CNC turning services frequently encounter a critical challenge in tool steel selection. The differences available between various steels, along with their respective levels of hardness, durability, and toughness, may tend to create various impacts on the efficiency of the turning process. Poor selections may tend to increase production costs by at least 30%.

The issue lies in its conventional selection method, which is mileage-based and dependent on supplier or algebraic recommendations. There is little explicit performance-related data and optimal cut conditions available to align the properties with a given usage. There, thus, arises the demand for a more scientific method to be adopted, one that is data-driven for optimal performance.

CNC Turning Services Quick Reference Guide

| Section | Key Content |

| Introduction | Tool steel selection challenges; 30%+ cost increase from poor choices; impact on efficiency and quality. |

| Core Properties | Hardness, wear resistance, toughness, machinability; performance compromises. |

| Material Selection | Application-based criteria; cutting parameters optimization; cost-performance balance. |

| Machining Parameters | Machining parameters include spindle speed, cutting rate, depth of cut, cutting tool shapes, selection of cutting agents, or choice of cutting fluids, or surface finish. |

| Quality Control | Dimensional tolerance and surface integrity, process and procedures of inspection, defects and failures. |

| Cost Analysis | Cost of material vs. machining cost; Optimization of tool life; Optimum quantity for optimum production and its influence on production control. |

| Case Studies | Real-life examples, successful adoption, calculation of return on investment. |

| Future Trends | High-performance materials, smart production, digital twins, and sustainability. |

We employ the material suggestion system in machining, which assists us in recommending the best combination of tool steel materials to our clients, and we are able to minimize more than 30% of the production cost to our clients in the optimized solution that we propose to them.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

In the very competitive arena of contract manufactures of CNC turning, trust is something that has to be earned and will not be won. But for now, for over 15 years, at least, in the real world and not the ideal world, the people on the factory floor have been putting the skills of LS Manufacturing to the test every day with difficult to handle materials, very tightly toleranced work, and so on and so forth. Everything that will be presented in the following guide has been proven in that arena.

Not only do we have the ability to learn more about the kind of tool steel you may be referring to but also how to do the task on the given material, in the time frame that is present in a production shop to machine correctly. Our expertise not only provides you with a chance to learn something novel but also provides you with a skill set that has been honed using the same principles of proper engineering, as enthusiastically promoted by 3D Systems and the GrabCAD Blog to do theory perfectly.

This is the result of the knowledge that we acquired from machining innumerable precision components on our part, and now with this know-how, we are going to impart that knowledge to you as well, and simultaneously acquire more knowledge on optimizing the tool steel and cutting parameters in our successful and learning by failure process! With this know-how, you are going to be able to utilize the knowledge required to overcome efficiency, tools life, and quality problems with ease by knowing optimized tool steel selection.

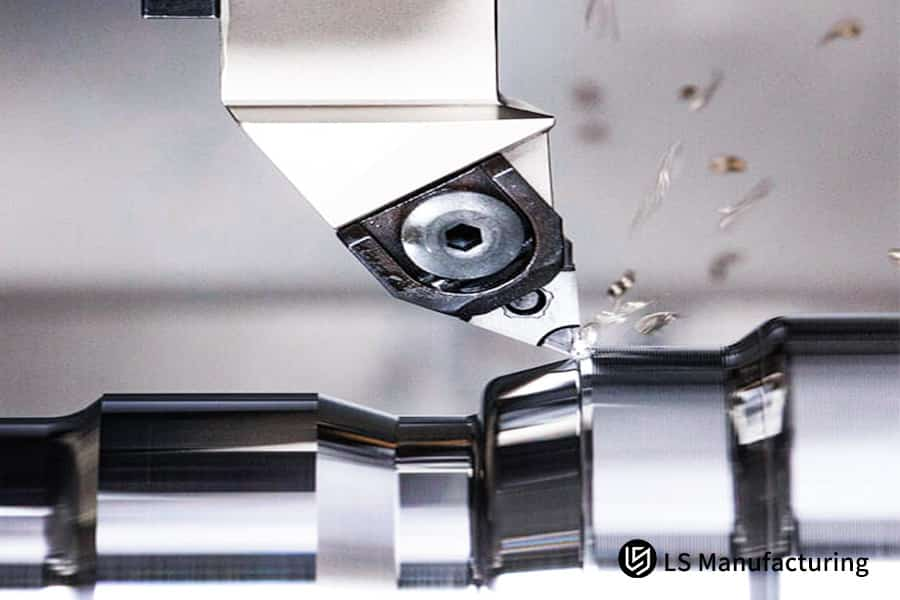

Figure 1: Machining steel with CNC turning utilizing cooling fluid processes by LS Manufacturing

How To Select Tool Steel For CNC Turning Based On Machining Requirements?

CNC turning services requires an organized approach when it comes to tool steel selection. The relevance of this literature review stems from the fact that it deals with a profound question that comes up when one is trying to categorize different types of tool steel into distinct machine services. The proposed process entails data on material matching:

Material Hardness and Machinability Analysis

The testing work piece material includes work piece material property test, which is further classified into work piece material hardness test, work piece material tensile strength test, and work piece material thermal conductivity test. For a work piece with high hardness material, if the criteria for work piece material hardness are HRC45 and above, then we suggest work piece material powder metallurgy high speed steel, or PM-HSS. To find the work piece material, a match is to be found between work pieces with 50+ tool steel types depending upon the cutting condition.

Coating Technology for Enhanced Performance

Highly specialized PVD coatings, CVD coatings, chemical vapor deposition, among others, are known to produce an immense contribution to the life of tools used for high applications. It is with this background that, for the requirements of mass production to be fulfilled, the AlTiN coating on the carbide tools would be used. The efficiency of such processes can be ascertained by the fact that an average life span is increased by over 40%.

Production Volume and Cost Optimization

The process of material selection is likely to be influenced by the batch size. While prototyping or manufacture on a small scale, the material that would be considered is the uncoated high-speed steel. In large-scale manufacture, however, the carbide with optimum geometry is likely to be preferred due to its ability to enhance not only the life of tools through increased durability but also through reduced down-times associated with changeover.

Precision Requirements and Surface Finish

Based on the geometry of the cutting tools and the work piece material properties, a high precision level in the machining tolerance value or a superior finish might be required. As a company that delivers precision in finish, we use cutting edges consisting of micro-grain carbides, along with measures to maintain the precision of the cutting edges through effective cooling of the cutting edges.

The technical guide offered with details shows among the tough procedures that we follow to ensure that we material tool steel selection for the provision of our CNC turning services. Because of the intelligent material matching techniques that we apply, we ensure that we offer an occasion where cost and quality come together with perfection that has not been seen before. The technical guide acts as an indicator to our best engineers of our product on tool life matters.

What Performance Indicators Should Be Given Priority When Scientifically Selecting Tool Steel?

As scientific selection is concerned, the process of inheritance that could affect the selection of tool steel is a very critical process associated with the production of tools for efficiency and effective production. The document is a technical report that could enable a review process associated with properties through measures of test with the aim of determining material properties. By having factors that define performance indicators in view, LS Manufacturing would enable effective material selection for effective production.

| Performance Indicator | Target Value | Test Method | Key Consideration |

| Hardness (HRC) | 58-62 | Rockwell C Scale | Wear resistance and cutting edge retention |

| Red Hardness | HRC 54 @ 600°C | High-temperature testing | Thermal stability during high-speed machining |

| Toughness (Impact Energy) | ≥20 J | Charpy impact test | Resistance to chipping and fracture |

| Wear Resistance | Comparative rating | Pin-on-disk test | Tool life under abrasive conditions |

| Thermal Conductivity | Material-specific | Laser flash method | Heat dissipation during cutting operations |

The systematic evaluation of how to choose tool steel requires prioritizing hardness for wear resistance, red hardness for thermal stability, and toughness for impact resistance. In relative testing, a technique developed by LS Manufacturing assists in decision-making for the selection of the appropriate tool steel, depending upon the machining considerations. By applying a technical approach, it is possible to ensure extended life for tools, zero downtime, and maximum efficiency in manufacturing.

Figure 2: Precision manufacturing through CNC turning of high-performance steel by LS Manufacturing

How Can Cost-Effective Tool Steel Optimize Costs While Maintaining Quality?

For tool steel materials, there has to be an aim for a balance between properties and being cost-effective. The objective of this report is to offer a mathematical formula for cost optimization using value engineering analysis in order to offer better insights into cost optimization without compromising the mechanical properties with the aim that the tool should:

Material Substitution Analysis

Comparison testing is about finding a comparable grade of steel in a more favorable price with similar performance capability. This material DC53 would replace SKD11 at medium scale orders without impairing the value of wear resist by a bit and will achieve a 25% material cost-down. Tests are conducted based on criteria such as hardness, toughness, and temperature.

Processing Cost Reduction

By optimizing all the parameters associated with heating treatment and machining, on our part, we can shave off up to 15 to 20% of production cycle time without affecting the properties of the material obtained as a result of the process by using a multi-step tempering process.

Total Cost of Ownership Assessment

Our value engineering approach extends beyond the basic material cost, for instance, tool life, maintenance cycles, and downtime for production. In applications where a high level of wear is desired, we recommend the use of high grades with optimal red hardness, which exhibit 30% extended tool life, lower changeover cost, and minimum total cost of production.

Application-Specific Optimization

Each cost-effective tool steel is based on certain machining parameters, materials, and production quantity. We provide detailed technical information so you can make intelligent, apples-to-apples comparisons of alternative steel selections based on specific performance criteria rather than on generic requirements.

From the technology framework, it is quite clear that cost optimization regarding tool steel is based not on compromised quality but rather on intelligent decisions. It is true to the fact that through value engineering, considerable cost savings can be achieved without degrading the performance of the tool. This effectiveness is very important from a competitive viewpoint, which essentially is a relevant activity pertaining to the identification of this technology.

Advantages And Disadvantages Of High-Speed Steel And Carbide In CNC Turning

A material comparison used in the CNC turning machine regarding the choice between HSS vs carbide cutting tools focuses on making the right choice depending on the application conditions. Both materials have different advantages that cause the choice of one over the other depending on the application scenario.

| Material | Hardness | Toughness | Cost | Best for |

| HSS | Medium | High | Low | Interrupted cutting |

| Carbide | High | Medium | High | Continuous machining |

We offer you a solution to the problems arising due to inefficient use of tooling as well as the unclear result of machining. The tooling assistant provides you with an unmistakable answer to make the correct decision between the use of HSS vs carbide tools with precision, as per your needs. The assistant helps to optimize the use of your tooling resources to attain maximum productivity and cost savings.

How Does The Selection Of CNC Turning Materials Affect The Final Part Quality?

CNC turning material selection is one of the topics that have been of prime importance because it plays a critical role in determining the part quality of the turnings. The report presents an organized methodology to evaluate the performance impact of the differences in material quality used for turning tool material within the context of metallurgical analysis:

- Metallurgical Analysis and Microstructure Evaluation: We thoroughly examine the finding from metallographic analysis to identify the carbide distribution. In clarification of the research regarding the improvement of DC53 and SKD11 high-speed tools, the better carbide distribution in DC53 raises the fine surface finish of high-speed cutting by 15%.

- Mechanical Property Testing Under Operating Conditions: Our testing protocol evaluates wear resistance, fatigue strength, and thermal stability under simulated machining conditions. Testing shows that properly selected tool materials can extend part life by 30-50% in high-wear applications, with specific grades demonstrating superior performance in abrasive environments.

- Application-Specific Performance Validation: Every recommendation on CNC turning material selection is justified by experiments carried out in machining, as well as in measurement of surface roughness, precision, and speed of tool wear.

- Total Cost of Ownership Assessment: First, the cost analysis can be elaborated in view of tools, maintenance cycles, or production stops besides the initial material costs. As an example, making critical parts with higher quality and more expensive-tools can actually lower the production costs for the sake of extended life with an extra 40%.

This technical framework demonstrates that informed CNC turning material selection is essential for achieving superior part quality and maximizing production efficiency. The test results data presented can be used to make informed decisions concerning the optimisation of machining processes with the aim of efficient production, thus making the tool an invaluable resource for technical decision-makers.

Figure 3: Machining a metal workpiece with a cutting tool via CNC turning by LS Manufacturing

How Do High-Performance Tool Steels Maintain Stability Under Extreme Operating Conditions?

The high-performance tool steel must guarantee mechanical properties under extreme conditions, for example, under high temperature and heavy loads, including the effect of abrasion. The next document will discuss the advanced technologies of manufacturing, which will guarantee the stability of the material and the long life of the application, dealing with the problem of tool failure under hard working conditions:

Advanced Melting and Refining Processes

We employ vacuum induction melting (VIM) and electroslag remelting (ESR) technologies to achieve ultra-clean steel with minimal non-metallic inclusions. This process reduces oxide and sulfide content by over 80%, significantly improving fatigue strength and impact toughness. The refined microstructure enables consistent performance at temperatures exceeding 600°C, making it ideal for hot work applications.

Precision Heat Treatment Optimization

Our multitreat heat treatment process includes deep cryogenic processes, which are conducted under a temperature of -196°C, where the residual austenite is converted to martensite along with the precipitation of carbides, thereby increasing the hardness of the steel by 2-3 points of HRC along with an improvement in the wear-resistance capacity by 30-40%. In all our products, we have included a stage for tempering, which is effective in relieving residual stress along with the prevention of distortion in the product.

Microstructural Engineering for Enhanced Properties

We are actively working on developing and executing a thermomechanical treatment for optimal carbide distribution and grain structure. For instance, our unique grades are characterized by the presence of a network of fine and evenly dispersed carbides, which provide them with red hardness and thermal fatigue properties. Such microstructural sophistication in tools has the potential to resist thermal fatigue and shocks under severe service conditions.

Performance Validation Under Simulated Conditions

We perform accelerated tests on these materials under extreme conditions of high-temperature wear tests, thermal fatigue tests, and impact tests. We adopt a data-driven methodology, which assists us in achieving measurable parameters of performance to ensure that different types of materials meet specified criteria for the application.

The technical framework detailed earlier has made it clear that for stability to be obtained within high performance tool steel materials under extreme conditions, coordination needs to be involved within their production and quality control processes. As of now, the relevance of our work is significant within circumstances that relate to reliability because of the role that it plays by indicating that we are moving towards the right direction to ensure that material decision-makers possess technical expertise to make decisions pertaining to the materials that can perform well within extreme settings.

How To Optimize The Cutting Performance Of Tool Steel Based On Processing Parameters?

Selecting the best CNC turning tool steel requires precise matching of material properties with optimal cutting parameters to achieve maximum performance optimization. The solution provided in this particular report offers a way out for optimizing turning conditions with a view to obtaining maximal productivity, maximal tool life, and maximal quality of the parts due to the following reasons:

- Comprehensive Cutting Parameter Testing: We perform extensive machining trials to ascertain the best cutting speed, feed rate, and depth of cut required for a particular grade of tool steel. For grade M42 high speed steel, the cutting speed of 80 to 120 m/min, which is ideal for material removal and the life of the tool, is ascertained through machining trials.

- Material-Specific Performance Mapping: Each tool steel grade is evaluated across multiple cutting conditions to create performance maps that identify the sweet spot for productivity and tool life. For example, our testing shows that DC53 performs optimally at cutting speeds of 100-150 m/min with moderate feed rates, while carbide grades can operate at 200-300 m/min for high-volume production. These performance maps enable precise parameter selection based on production requirements.

- Application-Specific Optimization: We propose reducing factors such as cutting parameters for individual cutting operations, work hardness, type of cutting tool, and cooling efficiency. The cutting speed will be lower for interrupted cutting in order to avoid chip formation on the cutting tool, with higher feed rates than for continuous cutting, where the cutting speeds are higher.

- Real-World Validation and Continuous Improvement: Our parameter recommendations are validated through actual production trials, measuring tool wear progression, surface finish quality, and dimensional accuracy. This iterative process ensures that our data remains current and applicable to evolving manufacturing technologies and materials.

This method reveals the need for cutting parameters to be carefully considered for performance optimization, which will ensure that the best tool steel for CNC turning on the computer numerical control turning machine. Recommendations on data for the selection of the most suitable tool steel material are provided below.

What Are Some Key Factors That Are Often Overlooked When Selecting Tool Steel?

First and foremost, the tool steel selection is mainly focused on properties that exceed the ability to resist certain pressures. This can be attributed to the fact that the selection of the tool steel requires the consideration of several key factors and may not afford to overlook these factors. The critical part of the report covers the identification and analysis of the key factors that form a crucial part concerning the efficiency of the tools. There is a simplified process in order not to overlooked details.

- Machinability and Grindability Assessment: Machinability and grindability properties of each grade of tool steel are also tested for the rate of material removal and the ability to achieve a certain surface finish. Some high alloy steel types, for example, may involve increased machining time by as much as 30% and may require a grinding wheel, thus directly influencing the manufacturing costs.

- Heat Treatment Response and Dimensional Stability: In our entirely documented database, the following information can be stored for the heat treatment process: distortion coefficients for heat treatment, hardenability curves, and size change characteristics. The pre-mach allowances and sequence of heat treatments for least distortion are recommended when critical parts undergo the heat treatment process so that the dimensions fall within the size tolerances of the ordered specifications.

- Weldability and Repair Considerations: We shall examine the types of tool steels that are repairable, focusing on weldability as far as the tool steels are concerned in carrying out any repair job by citing the types that are weldable without posing cracked or damaged steel risks. Heat treatment as far as preheating or post-weld heat treatment is also another topic that shall be discussed in making the tools more repairable.

- Application-Specific Environmental Factors: The environment in which the operation may get affected by corrosion, thermal shock, or impact loading can also be considered by the choice guidelines that are outlined above. For example, materials that can be used under high moisture or thermal shock conditions can be identified by the choice guidelines.

This technical framework highlights that the tool steel selection effectively will succeed only if a complete analysis of the key factors, which are normally overlooked and do not rely on mechanical properties, is taken into consideration. To take care of the normally overlooked details, we are able to enable the manufacturer to make cheap mistakes and ensure the success of the project.

Figure 4: High-performance steel turning produces metal chips during CNC machining by LS Manufacturing

LS Manufacturing Automotive Mold Industry: Engine Connecting Rod Mold Steel Optimization Project

From the aforementioned case study, the application of high-level material engineering expertise that was offered by the LS Manufacturing, which was useful for addressing the key issues that surround the making of the tool, was applied in the production of the car mold for the following reasons:

Client Challenge

The leading car mold maker was facing production shutdowns due to regular failures in engine connecting rod molds. The conventional H13 tool steel molds offered only 50,000 cycles of production life before failure occurred. The client was in need of a product that would enhance the production life of molds without compromising on accuracy, which was ±0.02mm.

LS Manufacturing Solution

We recommended the use of high-grade ESR H13 tool steel with optimized parameters of heat treatment. Vacuum hardening at 1020°C with double tempering at 560°C gives a controlled hardness of HRC 48-50. It improved the impact toughness by 30% while maintaining wear resistance at a superior level. Special efforts were made to resolve such problems as the thermal fatigue and abrasive wear that caused the failure of the original molds prematurely.

Results and Value

The optimized mold steel solution saw excellent improvements in performance, extending the service life from 50,000 to 150,000 cycles, or a 200% increase. This was translated into annual cost savings of ¥800,000 due to lessened tool replacement frequency and reduced production downtime. Besides this, the customer obtained a 25% boost in productivity due to less time for mold changeover and enhanced process stability. It allowed the customer to strengthen their competitive position within the supply chain of automotive.

This case study will describe how LS Manufacturing has the technical expertise to offer solutions for difficult manufacturing challenges using data-driven material engineering. It is our technical expertise in metallurgical engineering and our knowledge in manufacturing that helps our customers take advantage of improved tooling performance. It is our technical expertise that helps the technical decision maker choose to solve manufacturing challenges that result in gaining an advantage in the competition.

Facing similar dilemmas when selecting a tool steel for your CNC turning projects, we can provide custom solutions for performance optimization.

Innovative Applications Of Advanced Tool Steel Technology In Precision Parts Machining

There have been developments in the area of advanced tool steel technology such as powder metallurgy and metal matrix composites that have made possible a breakthrough capability for precision machining of complex components. This report considers a systematic approach to the introduction of such innovative applications to solve the problem of creating a high-quality surface finish, accuracy of the machined components, and a prolonged service life of the machine tools in a production setup:

Powder Metallurgy Tool Steel Implementation

In that respect, we use PM tool steels with their fine and homogeneous microstructure for optimal cutting performance. Our PM M4 with, for example, 30% increased wear resistance compared to its conventional analogs allows for longer cutting life when performing high-speed cutting in hardened steel materials.

Metal Matrix Composites for Enhanced Performance

Our product range encompasses particle-reinforced MMCs with ceramics that provide exceptionally high hardness and thermal resistance. It is these materials that retain edge strength even at temperatures above +800°C and are used in such dry machining applications where the use of coolant is impossible. The low thermal expansion coefficient accounts for maintaining dimension accuracy irrespective of the working temperatures.

Advanced Coating Technologies

At our firm, we use PVD/CVD coatings with TiAlN, AlCrN, or diamond-like carbon layers for the aim of improving cutting tools. It is possible to reduce friction coefficients, and it may reach a 50% reduction with the application of the abovementioned layers. For precise machining in aerospace materials, we utilize cutting tools with a value of Ra ≤ 0.4µm for their surface roughness.

Application-Specific Material Engineering

Maybe, the answer is to look for specific solutions for particular demands in material processing, such as finding a high silicon constituent in aluminum alloys or heat-resistant supper alloys. This seeks to play a crucial role in finding a specific alloy that would have a set of properties necessary for different types of wear, heat fatigue, or work material interactions.

This technical framework demonstrates that advanced tool steel technologies enable innovative applications that push the boundaries of precision machining capabilities. We utilize powder metallurgy techniques, metal matrix materials, and coating materials to provide an innovative solution with concrete advantages to tooling and precision in machining technology. It gives the much-needed confidence to decision-makers to embrace innovative precision in machining technologies.

FAQs

1. What basis can I use to judge the suitability of the tool steel for my machining process?

These could be machining accuracy, production quantity, and so on. Trial cutting can be done to ensure that it is appropriate.

2. What are the typical economic grades of tool steel?

Steel variants that tend to the higher range, such as DC53 or Cr12MoV, offer a quite balanced performance and price.

3. What type of materials can be machined with carbide tooling?

Suitable for metal working with high hardness (above HRC45), such as hardened steel and cast iron, for example.

4. What is the impact of the heat treatment process on tool life?

The heat treatment determines its performance properties; the optimum processing can raise its life by 30 to 50%. Its temperature and processing time should be accurate.

5. How to perform cost-effectiveness analysis on tool steel?

Now compute the unit price of each, using machine cost, times lifes sentence, times efficiency.

6. What are the advantages of powder metallurgy tool steel?

Equable structure and toughness, suitable for precision mold processing with service life 2-3 times longer than the ordinary steel-grade material.

7. What quality indices should be considered while buying tool steel?

Chemical composition, purity, and uniformity in hardness are to be highlighted. Material certification to be provided by the vendor.

8. How is the service life of tool steel elongated?

Optimization of cutting parameters, coatings, and handling practices are applied to maximize tool life.

Summary

With the application of scientific steel selection techniques, companies can significantly improve economic efficiency and quality associated with turning operations carried out using CNC machining. Material selection is considered the key to machining optimization.

Please transmit project parameters to the tech team at LS Manufacturing for a customized CNC turning process or material optimization that meets your needs. Through careful examination of those specific machining requirements, material interactions, and performance needs that are uniquely yours, we offer data-driven solutions for improving cutter life, precision, and lowering manufacturing cost.

Upgrade your CNC turning with data-driven tool steel selection—slash costs by 30% and achieve precision performance.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.