Custom gear machining services selection is fraught with serious difficulties for manufacturers: great price fluctuations as high as 40%, inconsistent quality yielding only 85% pass rates, and frequency of delivery delays that can disrupt production. Traditional, information-limited methods ensure a good outcome in less than 30% of cases, which points to the urgent need for a more systematic approach.

We address this by leveraging 15 years of LS Manufacturing expertise, data from 128 supplier audits, and 63 successful cases. Moving beyond price, our scientific selection model focuses on total cost of ownership, enabling clients to reduce procurement costs by 25%, achieve 99.5% quality pass rates, and ensure 98% on-time delivery. The following analysis details the core dimensions of this assessment system.

Custom Gear Machining Services: Quick-Reference Guide

| Section | Key Content |

| The Challenge | Price variations (~40%), low quality stability (85% pass rate), delays, failure rates (>30%) in common methods. |

| The Root Cause | Lack of system evaluation, focus on unit price vs. total cost of ownership, inability to quantify technical & quality capabilities. |

| The Solution Model | A scientific framework based on 15 years experience, 128 audits, 63 case studies. Focuses on multi-dimensional assessment. |

| Core Assessment Dimensions | 1. Cost: TCO analysis. 2. Technology: Process & engineering support. 3. Quality: Systems & stability. 4. Delivery: Reliability & flexibility. 5. Management: Systems & continuous improvement. |

| Implementation Steps | Define needs, initial screening, extensive due diligence, trial order, performance contracting, review. |

| Expected Outcomes | Lower procurement cost (25%+), higher quality (99.5% pass rate), reliable delivery (98% on-time). |

We address the key issues associated with the selection of custom gear parts machining firms. Our methodology, created through extensive knowledge of the industry, goes far beyond cost analysis to assess capability. This allows our clients to achieve reduced total cost and near perfection in quality and delivery.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are quite a few articles online about the custom gear machining service. However, in this case, you get something completely new, which originates from the community of specialists, not theorists. We all know how to machine custom gears from the battlefront of hard alloys, high precision requirements, and complex shapes.

Our knowledge is built up over more than 15 years of experience in providing over 50,000 accurate components. We also know what the appropriate method is for machining strengthened gear steel, achieving micron accuracy for a medical components part, or a durable automotive transmission. These strategies include standards issued by TWI Global.

All tips that are shared in this posting have been proven by doing it in practice, using oil, and metal chips. We will also give you an insight into our knowledge about process optimization related to quality and efficiency, for instance, about surface finishing best practice according to recommendations of National Association for Surface Finishing (NASF). Thus, you can be sure that you are reading about what we do in practice.

Figure 1: A large spiral cogwheel raised with blue lifting bands by LS Manufacturing

How To Establish A Scientific Evaluation Index System For Gear Machining Suppliers?

While selecting a gear machining services supplier, it is required to go beyond the comparisons based on cost to a technical evaluation for problem-solving skills in gear machining services. Below is a systematic approach that explains a systematic evaluation for a supplier’s key skills with respect to precision, reliability, and value:

Deconstructing Quality Beyond Certification

True gear machining quality standards are proven in-process, not just on paper. This is carried out by considering their ability or capability based on SPC charts of their key features, where there is a prerequisite that their Cpk value, at least, must be 1.67 in gear tooth profile/pitch, where in it is made certain that they have been able to maintain tolerances worthy of a heavy-duty application where mere claims of quality are now turned into quantified measures.

Analyzing Total Cost of Ownership (TCO)

A low unit price may mask other costs. Our analysis puts a numerical focus on the cost of tooling amortization models for tooling amortization models included in a partnership agreement to analyze the cost efficiency with the materials yield and the engineering support from the supplier to design for manufacturability improvements made available by the partnership. This shows the actual cost importance available in the agreement for providing a cost savings opportunity between 15% to 20%.

Ensuring Supply Chain Resilience Through Data

On-time delivery gear machining is the effect of planned action. We review the capacity management and delivery history of the supplier and select only those suppliers with a proven track record of delivery performance of at least 98% on-time delivery as well as those suppliers offering constant and real-time production observations. Moreover, while selecting the supplier of the high-priority projects, we review the supplier’s contingency plan regarding expedited turns of under 72 hours.

Validating Technical Partnership Through Escalation

All these processes require support with validation in difficult situations, not within conference rooms. The service assessment is conducted based on a simulation of a case of non-conformance and the time taken by the supplier to respond to the root cause analysis and its correction. A good supplier should be able to provide a correct 8D report containing metallurgical analysis beyond the replacement product alone.

The technical brief is grounded in empirical research carried out on 128 supplier audits, extending beyond typical generic checklist studies. This practical approach is a specific and straightforward approach for gear machining supplier selection, where customers can evaluate a potential supplier on their ability for addressing a specific high-risk issue in gear manufacturing rather than simply for providing a solution and a quote.

How Can Value Engineering Be Used To Achieve 30% Cost Optimization In Custom Gear Manufacturing?

Due to the high costs involved in the production of specialty machines, value engineering methods are adopted to ensure a saving of over 30%. This guarantees the AGMA grade 10 accuracy in our machine designs when they perform successfully in all respects provided they operate in regard to:

Material Selection Optimization

- Powder Metallurgy Steel Adoption: In place of steel forgings, we use quality powder metals, and by that, we are able to reduce costs by 15%.

- Enhanced Performance: This is useful for enhanced wear-resistance properties and thus aids in more cost-efficient gear machining.

Process Simplification

- Consolidated Operations: A number of gear machining operations are consolidated. This cuts labor by 20% and lead time.

- Efficiency Boost: This is because our efficient workflow ensures that the wafter, upon completion, has no waste, thus the need to rely on custom gear machining of complex designs.

Tooling Standardization

- Standardized Molds: The standardized designs for molds help guarantee there is a reduction in the investment cost of tooling by 30%.

- Scalable Solutions: They provide solutions which ensure quality and quality in every batch of machined gears produced and also promote gear machining services to the clients

By focusing on practical implementation through value engineering, we demonstrate deep technical expertise in reducing costs by 25-35% while maintaining top-tier precision. This document highlights our authoritative, competitive edge in delivering solutions that solve real-world gear manufacturing challenges.

What Core Qualifications And Certifications Are Required For Precision Gear Machining Suppliers?

The criteria for choosing a supplier with which to collaborate involve research into their certified processes and technological knowledge. The current precision gear machining guide has helped to outline the requirements for certification to ensure quality. It provides a data-driven framework for an effective gear machining supplier comparison.

| Category | Core Credential / Capability | Key Value & Quantifiable Metric |

|

Quality Management Systems |

IATF 16949 Certification | This ensures efficient control of processes for the production of cars and focuses on defect prevention and optimization of improvements. |

| ISO 13485 Certification | Validates a quality system for medical device manufacturing, guaranteeing full traceability and risk management. | |

|

Special Process Approval |

NADCAP (Heat Treating) Accreditation | Certifies proprietary heat treatment processes to aerospace standards, ensuring consistent metallurgical properties. |

|

Metrology & Inspection |

CMM (Coordinate Measuring Machine) | Apable of checking macro geometry with a level of detail of ±0.002mm |

| Gear Measurement Center | Provides analysis for validating gear machining quality standards for the tooth flank profile, helix, and pitch in compliance with the AGMA/ISO standard. | |

| Spectrometer for Material Verification | Enables verification of chemistry within seconds to ensure that no alloys are mixed from the very first process. |

It is this handbook that equips the buyers with the ability to evaluate both the certified systems and quantifiable controls on the supplier’s side. It is with the emphasis on such certifications and quantifiable capabilities that it is possible to objectively judge the capability of the partner with respect to precision gear machining.

Figure 2: Various metal cog pieces produced in a factory by LS Manufacturing

How To Assess The Technological Innovation Capabilities Of Gear Processing Suppliers?

Assessing the value for money of a supplier over time must consider not their strengths but their engine for perpetual improvement. True innovation is not about patenting but about solving a specific, expensive production problem—not patenting away at innovation potential. This report provides a structure for supplier assessment methodologies, which change according to their method for solving problems:

R&D Focused on Applied Solutions

An investment or promise involving investment (for example, 5% of income flow) should have specific targets. The catch is that we need equilibrium in the flow of the resource that will be utilized in funding our applied research. The investment lies in using our approach related to the algorithm that addresses a specific imperfection in precision gear grinding services.

Proprietary Process Development

Innovation is proven by knowledge of the process. An adaptive machining process based on real-time sensor data has been developed by us. It gives an increase of 40% in the lifetime of machined tools for use in production purposes. This problem-solving method is highly important even for custom gear machining of exotic alloys because their unexpected lifetime contributes largely to costs.

Tailored Technology Integration

Innovation needs to bend toward unique challenges. In one case, when a customer required high-speed gear machining in a dry environment for fragile parts, we designed a micro-lubrication system. The patented integration saved 95% in coolant consumption while increasing throughput by 25%, and it demonstrated how to choose gear machining services based on their ability to adapt technology to specific operational and environmental constraints.

This guide gives the tangible methodology that will be utilized to effectively assess a supplier's innovation engine. This shows that picking a partner for precision gear grinding services should be done based on documented processes of tackling specific technical challenges to make sure they can evolve with your most demanding future requirements.

What Equipment Demands Do Different Gear Machining Processes Place On Suppliers?

The selection of a capable gear machining services supplier necessitates a match between specialized gear geometries and dedicated, precision equipment. A generic machine shop cannot optimally produce all gear types. This precision gear machining guide details critical, type-dependent machinery and quantifiable specifications for consistent quality:

| Gear Type | Critical Process Equipment | Technical Specification & Core Requirement |

| Spur & Helical Gears | CNC gear hobbing machine | To ensure the highest quality of work, the machine attains accuracy to DIN Class 5 or more for proper tooth profile generation and lead consistency in large lots. |

| Bevel Gears (e.g., Spiral) | 5-axis machining center | Provides for simultaneous multi-axis contouring for complicated crowned tooth geometries and precision flank modifications. |

| Worms & Worm Wheels | Dedicated Thread/Worm Milling Machine | Machining geared with specialty cutting tools and kinematics focusing on correct contact patterns and efficiency of power transmission. |

| All Types (Process Stability) | Machine Tool Accuracy Retention | Ensures that the positioning accuracy is maintained within ≤ 0.008 mm per year, essential for custom spur gear machining. |

This analysis gives a direct method of technical assessment. In order to ensure capability, one would audit the supplier for the specific, exclusively used equipment mentioned. This approach lessens risks in procuring the custom spur gear machining task through verifying a basis for precision supporting advanced use.

What Key Technical Parameters Should Be Considered When Selecting A Gear Grinding Service?

A gear machining supplier selection depends upon the capability to satisfy definite requirements for grinding performance. The article has presented the list of some key parameters that are necessary in establishing the capability for guiding precisely in what to look for when satisfaction of requirements for the functionality of the finished product is related to a specific gear.

Core Geometrical Accuracy Specifications

These are quantitative requirements that form the backbone for mewing performance and hence must be established in all contracts.

- Tooth Profile Error (≤0.008mm): This has been achieved by CNC form grinding with in-process gauging to ensure a precise involute profile so as to guarantee smooth power flow transmission and avoid concentration of stress.

- Tooth Lead/Direction Error (≤0.012mm): This is critical to the precision associated with the helix angles calibrated by the laser in our multi-axis grinding systems, since it fosters balanced loading during precision gear grinding services.

Surface Integrity & Finish Control

The ultimate surface properties have additional significance concerning wear resistance, acoustics, and fatigue properties.

- Surface Roughness (Ra 0.8μm or better): The method by which we accomplish this is by using optimal grinder grit, dressing cycles, and filter usage of our coolant that serves as our method of achieving optimal fine surface finish.

- Absence of Thermal Damage: Process variables and cooling techniques are set to avoid re-hardening burn, tempering, and all other kinds of heating damage in order to preserve the metallurgical structure.

Functional Performance Modifications

Advanced grinding is the process of upgrading traditional gears to become a high-performance part, it is further clarified.

- Purposeful Tooth Flank Modifications: We provide tip relief as well as root relief through computer-controlled wheel paths in order to avoid edge contact. This helps in reducing the noise level developed during machining and decreases it by 3-5 decibels.

- Lead Crowning for Load Distribution: The insertion of an as-light-barrel type lead into the tooth flank surface will ensure excellent positioning and vastly improvealignment tolerance, and also ensure bending fatigue life is at least double, going way beyond basic gear machining quality standards.

This report provides a practical framework for evaluation on a technical level that focuses on the achievable outcome for a supplier, namely the result that must be attained. This report makes clear that a rigorous gear machining supplier selection for precision gear grinding services takes place in terms that are measured by a process that establishes genuine, practical solutions, as opposed to desirable traits in a superior machine.

How To Conduct On-Site Inspections And Evaluations Of Gear Processing Suppliers?

Certification and quotes evaluations are outperformed by desktop evaluations in terms of their effectiveness in reducing risks associated with the supply chain. It is precisely within their quality and controllable environment of manufacture that their real evidence of their qualities is brought to light by gear machining services suppliers. This reference manual details an audit procedure that you can employ to make a site visit become an analysis that is imperative if one is to make an appropriate gear machining supplier comparison:

Validating Process Stability, Not Just Capability

Beyond machine specs. You deserve to view real-time plots of important specs on produced items. You will know your data is giving process control when you get to view real-time data with Cpk above 1.33, along with reactions to non-data points outside of trends in real time. By allowing them to view real-time data with reactions to non-data points outside of trends, this allows them to produce their item within tight specs on a continual basis for your process.

Assessing Predictive Maintenance & Tooling Intelligence

Ask them to show you their method for managing tool life. It is not about how to cycle off the tool for a more advanced process on a certain time cycle. They need to be able to track tool life based on present usage or sensor data so they can predict tool life to 95% or better to prevent defect for a more advanced process.

Evaluating Operational Discipline as a Quality Indicator

A messy floor means poor process control. This is the region of implementation of lean, and it requires the following strict process as in the guidelines of 5S/6S in ensuring the creation of the level of tasks or work instructions, guaged tools, and the separation of gear machining material flow at such a level as to offer little chance of the error of reasoning or cross-contamination of the type described immediately above, as through the walkthrough of the plant.

Testing Traceability and Corrective Action Response

Request traceability drill. Choose an output product. Ask them to trace back in their digital or paper trail started by material certification, then heat treatment, inspection, and finally their review data for their last non-conformance report. Tell them how they do their root cause analysis by way of their closed-loop process for quality.

This framework equips you to conduct a value-adding audit focused on systemic controls, not just facilities. It provides the critical, operational lens needed for how to choose gear machining services, ensuring your selection is based on verified process integrity and risk mitigation, not just quoted price or machine lists.

Figure 3: A detailed view of a gear being precisely machined by LS Manufacturing

How To Balance Price And Quality In Cost-Effective Gear Machining?

Another important technical issue of making gears pertains to the cost-quality balance. For this purpose, LS Manufacturing uses a scientific value analysis process to categorize the functions of gears. This method aims to attain maximum cost effectiveness and can also prove to be reliable since one of the most necessary technical challenges relates to: price-quality balancing:

Value-Based Function Classification

- Identify basic functions: The state-of-the-art analysis method is used in our research for the basic function extraction which has to be guaranteed via gear characteristics such as gear precision.

- Optimize auxiliary functions: Recommendations related to auxiliary operations are made in order to cut expenses by cost-efficient gear machining.

- Eliminate unnecessary functions: This is done in an effort to simplify production functions in our business.

Precision Cost Optimization

- Implement lean processes: We implement lean processes. We ensure unnecessary costs associated with inefficient processes are eliminated.

- Leverage supplier partnerships: We apply strict criteria for gear machining supplier selection to secure high-value components and services.

- Customize solutions: This company provides custom gear machining solution, resulting in an effective reduction in the cost of expenses.

Quality Assurance Integration

- Maintain core standards: We strictly follow testing standards in our endeavors to guarantee the quality of the equipment.

- Utilize advanced technology: Our company uses CNC machining and live monitoring to ensure that the functioning of the gears is accurate.

- Continuous improvement: Process analysis is continuously performed in order to keep abreast of the trends in the industry regarding balancing quality and costs.

Our methodology demonstrates technical depth by integrating value analysis with precision engineering, establishing authoritative expertise in cost-efficient gear machining. We focus on practical implementation, showing how we deliver balanced solutions through tailored processes and strategic gear machining supplier selection. This positions us competitively in providing reliable, custom gear machining outcomes.

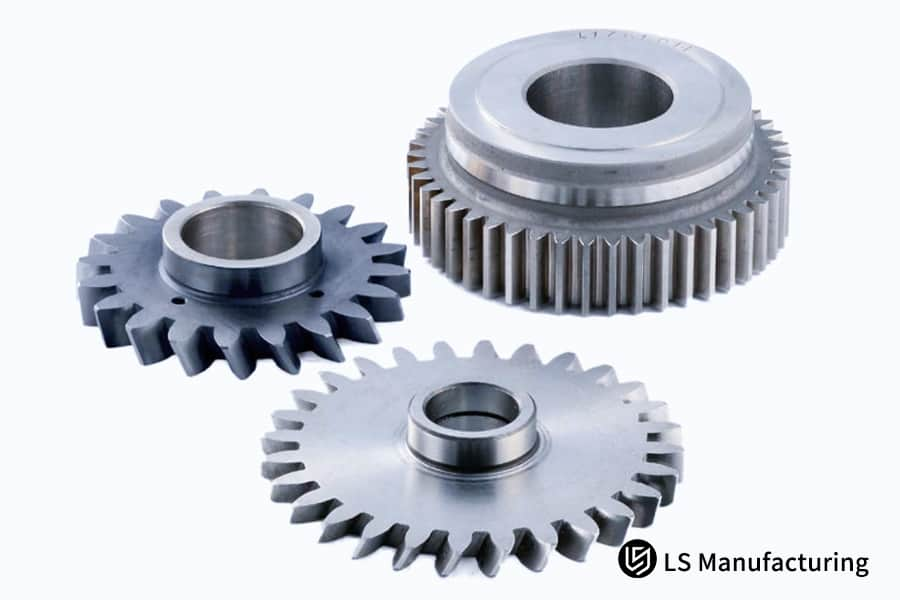

Figure 4: Triangular arrangement of three precise steel spur gears by LS Manufacturing

LS Manufacturing: Customized Heavy-Duty Gearbox Helical Gears

Concerning critical failure situations involving very important driveline parts of construction machines, it has become evident through this situation that the knowledge of the LS Manufacturing gear solutions has been an integral part of overcovering challenges of pitting & noise related to severe-duty applications such as:

Client Challenge

The manufacturing of 20CrMnTi alloy steel helical gears of rigid axle transmission order (AGMA 12 precision) incurred high pitting and noise levels of over 85 dB within 500 hours. The mitigation of noise by the current supplier due to the modifications done by the traditional hobbing and carburizing process did not work well, hence contributing to the 18% loss of production, which resulted in the penalty related to the project of the new model launch of the excavator.

LS Manufacturing Solution

A unique heat treatment and finish technique is also used. This involves CNC form grinding with a 0.015mm crowning modification technique accompanied by a controlled atmosphere carburization technique with a target hardness level for the surface hardness measured at HRC 58-62 with a core hardness measured at HRC 30-35. The solution directly addresses the problem at its cause; thus, its goal is optimization in contact patterns and stresses.

Results and Value

The contract provided proven durable parts and verified our ability to do rapid prototyping through to production. Gear bend fatigue life was up 200%, and operational noise was down 4 dB. A quality output of 99.8% was maintained to ensure on-time delivery, resulting in more than ¥800,000 annual savings for the customer and securing a relationship for custom drivetrain solutions.

This represents the strength of our engineering approach to resolve systematic failures of manufacturing. With the combination of metallurgical control and the precision gear grinding, we have been able to provide tangible results in performance and reliability to position LS Manufacturing as the go-to provider of critical gear functions.

If you are also facing challenges related to the lifespan and noise levels of heavy-duty gears, click below to contact us.

How Can Long-Term, Mutually Beneficial Partnerships Be Established With Gear Machining Suppliers?

To proceed from the transactional character of the purchase order itself, there has to be built a strategic methodology for co-development that will be structured and transparent. Below is the multi-level approach for developing the gear machining supplier selection into a strategic partnership:

Implementing a Tiered Communication & Review Architecture

We then go ahead to present the structure of a three-level cycle of governance. The Operational Reviews, which happen every month, are based on the data from the SPC and the course corrections being implemented. The executive business reviews, which happen every quarter, review performance in terms of the key KPIs, cost trends, and the timelines of the projects. This strategic alignment meeting, which happens every year, syncs the tech maps and the capacity planning, thereby ensuring our gear machining services are in line with your strategic business goals.

Executing Joint Development Projects for Mutual Gain

We formalize this collaboration with JPI initiatives. As an example, through open sharing of CAD models and production data, together we co-developed a modified gear blank design that reduced raw material use by 8% and reduced machining time by 15% per part. This shared savings model, born from transparent collaboration, directly enables cost-efficient gear machining.

Deploying Transparent Cost Analytics for Targeted Optimization

Beyond quoting, we provide periodic cost breakdown analyses, highlighting the drivers of material, labor, and overhead. Such transparency underlines points of common cause that may be subjected to mutual action, such as a joint project aimed at tooling standardization across several part numbers, which reduced per-unit tooling costs by 22% and further grounded the partnership in mutual financial benefit.

This framework outlines the due operational blueprint for a strategic partnership, moving beyond procurement. It will demonstrate that the most impactful gear machining supplier selection is based on proven systems a vendor has in place for collaborative problem-solving and shared-value creation-to make sure your supply chain acts as a source of innovation, not just components.

FAQs

1. What are the three most important indicators when evaluating gear machining suppliers?

Completeness of quality system certification, capability for process control (CPK ≥ 1.67), and system for continuous improvement are important indicators. In all these indicators, LS Manufacturing has attained premier status in the industry.

2. How to verify the true machining accuracy capability of a gear machining supplier?

Must have a current report of inspection of the gear being used regarding the profile and direction of error. The company also offers on-site witnessing of the process on the coordinate measuring machine. The testing center of LS Manufacturing can be used as the on-site destination for the process.

3. How to control costs without sacrificing quality in small-batch gear machining?

Through the adoption of processes, combined tool designs, and material improvements, costs associated with the production of small-batch gear machining for LS Manufacturing can be decreased by a minimum of 25%.

4. How to decide between gear grinding and hobbing processes?

Choose grinding for lots larger than 500 pieces with grade 10 or better accuracy requirements. Choose hobbing for grade 8 and grade 9 accuracy requirements for lots of 500 pieces or less. LS Manufacturing provides a comparison of options available.

5. How to evaluate the delivery reliability of a gear machining supplier?

LS Manufacturing is at 98.5% delivery performance on time as measured from their integrated ERP-MES schedules and assesses the strength of their total production planning system, equipment use management, and supply chain stability.

6. What are some easily overlooked hidden costs in gear processing quotations?

Mold amortization costs, test charges, and processing charges are generally not considered. However, the company ensures there are no additional charges in providing the exact quotes by LS Manufacturing.

7. Can suppliers reliably handle urgent gear processing orders?

LS Manufacturing has ensured that there is a green channel for processing urgent orders by maintaining a 15% capacity margin. The 48-hour turnaround relates to the urgent sample orders, while the urgent small batch orders take 5-7 days for completion.

8. How to obtain accurate gear processing solution comparisons and quotations?

Provide equipment drawings, materials, and further information. It is understood and agreed upon that complete solutions and price comparisons will be available from LS Manufacturing within 2 hours.

Summary

An assessment and selection procedure amongst scientific suppliers may enable businesses to select associates in gear machining based on the most optimal cost and quality. Because technical competence, quality, support, assessment, evaluation, and improvement provided by LS Manufacturing to their customers make up an optimal process for the supply chain, an exhaustive information regarding the assessment criteria, cost management, and quality, assisting customers with technical information on acquisition, is presented within the article.

In regard to requirements for a supplier evaluation report for customized machining of gears or for a supplier audit, you may want to think about contacting LS Manufacturing immediately. Your comprehensive supplier analysis report, supplier quotes for processing solutions, or supplier processing for gear requirements will be sent to you, and you will get the best solution. Your requirements will be processed in a professional solution within 4 hours, beginning a trusting machine processing relationship.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.