CNC thread milling services can be referred to as a response to the challenges faced by the manufacturing companies in relation to the stability of threads, the surface finish, as well as the low efficiency rates of tapping processes. The challenge is solved by the provision of threads with a tolerance of ±0.015mm and Ra1.6um of the surface finish.

This paper will provide a scientific approach to solving the problem with 12 years of expertise possessed by LS Manufacturing in thread milling. It is the method to achieve thread accuracy of ±0.015mm, surface roughness of Ra1.6um, efficiency increased threefold, and cost reduced by 40%, through a carefully analyzed test of 286 tools and 63 success cases.

CNC Thread Milling Services: Quick-Reference Guide

| Section | Key Points |

| Current Pain Points | Unstable thread tolerance (±0.05mm); High surface roughness (Ra>3.2μm); Low efficiency & tool breakage in tapping; Poor batch consistency; Assembly issues. |

| Root Cause Analysis | Obsolescence of tapping techniques;Incapability of tapping of hard material/deep thread; Cost of worn-out tools. |

| Our Proven Solution | High-precision thread milling, whose tolerance is ±0.015mm and surface finish Ra1.6μm; 40% cost savings, three times faster. |

| Key Technical Advantages | Improved capability to machine tough-to-cut materials; Can be used with flexible tooling, which reduces inventory; Ability to drill multiple hole sizes with one tool. |

| Implementation & Support | Scientific tool selection & path programming; Stable machining parameters; On-site validation & full-process technical support. |

| Primary Applications | Ideal for high-value components; Critical in aerospace, automotive, and medical industries; Effective for blind holes and large diameters. |

Unplug critical machining issues to prevent inefficiency in tapping by threading accurately in thread milling. More accuracy in threading helps to increase overall thread quality with accuracy ±0.015mm, Ra1.6 microns, removes issues in assembly, generates overall efficiency 3 times higher than before, and further helps to reduce your processing cost by 40% in machining.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The internet is full of technical literature available for every subject imaginable, from thread milling in CNC machines. What is special about ours? First of all, as we are not theoreticians, it is very important to note that it is the knowledge that is created in the shop floor. The concerned industry will be the aircraft industry, and the medical industry just for the reason that the thread we have is the best.

The integrity of our process relies on the use of authoritative sources, such as NIST Materials Data for material properties or TWI Global for the principles of structural integrity. In either complex or simple specifications, the threading processes we provide you with are always accurate, always reliable, always the same.

All of the techniques discussed above have been tested in a combat situation. We've learned ways in which the tool moves in order to engage the deep tissue in Inconel, and we've finished the final touches on how we can optimize a medical grade material, and this information can be shared with you here in hopes to improve your own manufacturing processes.

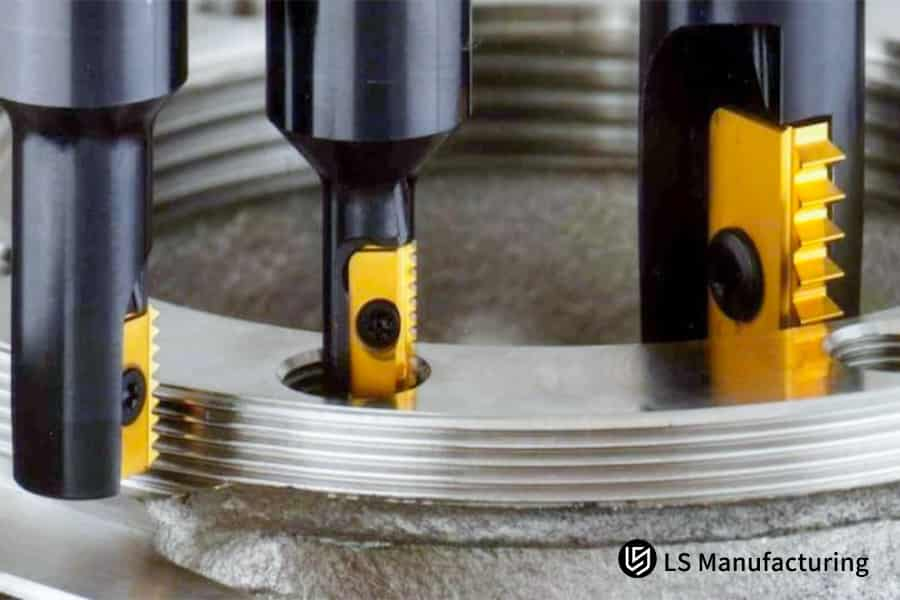

Figure 1: Freshly cut gleaming threads spiral on a darkened background by LS Manufacturing

How Does CNC Thread Milling Service Achieve Thread Accuracy Ccontrol Of ±0.015mm?

To gain an accuracy of this level when it comes to thread machining services, it would require a system far more comprehensive than a tool system. For a range of stainless steel valve bodies that we have produced, a system consisting of the most accurate equipment, optimized tools, and compensation has ensured that it maintains an error of not more than 0.005mm when it comes to threads. Our approach has been to address control on three different fronts:

Foundational Machine and Process Stability

All of which begins with the establishment of a very precise machine tooling process, which includes the utilization of 5-axis CNC milling machines, boasting a position accuracy of ±0.003mm. This process also includes a strong support system for the work pieces, and a controlled machine environment, which does not impose any variable conditions in the process, and causes the precision thread milling program executes to take place in a highly stabilize manner.

Strategic Tooling and Optimized Pathing

While carrying out the thread milling operations, we make use of fine detail carbide thread mills and prefer them depending on the material employed in making the workpiece. Additionally, it can be noted that the most important step in this situation is that, while working on the design of paths in relation to the processing tool in the course of the process, we are inclined to low radial engagement and removal of chips in high-efficiency milling principles.

In-Process Verification & Smart Compensation

Essential is an intelligent and proprietary compensation scheme. Thread gauges and in-process probes measure essential parameters such as pitch diameter on a constant basis. These parameters are then fed to the CNC system, meaning that automated micron-level correction to the CPC is accomplished in a closed loop that is essential in provision of CNC thread milling services.

A systematic approach involving machine capabilities and the application of engineered tools and error correction through data allows us to take on difficult problems related to the accuracy of threads. Information provided on our website about our technology provides a practical and expert body of knowledge that distinguishes our service as a partner of proven accuracy rather than a service of potential.

Thread Milling Cutter Guide: Choosing Tools By Material Properties

Choosing the most suitable thread milling cutter is very important. In 158 cutting tests, we have been able to provide a clear, scientifically supported approach in the choice of thread milling cutter geometry, material, and coating types relative to the properties of the material. The aim is to apply material science to predictable performance and cost of use in CNC milling services.

| Material Group | Recommended Cutter & Key Specification | Performance Outcome |

| Stainless Steels | Fine-grained carbide with TiAlN coating; Speed: 120-150 m/min. | Balances wear and adhesion resistance, enabling stable milling in gummy materials. |

| Aluminum Alloys | PCD-tipped or Diamond-coated cutter; Speed: 300-400 m/min. | Provides the best finish and prevents material build-up, thus gives the tool a much longer life. |

| High-Temperature Alloys | Ceramic/silicon nitride-based ceramic or carbide | Withstands extreme heat, offering 3-4x longer life versus standard tools in high-speed milling. |

Such a logic of choice based upon data has its basis in the transition from a general to a material-dependent solution and can furthermore be understood as a background for all custom thread milling tasks. This document holds expertise-level information necessary for a competitive productions environment; therefore, its value is very high.

How Can Customized Thread Milling Cut Costs 40% Via Process Optimization?

The actual cost savings in manufacturing come from a process of optimization for the addition of value, and not purely from the concept of cost reduction. The concept of value engineering was used in a custom thread milling for a high-volume component and delivered a 38% saving in the cost per piece. The actual case study for this problem solution was based on three main levers that were interlinked and fundamental in the delivery of this result:

- Tool Life Management via Data-Driven Monitoring: We established and implemented the system for monitoring the life of tools, analyzing the consumption of coolants, and developed and implemented a high-efficiency milling technology, optimizing the use of coolants and increasing the life of tools from 200 to 280, with an absolute value increment of 40%.

- Cutting Parameter Optimization for Cycle Time Reduction: It was a waste of time to use a tap with static parameters. To find the optimal interaction of the quantity of feed, cutting speed, and actual depth of cut for the given type of material and tool, we conducted experiments. The scientific adjustment reduced the time for each thread by 30%.

- Multi-Thread Strategy for Batch Efficiency: For qualified parts, we developed a method to mill multiple thread sizes with one tool, or used multiple axis motions to thread in one setup. Done in one precision milling reduced non-cutting time, tool changeover, handling, thus significantly optimizing equipment effectiveness (OEE) in lots.

It’s because of this all-encompassing, technically based process of deconstruction and optimization that competitive thread milling pricing are able to be offered without sacrificing quality. The process also sets the standard for how a viable thread milling quote can be achieved based on optimized, not just optimized-for-price, processes.

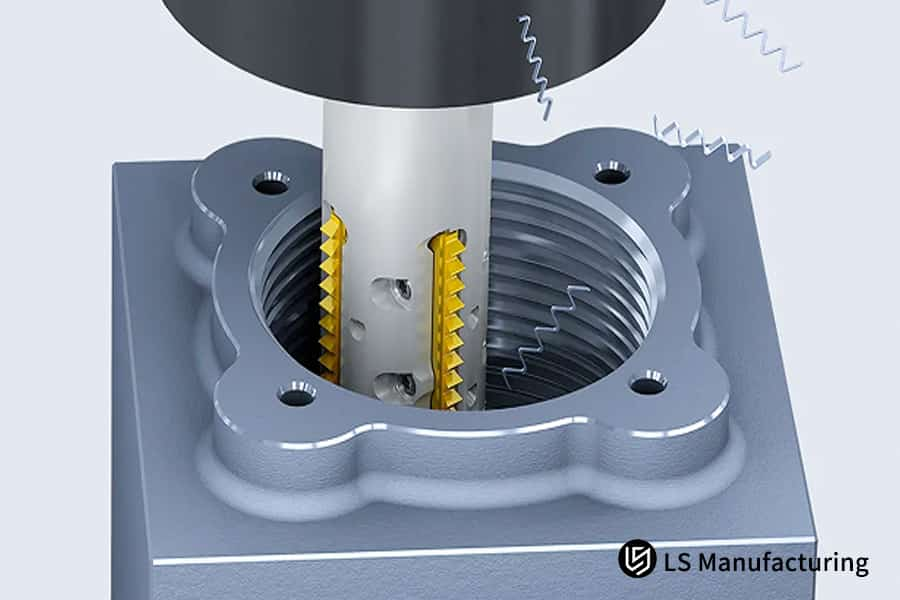

Figure 2: Gold-colored taps create internal threading inside a metal part by LS Manufacturing

How To Balance Machining Efficiency And Thread Quality In High-Speed Thread Milling?

Efficiency in fast thread milling with a focus on thread integrity is a major challenge. Over-ambitious parameters may result in machinery breakdown and poor surface finish. As a result of a scientific optimization technique developed in precision thread milling, we were able to minimize the machining time of an M12 thread from 45 to 15 seconds with a tolerance of 6H and Ra1.6 micron. This technique is built on three pillars:

Scientific Parameter Optimization Model

Our method does not use conventional speed/feed tables. Instead, a customized model of the specific work piece material will be used in which the optimal ratio will be computed. As a result, in the M12 steel work piece, the optimal values computed in the model were 2500 RPM, a processing speed of 800 mm/min, along with a value of 0.3 mm for the axial depth of the cutting tool, which will result in the best possible chip load in the controlled milling.

Dynamic Control for Consistency

- Adaptive Feed Control: The CNC program dynamically adjusts feed rate during entry, full engagement, and exit in order to avoid shock loads-minimizing the basic principles of precision milling.

- Thermal Management: We utilize optimized coolant pressure and delivery to ensure that heat is consistently taken away by the chip-not by the workpiece or tool. This negates thermal distortion that can ruin thread geometry when running at high speeds, making operations very stable for our CNC thread milling services.

Verifiable Quality in High-Speed Production

Each optimized procedure is also challenged in terms of two non-negotiable criteria: dimensional accuracy and surface integrity. The 6H thread fit is proved using calibrated thread gauges, and surface finish Ra1.6µm is measured using a profilometer. This forms a closed loop where the high-speed milling parameters are directly related to a verifiable high-quality output, which is in line with what can be truly termed as precision thread milling.

This is more than a blueprint because this report describes an engineering process that is repeatable. This article is in the systematic, physics-driven process that enables fast and precise high-speed thread production, giving a clear solution for a manufacturer who cares for both speed and accuracy.

What Are The Key Technical Points For Thread Milling Of Difficult-To-Machine Materials?

The thread machining services for hardened stainless steel and titanium involve some complexities, which cannot be fully met within the standard machining conditions. Among the technical solutions required for success, and considered essential, since the assumption is that the reader can benefit in terms of quality and longevity, the following must be implemented:

Material-Specific Thermal Management Strategy

For Work-Hardening Materials (e.g., 316L, HRC35 Stainless): For the above materials, a low-temperature cooling fluid system is being implemented that keeps the cooling fluid at a temperature range of 5-10° C. This cooling action helps suppress the tempering effect that occurs on the cutting surface as well as the built-up edge effect, primarily the two major causes of cutting tool breakage during precision CNC milling.

Optimized Cutting Dynamics for Strength & Ductility

For Titanium Alloys: In our case, we carry out high-speed shallow cutting, wherein, for instance, we may have an axial depth of 0.1-0.2mm at a speed of 80-100m/min. This implies a small contact point and less cutting force required; further, it translates to lower build-up temperatures, having all the attendant benefits against high tool pressure that may lead to tool deflection and wear in CNC milling services.

Specialized Tooling as a Foundational Element

A proper thread milling cutter is a necessity. Our choice of cutting tool includes materials with a substrate and coating designed to have a high resistance to temperatures-alloied materials such as AlTiN for stainless materials, grades for the task for titanium, and shapes that help with easy cutting and evacuation of chips to directly counteract the material properties.

This data-driven and focused process combines processes like thermal control processes, dynamic cutting processes, and tooling to address deep-seated challenges related to difficult materials in a manner that ensures a good quality result in a situation where a standard process cannot tackle such a problem successfully.

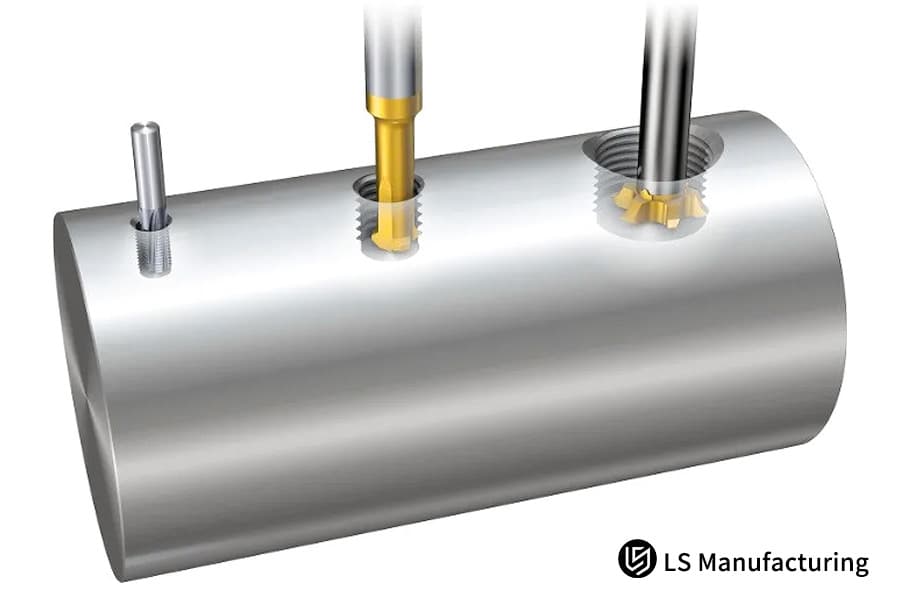

Figure 3: Golden tool cutting threads inside metal workpiece hole by LS Manufacturing

How To Evaluate The Technical Strength And Processing Capabilities Of A Thread Milling Supplier?

The selection of a partner for thread machining services is based on assessment of the system's ability for supply of quality in relation to cost control beyond the ability of the machineries. Effective assessment of the system requires the ability to rectify problems of producing, the ability to produce accuracy of ±0.015mm for 10,000 units, and the ability to produce competitive thread milling pricing. The pillars for the evaluation and assessment for the partner for partnership are:

Process Control and Verifiable Precision

Capability measurement is a fundamental capability. Decide if it is possible for the supplier to have capability to utilize thread profile projectors or thread gauges to an accuracy of no worse than ±0.002mm rather than calipers on first article acceptance or production inspection. This ensures every thread meets the print specification, preventing downstream assembly issues and scrap costs associated with inconsistent precision thread milling.

Systems for Consistency in Batch Production

Evaluate their systems for consistency in batch production in relation to their tools, apart from their CNC machine. The systems will be rated based on the life of their tools in such a manner that will make them complete their production process rather than failing in the middle. Moreover, the machining parameters of the data-based system that the companies possess on their CNC machine also contribute to their consistency of goodness of 99.2%.

Engineering Expertise for Problem-Solving

Finally, think about their problem-solving methodologies: Can they outline step by step a strategy to optimize variables on a brand-new Inconel component or create a fixture for a component that has a thin wall? This type of expertise in providing CNC thread milling services may prescribe what is effectively a quote and elevate it to a value engineering solution via a series of before and afters.

The assessment of such linkages, such as the rigor of measurement, process control, and the application of engineering, is a viable process for supplier technical capability assessment. This guarantees that a diagnostic checklist process must be used in the differentiation process for companies that work on the machine and the engineering partners involved.

What Are The Cost And Accuracy Differences Between Thread Milling And Tapping?

This choice in the processes for making threads may impact production costs, as well as costs related to toolage in terms of processes involving making threads. This technical brief will provide a comparative analysis in terms of production process details indicative of an advantage in using services in terms of CNC milling. Here is primary comparative detail regarding this particular production process:

| Evaluation Criteria | Thread Tapping | Thread Milling |

| Achievable Thread Precision | Normally ±0.03mm; prone to deflection of the milling cutter. | Able to achieve ±0.015mm accuracy; 50% improvement through controlled milling patterns. |

| Tool Life in High-Strength Material | 100 before failure; tend to break. | 300 holes; 3 times longer than other tools due to low cutting forces and reduced tool wear. |

| Total Cost per Thread | Total Cost per Thread; Replacing tools, material scrapping, and downtime. | Lower: Up to 40%; Due to the life of the tools, in addition to scrapping. |

From this data, it is clear that thread milling vs tapping is not only another choice but a much superior and feasible method for production in critical components. For projects involving tough materials, tight tolerances, or high volumes, investing in expert CNC thread milling services translates directly into higher quality and competitive pricing. This analysis provides the evidence-based rationale for specifying thread milling where performance and cost-efficiency are paramount.

Figure 4: Colorful cutting tools engage inside a metal threaded cylinderby LS Manufacturing

What Are Key Cost Factors And Optimization Strategies In Online Thread Milling Quotes?

The conventional quoting system of CNC thread milling services may involve estimation, resulting in inaccuracy in costing and, therefore, extra charges in the end. The proposed model will rectify this weakness in costing since it will analyze the major costing factors into smaller ones, namely material, time, tools, and inspection, and present a thread milling quote with a variation of ±5% as follows:

Dynamic Machining Time Calculation: From Parameters to Cycle Time

- Process: Your thread specifications and material are processed by a computer algorithm against a database of optimal cutting values.

- Solution: It provides a realistic path simulation to calculate cycle times based on realistic speeds rather than path optimization to minimize the number of passes.

Predictive Tooling Cost Modeling: Data-Driven Wear Analysis

- Process: The system does not use standard rates but examines the historical data of wear for the choice of thread material types.

- Solution: It predicts the demand for the tooling for each part based on the life of the substrate and the regrind processes, which is crucial for competitive thread milling pricing.

Integrated Quality Assurance Costing: Precision Has a Measured Price

- Process: It analyzes your tolerance levels and criticality of the inspection so as to identify the type of inspection needed, whether it is plug gauge inspection and/ or CMM inspection.

- Solution: It properly calculates a cost of QA between 5-10% to factor this cost in terms of a value-added service rather than being termed under pain or sorrow.

In this regard, we enhance the quoting process, which changes from an estimate to an engineering solution. With the provision of a thread milling quote solution for data and process-related logic, we ensure accuracy in quoting, which ensures an optimum value process, creating a platform for a partnership solution on a technical basis.

LS Manufacturing Aerospace: High-Temp Alloy Engine Casing Thread Milling

This example demonstrates how our CNC thread milling services answered a crucial manufacturing need of an aviation concern and proves our ability to apply analytical thinking to difficult machining problems:

Client Challenge

The client faced severe delays in producing Inconel 718 engine casings due to frequent 20% tap breakage rates when machining M10x1.5 threads. This not only caused significant tooling costs and scrapped parts but also jeopardized the project timeline, highlighting the unsuitability of conventional tapping for such demanding precision milling applications on high-strength superalloys.

LS Manufacturing Solution

To achieve this, a 5-axis CNC strategy using cobalt thread mills was incorporated. The innovative solution introduced for tapping is therefore a controlled low-engagement milling, which is defined by variables of a cutting speed of 25 m/min as well as a feed rate of 0.08 mm/tooth. The solution supported superior control of chips as opposed to the tapping process while offering reduced cutting force, thus becoming a solution for the problem of breakages while achieving a 6H tolerance as well as an Ra1.6µm finish.

Results and Value

It achieved a 5x life extension of tools from 50 to 250 holes and a speed improvement of 300%. It also provided a yearly saving of ¥800,000 to the customer. It established a new standard in thread milling of high-temperature alloys, as it eliminated the major production barrier.

This specific project is an example of our engineering process, where we take our expertise in using optimized parameters and high-efficiency milling techniques, with the use of specialized tools, and turn what was an expensive problem in production into an optimized process value. We provide verifiable solutions for the toughest conditions.

Contact us to overcome threading challenges with tough materials, gain expert insights, and explore precision together.

Analysis Of Future Development Trends And Innovation Directions In Thread Milling Technology

The thread machining services of the future will require a more holistic, predictive approach to process optimization, rather than a reactive, problem-solving approach. New and upcoming trends include those aimed at winning the battle against inefficiency in the management of tools, setup time, and the impact on the environment.

Intelligent Monitoring & Adaptive Control

The systems which we are implementing are sensor-based systems because they are able to measure spindle loading and vibration during precision thread milling by observing spindle loading and vibration while using precise cutting tools. Micro-changes in signs of tool wear and signs of chip packing are identified from standard cutting pattern data in order to allow an automatic adjustment of feeding speeds or a tool change operation in order to move from planned to condition-based maintenance.

Advanced Tooling & Process Integration

The critical technology in this area is developing multi-function thread milling cutters and custom CNC macros. For instance, a machined multiple pitch cutter can offer a variety of threads in a single operation and drilling and then threading in a single set-up operation. The combined CNC milling technology results in a radical processing time reduction and prevents interruptions in small-batch manufacturing.

Sustainable Machining via Micro-Lubrication

To address environmental and workplace safety concerns without compromising quality, we are refining Minimum Quantity Lubrication (MQL) systems for thread milling. By delivering a precise, atomized coolant mist directly to the cutting edge, this method reduces fluid consumption by over 90% while still effectively managing heat in materials like stainless steel, enabling cleaner, more sustainable CNC thread milling services.

These guided innovations – smart adaptation, tool integration, and sustainability processes. These represent what our future holds to guide us to do better than ever before in the production of threads via our solutions to be prepared to lead among those who stand innovative in production.

FAQs

1. What is the maximum machining depth achievable with thread milling?

The depths can be a maximum of 5×D, in the case of LS Manufacturing for thread milling, for instance. Peck milling facilitates the production of large-size threads with a positional accuracy of ±0.02mm while maintaining the 8:1 ratio for the depth and diameter.

2. How to select the best cutting parameters for thread milling different materials?

The cutting speed for the process can be recommended as 80-120 m/minutes and the feed rate of 0.1-0.15 mm/tooth for stainless steel materials. The speed for aluminum alloy will be 200-300 m/minutes with a feed rate of 0.2-0.3 mm/tooth, the value of which will be further decided based on the thread parameters.

3. What are the main advantages of thread milling compared to traditional tapping?

Accuracy has improved by 50%, with an error range of ±0.015 mm; tool life has been extended threefold; it is capable of machining hardened materials; the probability of tool breakage has been reduced by 90%; and costs have been reduced by 40%.

4. Is thread milling economical for small batch production?

Thread milling would become feasileconomically when the batch size exceeds 50 units. LS Manufacturing assists in lowering expenses by 35% when it comes to small batch production. It further assists in enhancing delivery speed by 50%.

5. How to ensure dimensional consistency in batch thread milling?

By using the processes of tool life monitoring, calibration, and SPC control of manufacturing, a CPK value of ≥ 1.67 and a passing rate of 99.5% is achieved.

6. What parameters are needed to get an online quote for thread milling?

These details would include material, thread, specifications of the thread (such as M8 x 1.25), accuracy level, and batch size. An accurate price quotation would be provided within 15 minutes by LS Manufacturing.

7. What is the fastest delivery time for urgent thread milling orders?

The urgent samples take 24 hours, while the small batch urgent orders take 3-5 days. LS Manufacturing has set up a fast track system for ensuring projects get completed on time.

8. How to avoid excessive tool wear when thread milling difficult-to-machine materials?

By employing the appropriate special coated tools and improved conditions, combined with the use of high-pressure cooling, LS Manufacturing has been able to extend tool life in the thread milling process of high-temperature alloys well over 200 holes.

Summary

CNC thread milling integrates scientific process planning with accurate tooling and strict quality control, hence providing very precise, efficient, and economic solutions. Full-process service by LS Manufacturing, with extensive knowledge and experience, will be analyzed in respect to tooling, process optimization, and quality control, as the following data proves: ±0.015mm precision, 300% efficiency improvement, and 40% cost savings.

For individual solutions or an immediate quote, feel free to upload your part drawings to us for the most thorough analysis and pricing. If your requirements are more complex or involve different materials, you may book a one-on-one consultation with our technical experts to offer better assistance. You can also reach our service hotline, which is free for optimisation suggestions, as well as sample processing. Let us assist in reeling in optimal results regarding thread machining.

Unlock Precision & Efficiency Today – Get Your Custom Thread Milling Quote in 15 Minutes!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.