Industrial gears form unobtrusive, critical parts of power transmission systems at the heart of heavy manufacturing. Unforeseen failures, times of no production, and their early wear mean heavy losses in production, apart from the very expensive repairs. The key problem is barely that of one bad gear but rather of a fundamental mismatch between the type of gear and the requirements of an application, besides a lack of deep insight on the part of a manufacturer into extreme, continuous operational realities.

From a simple catalog to choosing and optimizing performance, this guide is underpinned by decades of experience in LS Manufacturing through a proven methodology. We explain through real cases how precision-engineered gear solutions avoid surprise downtime and ensure maximum energy efficiency. Learn how to correctly match the most robust and efficient industrial gears with your operational demands.

Industrial Gears: Quick Reference Complete Guide

| Module | Content |

| Root Cause | The problems are unplanned downtimes and too much expenditure. These occur because of inappropriate applications of the gears and gear quality. |

| Solution Framework |

The framework for selection and optimization is provided based on several decades of industrial experience. |

| Gear Types & Applications |

Each gear type-spur, helical, bevel, worm-has its own strengths for specific load/speed combinations. |

| Critical Selection Factors |

The key parameters are load, speed, duty cycle, and alignment in addition to the environmental operating conditions. |

| Material & Heat Treatment |

The type of material and selected procedure for heat treatment have a direct relationship with strength, resistance to wear, and the fatigue life of gears. |

| Design & Engineering | Geometry, tooth profile, and micro-geometry are designed with precision for smooth and effective power transmission. |

| Lubrication & Maintenance | Selection of the proper lubricant and timely, scheduled maintenance is the key to a long, reliable life. |

| Real World Case Study | A steel mill case that shows how a customized helical gear solution eliminated chronic failure and downtime. |

| Steps for the Implementation of Process | Need analysis, consultation with experts, prototyped/tested, installation along with a monitoring plan. |

This handbook reappraises gear failure as a systems-engineering problem: optimum reliability results from the close matching of gear type, design, and material to operational demands, in conjunction with precision engineering, improved material, and proactive maintenance. In this holistic approach, there is no downtime, the costs are reduced, and efficiency goes up to a maximum.

Why Trust This Guide? Practical experience From The Experts At LS Manufacturing

Why Trust This Guide? Its insight was born on the factory floor, not in a textbook. At LS Manufacturing, we've spent over a decade steeped in the gritty reality of industrial gear machining where failure is just not an option. The helical gears we fabricate for mining crushers endure relentless loads, and the planetary gear sets for wind turbines need to make it through decades of service. This application-specific experience underlies every recommendation you read here.

Our approach is to be one where recognized industry benchmarks are rigorously applied. We apply the latest state-of-the-art design and failure analysis methodologies published through Society of Manufacturing Engineers (SME) and align our manufacturing processes with the sustainability and best practices guidelines provided by the Environmental Protection Agency (EPA). This allows for the creation of solutions that will be engineered from the first sketch to the last quality control, for maximum durability and efficiency, considering responsible production.

These are not theoretical principles but well-settled ones. Building on the thousands of gear solutions we have provided to customers, we do know how to optimize a tooth profile for quiet operation in application, how to pick the best material and heat treatment for shock loads, and how to design for longevity in corrosive environments. The knowledge isn't theoretical; it's the same prescriptive expertise that lets our clients avoid downtime and achieve peak power transmission reliability.

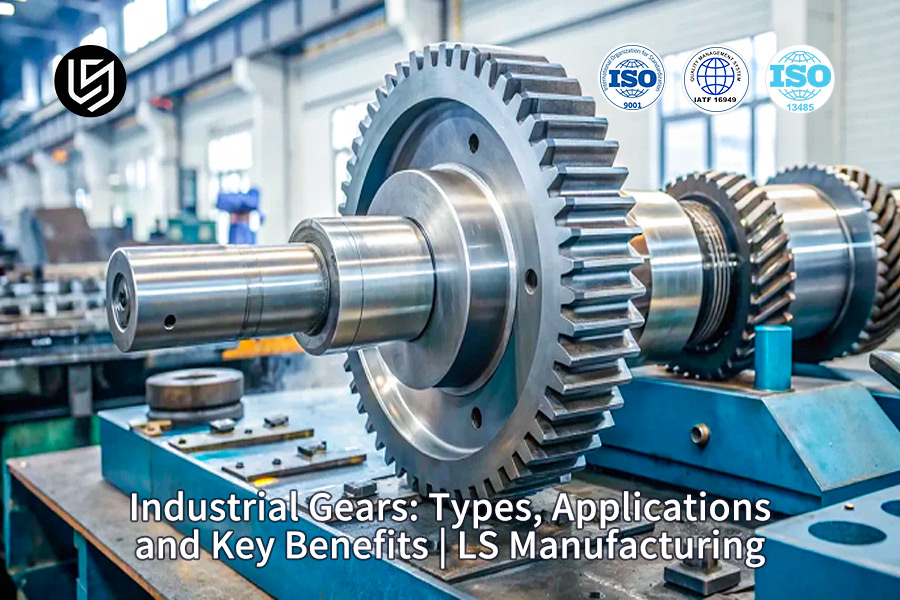

Figure1: Helical gear solutions, precision-machined for industrial applications by LS Manufacturing

Why Do Industrial Gears Act As The Core Cornerstone In Maintaining Reliability For Heavy Machinery?

Industrial gears are indispensable core cornerstones for ensuring the reliability of heavy machinery. Their role is not only to transmit power since, in fact, they become determining factors in the life of the general system, energy efficiency, safety of operations, a true embodiment of the saying that "to choose a gear means to choose the future of the equipment."

- Core Function in Power Integrity: Gears form the heart of the drivetrain in any industrial setup and allow for accurate torque transmission and motion control. It is enough to mention here that their functioning is vital for the work of heavy machinery under extreme load conditions and, therefore, their reliability absolutely cannot afford to be compromised.

- Divisive Influence on Life Span: Service life is directly related to manufacturing precision, strength of materials, and heat treatment of gears. Most often, a failure of gears creates a chain reaction to catastrophic consequences and much downtime; hence, it underlines the importance of gears as being at the core cornerstone in matters of durability.

- Critical Driver for Energy Efficiency: High-performance industrial gears hugely upgrade the energy economy of heavy machinery through reducing operational cost and environmental impact. These have high meshing efficiency as a result of the drive for energy efficiency, with less loss of power, apart from advanced gear design.

- Fundamental Guarantor of Safety: Gears resist not only shock loads, but also the continuous stresses which could lead to those kinds of major failures; hence, gears form the core cornerstone of systemic reliability and personnel safety.

Generally speaking, gears in any industrial setup form the core cornerstone for ensuring reliability, efficiency, and safety. The performance integration stipulates the destiny of operating equipment; hence, investment in quality gear will be one of the strategic and definitive choices for a secure and productive future.

How Spur Gears Differ From Helical Gears? Not About The Profile Of Teeth Only.

The most immediate difference is in tooth orientation: spur gears have teeth that are straight and parallel to the gear's axis, allowing sudden, full-face engagement. Helical gears have teeth cut at an angle so that contact is gradual and smooth, starting at one end of the tooth and progressing across its face. This key structural difference controls their key performance characteristics, particularly under load capacity and operational smoothness. A side-by-side review of their core attributes is presented in the table below:

| Feature | Spur Gear | Helical Gear |

| Tooth Design | Teeth are straight and parallel to axis of rotation. | Teeth are cut at an angle (helix) to gear axis. |

| Meshing & Noise | Sudden, full-face engagement promotes more vibration and higher operating noise. | Gradual, sliding engagement provides for smoother, quieter operation. |

| Load Capacity | Good for moderate loads, but the stress is concentrated across the full width of the tooth. | Higher load capacity since the teeth-being angled-will distribute the force more evenly across the face. |

| Efficiency & Thrust | Generally high efficiency with no axial thrust force generated. | Slightly lower efficiency due to sliding friction; generates axial thrust requires thrust bearings. |

| Application Areas | Suited to applications requiring average speed programs where simplicity, cost and efficiency are most important. | Optimum in high speed, heavy-load capacity, noiseless, smooth transmission applications. |

What this basically means is that in the choice between spur gears and helical gears, it is totally a matter of what one necessarily needs. While spur gears are brilliant in cheap, simple, and very efficient transmission at moderate speeds and loads, for the high-performance application scenario featuring high speeds, huge load capacity, and a critical need for smoothness and quiet operation, the better deal is helical gears despite their slightly higher level of complication and cost.

What Type Of Industrial Gears Will Deliver Absolutely Reliable Performance Against Harsh Working Conditions?

Selection of appropriate types of industrial gears is highly important in order to guarantee reliability for extreme working conditions. Harsh environments require more than a standard design solution, in order to bear such high thermal and abrasive mechanical stresses without failure.

| Gear Type | Core Advantage | Application in Harsh Environment |

| Bevel Gears | Power transmission at high efficiency across intersecting shaft angles. | Heavy impact loads in heavy-duty mining or steel mill equipment. |

| Worm Gears | High reduction ratios in compact, self-locking units. | Perfectly suited to very dusty or high-temperature applications - kiln drives, conveyors, etc. |

| LS Manufacturing | Utilizing advanced alloys and specialized hardening processes, | Ensures strong resistance to extreme wear, corrosion, and thermal fatigue. |

Mastering extreme working conditions necessitates the use of specific types of industrial gear such as bevel gears and worm gears, matched with advanced material innovations from partners like LS Manufacturing. Robust design matched by advanced engineering supplies uncompromising performance.

Figure 2: Heavy-duty steel spur gears engineered for power transmission systems by LS Manufacturing

5 Key Performance Indicators for Heavy Machinery Gear Selection

Designing the right gears for heavy machinery intended for extreme applications necessitates focusing on core performance indicators which are non-negotiable. These are the key metrics that directly define a gear's life, efficiency, and reliability under continuous operation in high-stress conditions. Given below are five such criteria to be assessed:

- Load Capacity: It is the maximum torque and force a gear can transmit without failing. It is a basic rating for any gears of heavy machinery and should always be higher than the peak of an application and also shock loads for safety in design.

- Precision Grade: The accuracy of the tooth profile and spacing defines the precision grade standards, which in turn defines the meshing smoothness, level of vibration, and efficiency. The higher the grade, the better quality power transmission is achievable with lower wear.

- Wear Resistance: This will determine the resistance of a gear toward degradation on its surface, caused by friction and abrasion. Good wear resistance prolongs service life, especially in surroundings where contamination occurs.

- Depth of Heat Treatment: A deep, even hardness case from processes such as carburizing provides resistance to surface fatigue (pitting) and tooth breakage. Depth and quality of hardened layer are critical for handling repeated, high-stress cycles.

- Noise and Vibration Control: Low operational noise means better precision in manufacturing, appropriate meshing, and good lubrication. The reduction of vibration reduces the stress on the whole drivetrain and consequently minimizes structural resonance.

In other words, overachievement in those performance indications-in particular-is what sets the pace in load capacity and precision grade. These are manufacturers, such as LS Manufacturing, which target specifications beyond standard benchmarks to ensure their gears for heavy machinery deliver uncompromised performance, plus a lower overall cost of ownership by extended durability.

How Do Customized Gears Address Unique Challenges That Standardized Products Cannot Meet?

Custom gears are engineered solutions for applications where standard products fall short. They address unique challenges that off-the-shelf options cannot, such as severe space constraints, specific torque-speed profiles, or corrosive operating conditions. The value of a true custom gear lies in its tailored engineering.

- Non-Standard Design: This key competence in customized gear manufacturing involves the design of special tooth profiles, modified geometries, or integrated assemblies to solve spatial limitations and realize unconventional motion transfer that is not available from standard catalogs.

- Specialized materials: Apart from standard alloys, special solutions may include the use of stainless steels, bronzes, or advanced polymers. This allows for immediate responses to special needs like resistance to extreme temperatures, operation in corrosive media, or the requirement for non-magnetic properties.

- Applied Coatings & Treatments: Surface improvements, including special platings, nitriding, or polymer coatings, are applied with the intention of increasing hardness, lowering friction, or offering a barrier to specific chemicals and abrasives.

Custom gears afford the ultimate flexibility to overcome unique challenges through intentional non-standard design, material science, and surface engineering. With deep application expertise, companies like LS Manufacturing employ such full-spectrum customization in performance optimization, reliability, and longevity where no standard product could ever serve.

Figure 3: Industrial-grade spur gear, engineered for precision and heavy-load applications by LS Manufacturing

Custom Mining Gearboxes: How LS Manufacturing Cuts Maintenance Costs by 30%?

The most critical problem to be solved by the largest mining equipmentcompany in the business was that the main ballmill gearbox, enduring severe shock loads, would fail every six months. Every failure caused an extended unplanned shutdown, extremely costly, with a big loss in production. These repeating failures underlined an urgent need for a gear solution that could last longer.

The Client Dilemma

Frequent, catastrophic gearbox failures occurring at six-month intervals generated unnecessarily high maintenance costs and substantial production disruption. Standard replacement parts could not cope with extreme impact loads of this application; therefore, an expensive operational cycle was generated.

The LS Manufacturing Solution

This was done on-site through a detailed analysis by our engineering team. The result was a customized gearbox solution with gears forged from special alloy steel, deep carburized, and hardened. Advanced simulation was conducted to optimize the tooth profile for stress distribution across and absorb shock impacts.

Results and Value

The new robust gearbox has concluded more than a 24-month on-site period in continuous operation without failure. This directly translated to improved performance for the client through a documented 30% reduction in annual maintenance costs and greatly increased yearly production output due to eliminated downtime.

This case study has shown how the application-specific approach by LS Manufacturing to gearbox customization targets and solves the root cause of failure directly. Besides being a product, it achieves a measurable reduction in total operating cost with a great boost in productivity while engineering a superior, longer-lasting component.

Tired of the same failures repeating on your industrial gear? Our engineering staff can design a High Durability solution to extend the life of your equipment.

What Is The Differential Value Of The Professional Equipment Makers Versus General Suppliers?

That creates a huge value difference in selecting a specialist gear manufacturer over a general supplier: the buying of just one simple component now converts into long-term reliability via a strategic partnership. The difference is not just in the product itself but in the wrap of wholeness regarding expertise around it.

- Technical Consultation vs. Transaction: Professional partner provides a priori engineering analysis to avoid the problems; Standard suppliers fulfill an order based on specification provided without diagnostic support.

- Material Science & Application: The supplier, like LS Manufacturing, will be selecting and preparing alloys for specific needs regarding stress, wear, and environmental conditions. A general supplier would have very few materials at hand and very limited applications knowledge.

- Philosophy of Quality Control: To a professional gear manufacturer, quality control means insistence on rigor in design, in machining and in heat treatment. The common supplier may well just do a final inspection, looking for conformance rather than optimizing performance.

- Proactive support includes lifeline value: through a real expert, advice will be given on failure analysis, field service, and predictive maintenance to maximize uptimes. On the standard supplier level, usually, the relationship ends with delivery, and support is confined to just basic warranty claims.

The core value difference is commodity purchasing versus investing in a solution. A partnership with a specialist gear manufacturer like LS Manufacturing automatically equates to access to an engineering resource that is committed, whose advanced quality control and support systems ensure best performance, lowest total cost of ownership, and unmatched operational security.

Do your Losses Of Efficiency Impact Gear Transmission? Is Your Machinery Not Giving You Its Full Potential?

The majority of gear transmission systems operate with a number of problems that often go unrecognized, silently draining productivity while inflating operating costs. Efficiency loss mostly reveals itself with subtle yet critical warning signs that ring an alarm for immediate attention and diagnosis of the problem. Normally, early identification of such warning signals can provide the first and perhaps most important step in preventing minor performance losses from growing into a catastrophically expensive system failure by protecting operational continuity and the bottom line.

Abnormal Vibration or Noise

Increased vibration or the variation in noises from gear meshing are early symptoms of misalignment and wear, with resultant damage to the driven gears and hence malfunctioning gear transmission. From the abnormal acoustic or kinetic signature, it goes without saying that parts have been deviated from ideal design parameters. This surely calls for thorough diagnosis so as to identify the exact cause-tooth pitting, inappropriate backlash, or failure of a bearing-so the root cause of efficiency loss is resolved before deterioration.

Rising Operating Temperature

Continued lubricant or housing temperature shows excessive friction caused by poor lubrication, overloading, or internal wear of components. The increment in temperature reflects a symptom of friction or increased internal resistance inside the gear transmission assembly. It is very critical to monitor such a trend because sustained higher temperatures lead to a rapid deterioration in lubricant and material fatigue, further accelerating their efficiency loss. A thermal problem diagnosis done precisely identifies the root cause-whether it is lack of lubrication, wrong viscosity, or mechanical overloading.

Unexplained Rise in Energy Consumption

This tends to indicate a gradual increase in power consumption for the same output from the system and is a sure sign that efficiency loss has taken place within the transmission-the drive has to work harder to overcome its growing internal resistance. Energy use is pretty directly measurable, which relates to increased costs of operations and reflects deteriorating conditions inside the gear transmission system.

A more formal problem diagnosis, in relation to power parameters, becomes important for quantifying efficiency loss and pinpointing those specific components-worn gears or failing seals, for example-accountable for the parasitic power drain. In other words, proactive monitoring of such signs becomes very important. What initially appeared like a minimal loss in efficiency can quickly grow into catastrophic proportions with larger failures, especially where those critical power transmission gears are concerned.

Normally, early and correct problem diagnosis of your gear transmission system is the best strategy to avoid costly downtime while minimizing energy waste and ensuring operational reliability over the long haul. With these parameters as guidelines, a scheduled inspection regime makes maintenance no longer just a reactive cost center but a very strategic function-one that preserves value throughout the entire operation.

Figure 4: A precision gear set combining stacked spur and helical gears by LS Manufacturing

What Is The Collaboration Process Of Gear Customization At LS Manufacturing From Consultation To Delivery?

At LS Manufacturing, we believe a successful gear customization project is defined by a transparent, professional partnership of collaboration. Structured collaboration at LS Manufacturing has been developed to take your specific requirements and mold them into reliably performing components, making sure clarity and confidence from initial concept to final installation are ensured.

Phase 1: Needs Analysis & Consultation

We start off our collaborative process at LS Manufacturing with deep discovery. Your team comes together with ours to understand the operating context, the performance targets, and specific challenges your application faces. It is essential to get this early dialogue right because that will finally determine what the engineering problem is.

This will make sure that the subsequent gear customization project will be driven not by some general specifications but purpose and performance needs. It is what forms the hallmark of a trusted, transparent partnership that defines working with LS Manufacturing. When everything is said and done, it is the explicit agreement over a crystal-clear vision of success at the beginning that aligns all stakeholders.

Stage 2: Technical Proposal & Quotation

Building on this knowledge, our engineering team will design a custom technical solution. This stage includes a detailed proposal spelling out the optimal geometry, material science, heat treatment protocol, and finishing processes for your application. After the outlined engagement, you get a precise quotation: the investment with all facets of the project scope and timeline clearly chalked out.

During this stage, the partnership between you and LS Manufacturing gets formalized in such a way that expectations become unequivocal between the parties for the gear customization job. Hence, it provides you with a specific road map as to what is going to be done without ambiguity.

Phase 3: Design Finalization & Approval

We provide detailed design documentation in extensive engineering drawings, CAD models, and performance simulations such as FEA for stress analysis, for your team's rigorous review. This is an iterative step since close technical collaboration may be involved to enable feedback and adjustments. We formally seek your approval for all design elements prior to any manufacturing. As such, the effort on gear customization, guided by experts from LS Manufacturing, meets all of the theoretical performance criteria.

Step 4: Precision Manufacturing & Quality Assurance

Your design enters our state-of-the-art production floor upon release and approval. State-of-the-art CNC machining, gear hobbing, and grinding - together with specialized thermal processes - give life to the design. At each milestone of manufacturing, our integrated quality assurance protocol calls for rigorous in-process inspections on CMMs, gear analyzers, and hardness testers. This proactive approach - a hallmark of LS Manufacturing - means every gear customization component is ensured to meet stringent specifications and quality standards before they progress through for reliability assurance.

Stage 5: Delivery & Ongoing Support

We carefully prepare the certified gears for tracked and secure delivery. We will consider protective packaging, and our commitment does not stop at shipment. More so, this provides for the supply of comprehensive documentation packs: inspection reports and material certifications that ensure technical support for successful integration into your system and supports the operational performance in the long run. The full circle of this comprehensive delivery and support phase completes the steps in the LS Manufacturing collaboration process and turns a project into a lasting partnership invested in enduring success for you.

All in all, our end-to-end collaboration process for gear customization is engineered for reliability. More than a part, a partnership with LS Manufacturing will bring to you a predictable and professional path from concept to on-site delivery, minimizing the risk and maximizing the value of your investment.

FAQs

1. What is the MOQ of gears at LS Manufacturing?

We are committed to providing maximum flexibility for our customers. That means LS Manufacturing supports anything from single-piece prototyping to mass production, where MOQ is flexibly determined based on specific process, material, and heat treatment requirements. With us, you work out just the right balance between project budget and needs.

2. What kind of lead time can I expect with custom gears?

Lead times are usually 4-8 weeks; actual time will depend on the complexity of the gear design and specifications and the quantity ordered. For urgent needs, we would evaluate and then optimize the production schedule to assure your project timeline and timely delivery, as in this case study.

3. How do you ensure that custom gears are precise and of quality?

We adopt advanced CNC equipment for precision machining and carry out 100% inspection by a coordinate measuring machine for every finished product to guarantee the quality control system throughout the whole process, so that the dimensions and geometric tolerances of each custom gear strictly conform to your drawings and technical specification.

4. Do you offer gears according to specific international standards, such as AGMA or ISO?

Of course, we routinely manufacture the LS Manufacturing gears to major international standards such as AGMA, ISO, DIN, and JIS, and also accommodate special enterprise standards of customers. We will provide full material reports, heat treatment records, and precision inspection certifications according to your requirements.

5. What type of measure do you take to protect intellectual property?

Our top priority is the protection of intellectual property for our clients. We consider client drawings and technical data to be trade secrets and are willing to sign legally binding confidentiality agreements prior to commencing any project in order to ensure your design has the highest level of security during collaboration.

6. Besides the gears themselves, does your company offer installation and technical support?

Yes, we have a set of comprehensive value-added services: detailed installation guidance, advice on preventive maintenance, and remote or on-site technical support and troubleshooting when needed to make sure you get full value from the product and a seamless operating experience.

7. How does your gearing price compare to the standard parts in the market?

Even though the initial unit price of customized gears is sometimes higher compared to stock parts, they can achieve significant service life prolongation, decrease failure rates, and less downtime loss by optimized design, selection of proper material, and precise manufacturing. Thus, it reduces the total cost of ownership for you throughout the whole collaborating process.

8. How to start a custom gear project?

What clients need to do to get a project started is submit basic requirements, drawings, or samples with the inquiry button or contact information. This will trigger an immediate response from our professional team within 24 hours with an initial technical analysis and transparent quotation, thus marking the formal start of an effective and professional cooperation process.

Summary

Industrial gear manufacturer LS Manufacturing uses its profound technical experience to make the choice of industrial gears a fully informed one because this will impact production efficiency and asset security directly. This article has demonstrated the features of the different types of gear and that through deep technical expertise and customization capability of LS Manufacturing, the most reliable and efficient gear solutions can be provided for the most demanding industrial applications.

Your equipment deserves the best drivetrain core. Feel free to contact the gear experts of LS Manufacturing today for a free first consultation on initial selection and a fast quote. Let us take care of your design or customization in the gear products to boost equipment performance while reducing the total cost of ownership.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.