Online CNC turning services have brought about a paradigm shift in how small-order parts procurement has been accomplished throughout the years. Usually, it becomes necessary for the design and procurement teams to be involved in this frustrating game of submitting designs to a black hole, with quotations coming back days later with little explanation to go on within them.

This problem can be solved easily by LS Manufacturing. With their innovative instant quoting system, transparency, and smooth process of manufacturing, all uncertainties that come along with the previous process are removed. Experience a world of smoothness and reliability in the innovative CNC turning services introduced by LS Manufacturing. In fact, thanks to this innovative breakthrough in their neighborhood, everything will run smoothly like online shopping.

Services Offered By Online CNC Turning: Quick Guide

|

Section |

Key Content |

|

The Pain Point |

Slow, opaque traditional process: RFQs go unanswered, quotes are vague, lead times slip, hidden costs appear. Disrupts projects. |

|

The Core Problem |

Inefficiency stems from information asymmetry, non-standardized workflows, and over-reliance on manual communication. |

|

The Solution |

The online system from LS Manufacturing. Offers "instant pricing," "transparent pricing," and an optimized manufacturing process. |

|

Key Benefits |

Speed: Instant quotes; Clarity: There are no hidden; Reliability: Predictable timelines; Simplicity: E-commerce-like experience. |

|

How It Works |

1. Upload CAD; 2. Get instant quote/DFM; 3. Order online; 4. Follow transparent production; 5. Get Quality Parts. |

LS Manufacturing mitigates the risks involved in the conventional quoting processes that were associated with delay, lack of transparency, anduncertainty in the conventional quoting processes. This will ensure that there is aprocess that provides instant and accurate pricing and scheduling information that helps engineers andpurchasers of CNC turning services complete small production jobs swiftly and with confidence, andeasy as online buying.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Online CNC turning services represent a digital extension of shop-floor integrity. Therefore, this analysis establishes operational guidelines for the digital realm, akin to the micron-level precision required for machining high-grade alloys. A single thread deviation, for instance, can compromise the precision of every component produced, underscoring the critical need for accuracy in online CNC services.

Our strengths lie in the ideology of focusing on excellence and safety. This entails the fact that, with the number of customized CNC machined parts we have processed to be over ten thousand, we as a firm have managed to thrive by focusing on the ideology of continuous improvement, which lies at the forefront of the ideology of Additive Manufacturing (AM). Additionally, we ensure that the safety element fits all the regulations offered by the occupational safety and health administration, Occupational Safety and Health Administration (OSHA) guidelines.

Each jot of the advice that has been shared in the context of this article is the sum total of what we have learned and gained from experiences while grappling with problem circumstance in our units. We have already had the expensive learning experience and are now able to help you avoid it with our online CNC turning services. You are essentially getting more than just the cost of the pieces of advice with what you pay, and that is the whole experience that is solely dedicated towards the fulfillment of your desire from the inception itself.

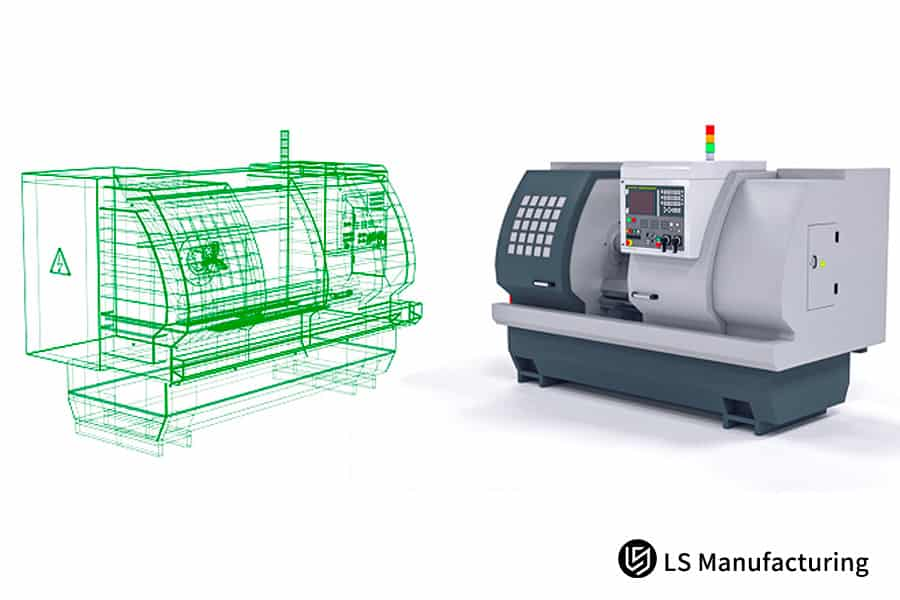

Figure 1: Close-up of a CNC lathe aligning two metal workpieces by LS Manufacturing

How Do Online CNC Turning Services Give Instant Quotes?

The immediacy of costing in the modern manufacturing world shows its beauty in the automation of processing through digitization. As soon as the customer uploads his 3D file, advanced software comes into action; it checks the file, prepares the calculations, and within seconds provides a comprehensive quote. The days of long delays have gone, and the customer receives a new level of instant quote CNC turning service from the world of online CNC turning services.

Automated Design Processing and Analysis

The step begins right from where CAD file upload has been initiated. The parsing system goes for processing by software, where all relevant points of interest in CAD file uploads have been identified; this includes critical features, sizes, and tolanced values. This results in applying an immediate filter to possible online CNC turning services regarding something that could cut costs or be negative.

Dynamic Data Integration for Precise Costing

This system cross-references each one of a few databases that are integrated, on a decision based on analysis, to extract information about material from a digital library, and determines optimal machining time through a high-level algorithm based on tools and setup. This level of database integration is on which functional-level transparency is based to offer a instant quote CNC turning.

Real-time Pricing, as well as Analysis of Price Components

Each of the above values is used in a pricing system which takes a shorter time, not more than three minutes, after which a detailed price quote is acquired. The detailed price quote breaks down material prices, machining labor prices, setup prices, as well as surface treatments, summing up the CNC turning transparent pricing strategy as it shows the customer price absolutely.

Seamlessness in Process and Feedback System

Right from the uploading process to the provision of a quote, everything is seamless and takes immediate action, creating an instant feedback loop for the designer or purchaser. This operational efficiency, powered by automation, is the defining advantage of online CNC turning services, as it dramatically accelerates decision-making and compresses the entire project timeline from concept to completion.

In conclusion, the instant quote CNC turning through a seamless integration of CAD analysis, cost calculation, and direct data access. This not only results in quick results but also plays a pivotal role in ensuring that CNC turning transparent pricing, thus revolutionizing the manner in which projects are executed in their entirety and through online CNC turning services.

Why Is Complete Price Transparency Crucial For Your Project?

Transparency in pricing is a pure fundamental concept of project management. It allows for proper, accurate budget planning, eliminating surprise costs and problems of money once completed. This will set up a strong, trust-based partnership with your manufacturing supplier from day one. Online CNC turning services build their business on this very fundamental principle of wanting to build a long-lasting relationship with their customers. Below is a simplified structure of how a typical transparent price quote would look like:

|

Category |

Item |

Description |

|

Material Costs |

Aluminum 6061 |

Stock material, dimensions: Ø50mm x 100mm |

|

Machining Costs |

CNC Lathe Operation |

Programming & machine time based on part geometry |

|

Setup Fee |

This is a one-time payment that entails calibration and fixturing |

|

|

Post-Processing |

Anodizing (Clear) |

Treatment surface finishing for corrosion protection |

|

Additional Services |

Standard Inspection |

Basic dimensional and visual quality check |

CNC turning transparent pricing is more than just an element in providing this service because, in short, this is very essential in cost control and cost planning in this service. There is analysis and optimization in all aspects of your order, from materials to completion, which makes this one truly the best custom CNC turning services because this process takes you through with ease.

Figure 2: Transforming a digital design into a precision CNC-machined product by LS Manufacturing

What Key Factors Ensure The Promise Of "Faster Delivery"?

Once again, the key to how "faster delivery" is defined utilizes an efficient online process to remove all those factors deemed normal in connection with the issue of the time involved in deliveries. Effective and efficient delivery systems operate by establishing an integrated process from the time of the quotation to the time of the manufacture. It is the speed with reliability that counts when fast CNC turning is concerned. It is the efficient transmission of online information where the basics of fast CNC turning are hinged upon for fast CNC turning as depicted below:

|

Process Phase |

Traditional Service Timeline |

Online CNC Turning Services Timeline |

|

Quoting & Approval |

Days to a Week (Manual Process) |

Minutes to Hours (Automated Quote) |

|

Order Processing |

1-2 days (manual entry, PO fulfillment) |

Immediate (digital integration, automated workflow) |

|

Production Scheduling |

Variable delay (dependent on planner availability) |

Near-instant (automated system integration with shop floor) |

Thus, faster turnaround times are realized by adopting an integrated CNC machining services model. This system employs automated planning and optimized processes that circumvent the limitations and inconsistencies of manual programming and operation, thereby guaranteeing expedited CNC turning production.

How Can Professional DFM Analysis Be Conducted Online And Optimize Your Costs?

Affordable manufacturing secret lies with expert DFM analysis. Even when you use an Internet-enabled platform with automation, this analysis will offer the kind of expert insight required for the optimization of your component for manufacturing. As such, manufacturability problems that could arise are identified and suggestions are offered about how to make it cheaper. This adds value to your custom CNC turning services at no cost to you.

Automated Geometry and Tolerance Review

The automated Design for Manufacturability (DFM) analysis activates upon file upload, screening for constraints specific to precision CNC turning—such as complex geometries or stringent tolerances—and delivers targeted insights by flagging components where revision would directly reduce manufacturing complexity and lower quotes.

Expert-Led Recommendations for Optimization

Following the automated assessment, there is always the possibility of providing expert recommendations. At this juncture, highly skilled engineers may recommend modifications in terms of undercutting depth adjustment, internally corner radius increase and/or non-critical tolerance conversion to standard. The targeted optimization here ultimately helps improve the overall evenness within the custom CNC turning services, for yielding faster machining time, the wear, and costs in general.

Interactive Feedback Loop for Cost Reduction

The technology supports an interactive feedback process wherein you can access comprehensive DFM feedback suggestions-including new, cheaper instant quotes provided. By this, you can personally estimate the direct, tangible costs of respective design changes, thus facilitating an even better decision during the optimization process of your part design, balancing optimization needs in both the part usage and part manufacturability during the custom CNC turning services.

Proactive Risk Mitigation and Quality Assurance

This analysis is a proactive quality gate. Any concerns with manufacturability are proactively resolved prior to entering into production. This is a proactive engineering resource, which translates into a smooth process and a final part with enhanced quality, an immense benefit of having an exceptional precision CNC turning partnership.

Online DFM analysis combines the automated screening process with expert knowledge, and as such, it adds an unimaginable level of value. It puts the conventional CNC turning services onto a level of an engineering partnership with expertise. It is a value-adding service that is essential if the best possible result with optimal preparation of designs for precision CNC turning manufacturing is to be achieved.

Figure 3: Precision CNC turning of custom metal components by LS Manufacturing

Case Study Of Online Machining Of Aluminum Alloy Sensor Housings For Automated Equipment: How Is 3-Day Delivery Achieved?

As regards the critical demonstration hosting processing for the present client, it must be emphasized that close calls in their production chain were only prevented by the efficient digital manufacturing processing. The next case study should focus on how the online fulfillment of aluminum sensor housing lids could have been possible within three days.

Client Dilemma

There was a situation that occurred for the suppliers of the automation equipment, wherein they were faced with a dilemma in respect of the urgency of the aluminum sensor housing necessary for one of the critical demonstration programs for one of the critical clients involved. The contract manufacturers committed to supplying the product in 2 days and taking 10 days for production; thus, they will not be able to attend the critical demonstration program whatsoever. This particular case depicts fast CNC turning.

LS Manufacturing Solution

The customer even loaded his design file online in the evening. An online quote and free DFM analysis was done online that contained only the optimization of minimal wall thickness. On receiving online approval, the production schedule was generated in relation to this order. The online progress of this order is being tracked by him, which vividly explains the LS Manufacturing online turning.

Results and Value

The complete order, from submission to delivery, was fulfilled in just three working days. The final cost came in 15% under the client's budget. The housings were received in time for a successful demo, which directly led to the client placing a follow-on batch order. This success story demonstrates the tangible value of the reliable online CNC turning services.

From the above example, it is apparent that speed, cost-effectiveness, and quality are not goals to be accomplished. Rather, it is because of the capability to combine the facilities of quoting, scheduling, and the availability of the online track facility, it has become possible for them to deliver a fast turnaround CNC turning service. The LS Manufacturing online turning makes the impossible possible in this way.

Your journey to manufacturing starts here. Upload your 3D file today for a near-instantaneous, transparent, and competitive quote.

How Can I Track The Production Progress Of My Parts In Real Time After Placing An Order Online?

Just what current production service providers offer you is complete visibility of your production order. And when you place an order, naturally, you will be automatically logged into the secured website where you can view the whole range of the following production procedures. For sure, there is definitely a revolution in the way you have access to the service.

Comprehensive Status Dashboard and Live Updates

Upon order confirmation, you gain access to a personalized dashboard. It displays clear, real-time statuses—such as order received, in production, quality inspection, and shipped. This continuous visibility is a defining feature of the superior CNC turning services, eliminating uncertainty and the need for status-check emails or calls.

Key Milestone Documentation with Visual Proof

The system provides more than just status text. At critical stages, automated notifications are sent along with photographic evidence. You might receive photos of the raw material billet, the part mounted on the machine, or the final inspected product. This visual proof builds confidence in the process and quality of your online CNC turning services.

Proactive Communication and Timeline Management

Information with regards to the pending updates or the possible delay will be distributed through the portal. This is very important as it ensures you with efficient timeline management on your end. Information on tracking includes the production timeline pertaining to turnings. It thus ensures adherence to fast turnaround CNC turning services because any bottleneck is sure to be generated immediately.

One-Stop Data Access and Seamless Processing

This is where all the documents involved in an order from the final quote and the accepted drawing down to the inspection report and the shipping label are maintained in the tracking database. This means that for your project, you simply have to look at the information contained in the one place indicated above. Much better next time with the online CNC turning services.

The live production tracking service is also an integral part of the service linked with the aspect concerning peace of mind. This service is mostly a medium through which live status updates, live milestones, and proactive communication pass. Thus, the service associated with the distribution of live status updates, live milestones, and proactive communication with regard to the CNC turning services is an indicator of both partnership and dependability; thus, the efficiency of the fast CNC turning service.

What Materials And Post-Processing Options Are Supported By The Online CNC Turning Service?

An effective Machining Website gives its customers a significant deal of flexibility when it comes to material and surface finish. These customers are comfortable because they are aware that various projects are processed based on their needs. These customers should be given various alternatives because they possess the capability to design models for end-use parts; this is because they have the ability to select various designs. Various alternatives are required in offering end-to-end CNC machining services.

- Common Materials Used: Starting material for the process requires standardized material; this is readily available. This range consists of a series of aluminum alloys including 6061 and 7075 aluminum alloy; stainless steel alloy including 303 and 304 stainless steel; brass; and mild steel. Standard material will encompass the entire or greater part of the requirements for precision CNC turning.

- Plastics and Engineered Materials: Plastics and Engineered Materials: Besides metals, it also deals with plastics andengineered materials. Examples of plastics used in this technique include Acetal (POM), a low friction plastic material, Nylon (PA), the strongest plastic material, and PTFE. The machining of plastics with precision is one of the CNC machining services.

- Full Surface Finishing Capability Offerings: After machining, numerous surface treatments are available to enhance part functionality and aesthetics. Standard offerings include anodizing (in various colors and types), bead blasting for a uniform matte texture, powder coating, and plating (such as nickel or zinc). These finishes are seamlessly integrated into the custom CNC turning services quote.

- Special Requests and Material Sourcing: For projects requiring specialized alloys, exotics like titanium, or unique finishes, the system facilitates easy inquiries. Customers can contact support for a quick quote on these non-standard options, ensuring the custom CNC turning services can adapt to even the most specific or advanced project requirements.

The various materials that come along with the package and the level of flexibility that is needed when handling specials make for a top-notch online supplier. It is this rationale that guarantees that the designers and engineers have all that is needed for them to be successful when it comes to prototype and production development. It is this ability that enables the precision CNC turning to be capable.

Figure 4: Expedited CNC manufacturing of custom metal components by LS Manufacturing

How Can We Ensure That The Processing Quality Of Online Orders Is As Reliable As That Of Traditional Methods?

The reliability of an online order's quality is guaranteed by a rigorous, behind-the-scenes system of checks and standards. Placing an order digitally does not mean compromising on precision; it leverages automation for speed while maintaining strict, traditional quality control protocols. This commitment is fundamental to the LS Manufacturing online turning promise.

- Structured Multi-Stage Inspection Protocol: There is an organized process for the implementation of quality for every order received. This comprises the first article inspection, in which it is verified that the initial specifications meet the criteria. Then the inspection levels the critical machining stages. Finally, final inspection is conducted. This is an imperative stage where quality cannot be compromized, more particularly for precision CNC turning.

- Investment in Advanced Metrology Equipment: Accuracy will be certified by the use of accurate instruments of measurement. The use of coordinate measuring machines, digital calipers, micrometers, and surface roughness testers will aid in the demonstration of objectivity by giving clear evidence of the accuracy of dimensions and the surface finish, thus living up to the standards demonstrated by professional CNC turning services.

- Adherence to Certified Quality Management Systems: This is an ongoing process and not an afterthought. This ISO 9001 compatibility ensures the processes follow global standards. Hence, there is a synchronization of all processes from the reception of the order to the final delivery for LS Manufacturing online turning.

- Experienced Technicians and Digital Traceability: Despite the automated ordering process at LS Manufacturing, there are machinists and quality technicians to monitor the process. In an actual situation, job traveler and inspection reports can even be provided on an order basis with the aim of having traceability. It is because of the balanced use of human and digital control capabilities for the process control at LS Manufacturing that the CNC turning services process will not fail.

The combination of convenience and quality assurance is thus made possible through online technology. The inspection process used for quality assurance and the best gauging and management systems used by the company make possible the quality assurance that can be harnessed through another process, for that matter, for LS Manufacturing online turning. For every single order placed, it will assure utmost quality for precision CNC turning.

FAQs

1.How accurate is the quick price quote? Would I need to pay a higher price for this later?

The above quote is correct, as it is an algorithm for calculation of material, labor, and processing cost, thus providing a detailed quote, asserts one user. When you accept your quotation, it gets frozen, so that there aren't any arbitrary quotations later on since it is a completely transparent costing system, explains another user.

2. What are the supported formats of 3D files? Drawing requirements?

We also deal with the standard 3D files like STEP, IGES, and X_T. You see, even the drawings and models with details such as dimensions, tol., material, and other details only uploaded to the website enable us to assess and create according to the drawings.

3. What is MOQ, and can one unit be ordered?

There is no minimum order requirement associated with our product order. Furthermore, our service is useful for all sorts of uses, particularly prototype products in R&D, trial products, and so on.

4. How long does it take from placing an order to shipping?

The fastest time that can be taken to process and deliver the common components is 24 to 48 hours. The time fixed for its delivery depends automatically on current order productions. One can also see online the processing time remaining to its completion in real time after placing an order.

5. Does it provide inspection reports on its products?

Dimensional data, inspection photos, and results of inspection may also be reported. At the critical process or parts, the FAIR inspection reports and critical dimensional reports are provided. This shall be necessary for traceability of quality across the process.

6. Do you have any recommendations for improving my design?

When the system gives a quote, you automatically get the DFM report free and suggestions about design for manufacturability with regard to the optimization of the design structure.

7. How can I keep my design drawings and intellectual property secure?

We fully respect confidentiality agreements, NDAs. And we use enterprise encryption solutions for file transfer and storage, compartmentalizing the encryption rights all the way to ensure your designs and IP are protected.

8. How do the customers initiate an online order?

You are welcome to visit our "Online Quote" web page. You just have to upload your 3D file, from which the system will identify and interpret the 3D model, help you with the parameters, and finally come up with an online quote. From there, you can place your order and start working immediately.

Summary

The web-based CNC turning services bring revolutionary changes to the manufacturing sector and connect the quoting, pricing, and subsequent delivery of the product through an internet-based and highly transparent method. This internet-based method brings immense development in the procurement method through the use of proper information.

Take the next step in the evolution of the manufacturing industry. Click on the “Get Instant Quote” button now and upload your 3D file to procure a detailed and transparent quote in less than 30 seconds and an accelerated delivery schedule. LS Manufacturing will now come into action as your trustworthy production partner.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.