In advanced mechanical transmission systems, gears play an essential, central role. Their performance directly signifies the efficiency, reliability, and lifespan of the whole machine. But a minute design deviation, as the initial domino tipping, can trigger a chain reaction that leads to system failure, unscheduled shutdown, and even substantial financial losses.

The majority of engineers have the tendency to make design errors while customizing gears, for instance, choosing the wrong materials, incompatibility of heat treatment processes, or inappropriate tooth profile parameters. These small appearing oversights can create serious risks subsequently during production.

LS Manufacturing has a high value for this challenge. With our deep experience and creative analysis, we exercise leadership in the early design stage, finding and removing potential pitfalls at the outset. This ensures that every custom gear we deliver offers improved performance, longevity, and system compatibility, thereby ensuring your project's success. To save you time, here’s a quick overview of the core conclusions.

Custom Gear Design Miastakes Core Quick Guide

| Key Dimensions | Mistakes to Avoid | LS Manufacturing Solutions |

| Requirements Analysis | Leaving out real operating conditions causes improper overloading. | Close analysis of operating conditions ensures the design is best suited for the application. |

| Material Processing | Incongruent materials and heat treatments could lead to uncontrollable performance or cost. | Scientifically select materials and subject them to heat treatments to reduce cost and enhance performance. |

| Tooth Profile Parameters | Ideal parameters, theoretically speaking, but with stress concentrations. | Optimize tooth profile design to eliminate possible risk and prolong lifespan. |

| Manufacturing Feasibility | Excessive focus on tolerances or decoupling of manufacturing and design. | Recommend economic tolerances and provide support in design for manufacturability. |

| Partnership Model | Focus on price without regard to technical cooperation and long-term value. | Be a design partner, providing technical support and cooperation. |

Successful custom gears are the product of an integrated, visionary design process. That includes more than isolated drawings to thoroughly considering operating conditions, materials, processes, and manufacturing feasibility.

Choosing LS Manufacturing as your design partner eliminates risk at the source. With a solid combination of technology and experience, you can ensure gear reliability and minimize total project cost.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Every insight in this book is not theoretical; it is the result of several decades of hands-on experience at LS Manufacturing with gear manufacturing precision. We realize that true mastery lies in pre-emtpion and resolution of those "ghost problems" which never get onto paper.

For example, LS Manufacturing helped an industrial robot manufacturer to solve persistent noise with the gears in its primary RV reducer component. By using systematic root cause analysis, we determined that the root cause was not just tooth profile error, but the resonance between microscopic tooth surface topography and some lubrication conditions.

Rather than just exchanging materials, our team worked with the customer to redesign the profile and heat treatment parameters, and incorporated a special running-in process. Lastly, this solution was able to reduce gear operating noise by 85%, making their product outstanding in worldwide competition.

This is precisely the value of LS Manufacturing: we don't just provide gears, but system solutions which have been proved under aggressive operating conditions.

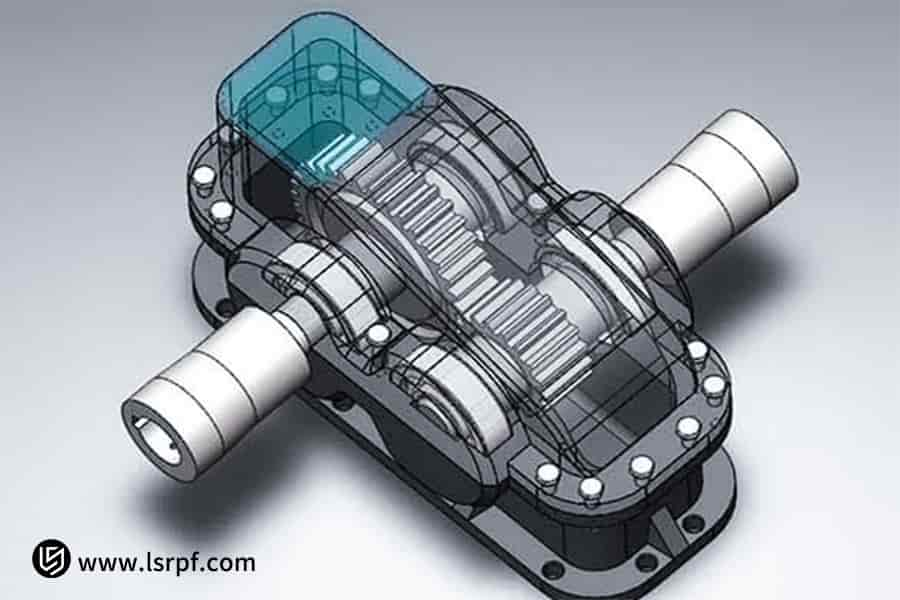

Figure 1: Gear design analysis and production optimization by LS Manufacturing experts

Why Can Gear Design Mistakes Lead To Catastrophic Consequences?

Even in a transmission system, a slight gear design flaw can have extremely drastic consequences far beyond the simple "unsmooth operation." Similar to the first domino that falls, it will trigger a chain reaction of catastrophes, which will end up costing the company much, much more than anticipated.

1. From Equipment Failure to Production Stalls:

Poor gear design will inevitably lead to abnormal noise, heavy wear, and even tooth fracture. Besides making the gearbox itself scrap, it will also lead to serious equipment shutdowns unpredictably, halting the entire production line and resulting in enormous direct losses in terms of output value.

2. From Repair Costs to Reputational Damage:

Emergency breakdowns mean expensive repairs and spares. More dangerously, however, is damage to your brand reputation. Poor reliability and late delivery will instantly destroy customer confidence and cause irreparable harm to your firm's reputation.

As custom gear manufacturing specialists, LS Manufacturing insists that optimal performance begins with collaborative design. Through close collaboration with you and our intervention early on, we actually avoid potential drawbacks, ensure the reliability and longevity of every gear, and in effect safeguard your production continuity and reputation.

Investing the time up front into the gear design process is the lowest-cost, highest-benefit action. This is the key to avoiding gear failure—smashing problems before they ever appear on the drawing board.

Mistake 1: Ignoring Operating Condition Analysis--Your Gear May Be Overloaded From the First Second

The first mistake made by the majority of engineers in designing special-purpose gear is over-reliance on theoretical calculations and ignoring actual operating conditions of the equipment. This may result in gears that are subjected to damage right from the first second of operation, with unforeseen overload conditions.

1. The Gap Between Theory and Practice:

Standard design formulas are usually developed at steady-state operation. Multiple start-ups, transient impact loading, and extended, uninterrupted operation in actual operating conditions, however, can induce stresses many times higher than theoretical. To ignore these conditions is to place a "time bomb" in your equipment which leads to directly pre-mature failures such as premature pitting and tooth fracture.

2. Accurate Analysis is the Cornerstone of Reliability:

A comprehensive gear design handbook emphasizes that good customization begins with meticulous observation of operating conditions. LS Manufacturing encourages you to collaborate with us to complete a full "Operating Conditions Questionnaire" before we ever start any project. We carefully analyze your equipment load spectrum, duty cycle, and ambient conditions and translate dynamic, complex, and real loads into precise design inputs.

Through this strict examination of the operating conditions, LS Manufacturing can select the optimal material and heat treatment process for your gear, which will give it the strength and durability necessary to withstand real conditions from day one, thereby eliminating the potential of poor design foundations.

Figure 2:Precision custom gear machining process for industrial applications

Mistake 2: Mismatching Material And Heat Treatment--The "Hidden Cost" You're Paying

In precision gearing, possessing the right materials is half the fight won. Much more crucial is possessing the right heat treatment process to go with them. This incompatibility is a costly "hidden cost" on most tailor-made gear production projects.

1. Double Loss of Performance and Cost:

Incorrect substitution of carburizing and quenching with quenching and tempering on heavily loaded gears will result in a compromise between surface hardness and core toughness, leading to failure by premature fracture or wear. Excessive use of state-of-the-art processing on lightly loaded gears entails cost for excess performance. Such abuse directly results in a significant reduction of gear life or unjustified cost increase.

2. Scientific Matching Achieves the Optimal Balance:

Maximizing deep understanding of material science, LS Manufacturing regards "materials and heat treatment" as an integrated whole. With every LS Manufacturing gear machining quote, we thoroughly calculate and weigh wear resistance, impact toughness, and cost economically based on your particular operating conditions to deliver the optimum combination.

Through this scientific collaborative approach, LS Manufacturing ensures all gear sets will be reliable for the design life at lowest cost of ownership, enabling you to translate unquantifiable "hidden costs" into quantifiable performance value.

Figure 3: High-quality metal gears manufacturing with advanced heat treatment technology

Mistake 3: Irrational Parameter Design--Theoretically Perfect Tooth Profiles Are The Culprit For Stress Concentration

In the production of precise gears, it is generally believed that there must be some theoretically ideal involute tooth form. But in real running conditions of deformations, heat increase, and application loads, this "ideal" tooth form is the original cause of edge contact, stress concentration, and overnoise.

1. Deviation between Theory and Reality:

A theoretic tooth profile, under fixed support, will be subject to minimal bending and torsional deformation under loading, and temperature rise will also change meshing clearance likewise. Accumulation of the above can prevent effective tooth contact at running-in, resulting in maximum force concentration near tooth tips, resulting in pitting and tooth fracture, and producing maniacal noise.

2. Active profile modification is key:

Industry standards for professional gear design specifically dictate that active profile correction methods should be used to counter these inevitable errors. The most valuable strength of LS Manufacturing is our ability to utilize advanced simulation software to pre-predict the gear deformation pattern in your particular operating environment and apply accurate micro-corrections to the tooth profile and tooth direction accordingly.

By this pre-emptive profile correction, LS Manufacturing is able to transfer severe stresses uniformly across the entire tooth surface with much greater gear load-carrying ability. This is then being made a guarantee of quieter smoother longer life, the ultimate in precision gear manufacturing value.

Mistake 4: Pursuing Extreme Tolerances? You May Be Paying The Price for "Overdesign."

There is a fallacy in precision gear manufacturing: the tighter tolerances and finer surface finish, the better the gear fit. This zeal for "extreme perfection" far too often leads to grossly disproportionate cost for grossly disproportionate "overdesign."

1. Unnecessary Costs and Potential Risks:

The cost of having equipment made to order goes up exponentially with every change of tolerance level. However, in most manufacturing uses, such as in this case, high tolerance is not required and will work to substantially increase cost of manufacture. Conversely, compromising on the finish of critical contact surfaces in cases of cost can straightaway lead to increased friction, excessive heat, and premature wear.

2. The Optimal Balance between Performance and Cost:

The underlying value of LS Manufacturing is to provide skilled economic advice under the realistic gear application conditions and operation levels. We do not specifically commit to the highest level of possible accuracy, but rather recommend the most economic balance of tolerance and finish for reliability and life consideration achievement.

With this actual-world engineering critique, LS Manufacturing helps you gain the perfect proportion of input and output in precision gear production so that a dollar is not wasted to make it better than it needs to be, wastefulness because of overdesign is eliminated, and a true win-win both in cost as well as performance is achieved.

Figure 4: Automotive gear applications and performance testing by LS Manufacturing

Mistake 5: The Disconnect Between Design And Manufacturing—The Distance From "Perfect Drawing" To "Manufacturing Disaster"

The most maddening example in precision gear manufacturing is an ideal concept in theory that cannot be economically produced because manufacturability is not remembered.

1. The Barrier Between Ideals and Reality:

A designer may design a better-performing tooth profile but one that is impossible with standard tooling, is extremely hard to install, or is impossible with practical grinding. Not only does this lead to inordinate production cost, but in trial production finds that neither accuracy to specification nor anticipated lifespan is achieved, grounding the project.

2. Ensuring Manufacturability from the Start:

Optimal custom gear manufacturing is closing the design-manufacturing gap. The largest strength of LS Manufacturing is the initial involvement of our engineers at the design for manufacturing (DFM) phase, critiquing the design from a manufacturing perspective. We examine toolability, machining process optimization potential, and testability to ensure that your design intent is effectively and efficiently converted into production.

Through this hybrid design and manufacturing collaboration model, not only can we avoid future production tragedies, but we can also streamline the manufacturing process, shorten the delivery cycle, and provide each gear you receive with improved performance as well as improved manufacturability.

LS Manufacturing: Overcoming The Persistent Problem Of Abnormal Noise In Industrial Robot Gears, Reducing Noise By 85%

One of the most prominent industrial robot producers in the world was beset by a foreboding problem: gears in its new-generation precision reducer were emitting unusual noises, causing product test failures and putting the project on hold. This is a photo of the solution to avoiding gear failure—the imperative to correctly determine the cause of the failure and present a systemic solution.

1. Customer Dilemma:

In product development, while testing its new generation of precision reducers, an industrial robot manufacturer experienced recurring abnormal noise and pitting in the gear assembly. Not only did this cause a single unit test to fail but also delayed product release by a month, creating massive team stress.

2. LS Manufacturing's Solution:

Faced with this issue, LS Manufacturing's engineering team executed a structured response:

- First, we re-checked material and heat treatment compatibility to ensure substrate performance.

- Most significantly, LS Manufacturing utilized the latest in simulation technology to enable precise tooth profile and tooth tip alteration, flawlessly compensating for microscopic gear deformation under service loads.

- Additionally, with our ultra-precision grinding method, we achieved a new level of tooth surface finish, effectively maximizing the meshing contact area.

3. Results and Value:

The precision gears made by LS Manufacturing that we provided directly solved the issue. Testing showed operating noise levels were reduced by over 85% compared to customer specifications, and life in fatigue far exceeded design. Not only was this a perfect application of gear failure prevention, but it also allowed the customer to bring a new product to market with success, positioning us as their premier, long-term strategic ally for precision gear manufacturing.

This example illustrates that actual precision gear production is so much more than just manufacturing, it is drawing; it is a deep understanding of the root causes of the issue and imposition of methodical engineering fixes.

Figure 5:Industrial metal gears production with quality control standards

Supplier Selection: Avoid These Four Traps More Deadly Than "Price"

When choosing a gear manufacturing supplier, prioritizing quotes alone can result in higher risks. The next four factors, more important than cost, can make or break your project as to whether it ends in a quality part or a set of issues.

| Evaluation Dimensions | Common Traps | LS Manufacturing's Guarantee |

| Technical Consulting Expertise | Only capable of manufacturing to drawings and do not have any design optimization recommendations to provide. | Providing comprehensive DFM analysis to reduce risk from the very beginning, we are your technical partner of preference. |

| Quality Control System | Rely on basic testing and cannot ensure batch consistency. | Providing comprehensive gear test center monitoring dimensions, accuracy, and material quality along the way throughout the manufacturing process. |

| DFM Experience | Manufacturing and design gap can lead to increased costs or delayed delivery. | Through our wealth of experience, we ensure that every design is economically and efficiently producible. |

| After-Sales and Support | Delivery results in an ending of the relationship with no one to address issues. | We provide after-sales and technical support services to ensure long-term stable supply chain relationship. |

Real cost-effectiveness comes from the ability of a supplier to create value for you throughout the total project life cycle. This complete range of capabilities underlies all LS Manufacturing gears.

Choosing LS Manufacturing is to choose not just a manufacturer, but a long-term collaborator committed to making your products more reliable and competitive.

How Can I Get A Gear Manufacturing Quote With Professional DFM Advice?

A quote request from LS Manufacturing Gears is more than a number; it's a priceless, free technical consultation time. Our quotations, as a gearing manufacturing supply expert, are inclusive of a comprehensive design for manufacturability analysis to help you make your plan more efficient and prevent potential risks ahead of production. To obtain the most accurate analysis and quote for your custom gear manufacturing project, please prepare the following important information:

- Detailed operating conditions: These are load, speed, operating conditions, and cycle times; they constitute the basis of design.

- Drawings or design intent: If you've got drawings, please submit them; if you have only a concept, our engineers can collaborate with you to develop the design.

- Material and life expectancy: Describe your material of choice and service life requirements, and we'll assess whether they are compatible.

With LS Manufacturing as your gears manufacturing supplier, you don't only receive transparent pricing but also a high-tech answer to improve product reliability and reduce overall cost. Contact us today to benefit from our technology-driven custom gear manufacturing solutions.

FAQs

1. What types of gears does LS Manufacturing manufacture?

LS Manufacturing has high-precision custom gears in a wide range of categories, including helical gears, bevel gears, worm gears, racks, and internal gears. With state-of-the-art processing facilities and test laboratories, we are able to provide reliable gear solutions for high-end applications such as industrial automation, robotics, and specialty vehicles. We can produce precision gears from module size 0.5 to 10.

2. How long does it typically take from inquiry to sample delivery?

Sample delivery is generally 2-4 weeks based on how process intense and complex the gear is. There is a fast prototype channel in LS Manufacturing for speeding up services for those projects with tight schedules to make sure we can meet your R&D schedule without compromising on quality. We also offer a detailed project schedule to keep you abreast of prototype manufacturing progress.

3. Do you provide technical support for gear design and modification?

LS Manufacturing not only provides gear design and redesigning, but such is embedded in a core value. Our experts will intervene early in the project. We provide a complete range of improvement solutions, from tooth profile optimization to material selection and heat treatment process, through expert Design, Measurement, and Functionality (DFM) analysis, positioning your design within the optimal balance among performance, cost, and manufacturability.

4. Are you able to accept small-batch custom gear orders?

LS Manufacturing values prototyping and small-batch orders as the foundation of long-term relationships. Whether you require R&D trials or small-batch runs, we offer versatile manufacturing solutions that guarantee the same level of quality and professional technical support as large orders. With this adaptive service model, you have your most trusted partner at every stage of your development.

Summary

Effective custom gear projects are the product of careful attention to design subtlety and intentional risk avoidance. By identifying and preventing the five commonly recognized design mistakes discussed in this article, you can not only thoroughly improve product reliability and life cycle, but also effectively streamline your project's overall cost of ownership. Being an LS Manufacturing customer is not just to locate a supplier; it's to locate a strategic partner that incorporates professional design consulting, precise manufacturing, and uncompromising quality control.

Don't let potential design flaws prevent your project from succeeding! Contact LS Manufacturing and send in your gear requirements or design plans to LS Manufacturing's skilled professionals today and get a free, professional Design, Function, and Function (DFM) analysis report including action-oriented suggestions and an accurate quote. Together, let's create a strong and dependable foundation for the success of your product, beginning with the first gear!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.