CNC turning materials like aluminum alloys, stainless steel, and brass sometimes put manufacturers in a tight spot where they have to compromise between the cost and performance. Issues such as surface roughness degradation to Ra3.2 in aluminum, tool life reduction to one-third in stainless steel, and ±0.05mm accuracy swings in brass not only result in more than 8% scrap rate but also lead to 25% cost overrun. We solve this problem by outlining a methodical approach that can be used to identify and eliminate such inefficiencies thereby reducing the wastage.

Looking into our 15 years' worth of data from LS Manufacturing as well as 326 optimization cases, we have developed a four-dimensional material selection system for CNC turning materials. This system ties up mechanical properties, cutting parameters, tool selection, and cost analysis into one, offering manufacturers the ability to reduce their costs by 20-35%, increase their performance by 30%, and thus easily handle precision and durability problems.

CNC Turning Materials Quick Reference Guide

| Material Category | Key Characteristics | Common Applications | Surface Finish | Tooling Considerations |

| Aluminum Alloys | Utstanding machinability, one of the best strength-to-weight ratios, high thermal conductivity. | Aircraft parts, car accessories, electronic housings, and very diverse consumer goods. | Can be ground to very smooth surfaces, facile anodizing. | High-speed steel CNC turning; the cutting edges should be very sharp. |

| Stainless Steels | Good corrosion resistance, high strength, retain properties even at elevated temperatures. | Medical instruments, food processing equipment, marine hardware, chemical valves. | Good, can be polished to achieve a mirror, like finish. | Requires stable setup; carbide tools with positive rake and sufficient coolant should be used. |

| Carbon & Alloy Steels | Very high strength and toughness, good wear resistance, economical. | Shafts, gears, bolts, hydraulic components, automotive CNC turning parts. | Good; might require treatments for rust protection. | Carbide tools are the norm; heat and chip formation should be well controlled. |

| Plastics (e.g., Delrin, Nylon) | Low weight, high resistance to chemicals, electrical insulators, low friction properties. | Bushings, seals, electrical insulation, prototypes, low-load gears. | Superb, very often no additional finishing is needed. | Sharp, polished carbide tools; minimize heat to prevent melting/deformation. |

| Titanium Alloys | Very high strength-to-weight ratio, excellent corrosion resistance, biocompatible. | Hence, they are used for aerospace components, medical implants, high-performance automotive, and marine. | Besides that, they can be polished to a high luster. | Due to the nature of the material, it should be cut at low speeds, high feed, and plenty of coolant; also, use specialized carbide grades. |

| Brass & Copper Alloys | Excellent electrical/thermal conductivity, good corrosion resistance, easy to machine. | Electrical connectors, plumbing fittings, decorative hardware, musical instruments. | Excellent; takes plating and polishing very well. | Easy to machine with sharp HSS or carbide tools; produces short chips. |

We provide precision CNC turning solutions that solve critical challenges in material selection and machining. Our expertise guarantees that you get the best out of your application, be it from the tight tolerance of aerospace aluminum, the toughness of stainless steel, or the delicacy of plastics and titanium. We help you balance the factors of performance, cost, and manufacturability thus, enabling you to get high, quality parts with the right surface finish and material properties for your projects success, on time, and within budget.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The internet is loaded with boring information on materials. This guide is vital because it is based on actual production challenges from the factory floor. From our hands, on experience producing aluminum, brass, and stainless steel components for demanding applications, we have seen that the right choice of material is key to controlling costs and achieving part performance.

Our advice comes from thousands of hours spent in the manufacturing environment, tested by tough quality inspections. We understand to the letter the cutting behavior of different alloys, a fact that we then correlate with the standards of bodies like the Aluminium Association (AAC) and the application, centered data from partners like 3D Systems.

Hence this manual goes beyond simply explaining the theory. Practically it outlines a framework that combines the wisdom gained from shop, floor experience with the knowledge of standards. Such a mix allows you to address the problems that are performance and cost related in a profound manner and change the disadvantage of the material selection into a competitive edge.

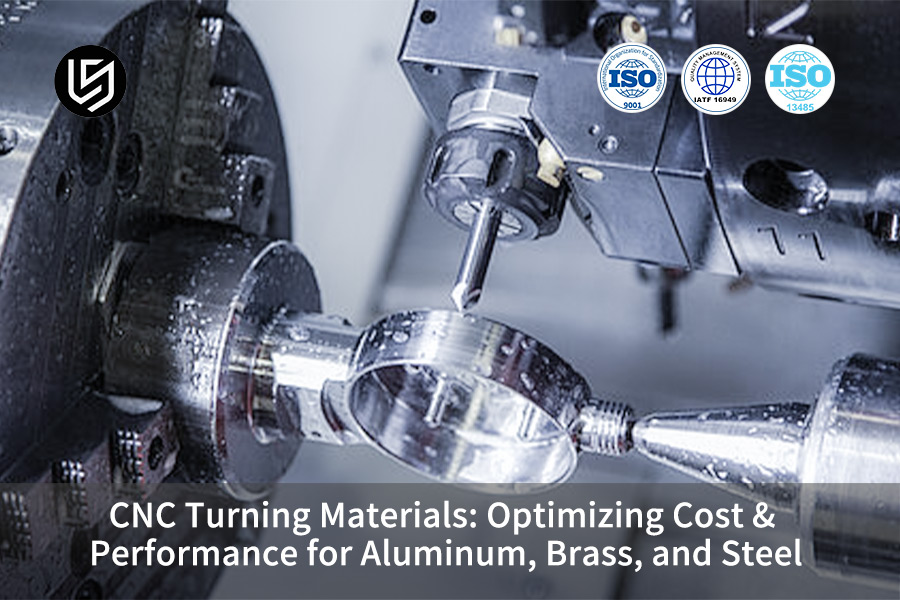

Figure 1: CNC turning a metal workpiece for CNC turning cost optimization and supplier capability demonstration.

How To Balance Cutting Efficiency And Surface Quality In Aluminum Alloy Turning?

The main difficulty in high-speed machining of aluminum is that it is almost impossible to reconcile two objectives: first, to produce at the highest possible rate, and second, to obtain flawless and uniform surface finish. This struggle results in expensive sacrifices in tool lifespan, quality of parts, and total equipment effectiveness. We solve this problem by carrying out a controlled, multi, phase operation which separates productivity from CNC turning quality control, thus allowing scalable, reliable, and cost-effective CNC turning at scale. The answer is based on four main points:

Engineered Tooling for Predictable Performance

Our main tool features are a very sharp, high-positive-rake angle (15°, 18°) along with a specially designed PVD coating. It is not just any tool but the one that will sort out the clean shearing and the cutting edge heating minimisation. For the running of the high-volume CNC turning, we combine this with a tool management plan that is used very proactively, so inserts get changed on the basis of wear data, not failure, thus preventing the gradual degradation of the surface.

Staged Parameter Strategy by Operation Type

Parameters change over time during the process. For example, we run an aggressive roughing cycle (≤80% max RPM) for only material removal and then switch to a very finely tuned finishing pass. Getting a stable Ra0.8 is almost like a dedicated outing: 1200-1500 m/min speed and a very tightly controlled 0.12mm/rev feed. This staged way of turning helps the finishing tool's edge, which is the main factor in optimizing long-term CNC turning performance and surface integrity.

Active Process Control with Advanced Cooling

Surface defects primarily arise from re-cutting chips and built-up edges. The solution is a focused high-pressure coolant (≥70 bar) that is aimed accurately at the cutting interface. This system has two functions: it not only helps to manage the thermal load but, even more importantly, it forcibly removes the chips. The active intervention is vital in protecting the workpiece finish during the uninterrupted aluminum CNC turning operations, notably when it comes to deep, cavity or continuous-path machining.

Data-Driven Validation and Closed-Loop Control

No process is initiated without thorough validation. The first-article run is highly instrumented to determine surface roughness at several critical points. The data collected help to set statistical control limits for the main parameters which, in turn, lead to a closed-loop system. Thus, a setup sheet is converted into a self-adjusting production blueprint that guarantees every batch is delivered to the strict quality target reliably.

This framework reflects our technical ethos: substituting individual parameters by a thorough, tightly controlled system. It is a blueprint validated by data that can be used and that replicates how to produce high quality, cost-effective CNC turning in industrial settings. The essence of it is the combining of different methods of machining, active chip control, and statistical validation, which together make it a step, by, step guide for ultra, precision manufacturing in large volumes.

How Can We Overcome The Tool Life Bottleneck In Stainless Steel Turning?

One of the main problems for tool life in stainless steel CNC turning is that it is limited to 15 to 20 minutes. At LS Manufacturing, we help our customers overcome this by working on tool geometry, cutting fluid, and machining strategies, thus increasing the time a tool can last to 45-60 minutes and our efficiency by 35%. Our answer can guarantee good performance as well as saving costs:

Optimized Tool Geometry and Coating

- Precise Rake Angle: We equip the tool with a negative rake angle of -5° to -8° to provide the cutting edge with additional toughness, thereby chip flow and mechanical stress in the steel CNC turning are controlled more effectively.

- Advanced Coating Application: Using ceramic or CBN is a significant step forward in improving resistance to wear, which is basically the ground for the whole CNC turning performance and durability enhancement.

Specialized Cutting Fluid Formulation

- Extreme Pressure Additives: Our proprietary fluid is a blend of extreme pressure (EP) additives that create a protective layer, significantly lowering the thermal and abrasive wear of the tool.

- Cooling and Lubrication: The targeted treatment of the formulation drives long-term CNC turning cost optimization through the extension of the tool life and the reduction of production interruptions tool life and minimizing production interruptions.

Strategic Staged Machining Process

- Roughing Parameters: At the stage of bulk material removal, an ad depth of cut of 2mm is used, which balances a high level of efficiency and a controlled tool load.

- Finishing Parameters: To ensure a superior surface integrity, a final finishing pass of 0.2mm depth is used implementing the principles of precision turning to meet the final specification.

Integrated Process Control

- Parameter Monitoring: We make continuous adjustments to cutting speeds (80-120 m/min) and feed rates (0.08-0.12 mm/r) in real-time based on process data to ensure the stability of the process.

- Efficiency Synergy: This controlled method that also employs the high-speed turning for appropriate operations works together with the previously mentioned methods to consistently deliver a 35% increase in productivity.

This documented methodology shows how deep our technical knowledge goes in changing difficult steel CNC turning into a reliable, efficient process. We offer tested, practical solutions that go straight to prolonging tool life, improving CNC turning performance, and realizing major CNC turning cost optimization. Our emphasis is on giving quantifiable results and top value in precision machining applications.

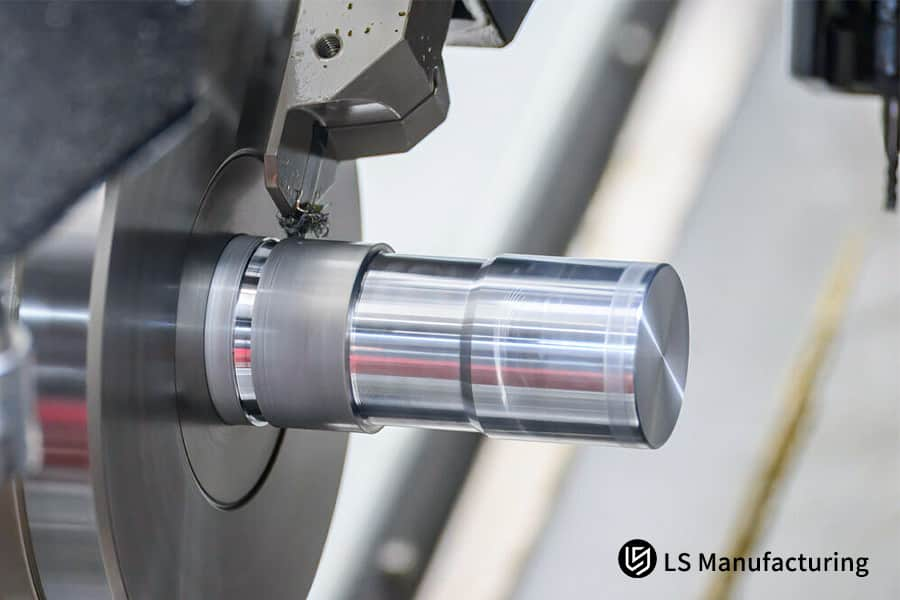

Figure 2: CNC turning an aluminum part for precision machining and Ls Manufacturing supplier capability demonstration.

How Can Micron-Level Precision Control Be Achieved In Brass Turning?

It is still extremely difficult to maintain micron, level precision during brass CNC turning, if you also include making thin-walled or long, shaft, type parts, then figuring out thermal deformation is the main reason for it. Here is the detailed approach through which we have systematically solved the problem of high-precision brass turning and turned it into a reliable and repeatable operation. The matter of greatest importance to us is that this paper presents a practical, data-driven framework for attaining excellence:

| Aspect | Strategy & Parameter | Target Outcome / Metric |

| Base Process Parameters | Focused on cutting speed (200-250 m/min) and feed (0.05-0.08 mm/r) that control the heat generated. | Sets up a CNC turning performance baseline that is both stable and capable of tightly controlling dimensional variations to ±0.01mm. |

| Strategy for Thin-Wall Parts | Used an intermittent CNC turning strategy to avoid heat build up and workpiece distortion. | Allows very thin, walled parts to be machined while still keeping the tolerances very tight. |

| Thermal Compensation | Used an in-process measurement system to obtain thermal drift information for real-time compensation. | Achieves control of the component straightness within 0.02mm even for very long (>200mm) parts, thus one of the most important criteria in precision turning is fulfilled. |

| Tooling & Surface Finish | Single-crystal diamond tools were chosen mainly because of their extremely sharp cutting edges and high wear resistance. | Almost every time a surface finish of Ra 0.4 or better was the result. |

This method proves that the highest precision in brass CNC turning doesn't come from one single factor but from the combination of highly optimized parameters, the use of adaptive strategies such as intermittent turning, and real, time compensation. The outlined method represents a clear, step-by-step guide for shops aiming at the highest levels of CNC turning performance and micron-level precision machining, thus maintaining their competitiveness in the most demanding high-value manufacturing industries.

How Does Material Selection Affect The Overall Cost Structure Of A Part?

Almost all the costs of a part are determined by the choice of material which not only directly accounts for the purchase price of the raw material but also indirectly affects machining time, tooling costs, and process stability. It is necessary to perform a comprehensive, data-based study for the CNC turning cost optimization. LS Manufacturing uses a proprietary Total Cost of Ownership (TCO) model to weigh the costs and benefits of each option, thus making the most of the decisions that normally bring 20-30% savings:

Implementing a Holistic TCO Analysis Model

We expand the idea of just looking at CNC turning material costs by creating a model that considers all factors affecting cost: raw material, machine time, tool wear, and scrap rates. Using our model for a batch of 1000 parts, it quantifies the difference vividly: thoroughly processed aluminum alloys may cost on average 15-25 RMB per piece, whereas stainless steel can be between 35-50 RMB. This model is our practical material selection guide, thus, providing a decision-making financial plan to be followed.

Analyzing Specific Material Cost Structures

Through the TCO model, we can see that there are totally different price curves. Aluminum material can make up ~40% of the total cost, however, its great machinability allows high-speed turning and low tool wear. On the other hand, stainless steel material may be only ~25% of cost, but due to very high tool consumption which can reach 30%, CNC turning performance and tool life become the most important variables. We have come up with the numbers to these so that we can directly aim at the most effective optimization.

Guiding Material Substitution and Application

Our evaluation of material substitution is based on performance criteria. If strength and corrosion resistance do not restrict, we suggest particular aluminum grades or free-machining steels as substitutes for standard stainless steel. This kind of substitution strategy immediately reduces raw material and tooling costs leading to the entire project being more cost-effective turning. We decide upon the candidate materials through our TCO simulation.

Optimizing Processes for the Selected Material

Material selection is just the first step in the process. After that, we tailor the entire CNC turning process chain to the chosen material in order to fully leverage its characteristics. In case of aluminum, this means ramping up speeds and feeds; optimization after material selection is the main reason why substantial parts of the 20-30% cost saving are achieved, allowing for a total value capture.

Our method offers a clear, measurable framework for CNC turning cost optimization which changes material selection from an uncertain step to a strategic engineering decision. We achieve the significant savings and trustworthiness that high-value, competitive turning requires by studying total cost structures and adapting processes accordingly. This document outlines the actionable steps we take to achieve cost-effective turning solutions.

Figure 3: CNC turning a brass part for cost optimization and industrial component manufacturing.

How To Scientifically Select Turning Materials Based On Application Scenarios?

Choosing the best material for a part that is to be machined is very important in engineering because it basically determines the performance, cost, and ease of manufacturing of the part. A scientific approach that moves away from generic suggestions to a data-driven one is a must to get better results. This paper is a guide to a step-by-step procedure for CNC turning material selection based on the application requirements that have been quantified:

| Application Scenario | Recommended Material | Key Performance Rationale & Data | Primary Benefit |

| Structural / Load-Bearing Components | 4140 Alloy Steel | Ultimate tensile strength ≥ 800 MPa is a key feature for the material to withstand high stress, thus a reliable base for durable turning applications. | It greatly improves the material strength and safety factor. |

| Thermal Management / Heat Dissipation Parts | 6061 Aluminum | The superior thermal conductivity (~180 W/m·K) of the aluminum geometrically enhances the heat transfer process, which is a must for thermal stability in precision turning. | Allows to increase the thermal performance of the equipment while keeping it lightweight. |

| Corrosion-Resistant Environments | 304 Stainless Steel | The product of 304 excellent general corrosion resistance will mean that part function and appearance can be maintained even when the parts are in harsh situations. | The product provides long-term reliability and less frequent maintenance. |

| Cost-Sensitive, High-Volume Production | Free-Machining Steels (e.g., 12L14) | Exceptional machinability leads to increased speeds, reduced tool wear, and lower total cost. | Enables CNC turning cost optimization in volume production. |

Efficient CNC turning material selection can only be done considering the quantified properties of the material versus the specific needs of the application. For this purpose, our method uses a multi-parameter material performance comparison matrix that not only guides but also balances functional requirements, manufacturability, and cost. This model based on data gives engineers the roadmap to the best and most reasonable in terms of the cost-effective turning solutions for competitive, high-value projects.

LS Manufacturing Automotive Parts Industry: Multi-Material Turning Optimization Project For Engine Mounts

The main task of the automotive industry is to find the perfect combination of weight, price, and durability. The present material optimization CNC turning case study of the case illustrates how LS Manufacturing developed a comprehensive approach for an engine bracket by changing the material and re, designing it by CNC turning:

Client Challenge

The client's engine bracket, originally AISI 1045 steel, was a real puzzle to solve. On the one hand, the raw material cost was 48 RMB per piece and the weight of the component accounted for 1.2 kg of the total vehicle weight, thus affecting the fuel consumption. In addition, the product was not very resistant to corrosion which resulted in yearly maintenance costs of more than 200, 000 RMB, which together with the product degradation, loss of value, and competitiveness, became a vicious circle.

LS Manufacturing Solution

Our response to the challenge was a thorough re, engineering of the product. First, we got rid of the steel and switched to 6061-T6 aluminum, which we chose mainly because of its high strength, to, weight ratio and natural resistance to corrosion. When it came to machining, we switched to a high-speed turning strategy (1500 m/min, 1.5mm depth of cut) and changed the design of the component's ribs to be more efficient. Thus, the method made use of the excellent machinability of aluminum for rapid production, and at the same time, the product was structurally sound.

Results and Value

The results were revolutionary. The unit cost was brought down by 42% to 28 RMB, and the weight of the part was reduced by 60%. The corrosion resistance was increased 3 times, thus the problem of annual maintenance was solved which brought a full saving of 350, 000 RMB to the client per year. This is a Made, in order to project launching a product with cost-performance balance, off at its best through precision turning and materials technology.

Such an undertaking is a proof of our skill to solve complex engineering trade-offs by means of integrated design and manufacturing analysis, challenges that we frequently face. This precise material optimization case study allowed us to produce a component that is not only lighter but also tougher and very significantly cheaper. It is through this empirical, data-driven method that we set the pace for the competition in a demanding, high-level automotive applications market.

Explore new avenues in turning technology and witness the miracle of reduced costs and weight.

How Do Material Selection Strategies Differ For Different Production Volumes?

Optimal material selection cannot be universally applied; the primary factor determining the choice is production volume. There are significant changes in economic and technical priorities when going from prototyping to mass production. LS Manufacturing employs a dynamic, volume-sensitive optimization model to guide this critical decision, ensuring the best cost-performance balance for every batch size:

Strategy for Low-Volume Production (<100 pcs)

- Priority - Machinability & Lead Time: To minimize setup and machining time, we mainly use materials that have excellent machinability such as 6061 aluminum or 12L14 steel. The main aim is rapid prototyping and testing the functionalities.

- Action: Our system frequently suggests the use of materials which are a bit more costly but easy to machine to compensate for the low volume, thus it facilitates faster delivery and lowers the total cost of small-batch turning.

Strategy for Medium-Volume Production (100-1,000 pcs)

- Priority - Balanced Total Cost Analysis: In this stage, we conduct an in, depth TCO analysis, with a focus on the balance between the material cost and the efficiencies gained in machining. It is at this stage that the right material selection strategy.

- Action: We deliberate between alternatives such as 4140 steel and aluminum thoroughly taking into account factors like material cost, tool wear and cycle time trying to identify the most cost-effective turning solution for the series.

Strategy for High-Volume Production (>1,000 pcs)

- Priority - Material Cost & Supply Stability: When batch production optimization at a very high volume, the cost of raw material becomes the most significant factor. For cost, effective grades, we concentrate on securing stable supply chains.

- Action: We suggest materials that are standardized such as certain aluminum series or free-cutting steels, and optimize processes for high-volume turning, thus allowing the cost per part to be decreased through efficiency and scale.

Our CNC turning material selection guide offers a scalable, data-driven framework that matches material selection with production economics. At the same time, by giving the appropriate strategic priority, machinability, balance or raw cost to each batch level, we manage to resolve the volume puzzle. This methodical approach provides dependable batch production optimization and greater value for manufacturers regardless of their size

Figure 4: Displaying precise metal turned parts for material selection guide and supplier capability demonstration.

Why Choose LS Manufacturing's Material Optimization Services?

Choosing the right material and machining process is a complicated technical problem that has a direct impact on the part's performance, cost, and the overall success of the project. Following general tips usually results in less, than, optimal outcomes. LS Manufacturing solves this problem by means of a tried and tested, data, driven system, which converts material science into a dependable manufacturing advantage and predictable cost. This is how we provide this professional CNC turning optimization:

Empirical Analysis with In-House Laboratory Validation

To validate our ideas, we start with verification. Our in, house laboratory equipped with advanced analysis instruments including spectrometry and metallographic microscopes enables us to verify the material composition and microstructure on the spot. The empirical analysis is a great preventative step that excludes the problems due to the difference in the suppliers material. Then, the CNC turning process is prepared for the actual material, not just the specification. This first step basically establishes our material expert service.

Decision Support Powered by a Proprietary Material Database

Our advices are supported by 15 years of accumulated data covering 86 material parameters. Initially, for the choice between 4140 steel and 6061 aluminum, we do not use generic charts. Instead, we extract from the history the data related to the tool wear rates, achievable surface finishes, and optimal parameters for precision turning, thus we can deliver a comparison based on facts that is a forecast of real-world machining performance and cost.

Solution Validation Through Documented Case-Hardened Experience

We draw on practical applications to inform each recommendation. Our collection of 326 optimization cases is a source of accurate reference material. When developing a new engine bracket, instead of making a hypothesis, we refer to and modify the material optimization case study that has similar requirements from the journal of material case studies. Thus, we gave a solution that was both innovative and based on proven results, and the implementation was free of risk.

Delivering a Predictable, Optimized Total Outcome

We combine analysis, data, and experience into one well, integrated service. The product is a complete package: a material specification, a perfectly detailed process manual for high-efficiency turning, and a CNC turning quote which is the real optimized cost. We figure out the whole equation, so that the final product fulfils all the performance criteria at the most efficient total cost.

By connecting the verification of experiments, the use of performance data from the past, and proven applications, we fix the material and process selection problems in complex ways. Our approach results in a trustworthy, optimized CNC turning quote and process roadmap, which brings security and worth to challenging, high-stakes manufacturing projects. This is the core of our material expert service.

How To Obtain Accurate Material Optimization Solutions For Turning Operations?

Simply cutting a quote won't give you a genuinely optimized material and machining scheme, it's your part function, and production goals, that must be matched by in depth technical analysis. LS Manufacturing achieves such through a well, organized, quick delivery of technical solution consulting that converts your requirements into a validated, executable plan. This is our methodological approach:

Comprehensive Initial Analysis: Defining the Parameters

- Requirement Submission: You provide a part drawing and key performance requirements (e.g., strength, corrosion resistance, weight).

- Expert Evaluation: Our engineers conduct a preliminary feasibility study, evaluating the manufacturability and pinpointing the significant cost, performance trade, offs to establish the optimization scope.

Data-Driven Modeling and Proposal Development

- Material & Process Simulation: We use our material database and process models to simulate results of 2-3 candidate materials, comparing performance, machinability, and cost.

- Integrated Solution Packaging: Within 24 hours, we provide a customized optimization report that outlines the recommended material, the optimized CNC turning parameters, and the detailed cost, benefit analysis, which altogether form the complete CNC turning quote.

Validation and Feasibility Assurance

- Risk Mitigation: We use FEA simulation or rapid prototyping to validate the integrity of the solution before mass production, especially for critical applications.

- Guaranteed Outcome: This stage guarantees that the proposed precision turning strategy is not only theoretically correct but also practically feasible, thus, your project is de-risked.

We give pinpoint material solutions through a thorough, quick consulting process that merges your specs with our empirical data and analysis. This approach yields a reliable, optimized plan for cost-effective turning that ensures both performance and value. We are committed to providing practical, trustworthy fast-turn solutions.

FAQs

1. What is the maximum length-to-diameter ratio for aluminum alloy turning?

The usual length, to, diameter ratio during turning is 10:1, and it can even get up to 15:1 with some special processes. A process evaluation based on the particular structure is necessary.

2. How to control work hardening during stainless steel turning?

Using sharp tools, controlling the cutting depth to ≥0.1mm, and using specialized cutting fluid will be very helpful in work hardening suppression.

3. How to control performance fluctuations in different batches of materials?

LS Manufacturing guarantees the stability of batch production through the inspection of the incoming material and adjustment of process parameters.

4. What verification tests are required for material substitution?

Mechanical property testing, durability testing, and environmental adaptability assessment are all part of the thorough verification plan offered.

5. What are the principles for selecting materials for small-batch samples?

Reducing trial production risks is the goal when processing performance is chosen as the priority. For samples, LS Manufacturing offers rapid prototyping services.

6. How to evaluate the overall cost, effectiveness of material switching?

To quantitatively assess the advantages of material switching, LS Manufacturing offers a full life cycle cost analysis model.

7. What special equipment is needed for turning special materials?

Depending on the materials, characteristics special tools, cooling systems, and clamping solutions are distinguished to be able to ensure the quality of processing.

8. How is material certification and traceability guaranteed?

Complete material certification packages are provided, and a comprehensive traceability system from raw materials to finished products is implemented.

Summary

Scientific selection of materials is a fundamental lever in manufacturing cost and performance optimization of CNC turning. It is possible to achieve significant cost reductions and performance enhancements by thoroughly analyzing material characteristics and optimizing the processing parameters. The material optimization system at LS Manufacturing turns the technical consultation to production implementation process into a single, customer, friendly journey.

In case you need material optimization solutions, do not hesitate to get in touch with LS Manufacturing's material expert team right now. Please send us your part information to get a professional material optimization plan! We promise a tailor, made material selection and process optimization plan to be delivered within 24 hours which will let you combine cost and performance optimization.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.