Gear machining faces persistent industry challenges including dimensional inaccuracy, excessive operational noise, and premature failure. These issues manifest during full-load operation as positional deviations, audible disruptions in quiet environments, and unscheduled downtime due to accelerated wear - all critically impacting production efficiency and brand integrity.

The root cause lies in fragmented traditional approaches where material selection disregards operational demands, cutting parameters rely on empirical settings, heat treatment lacks standardization, and quality verification occurs post-production. This disjointed methodology creates misaligned optimization objectives throughout the manufacturing chain.

LS Manufacturing's integrated "material-process-inspection" methodology revolutionizes gear machining through scientific material compatibility analysis, optimized multi-stage cutting strategies, and real-time quality assurance. This systematic approach achieves quantifiable improvements: ISO 6+ accuracy, 8-10 dB noise reduction, and 10,000+ hours service life. To save you time, here is a quick overview of the key findings.

Figure 1: Heavy-duty Industrial gear assemblies by Manufacturing

LS Manufacturing Precision Gear Manufacturing Solution Quick Reference Table

| Core Dimensions | Common Pain Points | Solution Overview |

| Precision | Tooth profile errors and cumulative pitch errors result in unstable transmission and vibration. | Ultra-high precision machining and testing equipment ensures perfect gear meshing, accurate, and reliable transmission. |

| Noise Meshing effect | High tooth surface roughness generate excessive noise. | It employs the techniques of tooth profile and direction optimization to reduce meshing impact and operating noise effectively. |

| Lifespan | Wear, pitting, and tooth breakage result in premature equipment failure. | Attention to choosing superior materials and advanced heat treatment processes is highly important, since it considerably enhances gear wear resistance and improves their fatigue strength. |

| System Integration | Poor matching of gears, housings, and bearings impairs overall performance. | From gears to systems, we offer complete transmission solutions that guarantee ideal synergy among components. |

This guide delves into every detail. We go beyond simple definitions, providing a clear decision-making framework, professional practical skills, and real-world case studies from our gear manufacturing process. After reading this guide, you will be confident in choosing the right tools for any project, making gear manufacturing more standardized.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

LS Manufacturing boasts over two decades of technological expertise in precision gear manufacturing. We have not only established a comprehensive gear manufacturing process system but also developed our own knowledge base in key technology areas such as materials science, heat treatment processes, and precision control.

Our technical team has provided gear solutions to hundreds of clients in the industrial robotics, high-end equipment, and automotive transmission industries. For example, we helped an industrial robot manufacturer overcome the precision bottleneck of articulated gears by customizing material selection and process optimization, increasing gear life from 3,000 hours to 10,000 hours and reducing noise by 8 decibels.

Excellent gear manufacturing requires precise matching of material properties, process parameters, and quality standards—this is precisely our core strength. This guide will provide you with a proven methodology for improving gear reliability, helping you avoid common pitfalls and quickly find the best solution for your specific needs.

How To Scientifically Choose Gear Materials According To Application Scenarios?

Material selection directly influences the final performance and service life of gear products in precision gear manufacturing. Scientific material selection does not pursue the highest performance but precisely matches application conditions, which is one of the key steps to achieve efficient manufacturing.

- High-load conditions: Carburized alloy steel (such as 20CrMnTi) is the first choice. Its core toughness and high surface hardness will perfectly bear the impact and contact fatigue, making the material the first choice for heavy machinery.

- High-speed conditions: Emphasis is placed on lightweight and dynamic balance. It can be made of high-strength alloy steel (like 4140) with fine heat treatment, or adopt lightweight materials like aluminum alloys.

- Corrosion-resistant/light-load conditions: Austenitic stainless steel, such as 304, or engineering plastics, like POM and nylon, can be used. They resist corrosion and reduce the noise, suitable for food, medical, or small transmission applications.

In precision gear manufacturing, scientific material selection must match the working conditions. High loads require carburized alloy steel, high speeds require lightweight materials, and corrosion-resistant conditions require stainless steel or engineering plastics. The key is to address the specific needs, not to pursue peak performance.

How Does Gear Cutting Affect The Final Transmission Accuracy?

In precision gear manufacturing, the gear cutting process is a core element in determining the accuracy of the gear tooth profile and surface quality, directly affecting the smoothness and efficiency of transmission. A different process path will result in drastically different levels of precision. The following table systematically compares the common processes and their accuracy performance, and illustrates LS Manufacturing's high-precision solutions:

| Process Method | Core Features | Typical Accuracy Grade (ISO) | Limitations |

| Hobbing | Continuous cutting, efficient and versatile | Grade 8-9 | The tooth surface is likely to leave tool marks with lower precision and poor surface finish. |

| Shaping | Suitable for internal gears and double gears , good flexibility | Grade 8-9 | Non-continuous cutting, relatively high tooth surface roughness. |

| Shaving | Finishing process, errors can be rectified and roughness of tooth surface can be improved considerably | Can be improved to Grade 7 | Not possible to machine hardened gears. Allowance to be provided in previous processes. |

| LS Manufacturing Process: CNC Hobbing + Shaving | First, high precision CNC hobbing ensures the tooth profile foundation. Finishing was done by shaving to fix the error. | ISO 6 ultra-high precision could be achieved stably. | Longer process chain, extremely high equipment and technical level requirements. |

In the process of gear manufacturing, there is usually a bottleneck in any one process. Our composite gear cutting process, through the beneficial complementarity of other processes, systematically controls the error chain, and this constitutes the heart of the technical guarantee enabling us to steadily provide high reliability in precision gear product manufacturing.

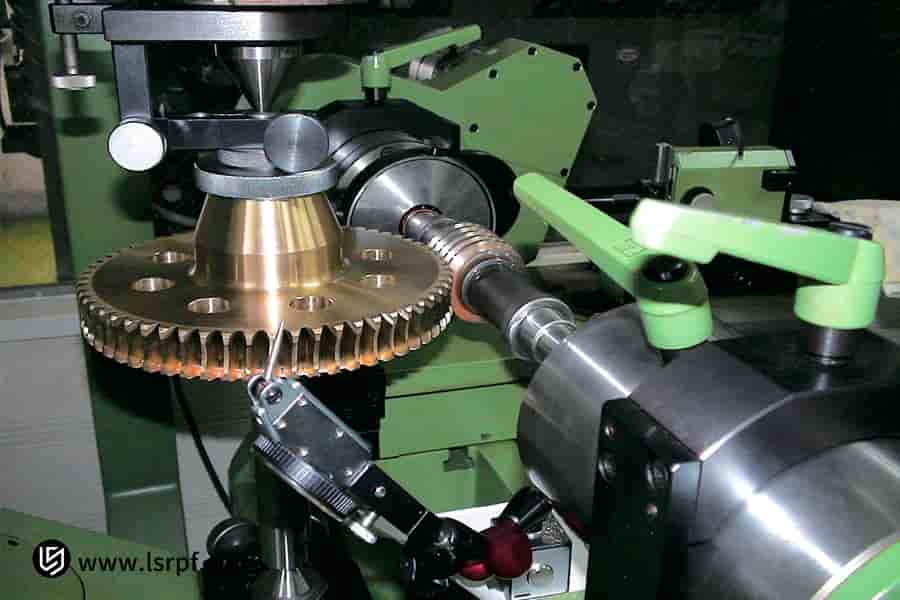

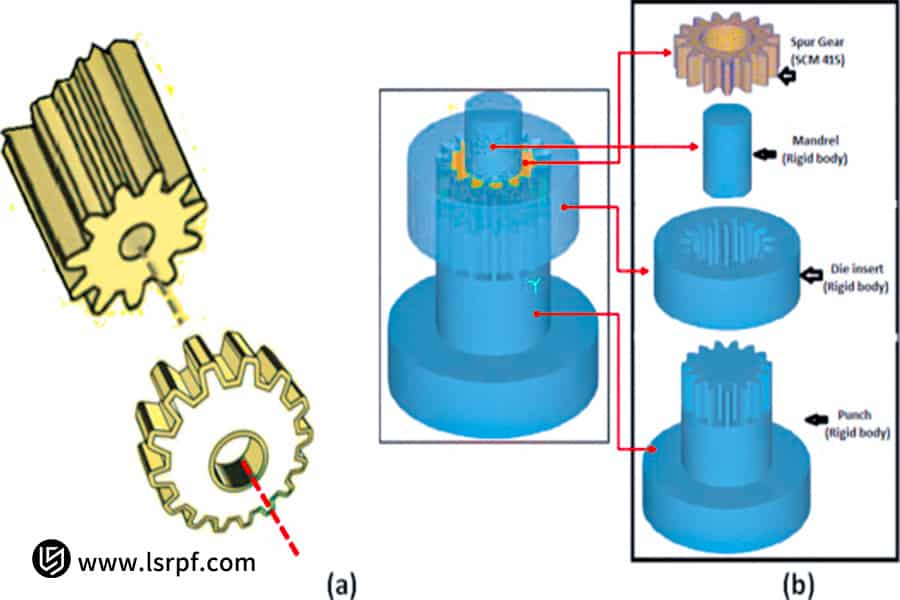

Figure 2: Gear manufacturing and precision craftsmanship by LS Manufacturing

What Does Heat Treatment Contribute Most To In The Life Of Gears?

In the manufacturing process of gears, heat treatment is an important step to put the soul into the gear. It decides directly whether the gear can resist fatigue, wear, and bear load in severe conditions, and it is at the core of the means of prolonging the life of gears.

- Improvement of gear surface wear resistance and contact fatigue strength: Carburization and quenching increase the surface hardness of gears, while largely improving the resistance of gears to wear. Good core toughness can effectively prevent pitting and spalling, thus extending the service life by great margins.

- Improvement of Anti-Seizing and Fatigue Resistance: Because of the lower nitriding treatment temperature and less deformation, a high-hardness and high-wear-resistant nitride layer is formed on the gear surface. It is especially suitable for high-speed and heavy-load gears with high requirements in terms of dimensional stability.

- LS Manufacturing's Unique Quality Control System: The manufacturing process of LS Manufacturing gear involves not only advanced processes but also an all-round quality monitoring system, from pre-treatment and precision furnace atmosphere control to post-tempering, ensuring that every batch of products has consistent and stable performance.

Excellent gear manufacturing does not just form and cut but relies on precise control over its inherent performance. Through scientific heat treatment and strict quality control, LS Manufacturing 's Gear Manufacturing instills in the gear long-lasting vitality, fundamentally ensuring the reliability of the transmission system.

Figure 3: Accuracy-critical forged gear components by LS Manufacturing

Why Is Gear Inspection More Important Than Manufacturing?

In precision gear manufacturing, inspection is not only the last checkpoint of quality verification but also the guide for quality through the whole manufacturing process. It guarantees the precise realization of the design intent and becomes even more important than manufacturing itself, since only through precise inspection is it possible to define a "qualified" gear. LS Manufacturing 's Gear Manufacturing has established a comprehensive precision inspection system covering the whole process.

| Inspection Category | Core Evaluation Dimensions | Core Inspection Equipment |

| Tooth Profile and Direction Accuracy | Meshing Smoothness, Noise and Vibration Control | Gear Measurement Center |

| Pitch and cumulative error | Accuracy of the motion, smoothness of transmission | Coordinate Measuring Machine (CMM) |

| Comprehensive Performance Verification | Fatigue Life, Load Capacity | Gear Comprehensive Inspection Instrument, Noise Test Bench |

Data-driven precision control is at the core of excellent gear manufacturing. A closed-loop quality system of "manufacturing-inspection-feedback" is implemented in LS Manufacturing 's Gear Manufacturing, where the real-time feedback of inspection data optimizes the processes. This will be the essential guarantee for our reliable commitment in precision gear manufacturing.

How Do The Efficiencies In Transmission Vary Between The Types Of Gear?

Gear selection is a very important and initial step in determining the efficiency, noise, and reliability during the manufacture of precision gears for a transmission system. Transmission efficiency can vary a lot by changing the tooth profile and meshing principle. Scientific selection provides the foundation for excellent gear manufacturing.

1. Helical Gears:

These teeth are at a certain angle to the axis, and the meshing process is progressive with high overlap, hence the transmission is smooth with low vibration and noise, and efficiency over 98% can be reached. However, in the helical gear transmission process, axial force is generated. Bearing selection and installation need to be highly precise. They thus become the most common choice in precision gear manufacturing for high-speed and heavy-load applications.

2. Bevel Gears:

Mainly, they are used for the transmission of power between intersecting shafts, for example, in automotive drive axles. Their efficiency of transmission is about 97%. Among them, curved bevel gears are applied to demanding applications because their meshing smoothness is higher and noise is lower than in the case of straight bevel gears.

3. Worm Gears:

A very high transmission ratio can be obtained with a single stage by spatially interlocking shafts, allowing smooth operation and self-locking in the case of reverse travel. Large sliding friction between tooth surfaces leads to lower efficiency, normally in the range of 70% - 90%, and has the tendency to overheating. They find application mainly in cases where high reduction ratios are required, and the efficiency is not critical.

By taking advantage of our deep expertise in the manufacturing of precision gears, we can assist you in selecting the most suitable kind of gear and transmission solutions to meet your demands for efficiency, noise, and space utilization.

Figure 4: Demonstration of industrial gear production by LS Manufacturing

Breakthrough In The Manufacturing Of Articulated Gears For Industrial Robots

Being the core component for power transmission in industrial robots, articulated gears directly determine the precision, stability, and reliability of the whole machine. The precision manufacturing of gears faces an extreme challenge in pursuit of high transmission accuracy, noise control, and long service life. The case here describes how our Gear Manufacturing provides a breakthrough solution for an industry-leading customer:

1. Customer Challenge:

A well-known industrial robot manufacturer encountered technical bottlenecks in the development of its new generation of products, including unstable transmission accuracy and excessive operating noise from articulated gears. This resulted in the robot's repeatability consistently failing to meet the design requirement of ±0.1mm, severely restricting its expansion in the high-precision application market.

2. LS Manufacturings' Solution:

We started from the source of materials, using customized alloy steel. Through digital simulation, we optimized the heat treatment process curve to ensure the best match between tooth surface hardness and core toughness. Finally, we used CNC forming grinding technology for precision machining, consistently improving the gear precision to the highest ISO 5 level.

3. Results and Value:

With this cooperation, the noise of robot joint transmission is significantly decreased by 8dB, making the working environment much quieter. Repeatability accuracy is improved consistently within ±0.05mm, far beyond expectations. Gear design life exceeds 10,000 hours, greatly enhancing the market competitiveness and user value of the equipment.

This case indicates that superior precision gear manufacturing is a deep synergy of material science, heat treatment processes, and precision machining technology. Our Gear Manufacturing, with its systematic solutions, successfully helped the client overcome technical bottlenecks and established its core advantages in the high-end equipment manufacturing field. If you would like to learn how this solution can be applied to your specific scenario. Contact our technical engineers for customized analysis.

How To Optimize Gear Manufacturing Costs While Ensuring Quality?

In the field of gear manufacturing, cost optimization doesn't mean simply cutting prices but achieving systematic efficiency improvement and waste elimination through value engineering methods while ensuring or even improving core quality. We are committed to helping clients achieve this goal in the following three aspects:

1. Process Path Optimization:

By precisely analyzing the final performance requirements of the gears, we match up the most economical and efficient combinations of processes. For instance, while meeting performance requirements, the process combination of "high speed hobbing + gear shaving" greatly reduces cost compared to the original complete process of gear grinding.

2. Batch Economy Planning:

We formulate optimal production batch and inventory strategies for our customers based on annual demand. Availing the economies of scale for gear manufacturing , better costs for raw material procurement and production scheduling are achieved, thereby realizing batch economy.

3. Improving Material Utilization:

Starting with blank design, near-net-shape technology is used to minimize machining allowance and optimize layout. Meanwhile, we classify the scraps and recycle them; through systematic improvement in gear material utilization, control the biggest cost items from their very source.

With deep process knowledge, large-scale production, and meticulous management of gear materials,LS Manufacturing 's Gear Manufacturing can offer its clients gear products that combine superior quality with optimal cost-effectiveness, achieving true value sharing.

How To Prevent Common Failure Modes In Gear Manufacturing?

In precision gear manufacturing, failure prevention is more vital than remediation post-failure. During this process, several failure analysis cases have been considered for integrating the prevention of major failure modes throughout the entire process, starting from design to manufacturing.

1. Pitting Prevention:

Pitting originates from tooth surface contact fatigue. Prevention requires ensuring sufficient tooth surface hardness in the design and selecting high-purity steel. In gear manufacturing, precisely controlling heat treatment processes such as carburizing and quenching to ensure the optimal balance between tooth surface hardness and core toughness can significantly improve resistance to pitting.

2. Tooth Breakage Prevention:

Tooth breakage is mostly due to overload or severe impact. In addition to the selection of appropriate gears for the avoidance of overload, strict control of material defects during manufacture and optimization of the tooth root transition fillet process to eliminate stress concentration ensure that the gear possesses good impact toughness.

3. Scuffing Prevention:

Scuffing occurs with high-speed, heavy-load conditions wherein the rupture of the oil film on the tooth surface takes place. Preventive measures include the use of extreme-pressure lubricants, friction reducing treatment such as phosphating or oxidation applied to the tooth surface, and selection of mating materials for each gear type that have excellent anti-scuffing characteristics.

Successful gear manufacturing requires deeply integrating the selection of the correct gear type, materials science, heat treatment, and surface treatment technologies to build a long-term durability mechanism for gears, so as to guarantee the reliability of the transmission system from its source.

Figure 5: Precision forged gear parts collection by LS Manufacturing

Why Do Leading Companies Choose LS As Their Gear Manufacturing Partner?

In the highly competitive global market, leading companies choose gear manufacturing partners based on their ability to provide system assurance-a combination of technological excellence and long-term reliability. The key advantages of us in the area of gear manufacturing are reflected along three dimensions.

- Advanced equipment guarantees exceptional precision: We have invested in a series of CNC gear machining centers and fully automated production lines in Germany and Switzerland. These have created a solid hardware foundation for precision gear manufacturing, guaranteeing that tooth profile accuracy and batch consistency meet the highest international standards.

- Deep process experience with complex issues: More than 20 years of industry focus has enabled us to gain rich process databases that can meet high load, low noise, long life, and complex requirements through proven customized solutions in different application scenarios.

- International quality system guarantees continuity in dependability: All our staff adhere to the quality management system IATF 16949 and integrate high standards in every process, from raw materials to finished products. This ensures that every product delivered from us will meet all the stringent requirements of the automotive industry.

The leading companies choose us as a strategic partner in precision gear manufacturing, not just as a supplier, supported with cutting-edge equipment, deep experience, and a rigorous system. We provide a solid foundation for our clients in product market competitiveness through our systematic gear manufacturing capability.

FAQs

1. What is the typical lead time for small-batch gear manufacturing?

The standard lead time from order confirmation to production completion for routine precision gear manufacturing projects is 2-4 weeks. We understand how urgent it is during development and prototyping stages, which is why we have prepared a fast-response channel. It prioritizes capacity allocation in order to ensure on-time delivery for small quantities and urgent orders.

2. What is the maximum gear size that can be processed?

The current sets of manufacturing equipment used in gear processing have a large processing scope and can produce stably with modules from 1 to 20, a maximum outer diameter of 800mm. This can meet most of the needs for gear processing, from micro-instruments to large industrial transmission devices.

3. Which materials are best suited for manufacturing high-load transmission gears?

In conditions of high load, the material for gears includes high-quality alloy steels such as 20CrMnTi and 42CrMo. After precision carburizing and quenching or tempering heat treatment, a high-hardness and high-wear-resistant surface and strong core can be obtained, which is very important for guaranteeing the load-bearing capacity and fatigue life of gears.

4. How to achieve consistency in mass production of gears?

In the mass production of precision gears, we adopt an IATF 16949 quality system. Core: It is the application of SPC statistical process control technology, and at the same time, an inspection model of "first-piece full inspection + manufacturing process inspection + last-piece confirmation" to systematically monitor key parameters and ensure high consistency and traceability of quality in all batches.

Summary

Precision gear manufacturing is the deep integration of materials, processes, and quality systems. We works with systematic solutions to transform expertise into reliability and competitive advantage for your transmission products.

Please submit your requirements now for a free personalized "Gear Manufacturing Solution Optimization Suggestion" from experts at LS Manufacturing. Click here to upload your requirements and get your personalized solution.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.