Gear machining services are usually caught up in the impossibility triangle that involves quality, speed, and cost, resulting in time delays for projects as well as overestimation of project budgets. However, this problem is not just solved but avoided since we, at LS Manufacturing, surpass other manufacturers with solutions that enable one to work well with quality within the required speed without considering costs.

Our approach begins with early design intervention. Using our patented gear machining dynamics optimization approach and our expertise in lean production flows, we correct the underlying issues of outdated parameters and inefficient processing. This approach enabled over 200 of our customers to experience a cost reduction of 35% and a reduction in lead time up to 50%.

Gear Machining Services: Full-Text Quick Reference Table

| Section | Core Content (Abbreviated) |

| The Pain Point |

The impossible triangle in gear procurement: high quality, short lead time, low cost. Results in delays, budget overruns, and eroded profits. |

| Root Cause (Why) | Obsolete methods of suppliers, use of outdated process parameters for machining, lack of DFM, inflexible processes, inefficient, wasteful. |

| Our Solution (How) | The methodology utilized in LS Manufacturing that integrates early design engagement with gear machining dynamics optimization and streamlining of lean manufacturing principles. |

| Key Technology | It is a proprietary technology that optimizes the gear machining process from a dynamic point of view. |

| Documented Results | Results of more than 200 clients. Results include an average 35% reduction in total cost and up to 50% shortening of lead times. This breaks paradigm barriers. |

| Client Value | Transforms gear procurement from a bottleneck into a competitive advantage through predictable cost, guaranteed on-time delivery, and superior quality. |

We are going to take a look into what is most imperative in this business and that is getting speed, quality, and affordability while procuring gears. We specialize in process-optimized lean concepts to incorporate into gear designs; therefore, we have succeeded in including cost predictability, speed, and getting quality in what seems to be a difficult process of procuring for many clients.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Even now, there are many articles on theory floating around in cyberspace, but believe me, this bible has been won and lost in the real world. Our shop floor is where we, in theory, fight every day against the facts of production of gears with a high load. We are talking about optimal teeth shapes to exclude the noise, compensation for distortions, which occur in the process of heating, and then, finally, only how to take advantage of material properties.

We not only know how gear geometries work but also depend on that knowledge. A defective gear within an aerospace transmission can cause a failure of the system, a defective gear within a car differential can cause a problem with customer satisfaction with the vehicle performance, and a highly precise gear within a medical tool has to work flawlessly for a decade or more. All of our processing methods are validated by ASTM International material standards and traceable data as defined by the National Institute of Standards and Technology (NIST).

The lessons that have been learned, which will be acknowledged below, come after many years of satisfaction with over 50,000+ custom gears. Every project has been a learning experience on its own, with which we have learned the most crucial facts with regard to ideal hobbing of alloy steel, compensations possible prior to post-hardening distortions, and the trade-off between speeds and finish.

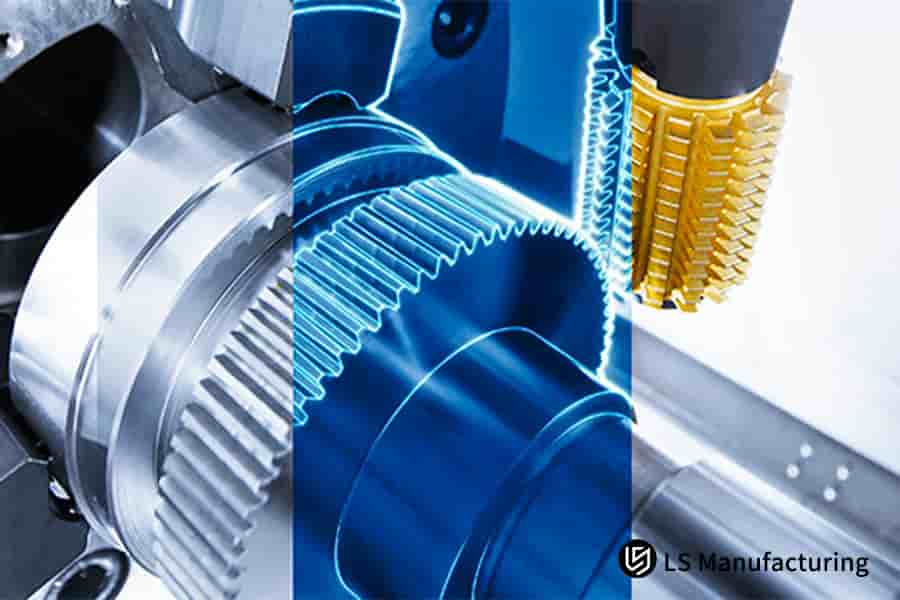

Figure 1: Precision gear shaping using lathe-based metal cutting methods by LS Manufacturing

Why Is It Difficult For Traditional Gear Machining Methods To Overcome The Bottlenecks Of Cost And Delivery Time?

The price equation of cost, quality, and time for traditional gear cutting services actually derives from inefficiencies in basic processes. Outmoded processes impose a hidden tax on productivity and quality. The solution to the bottleneck solution can be found in technical solutions for the three areas that are most important in this process:

Inefficient Toolpath Strategy Wastes Machine Time

The standard contour-parallel milling paths are straightforward but rather inefficient because idle time in the machining process accounts for up to 15% of the cycle time. Herein, we address the problem by using high-speed dynamic milling algorithms. This advanced machining technique will guarantee proper engagement of the cutter in machining to result in high metal removal rates. The result is a dramatically faster process that directly reduces gear machining cost per unit.

Poor Thermal Management Shortens Tool Life

The conventional type of coolant system is unable to control effectively the heating effect in the area of the cutting edge. The effect is more prominent in materials such as 20CrMnTi steel. The proposed system employs high-pressure through tools coolant systems. This precise thermal management, based on rigorous analysis, has extended tool life from 300 to over 800 pieces in documented cases, slashing tooling costs and downtime in high-volume gear manufacturing.

Lack of Standardized Process Libraries

Without the capability for a centralized database, every new or changed gear design involves a series of lengthy trial runs of machine and tooling setup. We solved this problem through the development of a proprietary cloud-based machining parameter database with pre-validated knowledge to immediately apply the best possible machining parameters based on a similar part design, thereby shortcutting engineering and setup times by more than 60%.

This report extends from pain points to detailing the exact engineering interventions that will contribute towards mitigating these challenges. It provides a benchmark related to engineering sophistication in terms of gear manufacturing partner assessment and with strong emphasis on process solutions rather than general competency.

What Is The Core Of LS Manufacturing's Gear Machining Methodology?

Traditionally, making gears lacks integration between key stages in design, consistency in the process, and quality control, as it reacts to problems rather than works proactively against them. Now, each of these flaws will be systematically removed by the integration of every process step seamlessly to maximum efficiency through three key pillars:

Collaborative Design Optimization (Proactive DFM)

- Early-Stage Value Engineering: Every quote is packaged with a full DFM report free of charge, suggesting value engineering ideas such as the utilization of radii instead of sharp corners for increasing the gear durability.

- Downstream Cost Reduction: This foresight-driven collaborations approach allows the avoidance of manufacturability issues, hence addressing the cost concerns related to heat treatment and finishing directly; this further encourages an ideal gear shape from the very beginning.

Data-Driven Machining Parameter Library

- Empirical Process Database: Our proprietary library stores proven cutting parameters (speed, feed, depth) indexed by material, hardness, and module, ensuring repeatable precisiongear and performance.

- Guaranteed Efficiency & Quality: For example, in finish milling of hardened steel gear, optimal results can be achieved in processing (S2200, F0.15, ap0.1mm) in terms of surface integrity and processing time.

End-to-End Lean Quality Management

- In-Process Metrology Integration: We utilize in-process probing with machines to check critical dimensions such as gear concentricity and profiles in real-time so as to enable tooling compensation.

- Prevention of Batch Defects: This is a closed-loop process of real feedback that prevents defects in the products at the point of manufacture, thereby eliminating costly defective products because the products are of the highest standard in terms of noise and vibrational levels.

This is the precision gear machining methodology that describes the steps we follow and how we can deliver predictability and reliability. It establishes our competitive edge in being the CNC gear machining company that focuses on solving problems in manufacturing, which makes us a gear manufacturing supplier such as LS Manufacturing.

Figure 2: Lathe-based production of gear components for mechanical systems by LS Manufacturing

How To Reduce Costs At The Source Through Forward-Looking Design Optimization (DFM)?

When cost effectiveness is achieved for custom gear machining during design, the objective of active gear design for manufacturability is to remove hidden production complexity. This section details our actionable DFM process, demonstrating how strategic modifications to part geometry, assembly logic, and material selection establish the foundation for cost-effective gear machining and optimal system performance.

| DFM Focus Area | Our Proactive Optimization Strategy & Measurable Outcome |

| Part Geometry & Complexity | The modular configuration of the gear housing prevented deep pocket milling. This reduced machining time by 20%. |

| Material Selection | The use of recommended leaded steel, 12L14 over conventional AISI 1045 steel, for high-volume pinion gears enabled easier machinability for the machined component, as this increased tool life by 35% for shorter cycle times. |

| Feature Standardization | In non-critical internal corners featuring sharp edges, the corners are aligned to the tooling radius to standardise the feature. This makes the process of cutting gears simpler. |

| Tolerance & Finishing | The rational discrimination between critical tooth flank tolerances and other non-functional surfaces allows a more effective loosening of specifications. Here, unnecessary grinding and inspection can be avoided. |

These examples from the industry show that cost savings and lead time savings are engineered and cannot be negotiated away. By including manufacturable gear design expertise upfront in the process, we are beginning to transform the initial design intention into the most optimal production possibility. By presenting a trustworthy and data-driven alternative solution option, our customers welcome a clean decision-making solution for investing. This in turn provides the foundations for successful outcomes and value addition in the complex production.

How Do Our Advanced Tooling Technology And Dynamics Optimizations Improve Efficiency?

The problem in realizing high productivity in precision gear machining of hardened alloys lies in the natural limits imposed on it by sources such as tool wear and surface quality. To meet this need, a complementary approach combining specific advanced gear cutting tools and a new process simulation method shall be utilized in the proposal to completely harness its advantage due to its major strength of high material removal rate and surface integrity.

Strategic Deployment of Advanced Cutting Tools

We utilize high-quality cutting tools like sandvik coromant coating carbide or mitsubishi CBN, depending on work materials. In cases of high strength materials such as 18CrNiMo7-6, their quality ensures sufficient wear and heat conductivity. This allows for significantly more aggressive initial cutting data, forming the foundation for efficient gear production and extended tool life compared to standard tooling.

Predictive Dynamics Simulation to Eliminate Chatter

Our proprietary solution foresees the complete gear milling process based on simulation results of interaction among cutting tools, components, and fixtures before any machining is done on a component. This further enables us to find areas where harmonics of vibration are located, which form regions where there is unstable spindle speed during machining, thus causing talk marks during machining, and we can pre-program around them.

Adaptive, Real-Time Parameter Optimization

The intelligence of the system is not only in planning but in cutting as well. The cut is essential in the use of micro-adjustments in the feed rate and spindle speed in the form of the full tooth entry point in the points of engagement defined. The micro-adjustments in the feed rate and spindle speed lead to effective chip control and elimination of vibrations, enabling milling in sizes 25-30% above previous specifications. This is the engine behind our fast gear machining services.

Quantified Results from Closed-Loop Validation

Our own internally developed test work has shown the efficacy of this approach conclusively. This is because, through a case study where the part in question was a gear made of Alloy Steel, it has been able to increase the material removal rate by 28% as well as improve the surface finish from Ra 1.2µm to Ra 0.7µm.

This is more of a technical note pertaining to certain actions that have been undertaken to remove basic bottlenecks of physical limitations that existed with conventional production techniques. It is important to highlight that our superiority with precision gear machining not only lies with cutting-edge technology but with the innovation of the cutting process itself.

Figure 3: Tailored gear fabrication for swift and cost-effective manufacturing by LS Manufacturing

How Does The Lean Manufacturing Process Reduce The Lead Time For Gear Manufacturing?

The lead times could be longer because of the underlying waste in the processes and not necessarily because of the machinations. Our Lean approach eliminates these wastes—longer setup, movements, and delays in information. This improves the overall gear manufacturing process and hence achieves a predictable quick workflow from the receipt of orders to shipment:

Setup Time Minimization via SMED

- Internal-to-External Conversion: We convert tasks of machine-downtime into prepared, external activities. In other words, setting tools is pre-set, and the standard components of the fixtures are prepared and completed outside.

- Outcome for Custom Batches: This has cut changeover time from 45 minutes to under 10 minutes on the 5-axis CNC machining centers, increasing flexibility in processing custom gear batches.

Cellular Layout for Continuous Material Flow

- Process Co-Location: The equipment is laid out in U-cells catering to gear families. This includes operations like turning, hobbing, as well as deburring.

- Reducing Transit Waste: This particular production system helps minimize the distance between components and also maintains low queues in stages, ensuring better component flow and minimizing WIP stocks.

Real-Time Transparency with MES Integration

- Live Progress Tracking: In terms of progress tracking, the manufacturing execution system has real-time monitoring systems in which all jobs are displayed along with their status. They are immediately informed of any stop in the gear finishing steps by the andon lights.

- Proactive Schedule Management: This tool enables the client to alter their schedules within a few seconds, ensuring accurate predictions about the capabilities of fast gear machining services.

Pull-Based Scheduling & Kitting

- Demand-Driven Initiation: This manufacturing takes place because of actual final demand observations, and hence it cannot enable any overproduction activities. This may be controlled in the form of kanban.

- Point-of-Use Preparation: This refers to a system in which all materials, equipment, as well as all procedures are pre-prepared and presented to the location of use prior to execution in order to avoid delays in search as well as to create continuity for quality control of equipment.

This is a detailed outline of specific principles regarding the lean gear manufacturing. This demonstrates the application of how optimized production workflow efficiency eradicates the problem of delay concerning gear production lead time. This also addresses why we can perform fast gear machining services effectively.

Figure 4: Close-up of metal chip formation during industrial gear processing by LS Manufacturing

LS Manufacturing Wind Power Industry: High-Speed Gearbox Gear Machining Project

There is a huge impact in the competitive wind industry regarding the issue of gear reliability and its influence on power efficiency. The study, within the context of the case study of the LS Manufacturing solution to the client who has a serious issue of reliability regarding supply chain, products, and related aspects of a wind turbine gearbox regarding noise and high-speed usage, will for this paper.

Client Challenge

The client had found field failures of the high-speed planetary gear sets manufactured from 42CrMo4 a number of times. Gear sets designed according to AGMA 12 were affected with noise levels of more than 85 dB and life of less than 18 months. Tooth profile variable due to conventional hobbing and case hardening had a lead time of 8 weeks, 40% over budget.

LS Manufacturing Solution

Our approach shifted to precision CNC form grinding to finish off the tooth geometry. For maximum load distribution, we used patented tip & root relief modifications with minimum excitation in the meshing. This was followed by a controlled nitriding treatment, where we controlled the nitriding potential with great care to obtain a consistent, compound-free white layer; a surface hardness value of HRC 58-62.

Results and Value

The end-state gear design realized a noise reduction requirement of 5dB with a projected service life increased bythree folds. Our integrated process control resulted in a 35% reduction in the cost of a unit with a lead time of only 4 weeks. Our customer realized an annual cost savings exceeding ¥2 million, faster implementation of projects, and greatly improved gear system reliability for end-users.

This case study demonstrates our ability to diagnose manufacture limitations for root causes and provide specialized data-validated processes. Quite simply, by providing measurable improvement in performance, cost, and lead time, we not only provide our clients with parts, but with engineering solutions to position them favorably in high-value industries.

Instantly unlock wind turbine gearbox performance and cost optimization. Access the complete technical path.

What Key Information Is Needed To Obtain A Quote For Precise Gear Machining?

This could be if your initial set of data is not comprehensive, which could result in unexpected expenses like gear machining cost in your future process downstream. The actual price quote in machining your gear indicates that the process of gear machining quote is not only complicated but also unmeasurable in terms of expenses only. The reasons mentioned earlier about your having your entire set of data assist in giving the best optimal production plan for your task because it not only guarantees your gear manufacturing price is taken care of and guaranteed but also allows us to provide you with these:

Complete Part Geometry via 3D Models

The foundation is a detailed 3D model (STEP/IGS). This allows our engineers to analyze the full gear design, including undercuts, fillets, and complex tooth root geometry, to plan optimal tool paths and fixture strategies. Missing or ambiguous 2D drawings lead to assumptions that cause costly revisions during production.

Material Specification and Heat Treatment Requirements

Substrate material, for example, 20CrMnTi, as well as surface hardness, for example, HRC 58–62, impact the entire process chain. This data is considered very important in determining the choice of gear cutting tools, as well as in the completion processes such as carburizing or nitriding, as it is one of the cost and life-defining factors for the generated parts.

Annual Volume and Critical Quality Characteristics

The annual number of products to be manufactured is the determining factor in choosing the least cost-effective method of production. Assuming a set of customized requirements such as the value of the tooth profile tolerance parameter for AGMA 12 or the value of the surface roughness parameter Ra 0.4, we can proceed to calculate a balanced approach towards quality control requirements and economic efficiency, depending on the annual number of products.

Tolerances and Post-Processing Specifications

Besides the geometry, there is the tolerancing of the critical dimensions, such as bore size and gear concentricity, and other secondary requirements if needed. This is to ensure that all the elements of the gear finishing steps, as well as the process of inspection as mentioned in the scope, are taken into account from the very beginning.

This data request represents the start of our collaboration in technology. From a simple inquiry about price to evaluating us on the combined feasibility of your request for us, you provide us with this data. This data allows us to provide you with a strong request a quote for gear machining with an established process in place and therefore allows us to provide predictability from day one on your project.

FAQs

1. What is the maximum module and size range of gears you can machine?

We have access to producing teeth on our gear machines. The modules for such teeth range from 0.5 to 20. The above is done with a maximum diameter of 2,000mm. The module will depend on what type of gear it is. We will have to take a look at a picture to make an accurate determination.

2. What is the typical production cycle for small-batch custom gears?

Prototyping or small series production in traditional materials takes only 2-3 weeks, this is the industry norm of 4-6 weeks.

3. How is gear quality maintained during mass production?

SPC (Statistical Process Control) is primarily utilized by us for observing critical sizes in real time. A coordinate measuring machine is also utilized by us for first piece, inspect piece, and finish piece testing.

4. What experience do you have in gear heat treatment?

We are actively cooperating with qualified partners for the area of heat treatment concerning carburizing, nitriding, and induction hardening. We also have the ability to solve overall issues in heat treatment for suppressing deformation and maintaining core toughness.

5. Can you provide gear modification services to optimize meshing performance?

Yes, skills in respect of CNC programming involve tooth direction and profile modification, crowning, and topological edge modification to reduce the noise level of transmission effectively and improve the loading capacity.

6. What are your common gear machining materials?

We can effectively machine carbon steels, alloy steels, stainless steels, cast irons, copper alloys as well as engineering plastics like POMs and nylons. We can even advise you on the most economic materials necessary for your operating conditions.

7. If I don't have detailed gear drawings, only concepts or samples, can you help?

Of course, our services involve reverse engineering and design optimization to manufacturing. If you provide some samples for us or explain your requirements, our professional engineers will be prepared to assist you with any stage with professional support.

8. What protection do you have for intellectual property?

We respect our clients' IP. Tight confidentiality agreements can be signed prior to beginning any projects and arrangements made for physical and digital segregation of your design and data.

Summary

Gear machining involves more complexity than Build-To-Order. The activity is engineered. Engineering knowledge combined with a set of philosophies distinct to LS Manufacturing can effectively counter the triple challenge of lowering costs, increasing quality, and reducing the cost of time delivery. The solution for all these factors is provided in manufacturing. The product is not delivered.

Does your project fall under gear sourcing? It is high time you altered your method of working and adopted an intelligent team-working environment. Currently, you just need to upload your designs of the parts and gears or get in contact with us that would provide you with a complete machined-gear package.

Get precision gear machining solutions now and break the impossible triangle of cost, quality, and delivery!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.