Custom gear design services are urgent needs for auto-making and robotics companies in dealing with critical challenges of low transmission efficiency, high noise, and short lifetime. Generic gears can meet the needs of high-performance equipment in a less-than-satisfactory manner because of the negative effects of competitiveness in the new energy auto field and robots involving high speed, low noise, and long lifetime.

These issues crop up due to a lack of understanding about the application, poor co-optimization, and varying levels of competence across suppliers. This paper discusses how LS Manufacturing can get a better customized gear solution through its integrated services that include demand, topological optimization, and manufacturing.

Article Quick-Reference Guide: Custom Gear Design

|

Section |

Key Content |

|

Current Challenges |

Low efficiency, high noise, and short service life. Standard gears cannot fulfill EV & robotics' high performance demand. |

|

Root Causes |

Lack of design and process-material synergy; lack of suppliers' expertise. |

|

Proposed Solution |

LS Manufacturing provides the entire chain of processes: need analysis, topology optimisation and precision manufacturing. |

|

Core Principles |

Stiffness, wear resistance, fatigue life, noise-vibration harshness (NVH) optimization. |

|

Design & Tech |

Advanced software simulation (FEA), topology optimisation, material science, micro-geometry optimisation. |

|

Manufacturing |

High precision CNC machining, grinding, specialized heat treatment processes, and comprehensive quality control. |

|

Case Benefits |

Improved functional performance, reduced noise, durability, faster time-to-market. |

In a heavy application area like EVs and robotics, custom design gears is very important to address the issues associated with standardized gears. Advanced application knowledge, simulation, and manufacturing tools seamlessly address the application level issues associated with efficiency, noise generation, and vibration or durability for the delivery of the best application-specific solution.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are so many articles available over the internet. Why is this article any different? That is because we are not just theorists but involved professionals in the real field of work. Our workshop is a real-life testing ground where we fight on a daily basis with demanding materials, tolerances, and gear tooth geometry complexities. This is a place where we "live" our knowledge about gear designs, not just "know" about them.

Our deep expertise is rigorously applied. We integrate stringent standards, such as those from the Environmental Protection Agency (EPA) and the National Association for Surface Finishing (NASF), into our entire process—from material sourcing to final inspection. This commitment ensures every gear we design meets the highest benchmarks for performance, sustainability, and surface integrity, tailored for applications from robotics to electric vehicles.

All the knowledge we share is tempered through our experience, proven out through our success. This guide encapsulates the best practices gleaned from project after project, and it gives you the insight you need to maximize your gear performance. Be confident that all the knowledge that is shared herein is what makes us successful each and every day.

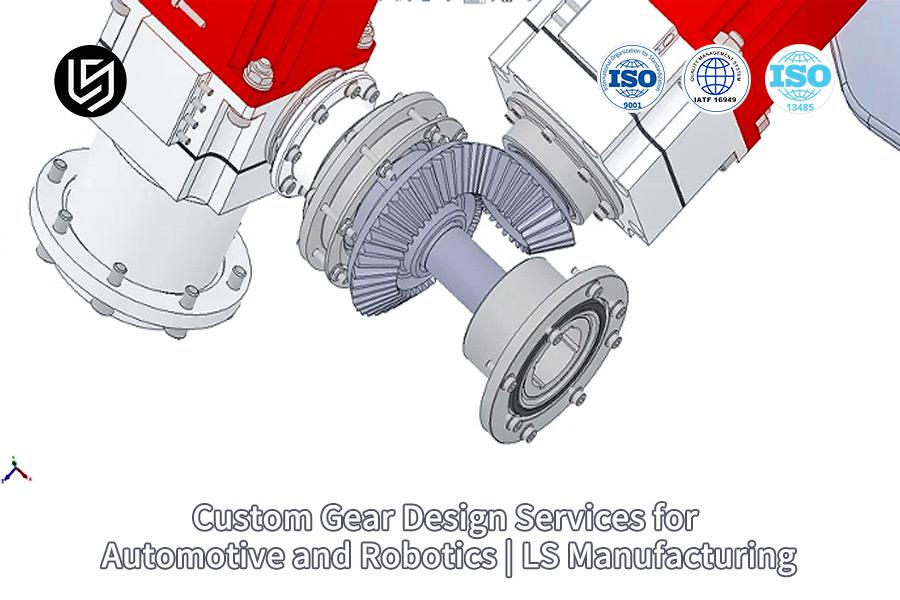

Figure 1: Exploded view diagram of an automotive gear assembly by LS Manufacturing

What Are The Core Principles That Should Be Followed In High-Quality Gear Design?

In the realm of high-performance applications, superior gear design is the cornerstone of reliability and efficiency. Moving beyond standard approaches requires adherence to a set of rigorous engineering principles. At a reputable gear design and manufacturing company like LS Manufacturing, these principles translate theoretical standards into durable, high-performing components. The core pillars can be systematically broken down as follows:

Strength and Durability Calculations

Relied on strong strength verification to ensure standards such as ISO 6336 are met, accurate calculation of the contact fatigue resistance of tooth flanks and the tooth root bending fatigue resistance has to be carried out. First of all, these calculations provide evidence as to whether this particular gear component is going to be subjected to pitting or breakage during use and hence form the basis of any custom gear design services.

Advanced Fatigue Life Analysis

Fatigue life prediction requires the analysis of real load spectra and application of concepts such as the rule of cumulative damage. In fact, that concept took the big step away from simple static strength calculation, considering the effect of variable loads in the period of time in causing material fatigue.

Optimization of Meshing Characteristics

Optimum power transmission and smooth flow depend upon optimum characteristics of meshing. The major methods are maximizing contact ratio to better handle loads and optimum values of the sliding velocity ratio to avoid wear and vibration. This is an important identifying feature in gear design.

Integrated Thermal Management

It is a fact that at high speeds or even when the machine is loaded, there would definitely be generation of heat. This needs good design methodology incorporating heat management systems such as optimal casing design and flow paths for lubricants, which may also include cooling systems. This needs temperature management. This is mainly done to avoid the adversities associated with high speed, such as breakdown of lubricant or loss of material properties.

Precision-manufacturing synergy

ISO 1328 accuracy class setting without consideration of the manufacturing process capabilities of a gear design and manufacturing company is irrelevant. Realistic precision is achieved with tolerances that complement manufacturing processes like grinding and/or honing to ensure the manufactured gear perfectly reflects its CAD model.

Ultimately, it is an entire realm of operations that goes into what constitutes efficient gear design. High-quality gear design have to integrate mechanical analysis, properties of materials, and manufacturing realities. For clients seeking custom gear design services, partnering with a firm that rigorously applies these interconnected principles—from initial calculations to final manufacturing—is key to achieving gears that deliver superior performance, quiet operation, and extended service life.

What Are The Design Differences Between Automotive Transmission Gears And Robot Joint Gears?

Automotive gear design and robotics gear machining are two different fields that encompass their own sets of challenges. The philosophy that would form the backdrop for effective design of the custom gear design services must be attuned to principles relating to the concept of divergence. The divergences will be made apparent in distinguishing key parameters.

|

Parameter |

Automotive Transmission Gears |

Robotic Joint Gears |

|

Load Profile |

Constant torque, Smooth torque. Resilient to cyclic loads. |

High dynamic loads. Capable of with standing starts and stops, reversing cycles, in addition to fully loaded operations. |

|

Precision (ISO 1328) |

High Precision, Grade ISO 6 to 8. The key emphasis is on-efficiency as well as efficient power transmission. |

Ultra-High Precision, Grade ISO 4 to 6. It holds a critical significance regarding positional accuracy and backlash. |

|

Life Expectancy |

Extreme Total Life (>10,000 hours). Tested by simulatingipple cycles like those encountered in real highway driving. |

Extreme cycle life under stress (>20,000+ hours). Tested by simulating shock-duty cycles. |

|

Noise Control |

Target: < ~70 dB; It mainly focuses on the reduction of the whine level in the high frequency range to improve the comfort of the customers. |

Target: < ~60 dB; The target tries to reduce the noise level so that noiseless operation can be achieved that would enable co-processing. |

Putting it all together, while the automotive gear design focuses on long-term efficiency, in robotics gear machining, there must be ultimate precision. In that respect, this dichotomy highlights the need for genuine custom gear design services in which all variables are designed to meet the needs of the operational envelope of the particular task.

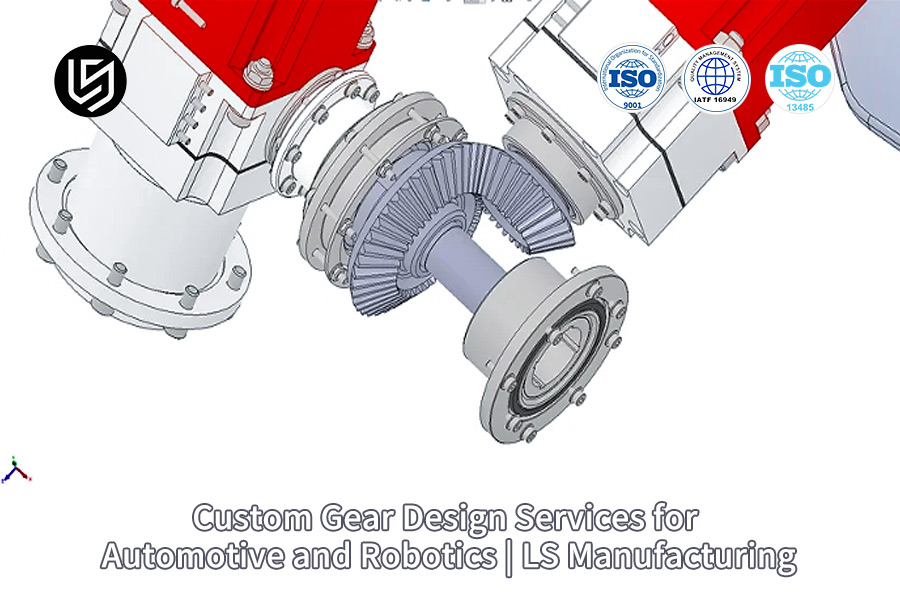

Figure 2: Precision robotic arm for gear manufacturing by LS Manufacturing

How To Improve Gear Performance Through Material Selection?

Material selection is one of the most basic foundations in the industry of gear engineering. This is because selection directly relates to functionality, longevity, and usability. In the related fields, for example, gear design for electric vehicles or the precision gear manufacturing, the material selection at issue shall not be something to be taken into consideration. Instead, this basic basic stands out as a foundation. This thus guarantees that the appropriate processing technique directly has an impact on the custom gear machining quotes.

| Category | Key Materials/Processes | Primary Performance Traits & Typical Applications |

| High-Strength Alloy Steels | 20CrMnTi, 42CrMo, 38CrMoAl | High core strength and toughness. Commonly case-hardened by carburizing processes. Used to manufacture high-loaded parts. |

|

Engineering Plastics |

POM, PA66 (often glass-filled) |

Carburising and nitriding are the techniques used to improve the surface properties of the material. Carburising: Hard surface and larger depth. Nitriding: hard surface with low distortion. PVD: lowers the friction coefficient value. Critical Operations for Enhancing Life in precision gear manufacturing. |

|

Critical Surface Treatments |

Carburizing, nitriding, PVD coating |

Excellent noise damping, self-lubricating and corrosion resistant. Ideal for lighter loads, consumer products, and applications where weight and quiet operation are priorities. |

The good material will always be tested at the system level with all basic parameters in mind: performance characteristics and developments on the surface of the material. Whether for quiet gear design for electric vehicles or any heaviness industry use, the primary criterion that stands at the end of performance characteristics in gear material use is the selection made by a professional consultant at the beginning stage of design to ensure that it performs well in order to achieve the "value" determined by the cost of custom gear machining quote.

How Does The Gear Manufacturing Process Affect The Final Performance?

Precision gear manufacturing entails a set of decisions that entail direct effects on the identified characteristics as discussed. The process that has been followed all along from the initial stages right up to the finish product decides the efficiency, vibration, and gear lift. An appropriate decision regarding the chain in the process pertains to one of the most challenging factors necessary in efficient gear design and manufacturing company. There follow the techniques involving direct cause-and-effect relationships.

- Gear Grinding by Grinding of the Gear: Precise grinding is required when the required accuracy of the gear is the maximum achievable quality, including ISO 4-6. This process is essential to compensate the deformation generated by the heat treatment and finer surfaces of the hardened surfaces. This is one of the basic precision gear manufacturing, where the smallest error of back lashes and geometric error cannot be tolerated, especially when the performance of the system is required to be sustained.

- Gear Honing for Noise and Surface Finish: The super-finishing technique performed on the gear after the hardening and grinding operation is gear honing. The purpose of its implementation is to reduce noise level by 2-3 DB, thus making this technique extremely critical to the automotive world. The gear-honing technique is extremely critical to be used when it is required to produce small batch gear production.

- Advanced Heat and Surface Treatments: Modern processes like laser hardening and ultrasonic rolling enhance material properties. Laser hardening allows localized, low-distortion hardening of tooth flanks, while ultrasonic rolling induces compressive stress to boost fatigue strength. These advanced techniques are powerful tools for a gear design and manufacturing company to extend service life and reliability in demanding applications.

- Hobbing & Shaving for Pre-Finish: Pre-finishing of gears may involve hobbing, which is carried out for external gears, or even the shaping process. Out of these three processes, modern computer numerical control hobbing can give decent quality while carrying out pre-finishing processes. Another possibility of shaving is the soft finishing process before hardening to deliver higher precision. This-finishing process is an economical way of mass production.

In summary, manufacturing is not a single step but a value-adding chain. The chosen sequence—from initial cutting to final super-finishing—is tailored to meet specific targets for precision, durability, and noise. This holistic process mastery is what distinguishes a true partner in precision gear manufacturing, ensuring the designed performance is fully realized, whether in mass production or specialized small batch gear production.

LS Manufacturing Industrial Robot Joint Gear Customization Case

One of the largest companies that provide industrial robots globally suffered from pits formed on their gears after only 2,000 hours of usage, which led to the loss of 0.1mm of their precision and 15% consumer complaints. The nature of this problem required a systems change with a focus on solving at the point of issue, which is the issue of fatigue failure. It required solutions and expertise in engineering at the level of services offered by LS Manufacturing gear customization. This is a fantastic case study, which, because of brilliance in engineering, achieves success. Here is the entire case study:

Customer Challenge

The customer-supplied joint gears had been failing in their intended life cycle due to pitting corrosion. This is pertinent to the level of accuracy required in the gear system. The other aspect of this case study is that concerning the failure modes of the customers. It is crucial to point out that this aspect of customer failure mode does not stop at the evaluation level concerning the performance aspect of the product but rather advances and reaches the level of destruction concerning the stages of integrity of the entire product.

LS Manufacturing Solution

Our approach was a holistic engineering intervention. First, the authors wrote, we used topology optimization to optimize the tooth profile, which resulted in a 25% reduction in maximum contact stress. We then specified a high-performance nitriding steel, achieving over HRC 60 surface hardness. The gear was finished via precision gear manufacturing grinding to ISO grade 4 accuracy, followed by shot peening to enhance fatigue strength by 30%, creating a comprehensively superior component.

Results and Value

Thus, the customized equipment contributed to achieving results that can be categorized as transformative. In terms of the life of the equipment, there was an improvement from 2,000 hours to 6,000 hours, registering a 200% improvement. Furthermore, the noise level reduced to 60 dB by 5 dB. or the client, this resulted in a 40% reduction in maintenance costs and a significant boost in end-product competitiveness, validating the investment in specialized LS Manufacturing gear customization.

In summary, this case moves beyond simple part replacement to showcase value-driven engineering. By integrating advanced design, material science, and specialized finishing processes, our solution for robotics gear machining turned a critical failure point into a performance advantage. It underscores that achieving reliability in demanding applications requires the end-to-end expertise found in true precision gear manufacturing partnerships.

Are you ready to optimize your custom equipment? Call our engineers today!

How To Control The Cost Of Custom Gear Projects?

Cost control in the case of a custom gear project is much more than comparing custom gear machining quotes. Cost control can be possible only when there is harmony between the performance and cost factors, especially when there is small batch gear production. "One stop solution" in the context of completion of the cost control process in a custom gear project may be a professional gear design and manufacturing company. The following are the points that shall be required strategies in order to achieve this in terms of quality and cost.

Material Selection Strategy

The approach towards material selection will be informed by the cost of material. Unlike the application of the best alloys, value engineering will make it possible to apply other materials that will do well when the most excellent methods are employed. This is of utmost significance in the small batch gear production because the materials used have a high impact within the industry of specializing in the said product because of the custom gear machining quotes.

DFM

When relating it to saving economically, it is in the design phase where the maximum saving was possible. The involvement of the gear design and manufacturing company in creating an optimal design with regard to the gear machining cost will make it simple to save regarding the machining time or the price of the tools, thus the custom gear machining quotes.

Process Precision/Precision Alignment

Where required precisions/finishes involve higher precisions, prices increase as appreciably as the precisions. There is exclusion of over-engineering in precision alignment, which is realized through precision analysis. This precision alignment is a key value provided by experienced gear design and manufacturing partners, especially for specialized small batch gear production.

Scalability/Volume Planning

It can also be counted on to be a fact that perhaps some limitations may apply to the original volume concerning the scalability of the production of products, and hence scalability right from the very beginning would be a huge help in the later stage cost reduction. The scalability plan would be aimed to raise the volume above the range of 25-30%.

An implication of this aspect will be relating the optimization process relating to the cost of the custom gears to the planning process relating to selection, design and alignment as well as volume strategy. Working closely with a capable gear design and manufacturing company ensures projects achieve optimal performance while controlling expenses, delivering maximum value beyond the initial custom gear machining quotes for both prototype and production phases.

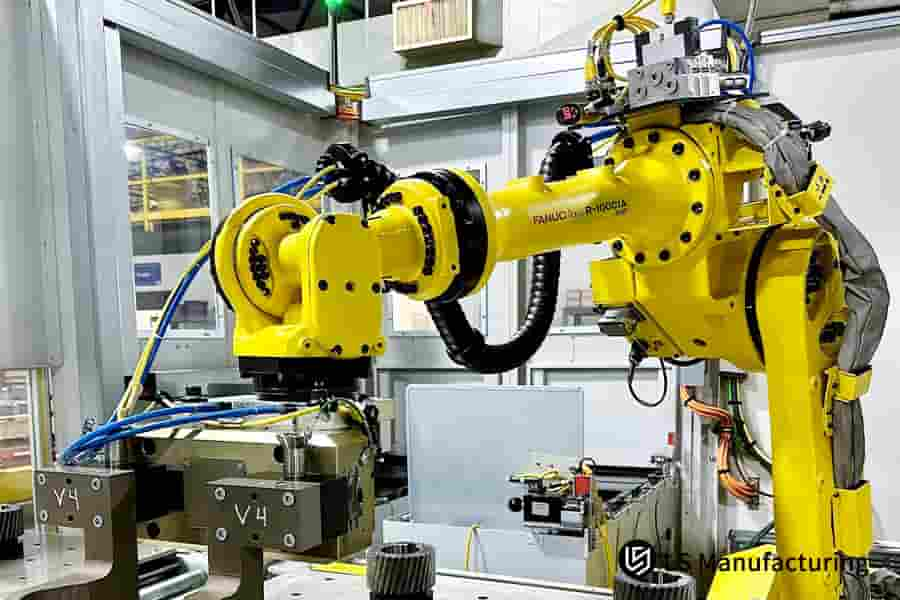

Figure 3: Gearbox for robotic chassis in a mobile robot by LS Manufacturing

What Are The Key Points For Quality Control In Small-Batch Gear Production?

Quality assurance with regard to small batch gear production is a necessity that needs to be an electronically integrated, highly data-intensive process right from the very outset of the production process. Unlike other products that have actually been manufactured, every product is essentially a “critical test” product for a service such as custom gear design services. Indeed, it is even impossible to highlight a discussion about quality when it comes to precision gear manufacturing that does not have a fully integrated approach regarding the entire quality control process. The key control processes are as follows:

- Material Certification and Starting Material Quality: The quality begins with the material; hence, the material certification in terms of chemical and mechanical quality is required. Based on the quality of material with certified specification, it will provide a good platform to perform the correct process for precision gear manufacturing.

- In-Process Monitoring and SPC: Implementing Statistical Process Control (SPC) on key dimensions is crucial, even for small runs. Monitoring critical parameters like tooth profile and lead during machining allows for real-time adjustments, preventing deviations and ensuring consistency throughout the entire small batch gear production cycle.

- Final Comprehensive Inspection: All gears are put through a complete check depending on size, and they require a gear-measuring center. The final inspection covers all the necessary tolerances, as specified by the custom gear design services, as provided by the original specifications.

- Complete Documentation and Traceability: The documentation related to the complete quality file should be implemented as follows. This should be linked with the documentation of all necessary certificates, followed by the inspection that has been performed at various stages in the process, and finally, the report related to the final inspection carried out on gear components, and the charts related to the heat treatment processes. The purpose is to trace out all those products that are generated in the process of small batch gear production.

In conclusion, quality in small batch gear production is secured through meticulous verification at each stage—from material to measurement. This disciplined approach transforms the precision of custom gear design services into tangible, high-performance components, delivering the guaranteed reliability that defines true precision gear manufacturing.

What Special Requirements Must Be met For The Gear Design Of Electric Vehicles?

An optimal gear design for electric vehicles has to consider all the various conditions that vary significantly from the conventional automotive gear design. The need to optimize at extreme points in order to satisfy a performance requirement is what really makes a custom gear design services.so specialized. The main tech areas given importance are discussed below.

- High Speed Efficiency: The gears must work at high speeds continuously above 15,000 RPM. It is an indication that there is a need to prioritize optimized macro and micro-geometry in order to reduce frictional losses as well as windage losses for enhancing the efficiency of transmission above 98.5%. In addition, balancing and lubrication are the other factors that need to be put into consideration while gear design for electric vehicles.

- Advanced Noise, Vibration, and Harshness Control: With no engine mask, gear whine is acutely perceptible. Achieving noise levels below 65 dB requires sophisticated profile and lead modifications (tip and root relief), along with exceptional manufacturing accuracy. This NVH focus is a cornerstone of modern automotive gear design for EVs.

- Lightweighting and Thermal Management: The lighter it is, the better it would be to achieve an efficient range. To achieve that, if topology optimization & the use of lightweight yet tough material are considered, one may achieve a weight reduction of 15-20% in gearboxes. It is necessary to optimize the design so that heating does not take place due to high-speed tasks, sometimes even with cooling lines embedded inside.

- Durability Under High Transient Torque: It can be assessed how difficult it would be for the gear to handle the higher transient torque provided by the electric motor. Design would need to allow the gear to be durable considering the presence of higher transient torque, as well as the demand for surface finishing, root fillets, and materials.

Gear design for electric vehicles involves melting all the above-mentioned factors of dynamics at high speeds, acoustic refinement, minimization, lightweighting, and torque support into one. All put together, they cannot be complied with above and beyond what needs to happen for automotive gear design and find their best solution with a custom gear design services, due to its direct influence on working in an electric vehicle.

How To Assess The Overall capabilities of a gear supplier?

Selecting a capable gear design and manufacturing company requires a systematic evaluation beyond basic pricing. A true partner must demonstrate excellence across technical, quality, and service domains to deliver reliable custom gear design services. For instance, evaluating a supplier like LS Manufacturing would involve assessing these key areas. The following framework outlines critical evaluation criteria for a comprehensive assessment.

Technological and Engineering Capabilities

Another important determinant is the technological capability of the supplier. The quantity of experience the supplier may have concerning the type of complexity associated with the use of design software and gear measurement centers, apart from the type of complexity of the processes connected with the processes, could also be considered another factor for which research should be conducted. A company excelling in custom gear design services will have a proven portfolio of complex solutions, not just standard catalog parts.

Quality Management Systems and Certifications

This can be the starting point for the selection process. Suppliers with any form of quality certification from auto manufacturers or with IATF 16949 and ISO 9001 quality management systems certification will be sifted based on the service they provide for traceability and gear management right from the material purchase to finished product delivery.

Innovation/Development Expertise

Research their credentials directly relevant to the body of work they do as innovators in their projects at R&D. Innovation can occur in product development and prototype development phases since the project is time-consuming and an innovation experience itself. The same innovation strategy has been incorporated in the example case study provided by the authors for the project completed as innovation; because it's not the triumph over success, but the triumph over the unknown.

Regardless of the best features

It is a fact that the qualities of the best entities were potentially overshadowed in regard to the quality of the services. Noteworthy is that the qualities of the service quality should be examined in terms of communicating the services, the time taken in answering regarding the issue in question and the quality in managing the projects. Best gear design and manufacturing company of your employees.

In summary, a thorough supplier evaluation balances hard technical capabilities with soft project management skills. The ideal partner, such as LS Manufacturing, seamlessly integrates deep engineering expertise, a certified quality system, innovative drive, and committed customer service. This holistic approach ensures they can deliver not just parts, but true value through expert custom gear design services and manufacturing partnership.

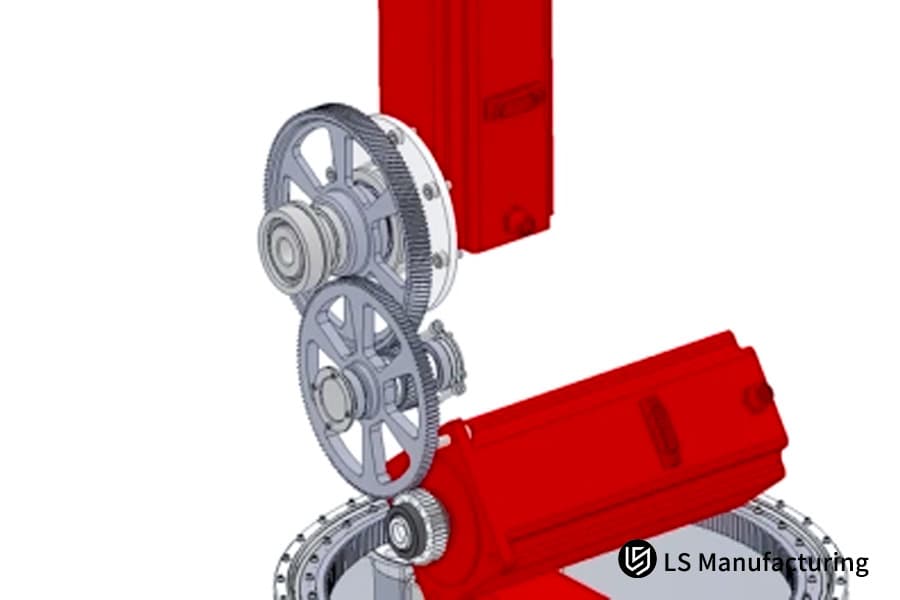

Figure 4: Close-up of a precision red gear drive system by LS Manufacturing

FAQs

1. What is the basic process of gear design?

The processes involved in gear design are somewhat intricate, involving a number of processes such as analysis of the demands or working factors, concept design, computation on the parameters, and eventually achieving a 3D design using computer simulations. Other test cycles that improve the design concept of gear systems to meet the demands of the solution to the task include strength tests, durability tests, noise tests, and optimization tests.

2. What is the smallest production lot size of gears?

Our interest would lie in the service provided in relation to the processing of the smaller batches. Minimum order quantity is, however, set at 10 units, although it seems the quantity is not an issue given that the usage of dynamic models in processing is sufficient to meet the demand that the client needs about customization, although this seems an impressive amount looking at the fact that quality processing of the service provided is needed to meet the demand of the client required in relation to the validation processing, trial processing, as well as the smaller scale manufacturers.

3. What is delivery cycle in a gear project?

Cycle Time: This would depend on the nature of gear and the material used, taking anything from 4 to 8 weeks. Before this becomes the point of entry in the order, there would also be a relevant analysis on the part of engineers concerning cycle time from design to processing stages or from heat treatment to testing stages.

4. Can you provide a fatigue life test report for the gears?

Yes, we can do a fatigue test according to international standards such as ISO 6336 and provide the test report of parameters and life curve. The test report provided is a guarantee for the reliability of our gear to work within actual working load conditions, offering data support for optimization and certification by customers.

5. How do you ensure gear noise control?

Noise reduction should be done from the system point of view, including optimal tooth profile and modification designs for minimum effects of meshing as much as possible; use of materials with high damping capability; and precision machining to ensure the quality of the surfaces. Comprehensive simulation and testing of acoustics are performed during the entire designing and manufacturing procedures so that the gear system can meet the demand for noiseless running.

6. Do you support expedited service for urgent orders?

We support the expedited shipping to meet the urgent orders. There is a fast response system in case of urgent projects. This reduces the response time. The production line is optimized, which helps to reduce the cycle time in large links. The special handling procedures, alongside other changes, will afterwards be agreed upon with the customer to see if it is possible to make the shipping faster.

7. What information is required for new project collaborations?

For new project collaborations, please provide information such as the application scenario of the gears, operating load, speed requirements, expected lifespan, mounting interface dimensions, and precision grade. If there are special environmental, noise, or efficiency requirements, please also specify them. Our engineers will conduct a feasibility assessment and solution design based on complete information.

8. How to obtain detailed quotation information?

We welcome detailed gear specifications, including module, number of teeth, material, precision grade, heat treatment requirements, and delivery quantity. After receiving the information, we will conduct process review and cost calculation, and provide a formal quotation including price, delivery time, and process specifications within 1-3 business days.

Summary

This detailed analysis clearly demonstrates that high-quality gear design and manufacturing requires comprehensive consideration of material properties, manufacturing processes, design methodologies, and other factors. Neglecting any aspect can negatively impact the final product's performance. LS Manufacturing, with its robust technical system, advanced manufacturing equipment, and extensive industry experience, provides clients with end-to-end gear solutions, from conceptual design to mass production, ensuring optimal performance in key areas such as transmission efficiency, noise control, and lifespan.

If your project faces technical challenges in gear design and manufacturing, please contact LS Manufacturing's professional team immediately. We offer free technical consultation and solution evaluation services, responding to your needs within 24 hours to ensure your project progresses quickly. Click to contact us for a customized solution and let professional gear solutions empower your products!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.