Rapid prototyping service could not have been more welcome, as it arrived at a time when the manufacturing sector was grappling with issues of long development time, high investment associated with traditional steel molds, and economic inefficiency in small-batch production, whether they liked it or not. The time involved in the development of prototypes, beginning from 4-8 weeks, together with the cost of the steel mold, beginning from $20,000 to $50,000, have become extreme hurdles in the development of inventions in the presented challenging surroundings by now.

This problem stems from the mind-set established by convention, and this has always impeded rapid improvement and often lacked understanding about the design and materials going into the modular tools. In this article, from over 200 LS Manufacturing case scenarios, it will be made clear that the optimal solution removes both aforementioned problems. In the next section, we shall outline how the cost savings from 40-60% and lead times of 2-3 weeks can be achieved.

Quick-Reference Guide: Rapid Prototyping Services

| Section | Key Focus | Core Solution |

| Introduction | Market Challenge & Value Proposition | Fixes the problem of long cycle times 4-8 weeks and high tooling costs $20K-$50K associated with traditional methods, enabling faster and more affordable iteration. |

| Technology Breakdown | Process Selection (SLA, SLS, FDM, MJF) | Comparison of technologies with respect to material, accuracy, speed, and cost to arrive at the best technology for the prototype, considering prototype attributes. |

| Rapid Tooling Strategies | Bridge & Soft Tooling | Securities methods such as silicone molding and aluminum tooling for low-cost production of 50 to 10,000 units in 2-3 weeks. |

| Design for Additive | Manufacturing (DfAM) Cost & Time Optimization | Leverages design freedom: weight reduction, component integration, in order to enhance performance and eliminate. |

| Material Science | Polymer & Metal Options | Guides material selection from concept resins to production-grade thermoplastics/metals for required mechanical/thermal properties. |

| Case Study Analysis | Practical Application & ROI | Examples of how costs can be reduced by 40-60% and the lead time reduced from months to weeks. |

| Implementation Roadmap | From Quote to Part | Certainly captures the efficient sequence of operations, which begins with consulting, and then technology selection, and thereafter DFM analysis, and finally manufacturing and then shipping. |

We offer solutions to the pressing innovation challenges that businesses face. These innovation challenges make businesses too expensive as well as too slow in product development. With access to the strengths offered by advanced rapid prototyping and tooling, businesses have the ability to create better products faster and more affordably, and it is because of this that iteration is crucial.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The strength of this guide, therefore, lies in the fact that this guide has been produced on the back of experience, not just theories. In the case of LS Manufacturing, they talk about more than 15 years of direct experience in the workshop, not only about prototype development but about trying to overcome the challenges faced due to rapid prototyping.

Our processes are developed in strict alignment with industry standards, referencing frameworks from authoritative bodies like the Society of Manufacturing Engineers (SME) and the Environmental Protection Agency (EPA). This commitment ensures every prototype meets rigorous benchmarks for precision, reliability, and sustainable manufacturing practices.

With more than fifty thousand custom rapid prototypes in our project inventory, we've learned from both our successes and also some very painful failures. Each strategy on this page has been discovered in the laboratory by the very hands that were covered in machine oil, full of metal shavings, and by quality control so that we might spare you the painful expense that we incurred.

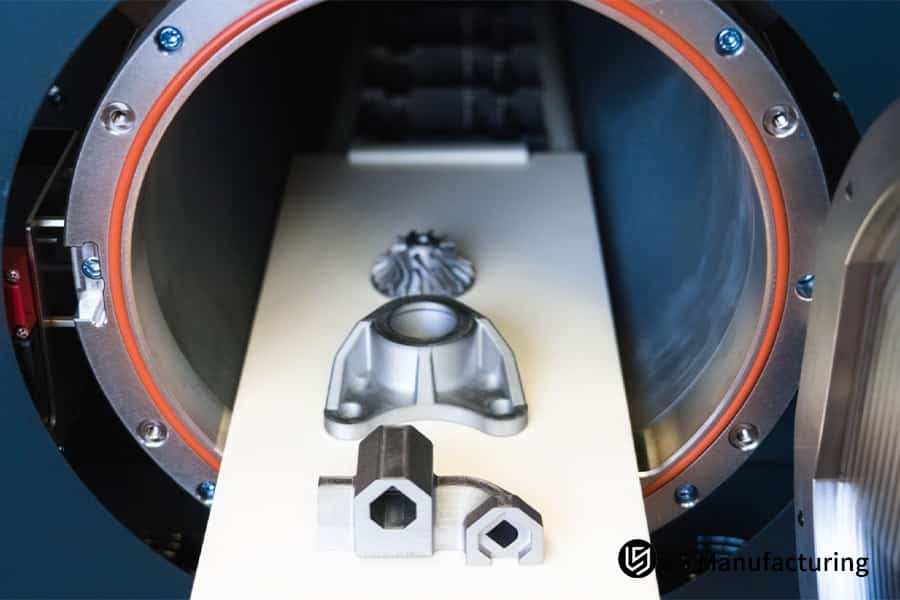

Figure 1: Accurate components produced by an automated additive manufacturing system by LS Manufacturing

How Can Rapid Prototyping Cut Costs With Innovative Tools And Technologies?

One of the most important challenges these days in the field of the offered rapid prototyping services relates to the quality and quantity aspect of reproduction without the cost and time associated with steel mold production. In this respect, the innovation required to tackle the above challenge hinges on the use of high-functioning aluminum alloys and high-functioning thermal management as indicated below:

Material Innovation: High-Performance Aluminum Tooling

Convents steel molds cost high and take time to manufacture. We implement cost-effective rapid tooling using 7075 aviation-grade aluminum. This material, apart from offering superior strength ratios, also allows machining at cyanide-hardened steel rates of up to 50,000 injection cycles, which would typically qualify as intolerable and would daleko slower and costlier to machine compared with conventional steel.

Thermal Management: Conformal Cooling for Cycle Time Optimization

One of the major bottlenecks in the production process is the homogeneous removal of heat. We use a conformal cooling channel. It is a 3D printed structure designed to imitate the shape of the molding cavity. This is much more effective than the inefficient straight-drilled cooling channels currently used primarily for the purpose of forcing the cooling process at a faster and equal rate. This leads to a highly optimized injection cycle time of 35 seconds.

Design Philosophy: Modular Systems for Flexibility and Cost Control

To control investing cost, we apply the modular design approach for the mold base and parts. The modular design allows reusing parts in various projects and only machines customized parts according to the task, while the rest of the mold cost is limited between $8,000 and $15,000, with a cost-saving of up to 40% compared to steel tooling.

Seamless Workflow: Bridging Development and Production

This service is optimized to make the transition from prototype to production tooling smooth. This is what is considered optimal for volume production of anywhere between 5,000 to 50,000 units a year. This method compresses the standard product development cycle to only 3 weeks of first article manufacturing, while real-world project data demonstrates a concurrent delivery of 25% cost per unit.

This article describes a proven, significant technical method of cost-volume paradox resolution to be used during the development process. It goes beyond typical service definition to offer a specific technical scheme regarding the developable part of high flexibility created through rapid prototyping, as well as a clear competitive advantage of the developers involving a term that is extremely short.

How To Select The Optimal Solution For Low-Cost, Rapid Tools In Different Material Applications?

The strategic selection of tooling materials is fundamental to successful low-volume production tooling. Achieving the optimal balance between cost, durability, and final part quality requires a data-informed methodology. This guide provides a concise, actionable framework for matching tool steel and aluminum to specific polymer resins, directly addressing how to reduce tooling costs through intelligent specification.

| Target Polymer | Optimal Tooling Solution | Key Performance Metric | Justification & Economic Rationale |

| ABS, PC, and Blends | 7075 Aluminum with Nitriding (HRC 60-62) | 50,000 - 100,000 cycles | ~60% lower prototype costs than steel. Best suited for prototyping & medium-volume production, where volume robustness is of foremost importance. |

| Glass-Fiber Filled (e.g., GF-Nylon) | H13 Pre-hardened Steel | 1,000,000+ cycles | Mandatory for wear resistance. The abrasive glass fibers will prematurely degrade aluminum, making steel the only cost-effective choice for part quality and tool life. |

| High-Temperature/High-Precision | P20 Tool Steel | 1,000,000+ cycles | Necessary for thermal stability, corrosion resistance, and sustained precision in demanding, long-run production environments. |

Low-volume production tooling can be optimized for cost by taking into account the abradability of the material. In contrast, aluminum tooling would be best for the general-purpose resin, but H13 steel tooling would be the investment required for the glass-filled materials in order to keep the cost of quality in perspective. Work together with the expert custom rapid tooling supplier to incorporate the specification approach.

Figure 2: High-accuracy machining for prototype tooling and small-batch manufacturing by LS Manufacturing

What Key Technical Challenges Arise When Moving Tools From Prototype To Production?

The requirements that effect the formation of a seamless transition between prototype to production tooling are dimensional errors, production defects, and poor debugging practices. The major way of fulfilling requirements through the basic approach helps solve the issues created by the following:

3D Scanning for Precision Validation

As part of the digitization of our prototype as well as the first moldings, we make use of high-resolution deviation scans of our three-dimensional data. This is because, here, we are able to identify a deviation map to provide us with directions regarding the adjustments that need to be made to our mold tooling during the CNC process. Tolerance levels are systematically verified to ensure that our final product is created as desired, to a range of ±0.1mm.

Predictive Moldflow Simulation

Advanced CAE software simulates polymer flow and cooling to predict defects like sink marks. This analysis allows us to proactively optimize gate locations and part geometry in the tool design, preventing flaws at the source. This predictive approach reduces mold trials, saving significant costs and enabling fast turnaround tooling.

Conformal Cooling for Stability

In addition, we integrate the use of conformal cooling channels through 3D printed techniques that take the contours of the mold cavities into perspective. This method of cooling the molds helps in reducing part warp effects during the cooling process. The process control in this regard addresses the significance of the application of bridge tooling for prototypes.

Removing the risk of scale-up of production by integrating precision metrology, simulation, and thermal management, it facilitates a reliable and cost-managed method of transferring complex designs to robust volume production.

How Can Small-Batch Tooling Achieve Economic Breakthroughs Through Process Innovation?

Economic viability in low-volume production tooling with production volumes between 500 units and 5,000 units cannot be achieved by relying only on classical high volume production. The primary problem with high production volumes is, in fact, optimizing the initial investment cost of the tool and meeting the unit costs. The below approach follows a reported structure in its aim to come up with cost-effective rapid tooling accompanied by inventions.

| Strategy | Implementation Method | Key Performance Impact |

| Tooling Platform Standardization | Utilizing standardized mold bases and modular components. | Reduces custom machining by up to 40%, slashing initial lead time and cost. |

| Thermal Management Optimization | Use of minimized valve gate hot runners systems. | This decreases the waste material-sprue from 15% down to less than 3%, thus directly. |

| Surface Enhancement | With the use of high-end surface finish processes such as chrome plating. | This has been able to extend the life of the tool by 30%+ when dealing with an abrasive material. |

Economic efficiency for on-demand manufacturing tooling is achieved by standardizing platforms to cut initial cost, integrating hot runners to reduce waste, and applying surface hardening to extend tool life. This integrated approach delivers a per-part cost reduction exceeding 25% compared to standard outsourced tooling, providing a technically robust solution for competitive, high-value low-volume production.

What Are Five Practical Strategies For Reducing Tool Costs?

Below is the technical process which helps to ensure the very high cost of the injections mold needed in the competitive manufacturing process is reduced. This process helps to ensure the very high cost associated with the injections mold by reducing the costs to a very great extent. The strategies which are used are:

- Strategic Design for Manufacturability (DFM) Optimization: The prudent design guidelines through data-driven practices tackle head-on mold-related defects and too much material use. Key takeaways include maximizing thickness at 2.5-3mm, reducing overall material usage by 15%, and applying no less than 1° draft angles on every vertical surface to ensure ejection success and minimize drag. The foregoing active role on DFM will forever be ingrained in our approach on how to reduce tooling costs.

- Advanced Mold Structure Consolidation: During we intend to include the actions in the mold structure to enhance the assembly efficiency by keeping the number of parts to be assembled low. In the case of undercuts, instead of using assembled parts, we intend to have slider mechanisms milled into mold blocks. This consolidation, managed by a custom rapid tooling supplier, cuts machining and fitting time by 30% and enhances mold longevity by improving structural integrity.

- Material and Component Standardization: We substitute the high grade steel imported with the pre-hardened steel (P20/PX5) steel. This leads to a saving in the cost of the material of 40%, without eliminating the consideration of the hardness. Lastly, we adopt the ejector pin system provided by the managed inventory. This will help the company by decreasing the lead time by 5 days. This will be facilitated because of the rapid prototyping services provided.

This structured design approach with optimized design and integrated tooling architecture clearly establishes a very high level of cost engineering with regards to the capability of expertise within the field of manufacturability. This report itself serves as the blue-print, which clearly has focus on the technical solutions that can be achieved with regards to the cost and time efficiencies available by using the injection molding process.

Figure 3: Tailored quick tooling for on-demand and limited production runs by LS Manufacturing

How Do Bridging Tools Play A Role In Risk Control During Prototype Validation?

In the present context, the risk management strategy that proposes the use of bridge tooling for prototypes would be an important fillip in the gap that exists in the transition phase between the prototyping stage and mass production. The risk associated with the high cost of investments in steel tooling before the final design and the validation of market acceptance would be addressed as follows:

- De-risking High-Volume Material and Process Validation: With a goal of creating over 5,000 functional components in under three weeks, we would utilize bridge tooling for prototypes, usually CNC aluminum prototypes. This would enable highly aggressive validation in near-production volumes, proving the performance characteristics, assembly mating, and market acceptance before locking into final tools, thereby avoiding the potential for a costly $50,000 capital equipment mistake.

- Accelerating Design Iterations for Production-Intent Validation: In contrast to 3D printing, the bridge tools immediately begin producing components with genuine polymers and contribute 85% of the overall mechanics. This fast turnaround tooling solution supports high-volume analysis for the position of gates, cooling, and ejection order rapidly. Any issues in sink or warp areas are identified and corrected in the aluminum tool level, and the design of the aluminum tool is directly replicated in the final steel mold.

- Enabling a Seamless and Data-Backed Transition: The core value lies in creating a low-risk, data-informed pathway. By serving as a functional and economic intermediary, this prototype to production tooling strategy generates conclusive performance data. This empirical evidence supports the decision for production steel tooling, ensuring the final investment is based on verified part functionality and manufacturability.

This is reflective of the methodological approach adopted in the minimization of financial and technical risk, which can be encountered in the product development stage. The methodological approach adopted offers an additional element within the business, which shows the validation of the analysis conducted with the intention of production occurring at a fast pace, which shows that the final capital expenditure required through optimization was justified.

What Manufacturing Process Innovations Are Needed To Support Rapid Delivery?

Compressed schedules cannot solve but only improve upon basic innovations that must happen to manufacturing execution to make way for compressed lead times. This report describes a level of technical adjustment that makes available a level of reliability as well as a level of delivery precision of tools within very short 21-day timeframes, as set forth:

Advanced Digital Manufacturing Execution

For the 5-axis CNC machining machine, the strategy is also parallel, where the mold bases, cavities, and cores are machined at the same time at the machine banks. This ensures that the machining of the cores takes only 5-7 days, with the bottlenecks removed. For the finishing of the critical features developed through setup, the accuracy of the process also remains at ±0.02mm, with the realigning removed, which plays an essential role when considering fast turnaround tooling.

Integrated and Concurrent Validation Processes

Mold validation is not an end process, but an integrated and concurrent process to prevent delays. We employ 24 hour mold trial services in a linked facility, and the testing begins immediately. Process parameters are dialed in on first articles, and critical dimensions are statistically verified to achieve Cpk ≥ 1.67 before leaving the trial press.

Agile Digital Infrastructure and Logistics

The compression of lead times is dependent upon the digital flow with minimal friction. We utilize cloud-enabled, on-demand manufacturing tooling platforms to expedite collaboration and approvals to prevent lag time. This digital thread from design release to programming allows the milestone of data-to-part within the 21 days timeframe—a capability developed and validated through our rapid prototyping services pipeline.

This approach proves that fast turn times are an intended result of parallel processing, validation integration, and digital agility. It's an approach which delivers competitive advantage to the age-old problem that fast turn times are inherently imprecise.

Figure 4: Personalized fast tooling and multicolored prototype models exhibited by LS Manufacturing

How Do On-Demand Manufacturing Tools Achieve A Balance Between Flexibility And Cost Control?

The production flexibility, which is with the technological trade-off to control the costs while producing in small batches, is very crucial. It follows after that the technical description of the system, since it uses the data-driven tool management approach, and its overall strategy will be as explained by these points.

Proactive Tool Health and Lifecycle Management

Our cloud-based monitoring platform tracks real-time tooling performance metrics, such as cycle count and injection force. With this data, our predictive algorithm provides maintenance alerts two weeks in advance using historical wear data, avoiding unplanned stops. This system is central to our on-demand manufacturing tooling model, maximizing asset utilization and lifespan.

Agile Manufacturing for Economical Small Batches

Cost-efficient modular, flexible manufacturing cells achieve a major goal. Mold bases are standardized, interchangeable inserts are used, and molds are changed over in less than 4 hours for different products. This agility changes the cost structure, allowing tooling investment to be spread over many orders to achieve a $1.5-$3.0 per-part cost at quantity as low as 500 units.

Integrated Digital-Physical Workflow

This is because the process has been founded on the concept of the digital thread. Once the submittal of the order by the client commences, the automatic process of production of the tools and the schedules initiates. Being the custom rapid tooling supplier, we combine the concept with the physical flexible cells to introduce the concept of low-volume production tooling to meet the actual need of the market without the cost of the idle production lines.

This is a highly integrated approach, which includes predictive analysis, cell design, and digital management of the process flow. This is a highly sound base, which would make it possible to achieve the two-fold objective of being cost-effective and responsive. This would provide the answer that would fulfill the basic economic requirement for performing a high mix production.

LS Manufacturing Medical Devices Division: Rapid Prototyping Project For Insulin Pump Housings

The healthcare sector, particularly in relation to medical devices, relies on rapid prototypes. The above-mentioned case describes how LS Manufacturing aided a client in solving difficult injection molding challenges of a critical part – that of an insulin pump housing through rapid tooling solutions.

Client Challenge

The client required an insulin pump housing made from the medical grade of PC and had to be ISO 13485 certified. The component had a very complicated thin-walled feature of only 1.2mm thickness, which had to be accurately made. The response from steel tooling had a lead time of 8 weeks and a price of $40,000, which threatened the entire project timeline for the clinical trial.

LS Manufacturing Solution

A 1+2 cavity fast mold and tool was developed and made with qualified aluminum and a conformal cooling system to achieve a cycle time of 30 seconds. Gas-assisted injection molding was carried out with high accuracy to prevent any sink marks on the wall to ensure the biocompatibility of the surface finishing of the housing.

Results and Value

The duration of the transition in the transition phase to the production stage of first article parts took a total of 18 days, and the total cost in final tooling was $15,000. The goal was met to ensure an even quality in the parts with first pass yield of 99.8%. The client’s clinical verification process had been shortened by an unprecedented four weeks to accomplish the production tool to support the production of 100,000 units a year.

As an example of what we do well at LS Manufacturing with high-risk projects, this particular example shows how we have used aggressive rapid tooling techniques on our particular project with our client to ensure our particular client achieved the production-ready design on their product development schedule with our high-velocity expertise, which comes from the medical industry.

If your project is facing time pressure and requires professional and rapid prototyping support, we will provide you with an efficient solution.

How To Evaluate The Overall Capabilities And Reliability Of Rapid Prototyping Tool Suppliers?

The choice of an effective and trustworthy partner to perform the task of time-critical tooling remains a decision of critical complexity. This report attempts to establish the point that besides general parameters, one has to look beyond in selecting the partners who are to ensure the success of this project. The parameters according to which the selection of the partners takes place are listed below:

- Verifiable Process and Quality System Documentation: We do facilitate the evaluation by sharing our quality manual and process control documents certified under ISO 9001:2015. We also allow our clients to examine our design control, corrective actions, and traceability processes. Even for rapid prototyping services, we issue first-article inspection reports and process validation, proving our continuing output.

- Technical Capability and Deliverable Guarantees: The presence of performance guarantees should be ensured. A good supplier should be one that provides written guarantees on the number of cycles of tooling life, like ≥50,000 cycles of aluminum production molds, along with material guarantees. The inspection of the part by a CMM within the company should allow an accuracy of ±0.02mm.

- Transparent Analysis and Data-Driven Validation: True reliability is demonstrated proactively. We provide clients with mold analysis reports, such as cooling line uniformity simulations, to predict and prevent warpage. This technical collaboration, a hallmark of a true custom rapid tooling supplier, transforms tooling from a black-box purchase into a co-engineered, predictable asset, ensuring both performance and cost-effective rapid tooling outcomes.

This framework provides a competitive methodology for vetting suppliers based on empirical evidence and guaranteed metrics. It demonstrates that true capability is defined not by claims, but by transparent processes, verifiable technical output, and a collaborative, data-driven approach to achieving reliable rapid prototyping solutions.

FAQs

1. What are the main cost differences between rapid prototyping and mass production tooling?

The major differences lie in material (aluminum vs. steel) and the number of cycles (50,000 vs. 1,000,000). The cost relative to the aluminum mold is 60% for small-batch verification.

2. How can I assess whether the product quality of rapid tooling meets standards?

These can be accomplished through the use of dimensional inspection, materials analysis, and life verification. A comprehensive First Article Inspection Report is also provided by LS Manufacturing.

3. What is the typical minimum order quantity (MOQ)?

The MOQ for rapid tooling can be as low as 500 pieces, depending on part size and material. Tiered pricing is available.

4. What expedited options are available for urgent delivery?

The type of services it offers in this regard include parallel engineering, simplified design, and standard mold bases. LS Manufacturing also offers accelerated delivery with delivery times as low as 15 days.

5. How is molding quality ensured for complex structural parts?

It helps in the optimization of gating and cooling systems through Moldflow analysis. For complex parts, LS Manufacturing has raised the production rate to 99.5 percent.

6. What is the response time for mold maintenance and repair?

There is technical support and general problems get solved within 48 hours. The warranty for free repairs covers the lifetime of the mold.

7. How is design intellectual property protected?

Safety is ensured with ISO 27001 certification, with the help of NDA agreements, secured production areas, and encrypted data transmission.

8. How can I obtain an accurate quote for rapid tooling?

3D files, material requirements, per annum usage, and surface needs will be provided. Quote to be provided by LS Manufacturing in 2 hours.

Summary

Scientific rapid tooling development helps to improve the outcome of rapid prototype development, the introduction of the end product to the market, and the combination process of prototype development and mass production.

To avail yourself of custom rapid tooling solutions or your free DFM analysis, you can simply submit your designs and receive expert process optimization suggestions and quotes within just 24 hours. You can contact the technical team of LS Manufacturing today to optimize your designs and make the best out of your project.

Submit your design files now to receive a customized rapid prototyping solution and accurate quote, and accelerate the realization of your creative ideas!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.