The titanium vs aluminum choice in consumer electronics, aerospace, and medical devices is a core challenge impacting performance, cost, and marketability. A key obstacle is the cognitive gap: lacking practical insight into machinability and mass-production feasibility makes it difficult for engineers to assess true lifecycle costs. Most suppliers also fail to provide comprehensive, one-stop analysis spanning from material science to precision manufacturing.

Core Comparison Of IPhone Body Materials: Titanium Alloy VS Aluminum Alloy Quick Reference

|

Characteristic |

Titanium alloy (predicted for Pro/Ultra models) |

Aluminum alloy (predicted for standard models) |

What it means for you? |

|

Strength-to-weight ratio |

Very high. At the same strength, it is 45% lighter than steel, but heavier than aluminum. |

Good. Very light, but a thicker volume is required to achieve the same strength. |

Titanium alloy bodies are more resistant to bending and accidental drops, and feel "solid" and not bulky. Aluminum alloy bodies pursue extreme lightweight, but the structural strength is relatively lower. |

|

Feel and texture |

Warm and skin-friendly. Has a unique brushed or matte texture. |

Cool and smooth. Easy to anodize to achieve colorful and bright colors. |

Titanium alloy provides a low-key and luxurious professional feel. Aluminum alloy offers a wider range of personalized color options. |

|

Durability (scratch resistance) |

Very high. The surface hardness is much higher than that of aluminum alloy, and it is not easy to scratch. Medium. |

The anodized layer provides some protection, but deep scratches will reveal the silver body. |

Titanium phones can still maintain a new look after long-term use, which is more "value-preserving". Aluminum bodies are more likely to show visible signs of wear and tear from daily use. |

|

Heat dissipation performance |

Poor. It is a poor conductor of heat. |

Excellent. It is an excellent conductor of heat and can quickly conduct internal heat. |

Aluminum bodies dissipate heat faster, which helps maintain high-performance operation. Titanium bodies require Apple to design more complex internal heat dissipation structures to compensate. |

|

Production cost |

Extremely high. The raw materials are expensive and the processing is extremely difficult. |

Economical. The raw material cost is low, the processing technology is mature, and the efficiency is high. |

This is the fundamental reason why titanium alloy is only used in high-end Pro/Ultra models, while aluminum alloy is used in standard models. The cost difference directly affects the product pricing strategy. |

Why Trust This Guide? Practical Experience From LS Manufacturing Experts.

Surface integrity for machined titanium alloy implants means life or death in medical applications, while the balance of strength with cost determines market success or failure for the crafted aluminum alloy frames. Over the last decade, we have amassed tens of thousands of data points about precision part machining data, while concurrently gaining deep knowledge about how best to optimize the cutting parameters for controlling the deformation of titanium alloy and thorough knowledge of the efficiency boundaries for mass production for aluminum alloys.

Every comparison in this manual is not a theoretical parameter list but a practical conclusion confirmed by actual data of tool wear, production capacity, and yield rates. We share these experiences with you, refined through the inspection reports of cutting, so as to offer a truly reliable reference for your decision-making and help you minimize risks.

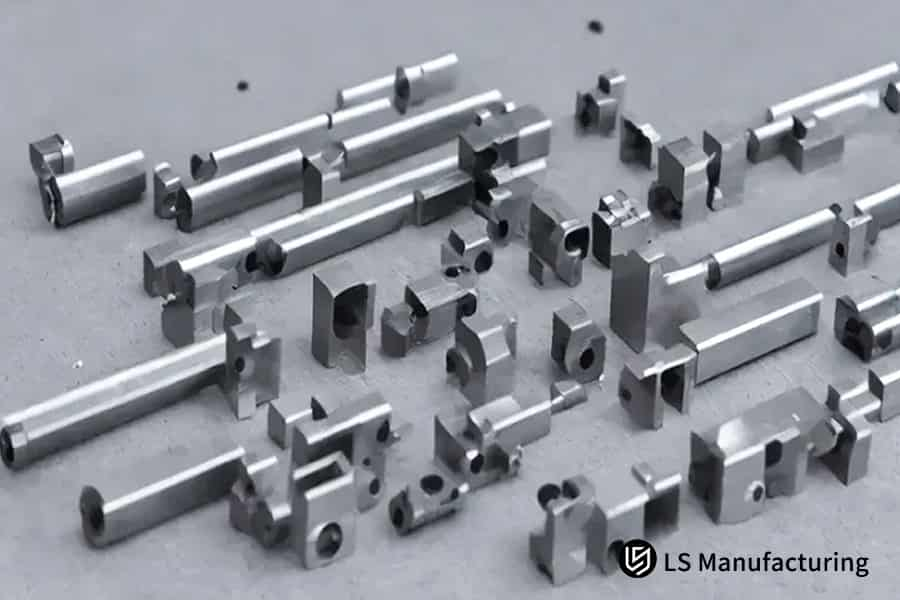

Figure 1: A comparative look about precision machining of titanium vs aluminum for iPhone bodies by LS Manufacturing

Why Would The IPhone 17 Be Made Using Both Titanium And Aluminum Alloys? What Does That Say About Product Strategy?

Market Segmentation and Value Anchoring:

Launching iPhone 17 titanium is way beyond a simple material upgrade; it will create an undisputed differentiated value with the strength, lightweight feel, and overall luxury of titanium for Pro models. This is not about improving physical performance but also about setting a clear high-anchor value in the minds of consumers and a distinct separation from the standard aluminum alloy version. The strategic positioning behind the iPhone aluminum vs titanium debate ultimately drives consumers to pay for "superior materials," with the Pro models clearly defining which iPhones are titanium.

Cost Control and Economies of Scale:

The application of an aluminum alloy is a model of mature supply chains and economies of scale. The superior machinability makes it possible to realize complicated unibody molding through effective and steady precision CNC machining, ensuring sophistication in design and structural strength while keeping cost within an acceptable range for the mainstream market. This "dual-track" strategy will guarantee that Apple can maximize profits while reaching a broad consumer base, directly addressing the core trade-offs in the aluminum vs titanium iPhone decision for different product tiers.

In summary, Apple’s practice demonstrates that materials are a medium of strategy, not an independent technical decision. Regardless of the material chosen, achieving design intent depends crucially on precision CNC machining. From the complex titanium mid-frame of the iPhone 17 to the detailed internal aluminum alloy structure, manufacturing capability unifies design, performance, and mass production feasibility.

Titanium Or Aluminum: The Final Confrontation Of Which Is Better For Your Project

The real key, however, lies in how these core performance parameters deeply relate to your application scenarios, performance boundaries, and cost targets. The logical reasoning behind the data presented will be given in the next section by comparing the data concisely and combining it with the sense of comparison of titanium alloys and aluminum alloys in engineering practice.

| Characteristics | Titanium Alloy | Aluminum Alloy |

| Specific Strength | Very high. An excellent strength-to-weight ratio essential to true lightweighting. | Fair. Light weight with generally lower absolute strength and specific strength than for titanium alloys. |

| Corrosion Resistance | Excellent. Particularly resistant to salt spray corrosion, suitable for harsh environments, and requires less surface treatment. | Generally, surface treatments such as anodizing are typically used to improve corrosion resistance. |

| Thermal Conductivity | The temperature is relatively low. This is not conducive to heat dissipation and should be a key consideration when designing high-heat components. | Excellent. Ideal for radiators, housings, and other applications requiring thermal management. |

| Machinability | The challenges are significant. Titanium alloys CNC machining demands high precision, with notable issues such as tool sticking and work hardening, resulting in high tool costs and machining time. | Excellent. Aluminum alloys CNC machining performance and high efficiency, which is the basis for the economics of mass production. |

| Comprehensive Cost | Extremely expensive. Both the raw material and processing costs are far higher than those of aluminum alloys. | Economical. Low material and processing costs, resulting in excellent cost-effectiveness. |

Titanium alloy is a "performance-first" solution, ideal when weight reduction, strength, or corrosion resistance is paramount and budget allows. In the titanium vs aluminum debate, is titanium stronger than aluminum? Yes, in specific strength, but the aluminum vs titanium choice balances performance with practicality. Aluminum alloy offers a balanced, cost-effective option for cost-sensitive projects requiring excellent thermal management and efficient mass production.

Why Is 5-Axis CNC Machining Irreplaceable For Making Such Complex Titanium Alloy Parts?

Manufacturing complicated and precision titanium alloy parts represents the peak of challenges in engineering and manufacturing technology in some of the cutting-edge fields, such as aerospace and medical devices. The high strength, low thermal conductivity, and significant work-hardening tendency of titanium alloys make the material prone to tool wear, workpiece deformation, and loss of precision CNC machining. 5-axis CNC machining has become one of the key ways to tame this high-performance material. Its core advantages are mainly reflected in two dimensions:

- Revolutionizing Precision & Efficiency with One Setup: It can also perform 5-axis CNC machining of polyhedral and curved surfaces and deep cavities in a single setup without any repeated repositioning, thus eliminating positioning error entirely. This advanced process, which minimizes cumulative tolerances, forms the very basis for achieving ultra-high geometric accuracy, exceptional surface continuity, and unparalleled consistency in structural integrity across complex, monolithic components.

-

Optimized cutting angles to overcome work hardening: Minimizing the heat of cutting, constraining work hardening, improving surface quality, and prolonging tool life can be ensured by dynamically adjusting the optimal spatial angle between tool and workpiece. This real-time adaptive control, guided by in-process monitoring, maintains the ideal cutting geometry and a constant load throughout the operation, thereby significantly enhancing machining stability, consistency, and overall process efficiency for superior component integrity. This level of control is vital for achieving the high-quality finishes demanded in consumer products like the iPhone aluminum chassis.

-

Complex internal geometries and thin-wall constructions are enabled: The 5-axis simultaneous capability allows complex internal passages, undercuts, and thin-walled features to be machined that a 3-axis machine cannot achieve. This is particularly important, for instance, in aerospace parts that need to integrate cooling channels within the design or for medical implants that require porous surface structure features in order to execute both functional performance and lightweight design in one single, consolidated part. -

Improved Chip Evacuation and Thermal Management: The flexibility in tool orientation provided by 5-axis CNC machining allows for smoother flow of chips, thereby avoiding chip recutting and minimizing heat generation as an important factor when machining titanium. This leads to superior surface finishes, reduced thermal stress on the workpiece, and better tool life to the benefit of both quality and cost efficiency. -

Reduced Lead Time and Lower Total Cost of Ownership: While the initial investment in a 5-axis machine is greater, the capability it affords to complete even the most elaborate part within just one setup greatly reduces fixture costs, handling time, and secondary operations. These advantages, along with increased precision and material yield, lead to a lower total per-part cost, especially when it comes to high-value parts used in critical applications, whether they are made from titanium and aluminum alloy or other advanced materials.

All in all, 5-axis CNC machining combines not only the capability to "do" titanium alloy CNC machining but also "doing it with precision, stability, and economy." Equipped with several high-precision 5-axis CNC machining centers and an extensive process database, LS Manufacturing is able to ensure that every single unit of a titanium alloy component-from prototyping to mass production-meets the most stringent reliability and performance requirements.

Figure 3: Choosing between titanium and aluminum for your CNC parts by LS Manufacturing

Can CNC Machining Of Aluminum Alloys Really Balance Cost And Performance?

In manufacturing decisions, if attempting to reach the highest cost-effectiveness, the choice of an aluminum alloy often forms a core strategy. This is not only because of material cost but also due to comprehensive advantages in speed, tool wear, and overall plasticity from aluminum alloy CNC machining, which allows systematic engineering for a superior cost-performance balance.

- Applying Machining Economics to Lay a Cost Foundation: The CNC machining of the aluminum alloy can enable extremely high cutting speeds and feed rates with tool wear significantly lower than that of difficult-to-machine materials, such as titanium alloys. That means shorter machining time and less spend on replacement tools in professional CNC machining services. It is always a good foundation for large-scale and economic production and greatly reduces the manufacturing cost.

-

Designing and post-processing to improve performance: Through topology optimization and built-in reinforcing ribs, CNC machining enhances the structural rigidity of aluminum parts while minimizing weight. Enhanced by hard-anodizing for hardness, wear, and corrosion resistance, these parts excel in diverse applications. In the titanium vs aluminum iphone debate, the aluminum iphone offers outstanding value. While is aluminum lighter than titanium? Yes, aluminum’s lower density enables efficient lightweighting at scale. -

Improved heat management capabilities: Aluminum alloys provide high heat conductivity, which is desired in heat sinks, casings, and other components that are intended to perform the role of heat management. In such cases, CNC machining allows for the precise fabrication of complex fin geometries and internal channels that improve heat dissipation without secondary assemblies or additional material, enhancing functional performance and system reliability even more. -

High recyclability and environmental sustainability: Aluminum is highly recyclable, with the reclaimed material retaining nearly all of its original properties. Such materials enable sustainable manufacturing and decrease lifecycle environmental impact, possibly at lower material costs in the longer term-all goals of aligning economic with ecological objectives in modern production. -

Adaptability to Advanced Joining and Finishing Techniques: Aluminum alloys lend well to a wide range of joining methods, including welding, bonding, and mechanical fastening, besides the various finishes such as powder coating, plating, and laser engraving. This allows design flexibility, improves aesthetic integration, and enables functional enhancements such as EMI shielding or enhanced wear resistance, while maintaining cost efficiency.

By integrating precision-controlled aluminum alloy CNC machining processes with innovative structural engineering simulations and enhanced surface treatment technologies such as advanced anodizing and ceramic coatings, we are able to fabricate components that are second to none in rigidity, durability, and lightweight performance. This holistic approach ensures exceptional mechanical properties and corrosion resistance, all achieved at a very competitive total cost, delivering outstanding value and reliability for demanding applications.

How To Choose The Most Suitable CNC Machining Service Provider For Your Precision Parts?

A capable supplier is the very foundation upon which project success and product excellence are delivered for precision CNC machining applications. The right partner ensures well-made parts that are cost-optimized and produced with reduced lead times, with significant added value in manufacturability design input. With so many different CNC machining service providers available, how does one systematically evaluate core capabilities? Following is a key evaluation checklist:

| Evaluation Dimensions | Key Considerations |

| Equipment and Technology Capabilities | Find out if they have multi-axis linkages, high-speed milling, and other equipment that would be necessary to offer precision CNC machining for complicated geometries. |

| Material and process knowledge | Check the extensive machining experiences and mature process parameter database on target materials, including titanium alloys and aluminum alloys, enabling informed decisions on aluminium or titanium for specific performance needs. |

| Quality Assurance System | Ensure that they have a fully developed quality control system, certified to ISO 9001, to make sure full traceability and consistency from incoming material to the finished product. |

| DFM Capabilities | Learn whether their engineering team can professionally provide feedback to optimize the designs for cost reduction and manufacturability enhancement at an early stage, even considering material-specific factors like titanium vs aluminum strength in structural analysis. |

| Project Communication and Management | Review the transparency of their process when it comes to project management and whether they are capable of providing clear project milestones and communication channels. |

| Industry experience and case studies |

|

Our core value lies in handling complex parts with advanced multi-axis machining capability and ensuring the reliability of each delivered product through a rigorous quality control system. Eventually, a suitable CNC machining service provider should go further than "machining according to drawings" and be a reliable technological extension and strategic supporter in your journey from concept to products down to mass production.

Figure 4: Exploring the design iterations and precision build of the iPhone 17 by LS Manufacturing

Custom Machining of Titanium Alloy Engine Mounts for Aerospace Applications

Customer Challenges

The availability of superior properties from the titanium alloy Ti-6Al-4V necessitated finding a way of overcoming problems in machining deformation and residual stress arising out of work-hardening tendency and low thermal conductivity, respectively, so that structural integrity over time can be ensured even under extreme loads.

LS Manufacturing Solution

We don't deal with this task as a simple machining process according to the drawings provided. By applying the benefits of multi-axis precision machining centers, we solved in a systematic way the key processes: optimization of each process's cutting parameters and path by using simulation software to handle heat and stress generated during cutting, designing special flexible fixtures which can reduce clamping deformation and ensure machining stability, adding specific residual stress control and aging treatment processes to stabilize the internal microstructure of the material.

Results and Value

The delivered titanium alloy support not only achieved the weight reduction of 35%, but its fatigue life far exceeded customer expectations by 250% above the specification requirements. Besides, the part passed all environmental stress screenings and durability tests the first time out to ensure a very key milestone in the customer's overall project.

This case proves that precision CNC machining services go far beyond the equipment itself. At LS Manufacturing, we deeply integrate our profound material knowledge, simulation-driven processes, and advanced 5-axis CNC machining technology to turn challenges with machining titanium alloys into reliable performance advantages. Thus, we can provide customers with CNC machining parts that well exceed expectations and guaranteed value.

Click to inquire and get a custom machining assessment and quote for your needs regarding titanium alloy parts.

From Prototype To Mass Production: How Does LS Manufacturing Ensure The Consistency Of CNC Machining Parts?

For precision manufacturing, the leap from successful prototype to stable mass production is a capability that ultimately validates the core capabilities of any precision CNC machining supplier. LS Manufacturing understands profoundly the fact that ensuring high consistency in the CNC machining parts from the first to the 10,000th depends not on luck but on systematic, quantifiable, and traceable control systems throughout the process. Our assurance of end-to-end consistency rests on three key bases:

Source Control and Standardized Operations

Consistency begins with the raw materials. We vigorously qualify every batch of materials to ensure stable performance parameters. This includes a clear understanding of how different alloys behave under machining, whether in the context of aluminum versus titanium or other advanced materials. Meanwhile, we standardize and document every validated machining process—including tools, parameters, and paths—to create unique production instructions. This ensures that every operator and every piece of equipment executes the same "best practices," the foundation for repeatable manufacturing.

Process Monitoring and In-Machine Measurement

Final Verification and Full-Dimensional Report

After each production batch is completed, the key components are fully dimensionally inspected by the coordinate measuring machine. We not only provide standard-compliant spot check reports but also detailed full-dimensional inspection reports, objectively reflecting the fit of each CNC machining part with the 3D model, thereby achieving quality visualization and transparency. This rigorous validation is what underpins reliable performance, whether for lightweight designs—a key consideration when evaluating is aluminum or titanium lighter—or for high-strength applications.

We minimize variables via closed-loop control across the entire supply chain, from materials to final inspection. This systematic approach is essential for maintaining quality at any volume, as required in precision-intensive applications like the iphone titanium vs aluminum manufacturing process. Whether you order ten or ten thousand pieces, each part delivers the same precision and reliability, enabling a smooth transition from prototype to market success.

FAQs

1.is titanium lighter than aluminum?

In fact, titanium is not lighter than aluminum; on the contrary, it is about 60% denser. Its advantage is in the following: parts made from the alloy can be thinner and lighter to achieve the same structural strength-a rather important issue both in aerospace and high-end equipment.

2. Just how high is the cost of titanium for iPhone?

Several times the precision machining time of aluminum manifold increases the production cost. The main factors making the cost of the frame made of titanium alloy for iPhones higher are: expensive raw aerospace-grade titanium alloy material, several times of precision machining time compared to aluminum, and tool wear cost extremely high. Hence, it will approximately be 3-5 times the cost of an aluminum alloy solution.

3. Is it possible to have aluminum alloy parts featuring strength comparable to that of titanium alloys?

Due to advanced strengthening heat treatment and topology optimization design, some high-strength aluminum alloys, such as 7075, have a specific strength close to that of some titanium alloys. However, speaking generally, titanium alloys still have unparalleled advantages over others in such respects as long-term fatigue resistance, corrosion resistance, and stability at higher temperatures.

4. What are common tolerances for precision CNC machining at LS Manufacturing?

Our standard precision machining capabilities at LS Manufacturing achieve a standard tolerance of ±0.025mm. With the optimization of process and temperature control, the features with stringent requirements can maintain the tight control of critical dimensions within ±0.005mm.

5. Does LS Manufacturing provide small-batch prototype manufacturing?

LS Manufacturing offers the capability for standardized precision machining at a typical tolerance of ±0.025mm. For features with stringent requirements, by optimizing processes and temperature control, we can further manage to keep critical dimensions within a tolerance of ±0.005mm.

6. What other applications does the titanium alloy have in "Phone with Titanium" apart from iPhones?

Apart from iPhones, several luxury foldable phones also use titanium alloy hinges and internal supporting structures for higher structural strength and durability within an extremely limited space that could bear frequent opening and closing in harsh conditions.

7. How to Avoid Distortion after CNC Machining of Aluminum Alloys?

One of the key processes involves controlling deformation during the course of machining. We systematically release and balance internal stresses during processing by incorporating multi-station sequential machining, symmetrical cutting strategies, and multiple artificial aging treatments to ensure dimensional accuracy on thin-walled parts.

8. What is the key factor in choosing between titanium or aluminum?

The ultimate decision between titanium and aluminum depends on your core needs: whether in the pursuit of the ultimate strength-to-weight ratio and durability with titanium or cost, processing efficiency, and heat dissipation with aluminum. We can provide data-driven professional analysis based on your specific application scenario.

Summary

The decision of titanium alloy versus aluminum alloy is decidedly not an either/or proposition but rather a systems engineering effort emanating from product strategy, performance objectives, and cost. From the differentiated strategy of the iPhone 17 to the highly demanding requirements within the aerospace industry, success depends on a perfect combination of deep materials science knowledge with the best precision CNC machining capabilities.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.