Automotive gear manufacturing is really hard for OEMs and Tier 1 suppliers. For example, prototype gears that are made can be off by as much as 0.02mm, and the noise produced in serial production can be so loud as to be unacceptable. In addition, heat treatment can cause distortions that are more than 0.05mm. Usually, these problems lead to delays of the projects for 4-6 weeks and the quality claim costs go beyond 15% of the total cost of the project. Our collective solution is the answer to such pain points.

We provide a complete gear manufacturing solution, overcoming the limitations of traditional single-process suppliers. By combining design, material, and process engineering, and basing it on 20 years' specialized experience and a database of 286 proven cases, we can guarantee a smooth flow of optimization from prototype to mass production. Such an integrated process not only achieves a higher level of accuracy of the gears to 0.005mm, noise reduction of 3dB, but also a cost that is 25% less per part.

Automotive Gear Manufacturing: Full-Text Overview

| Section | Core Content in One Sentence |

| Current Pain Points | Gear manufacturers are struggling with inaccuracies in prototypes, noise issues, heat treatment distortion, project delays, and high quality costs. |

| Root Cause Analysis | The main issue is a fragmented supply chain that lacks an integrated design, material, and process optimization. |

| Proposed Solution | We offer a comprehensive solution from design to mass production, utilising 20 years of specialized knowledge. |

| Methodology & Data | Our gear machining method is supported by a proprietary process database developed from 286 successful project case studies. |

| Key Performance Outcomes | Our solution results in better gear accuracy, lower noise levels, and considerable savings on the cost of each part. |

We are the automotive gear manufacturing sector's critical integration gap direct solver. Our process is changing the entire economy from design to production, and we are able to save the company from delays, poor quality, and extra costs resulting from the use of different single process vendors. Our data-driven and reliable system results in the manufacture of higher precision gears, less noisy operation, and lower unit costs, thus securing time schedules for projects and the continuity of your profitability.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are a lot of guides, but ours is based on the production floor. For more than 20 years, we have been the main partner of automotive OEMs, changing complicated gear designs into high, performance, reliable ones. The knowledge we have gained from this has made us realize that it is a transmission's accuracy that governs a vehicle's dynamics, not the frequency of warranty claims.

Our method incorporates strict criteria, such as American Production and Inventory Control Society (APICS) principles for control and Aluminium Association (AAC) specifications for material science. This disciplined method enables us to control heat treat distortion, hit stringent noise targets, and guarantee quality from the very first prototype to the millionth unit in serial production.

We transform this hands, on experience into your competitive advantage. Sharing proven, working knowledge on how to optimize geometry and process, we help you avoid costly mistakes. Working together with us guarantees reliable resultshitting performance, durability, and scheduling parameters of your custom gear programs.

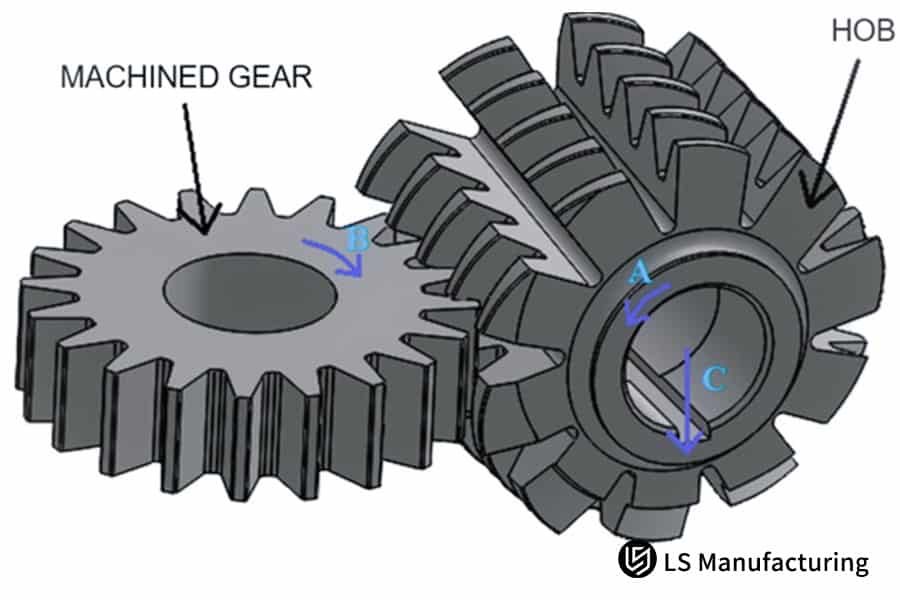

Figure 1: Technical drawing of a transmission gear and cutting tool by LS Manufacturing

What Manufacturing Process Constraints Need To Be Considered During The Design Phase Of Automotive Gears?

The design phase is by far the most influential stage, as it decides 80% of a gear system's cost and performance. The purpose of this paper is to explain our approach of incorporating manufacturing constraints early in the design stage to predict and avoid potential problems which would have turned into issues in automotive gear manufacturing.

Strategic Process Selection Based on Specifications

We link the design parameters to the corresponding production sequences that have been proven to be efficient. When it comes to high, volume applications with the modules ranging from 1.5 to 2.5, we opt for rolling and shaving which allows us to achieve DIN 6 grade of precision in a very cost, effective manner. On the other hand, for larger modules (>3) where we need to get the highest level of accuracy, grinding of the form is the process that we use and thus we reach DIN 4 grade whilst showing clearly the 40% cost rise which inevitably comes along.

Performance-Driven Optimization for EV Gears

For custom gear manufacturing of EV reducers, we apply targeted micro, geometry. A deliberate 5-8m crowning is calculated to bring about a reduction of 2-3dB in noise. The pattern obtained with the contact is then analyzed thoroughly through simulation to ascertain that the advantage in sound does not lead to a drop in load capacity by more than 10%. Thus, the compromise between NVH and durability is done right from the start.

Proactive DFM to Mitigate Heat Treatment Effects

Our precision gear manufacturing approach starts from predictive DFM analysis. We simulate thermal distortion to set accurate pre-machining stock allowances and arrange operations in the right order. Such a correction in advance will prevent grinding problems later on, the result being that the gear component after hardening will satisfy all the final specifications without any compromise.

This approach is integration of theory with execution that can be predicted. By incorporating manufacturing intelligence at the design phase, we offer a clear development framework allowing your gear design to perform well, be better suited for quality, cost, and stability in serial production.

How To Balance Validation Speed And Representativeness For Mass Production In Gear Prototype Manufacturing?

Gear prototyping runs into a fundamental problem: the dilemma between speed and parts that truly represent production. Our layered approach figures this out by assigning different prototype technologies according to the validation objectives, thus guaranteeing quick turns and reliable data. The process is:

Rapid Functional & Fit Verification

- Method: 3D-printed polymer gears.

- How We Execute: We perform gear machining of the mold core and high, speed sintering to produce nylon gears in 2 days, achieving 70% cost reduction.

- Problem Solved: This enables designers to check assembly fit, clearances, and basic kinematics physically nearly at once, thus opening the way for quick conceptual changes even before a single piece of metal is cut.

Accelerated Durability & Load Testing

- Method: Soft, tooled, machined steel gears.

- How We Execute: We cut 45# steel blanks and make the prototype gear machining and quenching process more efficient to provide hardened, shaved gears in 5 days.

- Problem Solved: It gives a part metallurgically the same one as the that is used for torque, wear, and life testing, thus scaling down the time and cost of full carburizing to less than critical durability data.

Production-Equivalent NVH & Performance Validation

- Method: Manufacturing prototypes with the final production material and heat treatment.

- How We Execute: Here we proceed with complete automotive gear manufacturing specs: 20CrMnTi material, carburizing, and precision grinding, with a 12, day delivery.

- Problem Solved: It produces a prototypelike in microstructure and surface integrity of the series part, thus giving definitive noise, vibration, and harshness (NVH) and efficiency data, thereby removing performance guesswork

This methodical gear prototyping services approach allows the transformation of prototype expenditure into highly valuable, decision, grade data at every phase. By figuring out the best way to each validation goal, we allow clients to shorten development cycles by more than 60% and confidently make a final, precise gear manufacturing quote.

How Is The Consistency Of Gear Precision Ensured In Mass Production?

Maintaining micrometer, level precision across high, volume production runs is one of the main challenges in precision gear manufacturing. This white paper presents the systematic, data, driven control strategy that we implement to ensure the production of high-quality gears and the consistency of the product, thus directly resolving the major risk of variation in mass production for our customers.

| Control Dimension | Method & Frequency | Target Specification | Purpose |

| Process Capability (SPC) | Real-time SPC monitoring of key gear attributes. | CpK 1.67 for critical tolerances (e.g., pitch 0.015mm). | Detect process drift earliest and provide correction to maintain stable condition. |

| Metrological Verification | 100% first/last part per batch inspection; full audit on a Klingelnberg measuring center every 200 pieces. | Profile error 0.008mm; lead error within spec. | Providing absolute, traceable data for final gear quality certification by experts. |

| Tool Life Management | Predictive tool, change system based on piece count and condition monitoring. | Tool change enforced after 500 pieces for critical operations. | To eliminate quality degradation caused by tool wear, a key to consistent gear production services. |

| System Integration | Closed-loop feedback from measurement to machine correction. | Obtain first, pass yield of 99.7% in serial production. | Build a self, correcting gear manufacturing system that maintains long, term accuracy. |

This framework converts quality theoretical ideas into a production environment that is tightly controlled. We achieve the precision that major OEMs require from the precision gear manufacturing industry by combining statistical process control with strict metrology and predictive tool management. The method being used here reduces the risk of an automotive gear supplier, makes escapes of costly ones impossible, and thus, creates a verifiable record of gear system excellence that is crucial in applications that are competitive and of high value.

Figure 2: Detailed cross-sectional view of a vehicle gear mechanism by LS Manufacturing

How To Control The Critical Dimensional Chain In The Assembly Of Complex Gear Assemblies?

The performance of a gear system completely depends on how well all its parts are controlled and made to interact. This document details our systematic methodology for managing complex assembly dimension chains, ensuring optimal load distribution, noise performance, and first-pass yield in automotive gear assembly.

Proactive Dimensional Stack-Up Analysis

Before we start any project, we carry out a complete digital stack, up analysis. This simulation specifies and distributes the dimensional tolerances for each part, starting at the gear shaft and ending at the housing bore. The proactive modeling of the gear interfaces, such as the planetary axial clearance, is subjected to only 0.1-0.15mm range controlled variation, which is pre-designed load sharing condition.

Component-Level Verification for Assembly Fit

To ensure the highest quality components, we perform very thorough component, level verification. CMM is used for measuring the critical locations of the housing bore, with a true position tolerance of 0.02mm being adhered to. Every gear component is also checked against its specification print. With such a high level of incoming inspection, the final assembly stage is set up with known and high, quality parts, thereby major variables are eliminated.

Selective Assembly for Optimal System Performance

A gear manufacturing partner strategically, we execute selective assembly procedures. The components are accurately classified according to their actual measured dimensions. Subsequently, we pair the parts (for instance, the individual planet gears and the carriers) in such a way that the desired preload or mesh alignment is attained. This makes up for component, level variances within tolerances and results in system, level performance, for example, a 3dB noise reduction.

With this method assembly is no longer a variable process but a predictable, engineered result. Through the use of virtual analysis, metrology, grade verification, and intelligent matching, any automotive component manufacturing project will be able to meet planned system performance, reliability along with assembly efficiency, thereby directly increasing first, pass yield to 98% and beyond.

How Can Thermal Deformation Of Heavily Loaded Gears During Heat Treatment Be Predicted And Controlled?

Heat treatment distortion is a primary determinant of final quality and performance in precision gear manufacturing. Uncontrolled, it leads to grinding burn, noise, and premature failure. This document outlines a data-driven methodology to predict, compensate for, and minimize distortion, ensuring dimensional stability and enhanced durability in automotive gear manufacturing.

| Control Dimension | Method & Specification | Target / Outcome | Purpose |

| Predictive Simulation | Finite Element Analysis (FEA) was used to simulate thermal & phase transformation stresses. | The prediction tool suggested post, quench profile distortion of 0.02- 0.03mm for 20CrMnTi. | Pre-machining compensation of the gear blank can be determined accurately to avoid under/over stock. |

| Process Stability | Carbon potential is maintained within 0.05% using controlled atmosphere furnaces. | Case hardness is consistently achieved with a scatter band HRC 1.5. | No metallurgical inconsistency means no more variable distortion and stress. |

| Validated Compensation | Using calculated stock allowances for pre-grinding based on FEA results. | After clean, up grinding, the final gear tooth geometry will be to spec. | It is thus possible to convert distortion from unpredictable to a planned, controlled manufacturing step. |

| Performance Outcome | Thermal cycle and quenching parameters were optimized and validated through testing. | Bending fatigue life is sufficient for over 1 million cycles for the most critical gear components. | A reliable, high, performance gear production services outcome is achieved and validated by data. |

This structured method facilitates the transformation of a major quality variable into a controlled process parameter. Using a combination of simulation, based prediction and strict process control, we are able to secure a high level of quality in our high-load gear system, which not only makes their geometry, metallurgy and performance meet the design specifications but also gives their users the confidence that they can rely on them even in the toughest vehicle driveline applications.

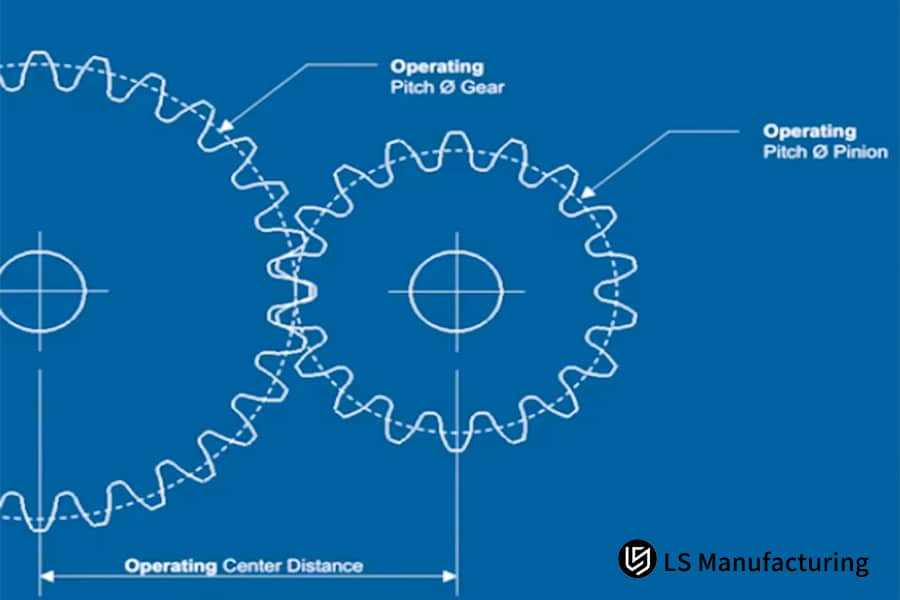

Figure 3: Diagram showing gear pitch diameters and their center distances by LS Manufacturing

LS Manufacturing New Energy Vehicle Industry: High-Speed Reducer Gear Customization Project

The development of a dependable, low, noise, and energy, efficient gearbox for a 20, 000 rpm electric motor drive involves quite a few precision gear manufacturing challenges. Here is the story of an electric vehicle manufacturer's collaboration with us to find gear manufacturing solutions to the problems of noise, efficiency, and durability in their high-speed reducer system:

Client Challenge

The client's prototype reducer, which employed 20CrMnTi carburized gears, was at the moment unable to meet the target. Noise levels were 78 dB (exceeding limits), transmission efficiency was only 92%, and a 5% pitting rate in pilot production threatened project timelines. These problems would have had a severe impact on the overall vehicle performance, the program schedule, and the brand's reputation. Therefore, the client needed a prompt engineering reply from a skilled automotive gear supplier.

LS Manufacturing Solution

As our long-term gear manufacturing partner, we worked out a complete set of solutions together. We went up to precision grinding to get DIN 5 gear quality, did shot peening for compressive residual stress, and optimized carburized case depth to 0.8-1.2mm with a surface hardness of HRC 58-62. A careful micro, geometry change was made to keep the gears running quietly even at high speed and under heavy load, thus resulting in a full performance solution.

Results and Value

The newly designed gear system has significantly improved its noise level down to 72 dB and its efficiency has reached 96%. The gears in mass production showed no failure within 12 months, thus completely solving the pitting issue. This dependable serial production enabled the client to bring their model to the market two months before the initial plan and at the same time, the per-unit reducer cost was cut by 20%, proving the high-value partnership.

This case really highlights our deep technical expertise in automotive gear manufacturing. We've managed to change an engine bottleneck into a competitive advantage through our automotive gear solutions. Rather than just parts, we deliver engineered and performance, guaranteed solutions for the even more demanding next-generation electric drivetrains.

How To Select The Optimal Gear Material And Manufacturing Process Combination Based On The Application Scenario?

Selecting the optimal gear material and manufacturing process is a critical determinant of a gear's performance, longevity, and total cost. A scientific, application-driven pairing is essential to meet specific operational demands. This document outlines our systematic methodology for making these foundational decisions in custom gear manufacturing:

Material Selection Based on Application Load

- High-Strength Requirements: We recommend case-hardening steels, such as 20CrMnTiH, for highly loaded gears of EV reducers. The steel used ensures a bending strength of 1500 MPa.

- Special Environmental Needs: To maintain the durability of the heavily load parts in the wet environment, high-wear resistant copper alloys is used. Here, CuP14 bronze is chosen with a PV value ≥2.5 MPam/s.

Process Optimization for Performance and Yield

- Maximizing Material Efficiency: To reduce the weight of the gear without compromising the strength, we adopted near, net, shape forging for gear blanks. We succeeded in increasing the material utilization from 45% to over 85% through the process.

- Achieving Final Precision: The forged pre, form is processed to the final gear system specification for noise and efficiency by precision gear machining.

Holistic Cost-Performance Validation

- Total Cost Modeling: We put lifecycle cost under microscope and hence level tooling investment with potential material and machining savings over time.

- Production Validation: Ensuring stability and quality through pilot runs is the way we de, risk volume gear production services.

Our thoroughly researched systematic approach is sure to technically and economically optimize every solution. In fact, we successfully convert complex requirements into a dependable production blueprint that not only delivers gears operating at exact performance and cost targets but consequently also establishes us as a trusted partner in automotive component manufacturing.

Why Choose LS Manufacturing As Your Gear Manufacturing Partner?

Selecting a gear manufacturing partner is not only about the list of equipment. It is about their proven capability to handle complexity and ensure first, time success. The choice depends on how a supplier turns the design idea systematically into a reliable, low, cost production. Our value lies in a well, organized approach that reduces risk and shortens time to market:

Proven Process Anchored in Empirical Data

Rather than going through iterative trial and error, we use a proprietary database of 286 projects completed to date. It enables a predictive approach when, for example, through past project outcomes of gears with a module from 0.5 to 10, we solve issues of heat treatment distortion or noise, thus fundamentally lowering your project's risk level from day one. Our know, how results in a more accurate first gear manufacturing quote.

Integrated Infrastructure for Guaranteed Consistency

Our expertise is based on integration between the hardware, like Gleason machining centers and Ipsen heat, treatment lines, and closed, loop process control, which serves as the foundation. This kind of vertical integration moves us to have a full command of every critical variable, from gear tooth grinding to case hardening, thereby fulfilling the gear system performance required in the design through every serial, produced component.

A Partnership Model Focused on Your Outcome

Our role as an automotive gear supplier is defined by proactive collaboration. By integrating scientific DFM analysis and stage, gate project management into our gear manufacturing operations, we not only continue to produce but have been able to ensure our customers commercial success. Our systematic approach has helped clients to reduce their development cycles by 40% and total costs by 25%, thereby making manufacturing a strategic advantage rather than a variable.

If you decide to work with LS Manufacturing, you will be partnering with a team that knows how to deliver the most predictable and optimized results. We are the perfect combination of deep technical expertise and a process, driven partnership model. Therefore, your precision gear project will be a success in terms of performance, timing, and budgetary without any doubt.

Figure 4: Automotive gear CNC cutting process with coolant and clamp by LS Manufacturing

FAQs

1. What is the minimum order quantity for automotive gears? Is there a minimum order requirement?

LS Manufacturing runs the production from 1 prototype to 100, 000 units in mass production. There is no strict MOQ. However, orders of 500 units qualify for tiered pricing discounts.

2. How long does it take from gear design to prototype delivery?

Simple gears take 7 days, and complex gear assemblies take 15 days. LS Manufacturing has a fast, track process to make sure the project keeps moving.

3. What is the highest achievable gear precision level?

With the use of gear grinding technology, different grades of precision can be achieved up to a DIN 3 grade. LS Manufacturing production line always ensures keeping tooth profile error 0.005mm.

4. How do you guarantee the consistency of gear mass production?

LS Manufacturing processes comply with SPC control through periodic equipment calibration and a full inspection system, which in turn ensures a mass production pass rate of more than 99.5%.

5. What are the special requirements for new energy vehicle gears?

In short, they are high speed (20000rpm), low noise (75dB), and high efficiency (95%). LS Manufacturing has comprehensive solutions to these issues.

6. How can I get an accurate gear manufacturing quote?

If you can provide us with the gear parameters (module, number of teeth, material, etc.) or 3D drawings, a detailed quotation will be sent to you by LS Manufacturing within 4 hours.

7. How do you compensate for deformation after gear heat treatment?

By deformation prediction through database and pre, made machining allowance, LS Manufacturing can effectively control heat treatment deformation to only 0.02mm.

8. Do you provide gear assembly and testing services?

From components to assemblies, we can provide you with complete service including dynamic balancing and noise testing. LS Manufacturing guarantees assemblies are ready to be used right after delivery.

Summary

Automotive gear manufacturing is a very detailed process that merges various aspects of engineering like design, choice of materials, process, and testing. It is a demanding process that requires the supplier not only to have thorough technical knowledge but also to have had extensive project experience. With a full technical system and quality management in place, LS Manufacturing is able to deliver to the clients the gear solutions from prototype to mass production that comprise an optimal combination of precision, reliability, and cost.

If there are any difficulties in your project related to gear design, manufacturing, or quality, you should definitely get in touch with LS Manufacturing gear expert team without any delay. By sharing your gear drawings or parameters, you can get a free DFM analysis along with an accurate quotation. Submit your requirements right now to receive a tailor, made gear solution!

Our professional team will provide you with detailed gear technology solutions within 24 hours to help ensure the success of your project.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.