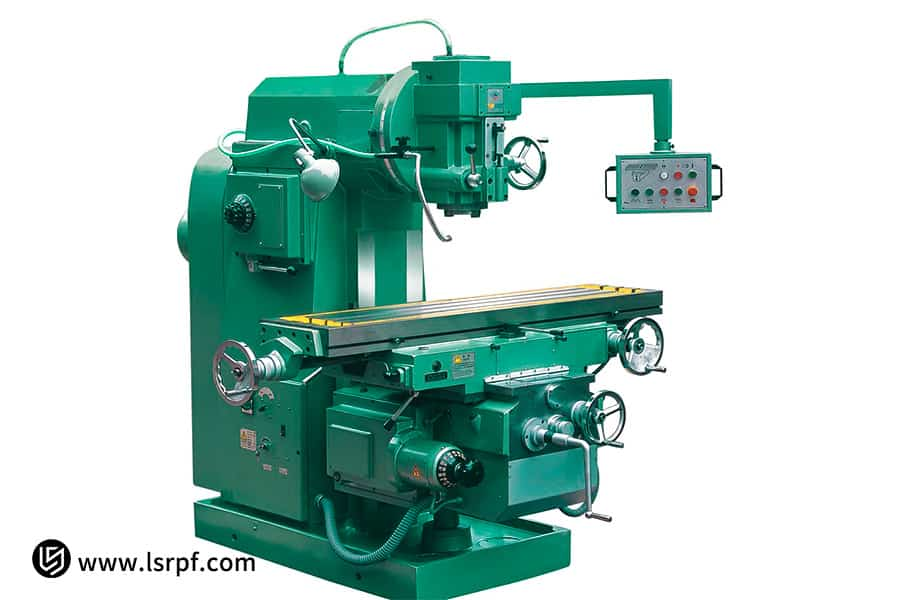

Is manual milling still indispensable in the high-speed era of automation? Yes. Since it is a fundamental and foundational machining operation, manual milling is the machining operation where the feed of the manual milling machine is operated directly by the operator to perform milling, drilling, and boring operations. Though it lacks the high speed of CNC machine tools, its unparalleled machining versatility and lower equipment investment and maintenance costs make it most attractive in small-batch production, prototyping sophisticated workpieces, and repair.

LS Manufacturing, leveraging its technical personnel's outstanding manual operating capability, combines this cost-effective machining method with modern engineering demands, providing customers precise and effective custom parts solutions, effectively solving a wide array of special and complex machining problems. To save you time, here’s a quick overview of the core conclusions.

Manual Milling Core Quick Reference Table

| Item | Core Content |

| Definition | An ancient method of cutting through manual control of milling machine's speed and direction of feed. |

| Key Equipment | Manual Milling Machine |

| Core Benefits | Very flexible, cheaper, easy to handle, ideal for rapid prototyping and repair. |

| Main limitations | Operator skill dependent, lower processing efficiency, mass production of complex curved surface is not convenient. |

| Typical applications | Machining small series of parts, producing fixtures and tools, prototypes, rework and refinish. |

| Value in LS Manufacturing | A commodity supplement to CNC machining, providing customers cost-effective, flexible, and fast customized solutions. |

Manual milling is not so old-fashioned in this computer age. Its special flexibility, lower cost, and more effective handling of unexpected circumstances clearly position it in contemporary production.

As demonstrated by LS Manufacturing, the synergy of old-time hand competence and technical supervision of the present generates unparalleled customer value in proto-typing, short runs, and crisis repair.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The advice in this book is based on more than two decades of broad technical experience on the part of LS Manufacturing in precision machining. We don't merely discuss theory; we draw on our actual hands-on experience in the shop into this book. LS Manufacturing's technical support has been able to solve thousands of intricate issues with manual milling techniques over decades—ranging from the refurbishing of high-dollar, large-capacity reference surfaces to creating precision parts from out-of-the-way materials for aerospace and automation machinery that cannot be fully worked by CNC.

Behind every technique lies an ancient principle which was tested by LS Manufacturing engineers; every application case originated from real instances of our own successful application of custom-made solutions to customers. We firmly believe that genuine expertise lies in the experience gained from successfully combining old know-how and new demands, and it is the guiding principle which LS Manufacturing can offer to you.

What Is Manual Milling?

What is manual milling? Simply, it is a basic machining process whereby a skilled operator personally controls and manually operates the feed and cutting action of a manual milling machine. Compared to CNC machine tools based on computer programs, it is based entirely on the operator's knowledge and experience, hence appropriate for small lot, high-flexibility machining conditions. LS Manufacturing has very high respect for the modern-day relevance of this very ancient practice.

- Core Definition: The essence of this process is precise control through "hand-eye coordination," giving the milling process unparalleled freedom and enabling instant response to fleeting design change and complex workpiece clamping.

- Core Applications: LS Manufacturing excels at leveraging manual milling to offer rapid prototyping, repair of tools and fixtures, and small-series production of custom parts, making customers save precious time waiting for programming and specialty fixture fabrication.

By the experience in manual milling machines, LS Manufacturing, based on manual milling, supports customers with a significant saving of investment and time costs at the start of projects, making ideas and drawings turn into actual parts in the most efficient and cost-saving way.

Figure 1: Advanced CNC milling solutions by LS Manufacturing

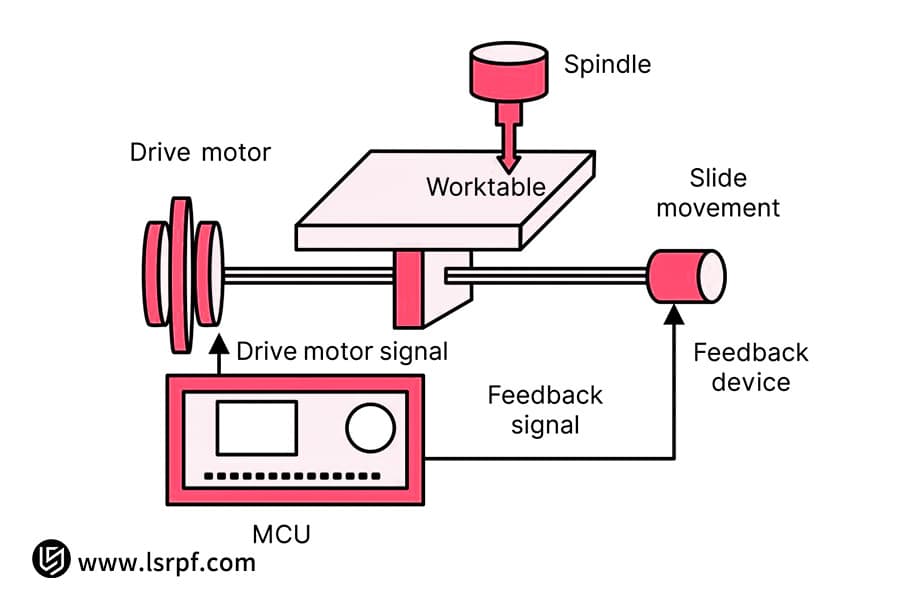

What Is The Working Principle Of Manual Milling?

The heart of hand-milling lies in the close "human-machine collaboration" between the skilled operator and the machine tool. It does not rely on computer software, but rather on the operator's precise manual control to drive the cutting tool of the milling machine to take away material from the immobile workpiece. Such a process can be broken down into a systematic approach in three significant steps:

1. Workpiece Fixing and Datum Calibration:

The workpiece to be machined is clamped firmly over the worktable by a precision vise or special fixture and precisely oriented to tools such as a dial indicator to check for correctness of machining datum. This forms the foundation of all precision machining.

2. Tool Selection and Spindle Start:

Based on the material and machining operation (e.g., machining planes, grooving, drilling), a suitable milling cutter is selected and fitted on the spindle. The spindle is turned on, and the cutter works at a high speed.

3. Manual Feed and Cutting Control:

The user controls the relative motion between the worktable and cutter in the X, Y, and Z axes by a handwheel, the cutting speed, cutting path, and cutting depth. The dimensions are kept under control during the process depending on experience, touch, and measuring tools. In LS Manufacturing solutions, our engineers implement this principle, with clever methods and attention to detail controlling the entire machining process in-house.

LS Manufacturing produces every part to your precise specifications and saves material waste through one-time molding and fine control and achieves double optimization of cost and quality.

Figure 2: Manual Milling Process by LS Manufacturing

What Are The Key Differences Between Manual Milling And CNC Milling?

There is a need to understand the differences between manual milling and CNC milling so that the optimal machining solution is chosen. Briefly, manual milling relies on the ability of technicians and is suited to flexible, small-lot production; CNC milling is programmable and most suited to mass production of complex parts. The principal differences are summarized in the table below:

| Comparison Dimensions | Manual Milling | CNC Milling |

| Cost and Control | Low capital investment, low running costs, suitable for low-cost projects | High capital cost, high programming and setup cost |

| Flexibility and Efficiency | Fast setup, simple conversion, fast response for small batch production | Very high efficiency and accuracy in mass production, but slow setup |

| Accuracy and Complexity | Accuracy depends on operator skill, suitable for regular geometries | Capable of micron-level accuracy and 3D surface machining of complex geometry |

We at LS Manufacturing do not simply sell one process. Instead, we carefully examine your project requirements (such as batch size, budget, complexity, and lead time), impartially considering the pros and cons of manual milling and CNC milling to guide you on the best process combination for you. We want to help you accomplish your production goals within your budget and in the most efficient way.

In Which Industries Is Manual Milling Widely Used?

Manual milling, as a fundamental and flexible machine technology, is a fundamental technology in many industry sectors. Its core value is that it can perform small-batch and highly complex or quick-response machining operations under the direct control of the operator. Manual milling is widely used, especially exceling in the following industries:

1. Aerospace:

In aerospace manufacturing, many mission-critical components (e.g., engine structural elements, composite material skin edges, etc.) are likely to require manual fitting, prototyping, or in-place machining. Manual milling, for example, is better for its flexibility in drilling holes on certain composite material parts and making fine adjustment during assembly. This ensures assembly specifications with tight tolerances. We also provide such precise manual machining at LS Manufacturing.

2. Automotive Production:

In the automobile industry, especially in prototyping production lines, tooling fixture rapid production and fixing, and manual milling demonstrate its cost-effectiveness and rapid response features. For example, in Toyota production plants, manual milling is utilized in cutting tool maintenance and fixing needed for powertrain production and prototyping. LS Manufacturing, with experience, can provide cost-effective solutions to automobile manufacturing clients.

3. Mold Manufacturing:

Extremely high flexibility and precision are needed in mold making. Manual milling is frequently applied to scribing, chiseling, sawing and filing, hole machining, and scraping, grinding, and polishing mold parts. For example, manual milling machines are the primary machines when machining forming surfaces, guide grooves, and template hole systems of common molds.

LS Manufacturing, with its years of experience, provides manual milling services to industries, helping customers defeat the problems of complex components and quick prototyping needs, demonstrating the eternal vitality of this antiquated skill in modern manufacturing.

From the high-accuracy aerospace to mass-production car making and the highly adaptable mold-making industry, the applications of manual milling are multifarious.

Why Is Manual Milling More Advantageous In Certain Scenarios?

Manual milling continues to have significant strengths within the contemporary high-efficiency production environment due to its unique worth. Faced with rapid prototyping, pilot mass production in small runs, or debugging of complex workpieces, the cost savings and versatility gained from manual milling machines are liable to make them the optimal choice. Specifically, its advantages are mostly expressed as:

1. Rapid response and extremely brief preparation cycle:

No complex programming or special tooling is required; trained operators can go straight to machining without spending time on slow CNC programming and simulation verification. This makes manual milling achieve "ready-to-work" processing productivity in emergency orders, design confirmation, or short-term modification cases.

2. Unparalleled cost-effectiveness:

Single-piece or small-lot manufacture is neatly avoided by human alternatives from high programming costs as well as special tooling cost. Investment and maintenance charges in machinery are far lesser than that of comparable CNC machinery, allowing customers to channel their funds directly into core value domains.

3. Work Flexibility Special Working Conditions:

In machining special parts, repairing parts, or handling special material characteristics, operators can regulate parameters and methods in real time based on the cutting condition and sound. This real-time capability to judge and compensate for "hand-eye coordination" is difficult for automatic equipment to completely replace.

LS Manufacturing has been able to cut sample delivery cycles by up to 50% for a majority of customers by being in a position to utilize manual milling processes with flexibility, and has significantly streamlined production efficiency in the production of small batches of complex parts, achieving the best possible balance of cost and efficiency.

Figure 3: Control loop diagram by LS Manufacturing

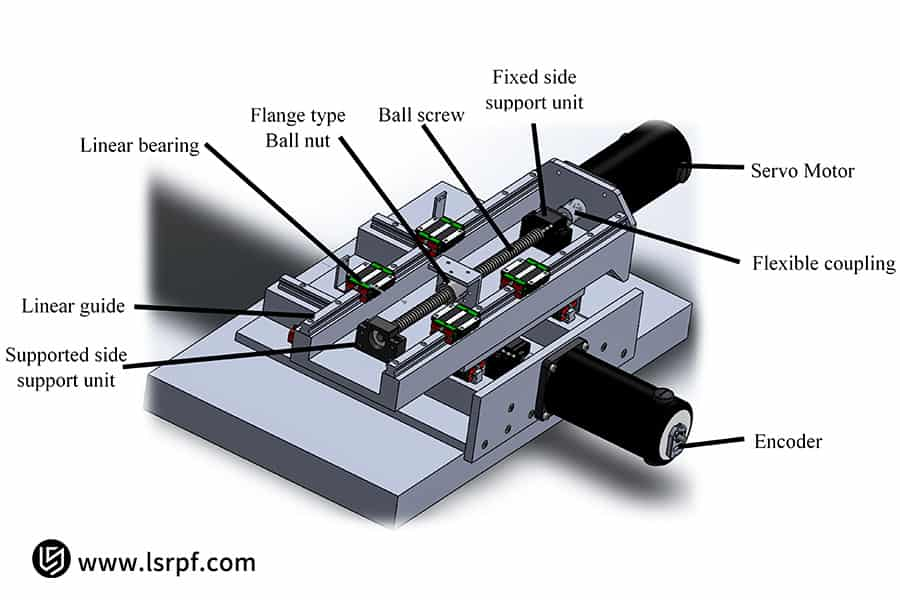

How To Choose The Right Manual Milling Machine?

The choice of the right manual milling machine is the first step towards ensuring the efficiency and accuracy of manual milling operations. Faced with a variety of models and configurations available, companies have to make reasonable decisions from actual processing needs. It is here very precisely that LS Manufacturing, being experienced, can add value to customers. The three following points must be addressed in choosing the right equipment:

1. Range of Processing and Table Capacity:

Based on the most frequent sizes of workpieces to be processed, select a table with sufficient area and travel. Equipment that is too small will limit processing capacity, while equipment that is too large will result in excess resources. Our engineers can help you properly assess your machining needs and recommend equipment of similar sizes.

2. Power and Material Type:

Machining aluminum alloys and high-strength alloy steels requires vastly different machine tool stiffness and spindle power. Selecting a model of the machine with the proper power and torque according to different types of materials is crucial to ensuring machining results and tool life.

3. Standards of Precision and Long-Term Stability:

Check critical parameters like guideway accuracy of the machine tools and spindle runout. A good and well-maintained manual milling machine is the prerequisite for stable quality of machining, which has the direct consequence of product yield and production cost.

Choosing the best manual milling machine requires a decision that must be carefully technical as well as economic. Not only do we provide superior machining capability at LS Manufacturing, but we also apply our vast experience in manual milling operations to allow customers to properly assess their needs and recommend the best equipment solution, offering long-term production integrity as well as return on investment maximization.

How Does LS Manufacturing Solve Customer Issues With Manual Milling?

When a auto parts supplier was facing critical project delays in excess of incurring too much cost for small-batch prototyping and too much CNC programming time, LS Manufacturing provided a highly effective, customized solution through flexible manual milling methods.

1. Client's Dilemma:

The contractor required preparing a batch of prototypes of the engine mount in a hurry but were faced with a dilemma: CNC milling was too laborious in programming and preparation, while the cost of small batches was prohibitively high; outsourcing, however, could not guarantee delivery terms, significantly impacting the schedule of developing the new model.

2. LS Manufacturing Solution:

After a deep analysis, we chose a manual milling-based quick response solution. Experienced engineers operated high-precision manual milling machines manually themselves, optimizing clamping and cutting paths according to the nature of the workpiece, skipping the time-wasting programming step. Machining started within 24 hours of receiving the drawings, permitting faster delivery.

3. Results and Value:

Through this successful LS Manufacturing solution, the customer reduced prototyping costs by 30% and shortened the delivery cycle by 50%, allowing the project to proceed smoothly. Through this partnership, not only was the client's urgent need addressed, but also demonstrated was the unique value of manual processes in modern manufacturing, and it solidified an ongoing cooperative relationship between the two.

This case illustrates that in the situation of small-batch, high-time-efficiency mass production of complex parts, LS Manufacturing, endowed with its mature manual milling technology and rich machining experience, is able to offer customers cost-effective and efficient customized machining services and become a trustworthy manufacturing partner.

Figure 4: Manual milling operations by LS Manufacturing

How To Evaluate The Cost-Effectiveness Of Manual Milling?

To assess the cost-effectiveness of manual milling objectively, enterprises should go beyond mere citation of equipment cost and possessed analytic work from three perspectives: initial cost, operating cost, and long-term benefit. Such routine evaluation process could objectively indicate the economic merit of manual milling in small batch and high-flexibility production situations. Especially, cost-effectiveness assessment should include the following key factors:

1. Initial Investment Analysis:

The cost of buying a manual milling machine is considerably less than the price of an equivalent CNC machine and no expense needs to be incurred on expensive programming software and post-processing hardware. This implies that companies are in a position to start with quick production using a less heavy asset at the project's beginning, consequently reducing financial risk.

2. Considerations in Operating Costs:

Operating costs are predominantly seen in the use of skilled labour and the wear and tear of traditional tools. Since it obviates the use of programmers dedicated to the task and extensive program debugging, its overall labour and time cost is usually lower than in automation solutions in small-batch, multi-variety production patterns.

3. Long-term benefit assessment:

The greatest long-term advantage is the value of opportunity garnered from its record flexibility—the ability to react immediately to emergency orders, design changes, and special material treatment, avoiding losses caused by plant shutdowns. Concurrently, lower maintenance costs and increased equipment life ensure a stable return on investment.

LS Manufacturing not only provides cost-effective manual milling service but also helps customers conduct complete cost-benefit studies so that all investment will ensure maximum returns in flexibility, speed, and reliability, providing meaningful data support for customers' manufacturing plans.

What Are The Future Trends Of Manual Milling?

With this era of smart manufacturing entering the mainstream, manual milling has not stayed static but has entered a new era of development through integration with digital technologies. As a valuable addition to modern manufacturing, manual milling machines are demonstrating their tried-and-true dynamism through technological uplift. The future of manual milling will be shaped by three different trends:

1. Tightly integrated with computer measurement instruments:

Older manually operated milling machines are increasingly becoming integrated with computer readout instruments and laser measuring instruments. Operators are able to receive precise machining dimensions in real time, significantly improving machining accuracy and efficiency, but preserving flexibility and overcoming the precision limitation of traditional methods.

2. Developing into an excellent complement to intelligent manufacturing systems:

Manual milling is a proper complement to CNC machining in flexible manufacturing systems, responsible for work such as small-batch customization, rapid prototyping, and maintenance of equipment, forming a symbiotic pattern of "automation for large-batch production, manual production for small-batch special parts."

3. Intelligent auxiliary decision-making systems:

The future generation of CNC milling machines is making use of machining parameter databases and process decision-making systems, providing operators with best cutting parameter suggestions, reduced reliance on operator experience, and more scientific and controllable machining.

Faced with the dynamic evolution of the manufacturing industry, LS Manufacturing also includes digital measuring and intelligent auxiliary technologies to the mix in order to offer customers solutions that are progressive but with the flexibility of legacy processes along with innovative precision in order to compete in a changing market.

Why Choose LS Manual Milling Services Of LS Manufacturing?

Among so many providers of machining services, using LS Manufacturing as your manual milling service provider means you get to experience a full package that combines the essence of old-world craft and demands of contemporary engineering. We understand that superior manual milling services do not only lie with the equipment but also in the skill of the operator and experience with customer requirement. Our forte lies in the following three spheres:

- Experienced Technical Personnel: LS Manufacturing has experienced technical personnel with over 15 years of experience working on manual milling machines, and it is thus possible for them to work on different levels of machining complexity ranging from plain parts to intricate workpieces and provide precision in every single cut.

- Rapid Response System: Schedules are critical to LS Manufacturing. Our flexible manual mill processes allow us to respond quickly to your urgent needs, bypassing lengthy programming and vastly cutting delivery cycle from drawings to finished products.

- Expanded Customization Capability: We do not offer generalized, off-the-shelf solutions. LS Manufacturing provides extremely customized manual milling service to meet your specific needs, whether materials selected, process routes, or control accuracy.

LS Manufacturing, with its hands-on experience in manual milling, finishes every job on time and to your specifications. Need a consistent, flexible, and seasoned manufacturing company? Contact LS Manufacturing today to get a tailored machining solution specifically tailored to your specifications.

Figure 5: Conventional Milling Machine by LS Manufacturing

FAQs

1. Is manual milling appropriate for mass production?

Manual milling is suitable for prototype fabrication or low volume manufacturing due to its flexibility although being inefficient. For mass production, LS Manufacturing recommends that CNC milling technologies are employed in order to have maximum efficiency in manufacture and cost reduction.

2. How accurate is manual milling?

Manual milling, under careful operation and micro-adjusting, can be of high accuracy of ±0.05mm. LS Manufacturing engineers handle the process carefully to cater customers and minimize errors.

3. Is CNC milling or manual milling cheaper?

Manual milling is less in initial equipment and is possible for low-budget projects or small batches; CNC options are better for long-term high-output requirements. LS Manufacturing will have the best price according to your requirements.

4. Does a manual milling machine need maintenance?

Their everyday lubrication, cleaning, and checking of main components may prove to be a miracle for lengthening the machine life. LS Manufacturing provides good quality maintenance instructions to help customers with effective long-term operation of equipment.

5. What type of material is manual milling ideal for working on?

Best on a variety of materials like steel, aluminum, and plastics, with better performance on soft metals and general-purpose plastics. LS Manufacturing varies process parameters based on material properties to yield the best machining quality.

6. Manual milling operators are trained how?

LS Manufacturing provides methodical training in equipment operation, process orientation, and safety protocol. With practice complemented with theory, it makes the trainees competent enough to gain basic competence effectively.

7. Can manual milling produce complex geometry?

Yes. Step-by-step machining and skilled cutting tools under the supervision of skilled operators can be used to produce complex geometries. LS Manufacturing has been able to solve many complex design issues over decades of experience.

8. What is the manual milling lead time for services from LS Manufacturing?

Standard work orders typically take 1-2 weeks to turn around; more complex work has additional lead time attached. We respect quick turnaround and make efforts to meet our customers' need for time. Rush orders can be rushed.

Summary

Manual milling, being an economic as well as efficient milling process, has always held a special and distinctive position in modern manufacturing. Its high flexibility, rapid response, and batchless production advantage enable it to be an invaluable complement to automation machining.

Skilled technical staff and abundant hands-on experience of LS Manufacturing have allowed it to effectively help numerous customers to deal with real problems such as prototyping, urgent orders, and composite parts machining, in fact, achieving the best cost-effectiveness ratio and bringing the most benefits to our customers.

If you are having trouble machining specialty pieces, low-volume lots, or rapid turnaround, take action now! Contact LS Manufacturing now at no obligation for free technical consultation and an honest price quote. Allow us to safeguard your project with our skilled manual milling expertise!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.