Helical gear milling is of great significance to the realization of silent transmission. Conventional spur gears are apt to produce impact noise under conditions of high torque or precision transmission due to instantaneous line contact. In fact, such problems stem from the fact that ordinary machining processes can't guarantee consistency in the helix angle and tooth surface precision.

This paper presents a real leap forward to the high-precision fabrication of helical gears using 5-axis CNC technology and demonstrates how LS Manufacturing secures the advantages of theoretical performance in transmission components by an integrated solution of design-manufacturing-testing.

Essentially, the application should be informed by an understanding of the working principle of a helical gear. The subsequent section will analyze how helical gears fundamentally solve traditional transmission inherent problems by progressive meshing.

Figure 1: Milling a large precision helical gear on a CNC machine by LS Manufacturing

Helical Gear Milling Full-Text Quick Reference Table

| Summary Module | Core Content |

| Pain Points in Transmission | Noises and vibrations arise easily with the impact meshing of traditional spur gears. |

| Root Cause | A standard manufacturing process does not ensure a precision tooth profile for a helical gear. |

| Answer | 5-axis CNC milling technology features high-precision machining. |

| Beneficial Principle | Helical gears have helically cut teeth in order to allow for a smooth progressive meshing. |

| Core Process | 5-axis technology now allows milling of complex helical gear surfaces in a single setup. |

| Quality Assurance | In manufacturing, the precise examination and feedback data form a closed loop. |

| Core Value | Eventually, in order for the transmission system to be effective with low-noise and stable operation. |

The guide systematically states that, in principle, the progressive meshing principle of helical gears can eliminate the noise and vibration problems of traditional transmission. 5-axis CNC milling is the enabling key technology that can develop this theoretical advantage into superior practical performance, with precision machining and closed-loop quality control; therefore, it is selected as a core solution for the improvement of transmission quality in high-end equipment.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

What separates us isn't about the general information; it's about the decade-long journey of manufacturing tens of thousands of precision helical gears. This path has taught us invaluable, very practical lessons in nuances around the interplay of material properties, critical planning of CNC toolpath strategies, and sophisticated coordination of 5-axis machine linkages. The following guide is a distillation of the hard-won and practical knowledge coming from an enormous number of success stories and setbacks that have helped us shape our approach.

Each parameter suggested here, each technique of treatment explained, has been tried and checked by ourselves on our own workshop benches, among chips and coolant of real production. And we share this concentrated experience with you in the following pages, with a clear purpose: so that you may avoid common pitfalls we have already found and overcome. We want to equip you with the insight enabling you to go directly to the heart of the matter, which is efficiently and reliably realizing superior, low-noise performance in your transmission systems.

Helical Gears Compared VS Spur Gears: A Transmission Revolution From 'Impact' To 'Slip-In.'

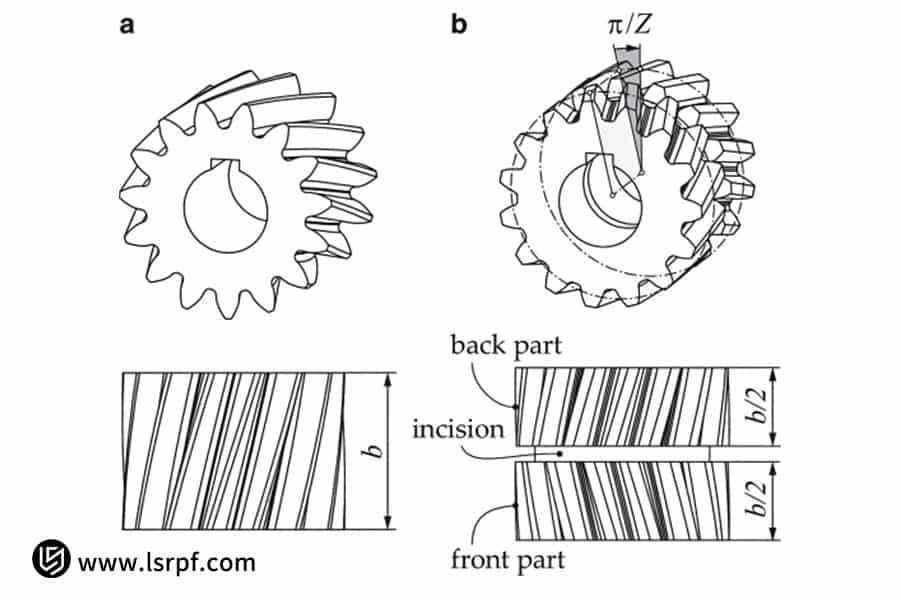

In principle, helical gears vs spur gears deals with two philosophies of meshing, the tooth profiles of spur gears being parallel to the axis with a resultant "line-to-line" impact when meshing, whereas for helical gears the helix angles introduce "point-to-point" progressive slip-in contact. This basic difference clearly brings out the advantages of helical gears - smooth, powerful, and quiet.

| Comparison Dimensions | Helical Gear | Spur Gear |

| Meshing method | Helical gears provide progressive continuous meshing due to the helix angle. | If tooth profiles are parallel, during meshing and in the moment of disengagement, contact happens all at once as an impact. |

| Smoothness of Transmission | Because at any instant more than one tooth is in contact and the load is transferred smoothly from one tooth to the next, extremely smooth running results. |

In the case of alternate single and double-tooth engagements, periodic vibration and shock can readily be generated. |

| Noise | Smooth meshing characteristics reduce impact noise at its very root. | Operating noise is a direct result of the impacts of meshing. |

|

Load Capacity |

Larger contact area results in better load distribution and stronger load capacity. |

Limited contact area can easily lead to pitting or tooth breakage under heavy loads. |

| Application Scenarios | Widely used in high-speed, high-load, and noise-critical applications. |

More commonly used in low-speed, light-load, or cost-sensitive general transmissions. |

In effect, helical gears overcome the noise, vibration, and load concentration problems caused by instantaneous impacts in spur gears due to progressive meshing. In particular, the helix-shaped teeth create a "slip-in" contact that is smooth in transmission and quiet, considerably improving the gear load capacity and service life owing to the increased contact area.

Figure 2: Precision CNC machining a large helical gear component by LS Manufacturing

Why Do Helical Gears Provide A Smoother And Quieter Transmission Experience?

Advantages of helical gears mainly reflect their transmission principle, quite different from that of spur gears. Unlike the instantaneous impact meshing of a spur gear, the helical-toothed structure of the helical gear realizes a fundamental optimization of the transmission method in essence. Particularly:

1. Principle of Progressive Meshing:

During meshing, the tooth surface of a helical gear pair gradually goes into engagement and disengagement along the helix angle, forming a continuous and smooth force transmission process; this avoids periodic impacts and instantaneous load variations during operation. This is in contrast to spur gears, where the teeth engage abruptly, hence considerably reducing the vibration excitations at source and allowing more dynamic quiet operations.

2. High Contact Ratio:

In helical gears, the teeth are in continuous contact along the helix, and several pairs of teeth always remain engaged at any instant. Such an interaction of the teeth in an overlapping manner necessitates that at any instant, the load will be distributed across several teeth, with an increased load-carrying capacity for the gear itself, thus providing far superior uniformity in the distribution of force for more continuous and stable torque transmission even at changing conditions of operation.

3. Excellent Vibration and Noise Reduction:

In the gear set, progressive meshing in concert with high contact ratio significantly reduces the vibration amplitude inside the system of transmission. The profile of the teeth is slanted to provide a smoother contact because of sliding action that dampens the meshing impacts and emissions of noise through air. This makes helical gears particularly suitable in high-speed applications with high-precision requirements where low acoustic emission and operational stability are crucial.

It is such a technical characteristic that will effectively dampen the impact, distribute the load uniformly, and ensure severe requirements for both smooth transmission and low noise met with respect to high-speed heavy-load transmission; it is the ideal solution to help raise the transmission quality of the equipment.

From Traditional Methods To 5-Axis CNC Milling: Helical Gear Manufacturing Processes In Modern Times

A helical gear manufacturing method reflects the constant pursuits in the direction of precision and efficiency. Traditional technologies in hobbing and gear shaping enjoy cost advantages during mass production, whose disadvantages are obvious: high-precision tooth profile control and flexible small-batch production. In contrast, the modern 5-axis machining of CNC helical gear cutting technology allows precise control of helix angle and tooth surface by digital programming; hence, it offers a better solution in manufacturing high-end gears.

| Comparison Dimensions | Traditional Hobbing/Shaping Processes | 5-Axis CNC Milling Process |

| Principle of Machining | Machining is based on a generating motion of an appropriate tool. | Multi-axis linkage has the ability to manufacture complex tooth profiles directly. |

|

Precision Control |

Much affected by tool wear and backlash of machine tool. | Digital control assures tooth profile and angle accuracy. |

| Manufacturing Flexibility | Tools are very specialized and adaptability to product changes is poor. | Adaptation to different specifications can be done by a program adjustment. |

| Surface Quality | The quality of the surface is dependent on the tool condition. | The best surface finish can be obtained by optimizing the cut path. |

| Shaping capability | The shaping of complex tooth-profiles cannot easily be achieved. | It can easily finish various kinds of shaping and optimization designs. |

This 5-axis CNC milling technology provides great precision in control and flexibility in machining, thereby effectively overcoming the limitations associated with traditional methods of helical gears manufacturing. Particularly for small batches involving high-precision shaping of tooth profiles, this technology does a commendable job.

Design Of High-Performance Helical Gears: A Key Parameter Selection Guide

A helical gear design directly depends on the precision of matching several core parameters, including but not limited to helix angle, module, and pressure angle. It is the enabling factors in combination that determine the transmission performance of the gear and the applicable scenarios. Scientific configuration of the parameters is therefore an important key to such particular goals as high smoothness, low noise, or high load-carrying capacity.

1. Helix Angle Selection:

The most important parameter that can be taken into consideration for balancing smoothness and axial force in a helical gear is the helix angle. While an increased helix angle gives an increased contact ratio-meaning much smoother meshing with lower noise, fitting for high speeds-a too big helix angle will build up great axial thrust, thereby increasing the bearing load of the gear set. In this case, it should normally be limited within 8°-25° to keep good balance between smoothness and structural complexity.

2. Module Determination:

Module is one of the major factors in balancing gear strength and transmission smoothness. It directly determines the load-carrying capacity of gears. Using a large module can raise tooth root bending strength and is suitable for high-load transmissions. But it weakens the contact ratio and may further reduce the smoothness of transmission. In general, under favorable conditions, taking a smaller module with an appropriate number of teeth can effectively improve meshing smoothness. In heavy-load applications, the module shall first ensure adequacy, then optimize smoothness by means of the helix angle thereafter.

3. Pressure Angle Optimization:

Standard pressure angle 20° keeps a good balance between tooth root strength and noise, and has an influence in both ways. Increased pressure angle improves the tooth root strength and avoids undercut, but surges the bearing radial force and operating noise. Noise can be reduced by a decrease in the pressure angle, but it will weaken the tooth root strength. The tooth profile trimming plus a little smaller pressure angle, such as 17.5° is suitable for applications with higher noise sensitivity. Following are the parameter selection tendencies under different design goals for your reference:

| Design Goal | Helix Angle Selection | Module Tendency | Pressure Angle Recommendation | Other Considerations |

| High stability / low noise | Greater angle: 15° to 25°, smaller module. | Smaller Module | Standard or Slightly Smaller: ~20° | Emphasis on Tooth Profile Edge Modification and Precision |

| Large Load-carrying Capacity | Medium Angle 8°-15° | Larger Module | Standard or Slightly Larger 20°-25° | Emphasis on Tooth Root Strength |

| Compact Structure | Smaller Angle (<15°) | Determined by Space | Standard (20°) | Optimize Tooth Width and Tooth Count Combination |

Great helical gear design represents the art of synergistic interaction mainly of three key parameters: helix angle, module, and pressure angle. In this respect, the designers have to define the priorities among the parameters in reference to the main aims such as "stability," "load," or "compactness." Thus, the first priority should be the helix angle for applications with high operational speed in order to enhance stability; for heavy-load applications, a sufficient module should be considered; and in cases of limited space, all the parameters need thorough optimization.

Figute 3: Final assembly of a precision helical gear drive by LS Manufacturing

Core Application Areas Of Helical Gears -Where Do They Play An Irreplaceable Role?

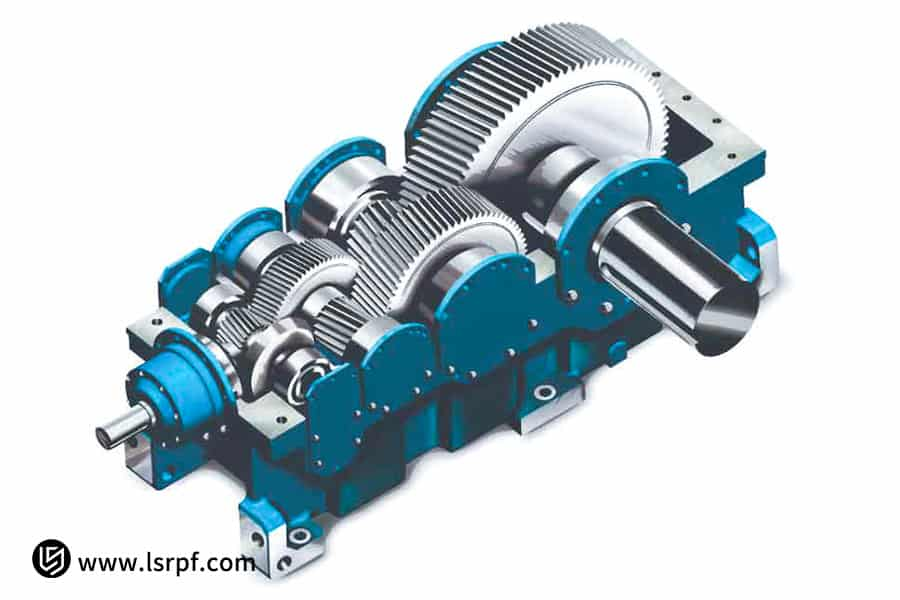

Advanced technologies in helical gear manufacturing are further amplifying the inherent advantages of helical gears, solidifying their critical role in many high-end fields. Equipped with superior features such as good smooth transmission, low noise compared to traditional gear products, and high load-carrying capacity, they have become one of the core technical elements that cannot be replaced in the following key fields.

- Automotive Transmissions: Since helical gear sets form the very basis of realizing smooth shifting and quiet running in automotive automatic transmissions, the effective progressive engagement characteristics of their teeth avoid traditional shock from gear shifting. Hence, extremely good comfort is assured for drivers and passengers alike, with load-carrying capacity that secures reliable torque transmission.

- Industrial Gear Reducers: Heavy-duty and efficiency operations ensured, since large contact areas and load-sharing characteristics enable helical gears to bear heavy-duty impacts under extreme operating conditions in high-torque gear reducers for mining machinery or heavy industrial equipment. This not only prolongs the service life but results in better system efficiency on account of reduced energy loss.

- Aerospace: Reliability and light weight are perfectly balanced. An aero-engine transmission system requires very high reliability and light weight. Components manufactured by precision helical gear technology can achieve lightweight with strength maintained, and stable transmission performance provides an important guarantee for safety.

- Precision Equipment: High-precision machine tools, medical equipment, and optical instruments are all based on micron-level transmission. The extremely small transmission error and low vibration characteristics of the helical gears enable positioning with high accuracy and stability, satisfying the rigid requirements of precision manufacturing and measurement.

In summary, the unique advantages of helical gears make them a core component in modern high-end equipment. The constant innovation in its manufacturing process, including precision machining and advanced materials, promotes continuous upgrading and breakthrough in product performance across various fields, enhancing overall efficiency and durability.

Case Study: How Does LS Manufacturing Help Industrial Gearbox Manufacturers Overcome Noise Challenges?

It is in solving real-world engineering challenges that the value of LSmanufacturing helical gear is fully demonstrated: one well-known industrial gearbox manufacturer had to bear the consequences of continuous gearbox noise at 75dB; there were cancellations of orders. Its original supplier provided gears which exhibited significant tooth profile deviations and abnormal meshing noise.

- Customer Challenge: The noise level of the customer's current gearbox under load reached up to 75dB, which is beyond the customer's required standard of 70dB. From test analysis, the root cause was inadequate precision on gear tooth profile error up to ISO 7 level and variation in helix angles, creating meshing impact and vibration noise.

- LS Manufacturing Solution: Precision machining was performed on a 5-axis CNC milling center. By customizing the toolpath planning, the involute profile of gear teeth can be precisely controlled to improve precision to the ISO 5 level. Optimized cutting parameters ensure Ra ≤ 0.8μm for tooth surface roughness. Full 3-axis measurement during the whole process ensured that the helix angle error was controlled within ±2.

- Results and Value: Delivered LS Manufacturing helical gear contributed to the reduction of the overall machine noise to 67dB, which was 3dB higher than what the customer had initially required. Full-load test performance for 2000 hours showed a 30% increase in gear life to 13,000 hours. This breakthrough not only helped the customer retain key orders worth more than ten million annually but also gave their products a strong competitive edge in the market.

This example illustrates how the LS Manufacturing helical gear resolves noise and lifetime issues through precision manufacturing processes and a strict quality control system. Technical solutions given to customers are to optimize tooth profiles for improvement in precision and to enhance general quality control, creating an unexpected leap of performance from standard meeting to excellence.

Figure 4: CNC machining process for a large helical gear by LS Manufacturing

How To Choose The Optimal Manufacturing Solution? The Art Of Balancing Precision, Batch Size, And Cost

How to make helical gears to achieve an optimized cost-performance ratio? That necessarily means weighing in systematically on three central aspects: The choice of a helical gear manufacturing solution itself involves striking an optimum balance between precision requirements, size of the production batch, and total cost.

1. Precision grade determines the process route:

Precision is, of course, the first consideration. Ultra-high precision gears, for example, Grades ISO 5 and above, must be made using 5-axis CNC machining, as its computer control ensures high accuracy in tooth profile and helix angle, which becomes important in critical applications. For general precision gears, Grade ISO 7-8, a high-precision gear hobbing provides an economical solution without compromising quality and durability in most industrial applications.

2. The batch size may affect economic decisions:

In the context of single-piece and small-batch production less than 50 pieces in a batch-5-axis CNC offers the maximum flexibility without any need for dedicated tooling, thus being very economical for making prototypes and custom orders. The best balance between the two methods is usually realized for medium batches ranging between 50 and 500 pieces: hobbing of gears to do the principal shaping, with finishing operations using a CNC mill center. In large batches of more than 500 pieces, investment in dedicated gear hobbing tools and automated lines brings substantial unit cost reductions through efficiency and economies of scale.

3. Total Cost of Ownership is a key decision:

With regard to selecting a manufacturing solution, simply looking at unit price is inadequate. Though the high-precision gears provided by LS Manufacturing are more expensive than ordinary ones by 15-20% each, the value they bring far exceeds the initial price difference: an improvement of 3-5% in the efficiency of transmission, over 30% extension to the service life of the equipment, and a 50% reduction in maintenance downtime. Over its life span, the total cost of ownership is actually reduced by 25-40%.

Our helical gear manufacturing solutions are designed to assist our customers in achieving substantial, long-term reductions in operating costs. This is achieved through exceptional precision control that minimizes energy loss, performance optimization under conditions of maximum load, and a drastically extended service life that reduces the frequency of replacement and associated downtime. In choosing us, you are choosing more than superior transmission components; you are choosing comprehensively a more economical and reliable solution for your entire powertrain system.

FAQs

1. What is the major difference between helical gears and spur gears?

The difference is essentially in the design of the tooth profile and the method of meshing. Normally, in spur gears, their teeth are parallel to the axis, which gives rise to instantaneous line contact. This leads to a poor and noisy transmission. As for helical gears, they engage through a helix angle to effect progressive meshing with high overlaps, which means smooth transmission, low noise, and high load-carrying capacity but including axial force.

2. What are the major disadvantages of helical gears? How are they overcome?

The biggest disadvantage is that the helical tooth structure generates axial thrust during transmission; this needs to be offset using either thrust or angular contact bearings. This increases the complication in the supporting structure and hence the overall cost. Our solution is to intervene at the early design phase, correctly calculate the axial force, and recommend or design a matching bearing system to ensure the reliability of the overall solution.

3. How does the helix angle influence gear performance?

A larger helix angle results in smoother transmission and lower noise, but also greater axial force. The optimal angle needs to be selected based on the specific application scenario (such as speed and load).

4. What sizes of helical gears can you machine? What materials do you support?

We provide large machining capacities, helical gears manufacturing in diameters ranging from 20mm to 800mm. We stock a wide range of materials, including various high-strength alloy steels, stainless steels, copper alloys, and high-performance engineering plastics for use under a wide range of operating conditions from heavy loads to corrosion resistance. We also provide material selection advice.

5. How long does it take from design to delivery of a helical gear?

It usually takes about 3 to 4 weeks for the processing of standard precision gears. But if it is high-precision gears, special heat treatment gears, and complex structure gears, the time will extend to 5 or 6 weeks. We also provide expedited processing services in case of rush projects and strive to keep as short a lead time as possible while keeping quality in focus.

6. How would you ensure the quality of machining for a helical gear?

Quality is ensured by a highly integrated quality control system: from the incoming inspection of the raw material and key process checks in manufacture to the finished product, using gear measuring centers and coordinate-measuring machines for full dimensional accuracy with tooth profile verification to ensure complete adherence to drawing specifications.

7. Do you provide small batches or a prototype?

Of course, our highly flexible CNC milling and gear hobbing processes are especially good at dealing with small batch, multi-variety, and prototype orders. This model can rapidly respond to your R&D and trial production needs, avoid mold costs, and efficiently provide low-cost initial verification.

8. How can I start a helical gear project? What information should I provide?

You need to provide detailed gear parameters, such as module, number of teeth, helix angle, pressure angle, etc., or you can also provide CAD and 2D drawings directly. We will reply within 24 hours after receiving such information, confirm the technical points with you, and give a preliminary solution and quotation.

Summary

Owing to their peculiar helical teeth, helical gears feature a number of merits in transmission smoothness, load-carrying capacity, and noise control; hence, being especially fit for applications with modern precision transmission systems. From the right choice of gear down to choosing a manufacturing partner who can realize your design intent precisely, it is only half the battle. Equipped with 5-axis CNC technology, rigid quality control, and one-stop "design-manufacturing-inspection" service, LS Manufacturing ensures your access to high-performance, high-reliability transmission solutions.

If you are experiencing transmission problems or looking for better product performance, then this is a good time to act. Feel free to consult with our LS Manufacturing transmission experts for technical consultation-for free-and a detailed project evaluation report. Contact us and let us infuse core competitiveness into your products with quiet, efficient, and reliable gears.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .