CNC turning cost challenges in manufacturing procurement can be largely attributed to the very high degree of information asymmetry, which results in the quotes differing by 50-80% on the price and an extra 15-20% of the total price coming from hidden fees. The undermining of budgeting due to material price fluctuations and wrong process choices is quite common and these two factors are often the main reason for 30%+ budget overruns. Our solution is to break down the supplier quotes and reveal the real cost drivers that are hidden behind the surface pricing.

CNC turning cost transparency is the main result of our structured four dimensions analysis framework which was developed on the basis of LS Manufacturing data spanning 12 years and covering 328 projects. By thoroughly analyzing the interaction between material, labor, tooling, and process optimization, we give the buyers an opportunity to raise the level of their quote transparency by 60% and at the same time, cut their costs by 25-40%, thus being able to not only make the right decisions but also efficiently control their budgets.

CNC Turning Cost Cheat Sheet

| Section | Brief Description |

| Key Cost Drivers | The material type, complexity of the component, quantity of production, precision tolerances, and surface finish requirements are among the factors that drive the cost significantly. |

| Cost Components | The total cost is made up of the cost of raw materials, machine hour operation, labor, tooling, setup, and factory overhead. |

| Cost Estimation | You can make a rough estimate by multiplying the cost of an hour on the machine with the cost of the material and the time you will spend on machining. |

| Cost-Saving Strategies | You can save your money by modifying the design, choosing the suitable type of material, and making improvements in the batch production. |

| Common Cost Pitfalls | To prevent unnecessary cost overruns, one should avoid such mistakes as over, engineering, inefficient setups, and poor material choices. |

We solve CNC turning cost challenges for our clients by providing accurate quotations, guidance on designing for manufacturability, offering efficient machining processes, and maintaining rigorous quality control. The products that result from our solutions are less expensive, generate less waste, are delivered faster, and are more reliable, which altogether ensures that our customers' projects are both cost, efficient and successful.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

You can encounter countless theoretical articles on machining costs. This publication is an offshoot of direct factory experience. We don't merely work out costs; we fight them daily while accommodating extremely tight tolerances for aerospace components and simultaneously running highly optimized production of automotive clients. Our understanding guarantees that your quotation takes into account genuine manufacturing issues instead of just spreadsheet figures.

Each and every one of the strategies here is real-tested. We have identified the true cost drivers of machining operations through the experience of machining titanium prototypes to high-volume stainless steel fittings. Such a deep understanding enables you to wade through different quotations, spot inefficiencies, and pose the right questions. We use practices that are in line with the industry standards, integrating the design-for-manufacturability concepts inspired by 3D Systems and the operational safety measures according to Occupational Safety and Health Administration (OSHA) requirements.

The pieces of advice enclosed are from expensive errors we have previously made. We let you in on how to get around the hidden costs in the choice of materials, setting up, and tooling. These are not just theories thrown out there; it is knowledge acquired through struggles which we want to share with you in order to save you time, money, and guarantee the financial and structural integrity of your project from the very first quote to the last part.

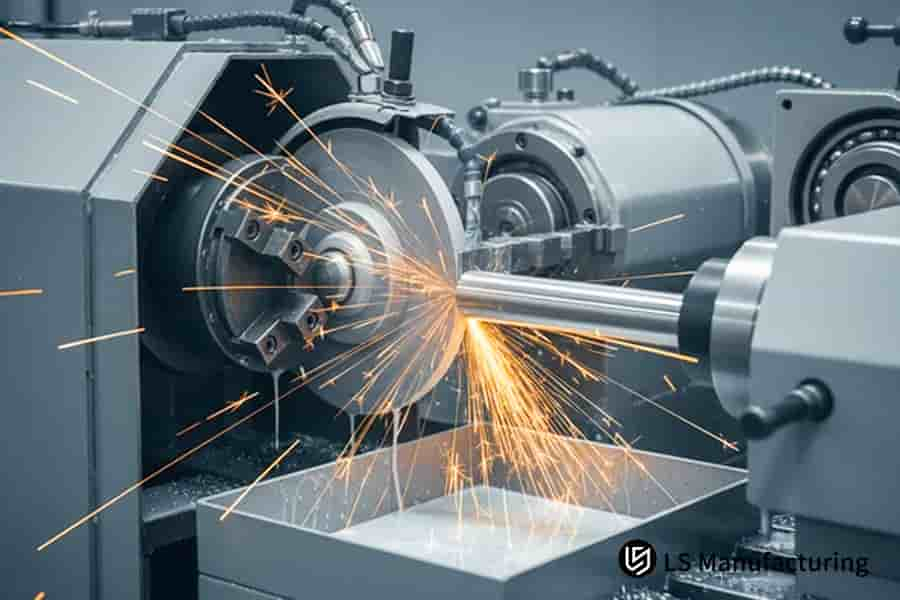

Figure 1: Processing high-precision metal alloy industrial component for accurate cost estimation and RFQ guidance.

How To Accurately Calculate And Optimize Material Costs In CNC Turning Quotations?

To accurately figure out the cost of CNC turning materials is one of the basics of doing business; however, the real optimization comes when one can solve the issues of utilization, selection, and price volatility. We don't settle for just calculating the volume of parts; we create a roadmap of substantial savings through a rigorous, data, backed approach that gets to the heart of these complexities:

Maximizing Yield via Pre-Machine Simulation

We counteract natural waste by running a virtual material cost analysis before making the purchase. By leveraging advanced nesting software, we determine the most efficient bar stock cutting layout for the entire batch production. This forward, looking measure, for example, in our case of 6061 aluminum bracket optimization, regularly lifts the material yield from 65% to 85%, which in turn lowers the CNC turning cost base by up to 15%.

Implementing Performance-Equivalent Material Substitution

Cost saving is not necessarily a matter of sacrificing performance. Our engineers have the technical know, how and always keep an updated database of alternative materials that have flushed out their mechanical properties. When a client needed a shaft component made, we suggested changing the material from 4340 steel to 4140, which still met the strength requirements and on top of that, the cost of the material only went down by 20%. This way, the technical approval process is done in such a manner that reliability is never sacrificed for the sake of savings.

Stabilizing Costs with Strategic Sourcing Agreements

In order to protect our projects against market fluctuations, we utilize long-term purchasing contracts for volume with CNC turning suppliers who are certified. These contracts, which specify OSHA, compliant material handling, not only set the prices but also guarantee the traceability of the materials. Thus, the price fluctuation is limited to a ±5% band, which allows our clients to have a stable and accurate budgeting for their projects.

Validating Strategy with Real Production Data

Any strategy for optimization undergoes a series of tests to check for its effectiveness. We keep a record of the parts that have been consumed and the cost that was incurred per part and then we compare it with the initial model of the quote. This closed-loop feedback, which is a part of our cost optimization protocol, makes it possible for us to continuously improve our material cost analysis and at the same time, we can be sure that the projected savings are being realized in the production of high-volume precision CNC turning.

By employing this method, materials which were once considered a mere expense are now an actively managed item. We offer our clients a line item in the quote not just for materials, but also a clear, technically, standing strategy for their control, thus final part costs are secured to be both competitive and predictable on the basis of feasible engineering decisions.

Which Factors Have The Greatest Impact On The Final Price When Calculating Processing Time?

Accurate machining time calculation is the basis for dependable CNC turning pricing, however, it is often violated by hidden inefficiencies in setup, process, and equipment. We solve this by putting in place a systematic approach that identifies and optimizes the variables that have the greatest impact on time estimates, thereby turning time from being a major cost variable into a controlled, competitive advantage:

Minimizing Non-Cut Time with Standardized Fixturing

A large part of the cost is tied to non-productive setup. We engineer and install modular, standardized fixture systems that are compatible with part families. In the case of a batch of aluminum connectors, this engineering intervention caused the reduction in per-batch changeover time from 15 minutes down to 5 minutes, which in turn directly lowered the fixed setup cost that was attributed to each unit in the CNC turning quote.

Maximizing Cut Time with Validated High-Efficiency Parameters

Theoretical cutting speeds are hardly ever at par with the rates of sustained production. Our efficiency optimization protocol applies a proprietary database that has been compiled from thousands of jobs in order to assign the material-specific parameters to the case. When this was applied to a 6061 aerospace fitting, a 40% increment in stable cutting speed was achieved, thereby sharply cutting down the cycle time while also preserving the tool life and surface integrity.

Calibrating Estimates to Specific Machine Tool Capability

An estimate from an ideal machine spec will not stand on a less powerful or outdated one. We adjust our CNC turning time calculation to the precise capabilities of the production machines pindle torque, horsepower, and rigidity. Thus, we neither make unrealistic speed assumptions nor will the quoted time for the complex turning operations be dependable and achievable. In this way, costly floor-time overruns are avoided.

Such a comprehensive approach thus resolves the chief problems arising from inadequate and exaggerated time estimates. We deliver a CNC turning pricing model that is not only transparent and backed by engineering but also capable of pinpointing and eliminating time-based waste, thus producing not just a quotation but a confirmed production plan that is efficient and predictable in execution.

How Can Tool Consumption Costs Be Reasonably Evaluated And Controlled In The Quotation Process?

Tooling cost is always a major issue in a CNC turning quote apart from being quite unpredictable. Instead of just making rough estimations, we have a well, balanced, data-driven control system to turn this uncertainty into a stable, minimized cost. This method well, addresses the main problems of random wear, non-optimal selection, and the abrupt failure of the tool:

Implementing a Dynamic Tool Life Tracking System

- Real-Time Monitoring: We installed spindle load sensors along with CNC controls to accurately monitor tool wear rather than rely solely on theoretical life predictions.

- Data-Driven Replacement: By changing tools based on actual performance data, not only has it helped us avoid a breakdown, but also prevented us from doing the changeover too early, which has led to a reduction in our CNC turning tooling cost from a 12% share down to 8% share.

Executing Validated Tool Substitution Protocols

- Technical Qualification: We have a thoroughly tested record of alternative tools, for example, we have a set of domestic inserts that are qualified for certain operations.

- Cost-Per-Part Reduction: Using a domestic insert which was tested and had a similar life and performance, the company made a 35% saving on a 4140 steel project.

Establishing a Proactive Tool Failure Alert Mechanism

- Condition-Based Monitoring: The tool examines the sensor signals to detect any unusual vibration or power patterns and thus, the tool failure can be predicted even before it happens.

- Preventing Cascade Failure: Scrapped parts and machine damage are avoided thus helping to achieve the motto of consumables management integration in complex CNC turning operations.

Our systematic framework redeems your tooling from just another volatile cost to a fully predictable, well, managed cost center. We address the problem of uncontrolled budget overruns through a CNC turning quote that is firmly based on engineering data-proactive lifecycle management, and confirmed substitutions. It guarantees part cost stability over the long term and shields your project from the concealed risks of conventional tooling cost estimation.

Figure 2: Custom CNC turning hardened steel alloy mechanical part pricing quote analysis.

What Is The Relationship Between Different Batch Sizes And The Cost Per Unit?

In custom CNC turning, the per-unit cost is not linear but changes significantly with the quantity of the order. Grasping this economy of scale is vital for making a correct budget and for strategic sourcing. This research measures the cost effect of different batch sizes and offers a method to enhance production planning for maximum economic efficiency:

| Batch Size | Primary Cost Impact | Our Optimization Strategy |

| Prototype (1-10 pcs) | Initial major cost for setup and programming, which cost 3-4 times the per-unit rate of a production batch. | We limit the prototype costs to only 1.5 times the production rate target by using modular, pre-engineered fixturing and shared setup protocols. |

| Low-Volume (11-50 pcs) | Setup cost is spread over more units, per-unit cost greatly decrease but remains volatile without proper strategic planning. | By scheduling production our compatible low-volume orders are combined into shared runs, thus, a larger virtual batch production is created and cost is lowered. |

| Mid-Volume (50-100 pcs) | With the help of parameter and toolpath optimization efficiency gains, CNC turning pricing becomes more and more predictable yielding the most stable costs. | Our data-driven process optimization is the raw material of which we extract the largest fruits of the fine-tuned parameters achieving up to 30-40% per-unit cost reduction. |

| High-Volume (100+ pcs) | Diminishing return on the time invested; material and tooling are the main cost factors, machine time is negligible. | The emphasis is on supply chain optimization and predictive consumables management, when subordinating to the final margin gains. |

Our quantitatively guided model figures out the non-linear dose, response relationship the precision CNC turning cost. We tackle the problem of expensive prototypes and highly fluctuating prices for small batches by planning order consolidation and process optimization. This gives our customers a clear, actionable plan to run economy of scale benefits that are not limited to the size of their first order.

How Can Design Optimization Reduce Machining Costs In Turning Operations?

Design choices made before manufacturing start account for as much as 70% of a project's total CNC turning budget. Good design for manufacturing (DFM) is not a mere suggestion but a very crucial engineering discipline for major cost reduction. We make up for the lost time between design goal and production efficiency through a comprehensive, data oriented study that reveals and puts into practice the following optimizations:

Simplifying Geometry to Minimize Setups

Complex CNC turning parts often require multiple machines which exponentially raise the time to handle and the cost. We analyze and prioritize the design features that can be accessed only from one orientation. For a sensor housing, we reversed the inside groove thus removing the need for a secondary set up and decreasing the total CNC turning cycle time by 30%, hence directly saving labor and machine costs.

Specifying Tolerances Based on Actual Function

Too tight tolerances, that are unnecessary, are one of the biggest reasons for the high cost. In order to distinguish the critical areas of the fit from the surfaces that are not-critical we make a functional review of the component. For example, by simply changing the bore tolerances from IT7 to IT9 for a hydraulic manifold we shortened the machining time by 20%, thus we saved a lot without sacrificing the component's performance in the precision turning application.

Standardizing Features to Streamline Production

The ever, increasing number of different thread sizes, radii, or groove dimensions requires tool changes and specialized tooling very often. We are in favor of standardizing these features which belong to the same part family. By limiting the internal threads to only two sizes on an engine component, the number of different tools needed was reduced by 60%, tooling inventory cost dropped, and the non, cut time was minimized, which altogether greatly optimized the overall CNC turning budget.

This proactive design for manufacturing engagement changes theoretical savings into measurable results, with our studies regularly reaching a 15-25% cost reduction. We tackle the problem of the very high inherent part cost by giving our clients the exact, changed, manufacturable designs that increase producibility without compromising functional integrity, so that performance and economic efficiency are guaranteed.

Figure 3: CNC turning hardened steel alloy precision custom shaft pricing quote analysis and guide.

In What Aspects Do The Price Quotes Of High-Quality Suppliers Differ From Those Of Ordinary Suppliers?

An initially lower quote is a common way of hiding substantial subsequent costs. The real difference between suppliers is not the price they start with, but rather their engineered methods of defect prevention, reliability assurance, and project value protection. This study explains the areas in which a higher investment brings a real return, going past simple CNC turning RFQ comparisons:

| Evaluation Dimension | Standard Supplier Focus | Premium Supplier Investment & Outcome |

| Process & Engineering | Meets basic print specifications; minimal process optimization. | Dedicates 8-12% of quote to value analysis and precision turning process development, thus reducing your total cost by 15-20% through increased efficiency. |

| Quality Control | Relies on final inspection, leading to higher escape rates (e.g., 3% PPM). | Uses Statistical Process Control (SPC) for real-time monitoring. This way, defects are down to 0.5% and expensive rework or failures are avoided. |

| Supply Chain Reliability | Gives estimated windows; production schedules may get disrupted if there are deviations. | Has strong planning & rapid response protocols, thus delivery accuracy ±1 day is achieved, and your project continuity is guaranteed. |

| Technical Collaboration | Transactional; simply delivers the order as specified. | Design for manufacturing (DFM) is a proactive partnership that works to optimize part geometry and material selection resulting in the best CNC turning product. |

We address the vital problem of hidden cost risks in the supplier selection process. Our approach offeres a transparent value analysis framework by which one may quantitatively see how investments in process engineering and control can effectively save your project from delays, defects, and disruptions that are the major contributors to the true cost of manufacture.

LS Manufacturing Automotive Parts Industry: Steering Knuckle Machining Cost Optimization Project

A Tier-1 automotive supplier had to make a tough decision as the quotes for CNC machining of a critical steering knuckle had the spread of about 65%, making the CNC machining pricing quite non, transparent and raising quality concerns for this safety, critical component. This cost optimization case study details our technical intervention and the delivered value:

Client Challenge

It was a C45 steel steering knuckle part forged that needed precision CNC turning of the bearing seats to IT7 tolerance and fine threading. The current manufacturing method had 4 different setups and was causing positional errors (0.1mm deviation) and per-unit price was very high at 140 RMB. This high, priced variation and quality problem were directly endangering the profit margins and the security of the supply of their high-volume automotive parts assembly line.

LS Manufacturing Solution

Our engineers rethought the process and made it possible to manufacture everything with one set, up in a 5-axis turning center. We built a custom mult, function toolholder to carry out drilling, boring, and threading operations in one chucking, thus eliminating alignment errors. Lean line optimization synchronized tool changeovers with robot part handling, reducing non-cut time by 40% and enabling a predictable, lower CNC turning quote.

Results and Value

The new process resulted in a unit cost of 92 RMB (reduction of 34%), also the geometric accuracy was improved by 60%. On-time delivery was at 99.5%, thus the client production run was very smooth. The savings of 2.8 million RMB a year were reinvested into further R&D, thus demonstrating that a proper value analysis turns a simple how to get CNC turning quote into a strategic partnership and a tangible competitive advantage.

This work went to show that genuine cost optimization is really about fundamental process innovation rather than supplier negotiation. By removing the main technical limitations and refining CNC machining pricing strategies, we are able to supply measurable savings as well as supply chain resilience, thus proving our capability to carry out complex, high-stakes automotive manufacturing projects where both performance and cost matter.

Discover transparent CNC turning cost optimization with expert analysis and reliable delivery solutions.

How To Create A Reasonable Budget For A CNC Turning Project?

Making a CNC turning budget that is accurate involves going beyond simple guessing to using a proper project costing methodology. Attempts to predict the costs may lead to errors because of ignoring certain hidden variables. To solve this problem, we use a transparent, data-driven cost estimation framework that details each expense component and checks it against the actual costs:

Establishing a Transparent Material Cost Model

- Precise Calculation: We precisely determine the cost of the raw material with the formula: [Weight of Finished Part + Allowance for Machining] Material Price/kg a validated 1.2 Kerf & Clamping Loss Factor.

- Proactive Optimization: The method identifies the areas that generate the most costs, such that the design for manufacturing changes can be made at the early stages to reduce waste, thus leading to direct savings in procurement cost, the biggest variable in the budget.

Calculating Machining Costs with Validated Parameters

- Accurate Time Estimation: Machining time calculation uses cycle times derived from our proprietary database of optimized feeds & speeds for specific materials, not theoretical maximums.

- Rate Application: The verified time is multiplied by a machine-specific hourly rate that accounts for depreciation, power and maintenance, thus the CNC turning quote will be a reflection of the true cost of production.

Applying a Comprehensive Overhead Framework

- Full-Cost Transparency: We earmark 12-18% for engineering, quality control, and project managementthese are the activities that ensure a reliable CNC turning, but the ones that very often get left out in the cheapest quotations.

- No Hidden Fees: A methodical roadmap like this lays down the final project costing so that it is complete and defensible, thus, it eliminates surprises and builds trust through financial clarity.

Validating with Our Digital Budgeting Tool

- Instant Scenario Analysis: Through our online platform, clients can key, in (material, quantity, drawings) for an instant and detailed budget breakdown with ≥95% accuracy.

- Informed Decision-Making: Clients can know the cost sensitivity through this tool and take early, data-backed decisions resulting in budgeting becoming a planning strategic activity instead of a hurdle from a reactive step.

This methodological way of working addresses the main issue of budgetary uncertainty. We give our clients a collaborative and transparent CNC turning cost estimation process that takes complex variables and turns them into a reliable and actionable CNC turning budget, thus ensuring financial predictability and project success right from the very first stage.

Figure 4: Precision turning stainless steel alloy custom component manufacturing for accurate pricing quotes.

Why Choose LS Manufacturing's Quote Analysis Service?

Sourcing managers are in a tight spot: they have to figure out the complex CNC turning quotes in detail to be sure of their fairness and getting the best value without being manufacturing experts. Our service cuts through the confusion and/ or turns indecipherable bids into clear, helpful information for CNC turning supplier evaluation and negotiation, after more than ten years of gathering data as a basis:

Validating Quotes Against a 12-Year Empirical Cost Database

We compare each quote to our unique database of thousands of completed high-volume turning projects. With our help, you can immediately spot those items that we have not seen before on costs and prices that are wildly different from the ones that have been norm for a certain material or complexity, thus identifying overcharges or extremely cheap bids that might be of low quality, hence, making your cost analysis more of a factual approach than just an assumption.

Providing 100% Transparent Cost Breakdowns

By breaking down every quotation into its basic components: raw material, machine time, tooling, setup, and overhead, we are able to give you a detailed comment on each one based on our data and assessment of how reasonable it is. This detailed level of transparency which is generally lacking in most quotations, allows you to question the specific costs and are able to see what exactly is behind your CNC turning project's price.

Delivering Actionable Optimization Strategies

Our analysis is not just about evaluation but also prescription. We offer very precise and technically sound recommendations like design changes for easy manufacturing or different material grades that in fact, the main sources of production costs. These proactive engineering suggestions usually point to a potential saving of 25-40%, thus shifting the quote analysis from being a mere review to a real value-creation tool.

Our tool of forensic insight and technical leverage helps you secure getting CNC turning quotes keeping in view the engineered value. In other words, you get to pay the right price for the value, engineered commodity instead of the inefficiency or risk, thus safeguarding your project's budget and performance integrity through high-level supplier evaluation.

FAQs

1. What hidden costs are included in CNC turning quotes?

Fixture, programming, and inspection costs are the main ones. A reputable supplier displays them clearly, and these usually amount to 8-15% of the total cost.

2. How to determine if a quote is reasonable?

Ask the supplier for a cost breakdown and then check the shares of materials, labor, and tooling. A typical cost structure is 35-50% for materials, 30-40% for labor, and 8-12% for tooling.

3. How to control costs for small-batch processing?

LS Manufacturing achieves small-batch costs up to only 1.5 times the cost of large, batch production by standardizing materials, combining process steps, and fast mold changes.

4. Are rush orders always subject to a price increase?

A delivery time reduction of 30% will generally cause a price increase of 15-25%. However, some of this cost can be saved by means of production optimization. LS Manufacturing limits rush order price increases to 10-20%.

5. How to mitigate the impact of material cost fluctuations?

LS Manufacturing keeps price fluctuations within ±5% by entering into price-locking contracts, making safety stock, and optimizing material specifications.

6. What should be considered when quoting complex parts?

Pay attention to special tooling, clamping solutions, and inspection requirements. These invisible costs can represent 20-30% of the total price.

7. Do you provide cost analysis reports?

LS Manufacturing compiles a detailed cost analysis including process optimization recommendations that can help customers cut costs on average by 25%. It is a free service.

8. How to obtain an accurate quote?

Preparation of complete drawings, technical specifications, and batch details is necessary. LS Manufacturing enables a clear quotation with cost breakdowns in 2 hours.

Summary

Scientific CNC turning cost analysis requires a systematic evaluation framework. Through in-depth quote analysis, process optimization, and supplier evaluation, cost transparency and optimization can be achieved. LS Manufacturing's cost analysis system provides customers with a complete solution from quote analysis to cost optimization.

Upload your part drawings now to receive a free "CNC Turning Cost Optimization Analysis Report"! Our cost analysts will provide you with a detailed quote analysis, cost-saving solutions, and accurate budget recommendations within 4 hours. Consult us now to receive process optimization suggestions to help you achieve cost optimization.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.