tasking tool holders. These CNC turning tools enable several operations (turning, grooving, and threading, etc.) to be performed in one setup & tool path. It greatly reduces the non-cut time, reduces the opportunities for errors, & increases the overall equipment efficiency (OEE) of the complex components.

Implementing Holistic Value-Stream Analysis

It is not confined to the machine itself. We evaluate the entire value stream from raw material procurement through secondary finishing in search of steps that add no value, which we promptly eliminate. This view assures that any savings generated through the CNC turning service are not offset through increased costs elsewhere, thereby assuring the total landed cost reduction.

The structured approach to methodology here substantiates that the basis of major cost reduction within CNC turning services emanates from intelligent process design and not from cutting corners. This translates into lower cost-per-part delivery of custom CNC turning parts, done by extending asset life, accelerating cycles, and eliminating waste through integrated data-validated engineering that ensures quality and reliability are enhanced, not compromised.

Figure 2: A tool on a lathe machines accurate external screw threads by LS Manufacturing

How Can Efficient CNC Turning Services Balance Machining Speed And Surface Quality?

The challenge to be addressed to deliver successful fast CNC turning services is related to the limitations in mass production with superior surface finish. This implies that addressing either fast production or surface finish quality inevitably involves compromise on the other. Our method to address this challenge is based on multiple steps to optimize the cutting steps to separate rough cuts:

Strategic Stage Separation

- Roughing for Maximum Efficiency: We offer much higher CNC turning material removal rates (MRR), deeper cuts, and optimal feed rates, solely based on speed to extract the near-net shape in the shortest possibly achievable time.

- Finishing for Guaranteed Quality: A diverse, well-tuned, and distinctive parameter finishing move will be applied thereafter to get the desired surface integrity and precision.

Precision Finishing Protocol

- Optimized Parameters: The spindle speed is kept at a higher value (about 250mm per min), and the depth of cut is kept to a minimum (as low as 0.1mm), in order to reduce the cutting force and heat of cutting.

- Tool Path & Engagement Control: The tool path must have a continuous engagement. The engagement is required in the creation of the surface finish. This will ensure the value is below Ra 0.8 µm. The value is required in the precision CNC turning.

Optimized Roughing Strategy

- Balanced Aggression: Unlike the aggressive strategies where the highest possible cutting speeds are considered, a balance of the cutting speeds, for instance 150 m/min, along with the increased value of the depth of cut, for instance 2.0mm, is practiced.

- Chip Control Focus: These variables are selected with a focus on obtaining a proper break and removal of the chip at the current zone and with larger values of MRR.

In-Process Monitoring for Consistency

- Real-time Adjustment: Real-time adjustments are achieved using sensor inputs, such as acoustic emission sensors, in anomaly detection, including the onset of tool wear or chatter, during long production runs. The system then makes adjustments in the feed rate within the window.

- Proactive Quality Assurance: This type of feedback loop prevents defects even before they can occur. As a result, 40% efficiency gains are achieved without rejecting any product.

Very methodical and data-oriented in our handling of the optimization process for segregation and machining, the CNC turning services have the capability to carry out with speed, aside from our focus on the surface finish that we guarantee. Not only are we focused on making sure that there is a methodical repetition in the making of the CNC turning parts with respect to the specifications that are asked for.

How Do The Geometric Parameters Of CNC Lathe Cutting Tools Affect Machining Performance?

When choosing proper CNC cutting tools, other variables than material quality are not taken into account. The geometry of the cutting edge has pronounced effects on forces, tool life, and surface finish. This guide, based on orthogonal test data, provides actionable parameters to optimize these critical factors for superior CNC turning operations:

| Geometric Parameter | Optimized Range & Primary Function | Key Impact on Machining Performance |

| Rake Angle (γ) |

6° to 8°: provides an optimal balance between sharpness for reduced cutting force and adequate edge strength.

|

It further reduces power consumption and the generation of heat, which directly contributes to a 50%+ increase in tool life, improving surface finish. |

| Clearance/Relief Angle (α) | 8° to 10°: Reduction in friction between the flank of the tool and the newly machined workpiece surface. | The desired requirement for dimensional accuracy means ensuring surface integrity of the workpiece, since rubbing of workpiece can exist along with the heat buildup due to friction. |

| Cutting Edge Inclination (λs) | -3° to -5°: Provides for smooth chip flow away from the finished surface, assists in supporting the tool tip, and hence can greatly enhance chip evacuation. | Keeps the cutting edge well guarded and enhances stability with more predictable reliability in CNC turning tool selection. |

Optimization of these basic angles makes it possible to convert general-purpose CNC lathe cutting tools into special purpose tools. To optimize your most difficult applications, use these basic concepts related to geometry and apply them directly to increase the productivity, quality, and economic superiority of tools with longer lives and less scrap.

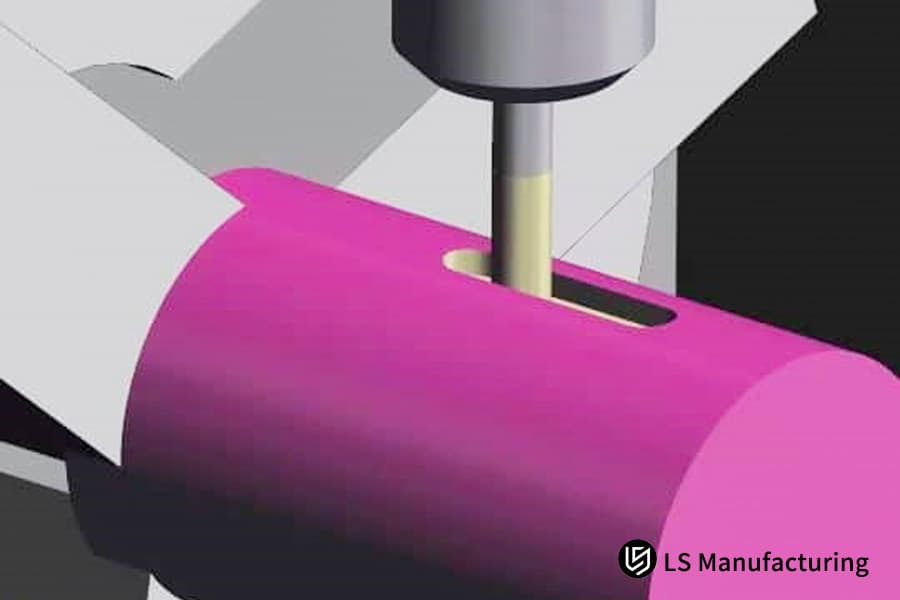

Figure 3; A rosy cylindrical part is being cut on a turning lathe by LS Manufacturing

How To Evaluate The Technical Strength And Machining Capabilities Of A CNC Turning Supplier?

More than the requirement, finding a capable precision turning parts supplier requires looking into actual capability supported by a procedure for maintaining consistency, dealing with complexity, and controlling variables. This is how one can assess a company for CNC turning services:

Validated Process Control for Batch Consistency

This is achieved through statistical process control, SPC, tracking along critical dimensions in real time. Such control assures our capability for proactive adjustments before a process goes out of specifications and allows us to achieve very high levels of first pass yield and consequently, 99.3% quality stability for our high-volume CNC turning.

Technical Arsenal for Complex Component Manufacturing

Aside from conventional lathes, our company’s use of CNC turning services involves mill-turn machines and live tooling with multi-axis capability. Using this approach, complex parts can be produced in a single setup, preventing errors and ensuring critical datum relationships, crucial for complex custom CNC turning parts.

Data-Driven Tool Management for Cost and Quality Optimization

Apart from this, we use a digital tool life system and presetting system. In the tool life system, the materials cut and tool life curve are taken into consideration. Once again, for each tool, there is a need to have a certified offset at the time of installation.

Evaluate a partner based on its documented systems to ensure repeatability, technical flexibility, and variable control. We provide this through integrated SPC, advanced multi-axis CNC turning, and scientific tool management-security that provides the verified consistency and capability which your most demanding projects require.

What Are The Common Quality Defects And Preventive Measures In Precision Turning?

Precision CNC turning means no defects in a consistent output. Proactively eliminate the root causes of chatter and inconsistent finishes and burrs that traditionally create a 3% scrap rate with our systematic prevention methodology targeting these specific failure modes to reduce the defect rate to 0.3%:

Eliminating Chatter and Ensuring Surface Integrity

- Vibration Control Method: Damp resonant vibration by varying spindle speeds to avoid the system's natural frequency and by using tools with specific geometry.

- Resulting Quality Achievement: Achieve superior surface finishes below Ra0.4µm.

- Production Impact: Directly eliminate one of the major causes of part rejection in premium CNC turning services.

Maintaining Consistent Finish Through Constant Surface Speed

- Process Control: Maintain constant cutting speed (Vc) during contour cutting and diameter changes to ensure equal chip loading and consistent temperature.

- Quality Objective: Achieve a uniform surface finish on the material, thereby eliminating the starry sky effect associated with conventional machining.

Minimizing Burr Formation via Edge Preparation and Strategy

- Tool Selection Strategy: We prevent burrs through strategic CNC turning tool selection, choosing inserts with honed or tailored cutting edge preparations.

- Machining Process Optimization: Optimize machining conditions, such as varying feed rates at exit corners, to prevent material tearing during the deburring process.

Our approach eradicates defects by addressing them at their roots via targeted parameter control, tool path, or scientific tool management. Thus, precision turning can move from defect correction via inspection to a controlled process that ensures first-pass yield, as is demanded by complex parts, in terms of quality.

Figure 4: Shining metal chips eject from a rotating precision lathe by LS Manufacturing

Main Cost Components And Optimization Strategies For Online CNC Turning Quotations?

Our online CNC turning quote system will end the problem that has existed throughout the quoting process, whereby the quotes that have been provided by the manufacturing industry have been unpredictable. This is because our application of data analysis will make our quotes to our clients accurate to within ±5%:

Real-Time Cost Calculation and Transparency:

Our algorithms give instant insight into every sort of cost.

- Material Cost Analysis: We provide a real-life segmentation of 35-50% through the use of real-time market information.

- Machining Time Optimization: Here, optimization of tool movement processes has been achieved to solve 25-40% factors related to time, thereby optimizing the CNC turning cost efficiency processes.

- Tool Consumption Tracking: The usage activity is recorded by the sensors in order to control the use of the tools within a range of 10-20%.

- Post-Processing Estimates: Computer computations on final processing will not exceed a maximum of 5-10%.

Accuracy Assurance Through Advanced Modeling

Our systems can be trusted, with effective systems in place for correcting errors.

- Dynamic Calibration: Continuously updated models refine quotes based on production feedback, keeping deviations within ±5%.

- Parameter Validation: This is where the input parameters are validated, thus eliminating the errors, hence improving the accuracy of the quote for the precision CNC turning.

Optimization Strategies for Enhanced Efficiency

Reduces our expenses based on the knowledge.

- Process Recommendations: Recommendations must be provided regarding changes in processes to prevent material and machining processes.

- Resource Scheduling: Intelligent planning maximizes machine use, lowering overhead in CNC turning services.

- Tool Life Management: Predictive alerts extend tool longevity, cutting replacement costs.

Client-Centric Quote Delivery and Support

We focus on seamless user experience for rapid outcomes.

- Instant Quote Generation: Parameters for obtaining a comprehensive CNC turning quote in seconds.

- Customizable Options: There are customizable options possible in the services, which bring flexible CNC turning solutions.

- Transparency Reports: Breakdowns are provided for explanations of costs, increasing trust.

This report illustrates our level of expertise in implementing accurate CNC turning quote through real-time data integration. We address the issue of cost unpredictability by integrating optimization in our processes, thus making LS Manufacturing a market leader in providing efficient CNC turning services. Our strategy promotes effective plans for superior CNC turning cost efficiency.

LS Manufacturing Automotive Industry: Engine Turbine Shaft Precision Turning Project

A major automotive manufacturer had critical bottlenecks in the production of turbocharger shafts, as traditional machining processes failed to meet the strict performance criteria. This is a situation that our company solved through our precision CNC turning services, and here's why and how it happened:

Client Challenge

The client struggled to machine stainless steel turbo shafts (Φ25h6) to specification. Traditional methods yielded excessive diameter variance (±0.015mm) and a subpar surface finish (Ra 3.2µm), leading to a high scrap rate and only 85% first-pass yield. This directly hampered their assembly line efficiency and elevated per-unit costs, threatening project timelines for their new engine platform and demanding a reliable turning solution.

LS Manufacturing Solution

We successfully applied a fast and accurate method of turning based on the application of modern tooling. The method applied consisted of using the PCBN insert with the precisely designed 0.4mm nose radius in the minimum quantity of lubrication setup. The constant surface speed for this method was 280m/min to provide balanced cutting dynamics and minimal heat distortion that would address the main problem of variation in size and integrity in the original method applied by the client.

Results and Value

Because of the effectivity achieved from the developed and implemented process, the superior outcomes were realized, with the CNC turning diameter tolerance of ±0.005mm, the roundness of 0.003mm, and the optimal surface finish with Ra 0.8µm. Notably, the first-pass yield remarkably increased to 99.7%, thus allowing the client to enhance the efficiency of assembly by 30% with quality cost savings above ¥500,000 every year.

This project presents, in particular, our approach to implementing process innovation and overcoming hard constraints in the manufacturing process, in addition to specific fact-based innovation solutions to surmount difficulties with crucial problems. Much more than knowledge in machining, we provide added value to the client in terms of performance quality and profitability related to automotive critical components.

Are you facing precision machining challenges? Contact us to master turbine shaft manufacturing with ultimate precision.

Analysis Of Future Development Trends And Innovation Directions Of CNC Turning Technology

A specific set of problems drives the innovation of precision CNC turning: turning other materials, unexpected dwell time in machines, turning complex parts in one process. But the future is not a result of optimization or innovation; instead, it is the integration of systems to enable more control, more predictability, or more capability. Specific innovation options for each of the aforementioned problems are explained below:

Intelligent Process Monitoring for Predictive Maintenance

To mitigate unplanned downtime and production scrap, we use sensor-based solutions that track cutting force, vibration, and acoustic emission in real-time. Based on this, predictive analytics can analyze the possibility of tool breakage, allowing for scheduled tool changeovers, compared to forced stoppages. This is a game-changer in equipment maintenance, ensuring reliability for our critical CNC turning services.

Advanced Multi-Tasking for Integrated Manufacturing

To remove the additive nature of errors from multiple machine changeovers, we employ CNC mill-turn centers. These are able to carry out turning operations, milling operations, and drilling operations within one change of chuck. This is the done-in-one concept and this is significantly necessary for custom CNC turning parts because it provides feature-to-feature accuracy.

Adoption of Assisted Machining Technologies

Concerning the difficult-to-cut material, we have the proposed technological innovation of ultrasonic assist turning in high temperature alloys. In ultrasonic-Assist Turning, higher frequency waves are incorporated into the cutting tool, thus reducing the cutting force and the heat produced. It provides the ability to carry out productive precision turning of the difficult-to-cut material with superior surface quality, beyond the capabilities of conventional precision turns.

Our orientation is development-oriented. There is provision of solutions that address current problems through the application of intelligence, integration, and specialized processes in manufacturing. There is a better approach to development that aims at the optimization of CNC turning through the development of a system that provides the benefits of reliability, complexity, and the application of innovative materials, which provides a competitive advantage in difficult manufacturing processes.

FAQs

1. What is the highest possible precision available on a precision CNC turning?

Precision turning from LS Manufacturing has the ultimate precision of ±0.002mm, roundness up to 0.001mm, surface finish Ra0.2μm, which can meet the demand for high precision parts.

2. How to choose the best turning cutting parameters for working with different materials?

LS Manufacturing established a parameter database through extensive testing: stainless steel Vc = 150-250 m/min, aluminum alloy Vc = 400-600 m/min, titanium alloy Vc = 50-80 m/min. Specific parameters need to be optimized based on the part structure.

3. How to reduce unit machining cost of precision turning?

Optimizing tool selection to enhance tool life by 40% and improving the performance of cutting parameters to enhance efficiency by up to 35%, LS Manufacturing can reduce its unit cost by 30-40%.

4. How would one ensure the dimensional consistency in batch turning?

By using high precision fixture ≤0.005mm, frequent equipment calibration, and SPC process control, LS manufacturing is able to produce batch production dimensional accuracy CPK≥1.67.

5. What do I need to provide for an online turning quote?

Please provide information such as material, drawings, precision requirements, and batch size. The online system of LS Manufacturing will give you an accurate quote and a process plan in 3 minutes.

6. What is the shortest time required for urgent orders of turns?

Urgent sample orders are delivered within 24 hours, with small batches delivered within 3-5 days. To ensure progress in projects, LS Manufacturing set up a rapid response channel.

7. How to improve the turning effect of difficult-to-machine materials?

The LS Manufacturing process can double the tool life when machining harder materials such as high-temperature alloys. This is achieved through the proper selection of tool material, cutting parameters, and cooling pressure.

8. How to solve the common vibration mark problem in turning?

Through optimization of the overhang of the cutting tool, the rigidity of the system, and the cutting parameters, the LS Manufacturing ensures a quality finish, free from vibration marks, Ra0.4μm.

Summary

On the basis of scientific planning, appropriate usage of the tool, and quality control, precision, efficiency, and economy can also be achieved while machining parts using CNC turning. LS Manufacturing provides complete solutions. The techniques used in LS Manufacturing, with the aid of data, especially the usage of the tool, would be analyzed in this study.

To obtain customized turning quotes, you can upload your drawings in 3D to enable instant analysis and quotes. To learn more about complex parts, you can also schedule a consultation free of charge to learn more from our technical experts. We also offer full support. You can call our service hotline to get free sample processing improvement advice and sample processing improvement services to achieve optimal precision turning results.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.