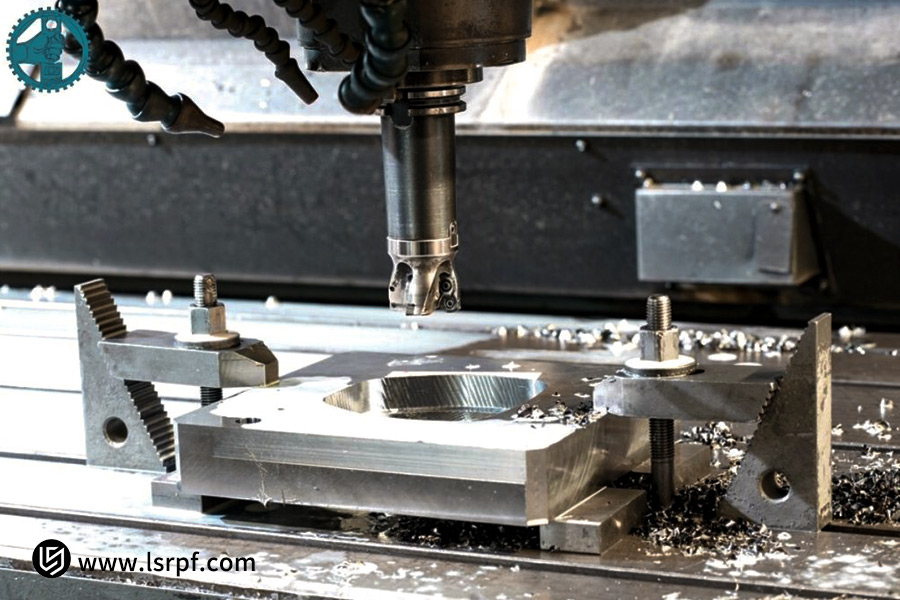

At the epicenter of modern manufacturing, CNC machining aluminum has emerged as a critical cornerstone for producing extremely advanced, high-precision components because of its unmatched efficiency, breathtaking precision, and excellent reproducibility. From the aerospace sector to consumer electronics, aluminum and aluminum alloys are the material of choice for most industries because of their light weight, high strength, and machinability.

But the road to perfection is not always easy. The inherent material properties of aluminum—its low yield strength and high coefficient of thermal expansion—leave it most susceptible to cutting forces, clamping forces, and heat in CNC machining of aluminum, leading to unstable part warpage and harmful residual stresses. These stresses and distortions are typically concealed until after machining, resulting in dimensional inaccuracies at best and entire workpieces discarded at worst, highly compromising the quality, structural integrity, and assembly accuracy of the finished CNC-part.

This tutorial will analyze the root causes of such problems in a systematic and logical fashion and provide an extensive list of tested solutions to help you design flawless CNC-machined parts. To save you time, here's a quick overview of the key findings.

CNC Aluminum Machining Deformation and Stress Prevention Quick Reference Table

| Control Links | Core Objectives | Key Strategies |

| Process Parameters | Reduce Cutting Forces and Heat |

|

| Fixture Design | Evenly Distribute Stress |

|

| Tool Cooling | Efficient Cooling and Chip Removal |

|

Prevention and control of warpage and stress in CNC aluminum parts is a systematic, multi-disciplinary approach. This handy quick reference chart clearly illustrates the interrelationship of three basic technical disciplines:

- Minimized cutting forces and heat input at the source by optimized process parameters.

- Accurate fixture design provides stable support to the workpiece without adding external stress.

- Effective tooling and cooling methods control and direct heat generated during machining directly.

Why Trust This Guide? Practical CNC Machining Experience From LS

Our experience at LS Precision is that theory must be tested by practice in order to create value. Every method in this guide is not theoretical instruction but the culmination of our collective, proven, and maximized experience, day in and day out, on the machine, with thousands of difficult CNC parts. We've faced the aluminum deformation issue head-on and logically condensed efficient solutions to provide you with an open, stable, and efficient path.

Our expertise is self-explanatory. For example, by applying a "high-pressure internal cooling + dynamic milling" method, we successfully reduced the flatness error of a specific aviation aluminum part from 0.15mm/㎡ to less than 0.05mm/㎡. By using a standardized "stress relief annealing after rough machining" process, we completely eradicated the historical issue of precision variation in the fit of a series of thin-walled cavity components. These field examples provide the firm foundation and assurance for all the recommendations throughout this handbook.

Why Is Aluminum Processing Prone To Deformation And Stress? What Are The Root Causes?

CNC machining of aluminum is widely adopted for its precision and efficiency. Parts made of aluminum are prone to residual stress and deformation when machined, which can significantly lower the quality of the end product. This problem essentially occurs because of the interaction between aluminum characteristics and machining itself.

Aluminum properties

Aluminum has a high coefficient of thermal expansion and low hardness, which are intrinsic characteristics tending to deform it. Aluminum is very sensitive to temperature. The local heating in the process of machining causes uneven expansion of the material when it is heated, followed by uneven contraction when it cools down, leading to deformation and residual thermal stress. Moreover, aluminum is relatively soft and thus more susceptible to plastic deformation or intra-material reorganization of stress under applied external mechanical loads.

Machining process

From a machining perspective, cutting forces and cutting heat are the external causes directly leading to deformation. Hot temperatures are generated in the tool-workpiece contact region. In instances of inadequate cooling, the high temperature can cause material expansion and localized softening.

Conversely, shearing and extrusion of the material by the tool while cutting will disturb the internal equilibrium of stresses within the material. This is most especially true when the cutting parameters are inappropriate or the tool is blunt. Extreme mechanical stresses result in direct deformation of the workpiece. Additionally, incorrect clamping adds extraneous stress, adding potential for deformation as well.

The intrinsic cause of deformation and stress in machining aluminum is coupling between the material's inherent characteristics and the thermal and mechanical stresses during machining.

How Can We Reduce Deformation Risks By Optimizing Machining Parameters?

In contemporary precision manufacturing, the performance of the CNC machine tool is a satisfactory foundation for producing good quality parts, yet the equipment's maximum potential can be achieved only when process parameters are properly set. The key to the optimal setting of cutting parameters is to use the principles of "high-speed cutting (HSC)."

1. Cutting speed:

The initial step is to use high cutting speed (200-300 m/min is recommended). The faster the speed, the more slender the chips, more consistent cutting forces, and more heat removal from the chips rather than transferring it to the workpiece.

2. Feed rate setting:

The feed rate setting is significant. A greater feed per tooth (0.1-0.2 mm/tooth) is recommended so that there is no excessive friction between the tool and the material to lead to heat generation. This, however, needs to be compensated by keeping the depth of cut low so that there are no high cutting forces.

3. Controlling cutting depth:

Radial depth of cut control is most critical. A "small depth of cut, high feed" strategy needs to be adopted and the radial depth of cut should be restricted to 5%-20% of tool diameter. It thus reduces cutting forces, in effect minimizing bending stress and workpiece deformation.

4. Cutting strategy:

Cutting strategy is also important:

- While programming, have the highest priority for downcut milling and employ a smooth and constant cutting motion to avoid shock loads due to sudden in-and-out movement.

- By utilizing the good dynamic performance of modern CNC machine tools, employing trochoidal milling or dynamic milling strategies can maintain constant cutting load, but further enhance the stability of the process and low temperature rise.

By employing a science-based parameter set, such as high-speed machining, operators are able to optimize the performance of CNC machine tools, in effect improving machining stability and part quality.

How Does Fixture Design Affect Aluminum Machining Accuracy?

In CNC machining of aluminum, fixture design has a significant role to play in the impact it has on the precision of the final product, second only to machine tool performance and tool selection. A substandard fixture design would result in direct workpiece deformation, vibration, or displacement, ultimately leading to compromising precision machining.

1. Pros and cons of different fixture designs:

Different fixture designs also possess varying strengths and weaknesses:

- Platen fixtures are convenient and uncomplicated but prone to localized deformation by a lack of clamping points or irregular application of pressure.

- Vise fixtures are quick and easy to install, but impose stress by improper jaw parallelism or regulation of clamping force.

- For complex or thin-walled aluminum parts, vacuum cups and contoured fixtures are the best options. They are able to provide large, uniform support and suction, distribute the clamping pressure uniformly over the entire bottom surface, and practically prevent localized deformation.

Best practices for aluminum part clamping

Aluminum part clamping best practices require two primary guidelines:

- Optimize support contact area. Support points need to be located strategically according to the workpiece shape, particularly in the direction of overhangs to avoid deflection of tools by cutting forces.

- Control the volume and the surface area of clamping force, and employ a torque wrench and step-by-step tightening in symmetric manner first to avoid over-tightening at a single point. For very thin parts, specialized techniques such as cast supports from low-melting-point alloys can even be employed.

With effective fixture type selection in line with part shape and stiff support and clamp force control, clamping-induced secondary stresses can be minimized, preserving geometric accuracy and consistency in CNC machining of aluminum.

How Important Are Tool Selection And Cooling Strategies For Controlling Deformation?

Tool selection and cooling strategies in CNC machining of aluminum are far from being secondary; they are essential elements directly engaged in regulating the generation and transmission of machining heat, and thus workpiece deformation magnitude. They remain one of the superior ways of regulating the forces of cutting and heat at the generation point.

1. The influence of tool geometry on machining quality:

Tool geometry and coating technology most directly influence the smoothness and thermal distribution of the cutting process. For aluminum, high rake angles and big chip flutes are maximally realized through sharp tools. Such a shape significantly reduces cutting resistance and thereby enhances cutting smoothness and reduces plastic deformation and heat from the "squeeze" effect. A three-edge design creates a situation where there is good rigidity with sufficient chip space.

2. The impact of coating technology on machining quality:

In addition, specialized coating technologies (such as coatings solely for non-ferrous metals) not only reduce tool wear but also effectively suppress cutting temperature increases by reducing the coefficient of friction.

3. Cooling strategies:

Efficiency in cooling systems is inversely related to the timely removal of machining heat. Traditional overflow cooling often finds it challenging to precisely penetrate the hot zone around the tool tip.

Due to this, high-pressure internal coolant (HPCO) has become increasingly popular as the best technique of deformation control. Coolant in excess of 70 bar is precisely sprayed to the cutting edge through toolholder channels. It does three things:

- It reduces cutting temperatures instantaneously;

- It rinses chips effectively away so that the machined surface is kept free from secondary burns;

- It forms a lubricating film between the tool and the chips that reduces frictional heat generation.

By employing sharp cutting tools dedicated for machining aluminum and utilizing high-pressure internal coolant technology, heat generation in cutting can be minimized and effectively removed, naturally negating thermal stress-induced deformation. This is a basic technical guarantee of part dimensional precision.

Where Are Heat Treatment And Stress Relief Processes Most Effective?

In CNC aluminum machining, stress relief and heat treatment are not corrective one-step processes; they are significant control actions step by step. It is highly dependent on timing, and choosing the appropriate step makes all the difference. It is primarily used in two significant stages:

1. The optimum step is following rough machining and before finishing:

This is the most frequent and most productive period. After rough machining, when the largest portion of the stock has been removed, the residual casting or rolling stresses in the workpiece and the added stresses introduced by this machining operation are at an unbalanced maximum.

2. Stress relief annealing:

Stress relief annealing (typically heat to 300-350°C, hold 2-4 hours, and then furnace cool) is now the optimum way to relieve and equalize most of these stresses and develop a stable condition of stress for future finishing, and thus ensure long-term dimension stability.

3. Material pretreatment process:

Also, stress relief of raw aluminum sheet during material pretreatment process (i.e., before machining) is equally effective, especially for large material or initial stress state unknown material. For parts with ultra-high accuracy requirements, another stabilization treatment (low-temperature aging) may be introduced after semi-finishing to remove micro-stresses induced in the process.

Incorporating it as a proven link between the process between rough machining and finishing can prevent cumulatively and transmit stress systematically and economically, and is one of the most effective measures to ensure the quality of high-precision CNC aluminum machining parts.

How Do Online Machining Services Ensure The Quality Of Aluminum Parts?

Choosing online CNC machining services is convenient for customers, but how are we to break through the constraints of distance and ensure the accuracy and reliability of aluminum machining? This relies on the service platform having a systematic, digital, and all-around quality control system during the process.

1. Process review:

Consider the example of LS online service platform. Our quality control starts with an intensive review of process. Upon receipt of customer drawings, our engineering department performs a professional Design for Manufacturability (DFM) analysis, pre-planning deformation-avoidance processes adapted to the peculiarities of the aluminum component. This involves optimizing clamping scheme, cutting parameters, and machining sequence.

2. Real-time monitoring:

Real-time monitoring is the cornerstone of production. Modern CNC machine tools incorporate sensors to monitor data anomalies such as cutting force and spindle load to provide stable machining conditions. Every essential process step is recorded for full traceability.

Testing and verification

Machining is not the final step; rigorous testing and verification are the final check before delivery. LS Precision uses precision CMMs and laser scanners to perform 100% measurement of key dimensions for both first-article and batch production, generating full inspection reports to verify that each data is perfectly aligned to the design drawings, thereby guaranteeing part fitment and function.

LS Precision's reliable remote CNC machining service is more than simple order-based production. Through a three-limbed closed-loop quality control mechanism consisting of pre-process inspection, open production processes, and end-of-line high-precision inspection, we minimize the risk of aluminum part deformation, thereby enabling customers to obtain high-quality machined parts remotely.

LS Case Study: How To Solve The Problem Of Deformation In Aerospace Aluminum Machining?

1.Client challenge:

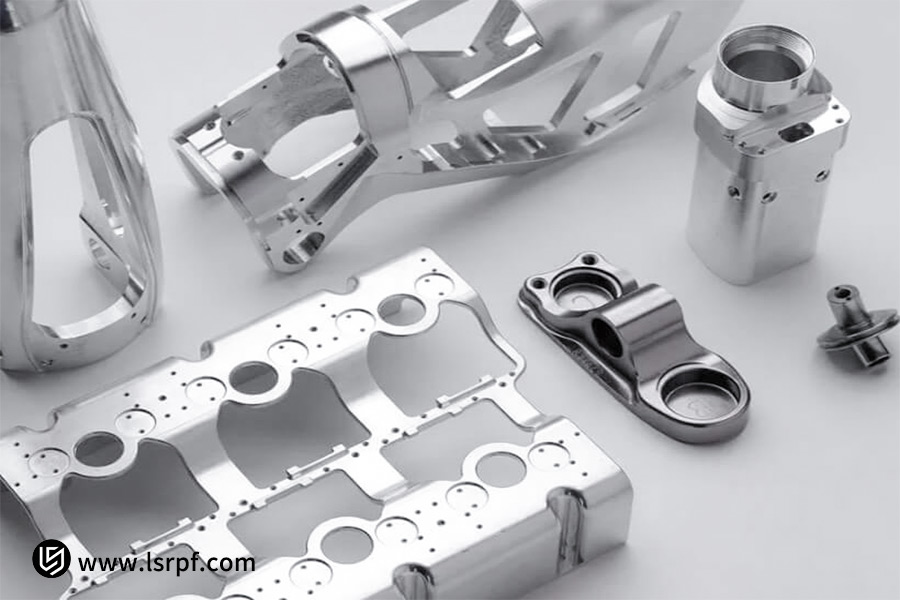

An aerospace customer ordered machining of a batch of big-sized aluminum alloy frames for air-borne equipment. The components, 800 × 500 × 50 mm in size, contained numerous thin walls (the thinnest, only 2 mm) and deep cavities. They consisted of 7075-T6 aluminum alloy and contained numerous thin walls (with the thinnest being only 2 mm) and deep cavities.

With traditional techniques, the finished parts suffered from severe warping, flatness deviation up to 0.3mm, and uneven wall thickness in sections, failing to reach the very stringent aerospace tolerances (overall flatness ≤ 0.05mm). Control of machining stress and deformation became the principal delivery bottleneck.

2. LS Precision's solution of innovation:

Brought to this classic conundrum, the LS team abandoned conventional trial-and-error methods. Rather, drawing on its expertise in custom CNC machining and manufacturing, they designed a systematic and innovative solution:

- Phased Stress Relief Processing: This breakthroughs machining into five steps: roughing - stress relief - semi-finishing - secondary stress relief - and finishing. After roughing has removed the majority of the excess stock, the workpiece is removed from the special fixture and subjected to low-temperature aging to release entirely internal stresses before being re-clamped for subsequent machining.

- Multi-Dimensional Collaborative Control: A dedicated combined vacuum suction cup and multi-point auxiliary support fixture was used to impart uniform suction as well as support on the bottom surface of extremely large, thin-walled parts. Tooling strategy-wise, all sharp cutting high-rake aluminum cutting tools were utilized, and cutting conditions of low depth of cut, high speed, and high feed were strictly adhered to. Internal high-pressure coolant (pressure >80 bar) was used throughout the entire process to significantly lower cutting force effect and heat generation.

- Real-time monitoring and compensation on-machine: On-machine measurement by the machine tool probe of the workpiece following critical processes receives real-time deformation data. Dynamic compensation is subsequently applied to the finishing toolpath based on this data, anticipating in advance "compensation" for any deformation.

3. Final result:

Thanks to this full, customized CNC machining service, LS Precision successfully solved the machining deformation issue of this aerospace aluminum part. The flatness of all exported parts was turned out uniformly within 0.04mm, completely meeting design demands, and achieving significantly improved wall thickness consistency. This case study earned widespread customer praise as well as set the standard operating procedures for LS's machining ultra-large, ultra-thin aluminum parts, demonstrating its superiority in resolving complicated problems.

How To Assess The Optimal Balance Between Processing Cost And Quality Control?

In the manufacturing industry, CNC machining cost and product quality are oftentimes the two parameters most prized by customers. However, there is normally always a conundrum in finding the lowest quote and in pursuing the highest quality. A wise decision is not all about choosing the lowest expense or the highest quality but about achieving the optimum point of trade-off between cost and quality control based on the final-use application of the part.

Cost reduction must be tackled on a multi-faceted basis. Selecting cost-effective grades of material, reducing non-critical dimensions proportionately without affecting functional performance, employing efficient standard equipment, and planning layouts to the best extent possible to reduce material waste can all effectively control CNC machining costs.

Yet each cost reduction step should be considered on the basis of its possible impact upon quality risks. The levels of quality control are typically grouped as follows: basic (inspection of critical dimensions), standard (full dimension report), and high-precision (full dimension report + complete geometric and positional tolerance check).

- Each level requires additional test time, equipment, and manpower, thus costs. A part employed in an ordinary house does not require aerospace-level testing, for example.

- The key to setting optimum balance is to specify requirements correctly. Talk about the part function, operating conditions, and quality needs with suppliers so they can design the most economical process and inspection plan accordingly.

LS Precision's excellent suppliers can provide customers with the highest quality possible for their application at a reasonable CNC machining price, not too quality, nor too cheap, but the best value for money.

FAQs

1. What is the minimum machining distortion that can be controlled?

With systematic improvement in process like high-speed cutting, multi-step stress relieving, and special fixtures, LS Precision maintains machining distortion on big, thin-walled aluminum parts to 0.1mm. Accuracy depends on the precise part structure (e.g., wall thickness and location of ribs) and material condition. We provide precise predictions and commitments at the process review phase.

2. How can we determine whether machining stresses have been completely eliminated?

LS Precision applies cutting-edge testing facilities such as X-ray diffraction (XRD) residual stress analyzers to measure stress distribution on the workpiece surface after machining in quantitative terms. The technology accurately and non-destructively obtains stress values and distribution, ensuring they are under design limits, allowing for scientific measurement of effective stress reduction.

3. Can small-batch processing enjoy the same quality control?

Yes. LS Precision adheres to the "quality is not compromised by batch size" philosophy. In case of small-batch orders, we adhere to standard processes in each step of the process: from first-article three-dimensional coordinate measurement (CMM) to SPC statistical process control of key processes to ensure the quality reliability and consistency of each product are identical to large-scale production.

4. Does the online quote include a process optimization solution?

Yes, the quotation for CNC machining online provided by LS Precision is not just an expense; it's a first technical answer. Our engineers will do a design for manufacturability (DFM) review of your drawings and provide complete process optimization suggestions along with the quotation, for instance, how to adjust the structure to reduce machining intricacy or cost, in an attempt to create value from the outset.

Summary

Preventing CNC aluminum machining deformation is more than a simple matter of making one adjustment; it's a process that's dependent on materials, fixtures, tooling, programming, and final inspection. According to our rich experience and numerous successful cases in CNC machining, LS Precision Manufacturing offers systematic solutions from design to finished product so that your project is getting the best quality and reliability.

Upload your CAD files today and receive free Design for Manufacturing (DFM) and manufacturability analysis report and precise quote! Put your next project on the hands of our experts and ensure hassle-free high-quality production.

Upload your design drawings now and get an instant CNC milling quote ( CNC milling price), let LS be your strong backing in pursuit of ultimate CNC milling precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com