Metal 3D printing is revolutionizing the world of manufacture at a speed never experienced before, freeing design and engineers from traditional constraints. From high-performance aerospace components to individual medical devices to complex, weight-saving industrial equipment, accurate metal material selection is the door to unlocking these uses. This article fully addresses the top 3D printable metals like titanium alloys, aluminum alloys, stainless steel, high-temperature alloys, tool steels, and precious metals, their characteristic properties, appropriate processes, and primary areas of use, releasing the limitless potential of additive manufacture with metals.

Quick Reference: Choose Your Tap at a Glance

| Type of Metal | Principal Characteristics and Typical Uses |

| Titanium Alloy (Ti6Al4V) | High strength-to-weight ratio, good biocompatibility; aerospace structural components, high-performance vehicle components, and orth |

| Aluminum Alloy (AlSi10Mg, Scalmalloy) | High electrical and thermal conductivity, lightweight; vehicle parts, lightweight, drone chassis, spaceship panels. |

| Stainless Steel(316L, 17-4PH, 15-5PH ) | High corrosion resistance, excellent mechanical properties; food processing equipment, marine hardware parts, tool holders, medical devices, and industrial pipes and valves. |

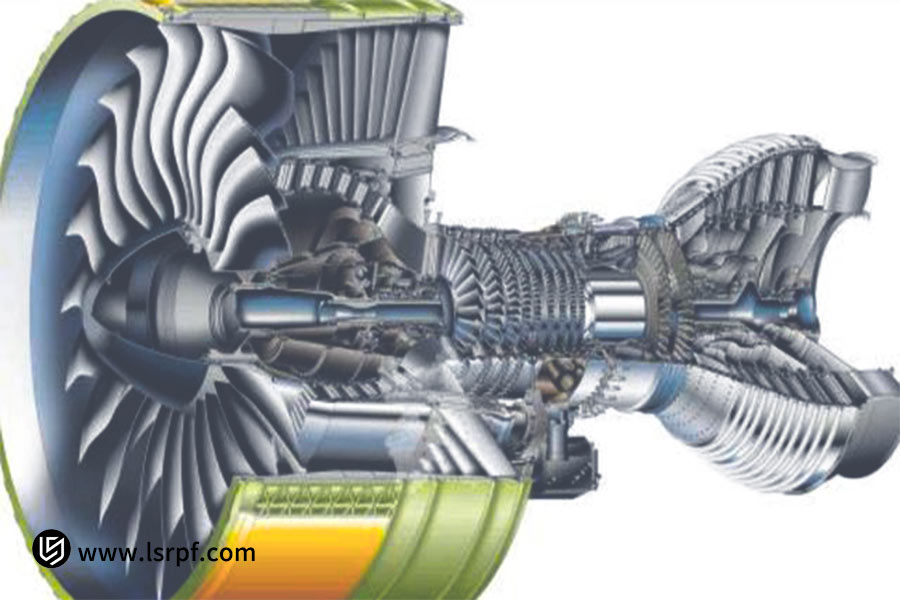

| Superalloy (Inconel 718/625, Hastelloy X) | High strength at elevated temperatures, oxidation resistance, and creep resistance; aircraft engine components (impellers of turbine blades), gas turbines, rocket engines, and high-temperature furnaces. |

| Tool steel (H13, Maraging Steel 300/350) | High hardness, high wear resistance, and high heat-treated strength; insert for an injection molding, die cast molds, cutting tool, and high-performance functionally |

| Precious metals (gold, silver, platinum) | High value, unique qualities (conductivity, bioinertness, catalytic activity); applications in jewelry, special electronic contacts, and special medical/research devices. |

| Copper alloys (pure copper, CuCrZr) | Excellent electrical and heat conductance; applied in heat sinks, heat exchangers, induction coils, motor windings, and conductive connectors. |

| Cobalt-chromium alloy (CoCr) | Superior wear resistance with high strength and good biocompatibility; application for dental restoratives (crowns/bridge) |

Why Trust This guide? Practical Experience From LS Experts

At LS, we not only comprehensively understand but resonate intimately with your agony of productizing high-tech ideas in repeatable metal parts––cost control, time issues, or even the exact boundaries of intricate geometries. Sympathy with your agony, we promise you complete metallic 3D printing solutions a long, long way from bare hardware. We also provide you with highly trained and seasoned professionals. Choose LS, and you opt for an experienced side that empathizes with your needs and is dedicated to taking you all the way through, from beginning to end, to streamlined processes and uncompromising quality.

Our expertise generates value for you:

1. We provide customized titanium alloy implants to medical clients within three days exactly and in time, effectively cutting down valuable patient waiting time, and saving lives.

2. With our customers in the aerospace industry, we worked together with them to miniaturize aluminum alloy component structure to unprecedented reductions of 40% and above, and offered total support along the way to help them successfully obtain stringent industry certifications.

3. In accordance with major customers' precision production requirements, we immediately and wonderfully fabricated stainless steel fixtures and cut shipment time exactly in half from standard processes and saved considerable dollars.

LS, with its professionalism and experience, offers total capability, allowing you to solve issues in manufacture and capitalize on our value proposition.

Titanium Alloy: The King of Lightweight, High-Strength

Detailed Introduction to Ti6Al4V (Grade 5 & 23) and Other Titanium Alloys

Ti6Al4V

It also known as TC4 titanium alloy, is a typical α+β titanium alloy. Its chemical composition primarily consists of: titanium (Ti) as the matrix; aluminum (Al) (6%) to enhance the alloy's strength and thermal stability; and vanadium (V) (4%) to improve plasticity and corrosion resistance. Ti6Al4V combines numerous advantages, including strength, toughness, heat and corrosion resistance, and low density. It is the world's most widely used titanium alloy, accounting for over 50% of global titanium alloy use. Simply put, it is harder than aluminum, lighter than steel, and more corrosion-resistant than stainless steel.

Grade 5 (Ti-6Al-4V)

Grade 5 (Ti-6Al-4V), the workhorse grade, is the most widely used workhorse titanium alloy because it offers the best combination of tensile strength (≥895 MPa), yield strength (≥830 MPa), and progressively high ductility (elongation ≥10%). Low-interstitial-content Grade 23 (Ti-6Al-4V ELI, Extra Low Interstitial) markedly enhances, without reducing high strength (tensile strength ≥828 MPa), fracture toughness and damage tolerance. It is particularly suited to safety-critical load-bearing structural components requiring maximum reliability, high resistance to multi-axial stresses, or low-temperature service, e.g., deep-sea oil well exploration risers, aeronautical parts, and joint prostheses.

Aside from Grade 5 and Grade 23 series, titanium alloy family further contains high strength and durability TC21 (with tensile strength of ≥1100 MPa), high temperature resistance TC11 (-capable of being utilized within 500°C), and commercial pure titanium TA1/Ti Grade 2 (-good corrosion resistance and formability, commonly seen in chemical engineering as well as general medical applications). The alloys all genuinely control content within constituent elements like Al, V, Ru, and interstellar elements (O, N, C, and Fe) in an effort to satisfy different and stringent service environments' needs for high strength, high toughness, high corrosion resistance, good Weldability, and high bio compatibility.

Features

High strength-to-weight ratio, high corrosion resistance, and good biocompatibility. Ti-6Al-4V titanium alloys provide the ideal balance of mechanical, corrosion, and physical properties.

High strength-to-weight ratio: Although its density is only 4.43 g/cm³, just 60% that of steel, titanium alloy specific strength equals, if not exceeds, that of high-strength alloy steels. Accordingly, titanium alloy components, subjected to a like load, exhibit an overwhelming 40% plus weight reduction. Its yield strength, usually 800-880 MPa, is such that the material exhibits, even at elevated stress, ductile deformation and is much less likely to fail through brittleness.

Good corrosion resistance: In aggressive mediums like hydrofluoric acid, acetic acid, and formic acid, an extremely quick passive titanium oxide thin layer adheres to its surface, which equips it with good corrosion resistance, thereby allowing it to be utilized in a chemical use as well as an aqua atmosphere.

Higher Biocompatibility: Titanium alloys, especially Grade 23 ELI, are non-sensitizing, non-toxic, and non-magnetic to human tissue. Titanium alloys' elastic modulus is very close to that of human bone, minimizing stress shielding considerably and causing better osseointegration. Wear resistance and bioactivity can be further enhanced through surface treatments (e.g., titanium nitride coatings), and hence it is favorable for artificial joints (hip and knee joint), bone plates, bone screw, dental implant, and advanced craniomaxillofacial implant. Customized titanium alloy prosthetic implant that was used during the world's first "3D-printed total cervical vertebral body replacement" was serviceable for eight years in that patient and went back to high-standard life, demonstrating its high level of biocompatibility and long serviceability.

Relevant Processes: Titanium alloys are more accurate and efficient in the case of 3D printing to allow for potentialities of designing customized components, for instance, SLM, EBM, and DED.

Applications: Because of their outstanding properties, titanium alloys have emerged as a flagship product in a range of high-performance applications, ranging from aerospace stents, engine parts, medical devices joint replacements, craniomaxillofacial implants, high-performance racing cars, to sports devices.

Stainless Steel: The Backbone of Corrosion Resistance and Industrial Applications

Detailed Description of 316L (Corrosion Resistant), 17-4PH / 15-5PH (Precipitation Hardening), 304L, 420, etc.

316L Stainless Steel

With 316L stainless steel being a molybdenum-bearing stainless steel, it is more resistant to corrosion compared to 304 stainless steel, and therefore it is a suitable material for equipment in pulp and paper manufacturing. 316 stainless steel also resists harsh industrial and marine atmospheres. 316L stainless steel also resists carbide precipitation longer than 316 stainless steel and is therefore qualified for high-temperature applications. As a low-C alloy of 316 steel, 316L carries the same attributes as 316 steel but with enhanced intergranular corrosion resistance. This is a specific requirement in 316 steel application where intergranular corrosion resistance is an important parameter. Among all the forms of stainless steel, 316L and 17-4PH are commonly considered to be the golden couple of 3D printing. Out of all these forms of stainless steel, 316L, with its better corrosion resistance and with enhanced biocompatibility, performs well in medical applications.

17-4PH / 15-5PH (Precipitation Hardening)

Stainless 15-5 is a martensitic stainless steel that is put to a variety of uses. It is perfect for use in projects where a degree of enhanced corrosion resistance and transverse performance is needed over that of other martensitics. Heat treat temperature can then be varied to shift the degree of strength and hardness needed for an individual project.

17-4PH is an alloy from a family of precipitation-hardening martensitic stainless steel alloys that exhibit high hardness and strength and moderate corrosion resistance up to 600°F. It enjoys useful fabricating qualities and may be age-hardenable via a single 900-1150°F anneal. This alloy has seen extensive service in oil field and petrochemical processing equipment, fittings, and hardware.

304L Stainless Steel

It is 304 alloy steel with low carbon content. 304L has low carbon, which reduces deleterious carbide precipitation during welding. For this reason, 304L "can be welded" in hostile corrosive environments without annealing. The grade's mechanical properties are slightly down from standard 304 grade but is commonly being utilized because of its versatility. As with 304 stainless steel, it is commonly being used in brewing and winemaking industry, but can be used to create non-food industry product applications, which include chemical storage containers, mining, and building. It is ideal to be used in metal components like nuts and bolts that are exposed to seawater.

304L enjoys stable demand that exists in non-application uses like prototype-making because of its cost competitiveness. 420 grade steel is a high-carbon martensitic stainless steel with 12% minimum chromium level. 420 grade steel, and stainless steel in general, can be hardened from its initial state by heat treating. 420 grade steel, after being in annealed form, is relatively ductile and is superb in corrosion resistance after polishing, after surface grinding, or after quenching. 420 grade steel is ideal for any type of precision machines, bearing-type uses, electrical devices, instruments, meters, vehicle transport, kitchen appliances, food service, and stainless steel medical devices.

Properties: Very high corrosion resistance, superior mechanical properties or can be heat treated to high strength, and relatively low cost.

Application Processes: Because of their high strength, corrosion resistance, heat treatability to high strength, and compatibility with mass popular metal 3D processes such as SLM, DED, and Binder Jetting, stainless steel is well known to 3D print metals.

Application: Chemical, food, marine industry pipe valves, medical devices, tool or mold pieces, architectural hardware, and general function pieces.

High-Temperature Alloys: Guardians of Extreme Environments

Extensive overview of nickel- and cobalt-base alloys such as Inconel 718, Inconel 625, Hastelloy X, and Haynes 282.

Inconel 718

It is a high-performance nickel alloy, which is basically utilized in corrosive and also in high-temperature environments. It provides high strength, high-temperature resistance, corrosion resistance, and highest order weldability and machinability. It has high nickel, chromium, iron, and other alloy content in its chemical composition, which provides severe heat and oxidation resistance.

Inconel 625

It is a nickel-base alloy containing nickel, chromium, and molybdenum and trace levels of titanium and aluminum. It demonstrates good corrosion resistance and high-temperature characteristics. It is adequate in properties for use in a range of hostile environments since it is strongly corrosion and oxidation resistant.

Hastelloy X is a molybdenum and chromium high-temperature alloy with a high iron content that is a solid solution-strengthened alloy.

Hastelloy X

It is oxidizing and corrosion resistant and has high creep strength and toughness even at high temperatures (e.g., below 900°C) and also in carburizing and nitriding atmospheres and in neutral as well as reducing atmospheres.

Haynes 282 alloy

It is a advanced Y-grade strengthening superalloy which was developed particularly for high-temperature structural service, especially for ground and turbine engine usage in aerospace. It offers an excellent balance of weldability, thermal stablity, creep strength, and machinability compared to commercial alloys.

Properties: outstanding high-temperature strength, high oxidation, creep, and corrosion resistance.

Applicable Process: SLM, EBM, with special expertise in DED

Applications: Aircraft engine applications, hot section gas turbine components (turbine blades, combustors), rocket engine components, nuclear power components, high-temperature furnaces.

Tool Steel and Die Steel: Wear-Resistant and Durable

Detailed Introduction: H13 (hot work), Maraging Steel 300/350 (age hardening), 18Ni300, M2 (high-speed steel), Toolox 33/44, etc.

H13

It is an alloy tool steel and a high-speed working steel and is applied mainly to high-temperature high-pressure dies, such as hot forged, aluminium alloy cast, and hot extrusion dies. H13 possesses high hot strength, red hardness, and toughness and superior thermal fatigue resistance and is thus a very good performer in service at high temperature.

Properties: Large hardness, large wear resistance, and large resistance to high temperatures (hot work steel); extremely high strength after heat treatment (maraging steel).

Maraging Steel 300/350 (age hardening)

Age-hardening, or Maraging Steel 300/350, is a high-strength steel consisting of a low-carbon, or free-carbon, martensite matrix that achieves hardness from precipitation of intermetallic compounds on aging. It does not, as does conventional high-strength steel, achieve hardness from carbon but from precipitation and dispersion of intermetallic compounds and, therefore, differs from conventional steel in several aspects. Characteristics include high strength, high toughness, low hardenability, good formability, easy to heat treat, no distortion during aging, and good weldability.

18Ni300

It is an alloy of the Maraging 300 series and has its composition and its qualities. Its major advantages are its minimum distortion when aged in low temperatures in an effort to achieve dimensional stability of accurate components; its cold working hardenability is low, which ensures that it is ideal for complex stamping and forming. Its applications are in missile shells, high-output racing car connecting rods, and precision casting shot molds.

M2 (high-speed steel)

It is high-speed tool steel on molybdenum foundation, an alloy of mostly carbon, molybdenum, tungsten, chromium, and vanadium. High resistance to wear, shock, and high temperature (retaining qualities to 600°C) exists in this steel, which can be utilized in cutting tool, mold, and high strength component manufacture. High distribution uniformity of carbide and high tough property characterize this steel, which is however, however, inclined to overheating and necessitates strict control of heat treating parameter. Addition of cerium, an ultimate rare earth, fine grain refines size of carbide, reduces alloy segregation, and enriches high temperature capability and processability.

Toolox 33/444

Toolox 33/44, which is a revolutionary steel that's heat treatable, is pre-hardened to HRC 33 (Toolox 33) and HRC 44 (Toolox 44) in the mill, which eliminates cost and cycle time for heat treating. High machining effectiveness, high direct cutting speeds, which are faster, and good EDM performance and polishing, reducing polishing time one third exist in this steel, which has high machining effectiveness. Compatible surface treatments further optimize wear resistance. In large size, it is commonly useful in injection molds, car stamping dies, and robots fixtures, reducing lead time.

Applicable processes: SLM, EBM, with particular strength in DED.

Applications: Injection/die casting mold inserts, particularly those with conformal cooling channels, stamping/forming dies, cutting tools, and wear resistance parts.

Precious Metals and Specialty Alloys: Meeting Unique Needs

Gold, Silver, and Platinum

They are the precious metals for meeting unique needs in 3D priting.

Jewelry: Jewelry must be chemically inert at standard room temperature and pressure and corrosion-proof against major constituents of water and air. Chemical stability is excellent in gold. Silver is whitish-silver in metallic look, is easily obtainable, and is cheap and has emerged as the favourite choice for jewelry. Platinum, which is white gold, is whitish-silver in metallic look, is highly ductile, and is corrosion-proof against corrosive strong acids and strong alkalis and has an extremely high melting point.

Special electronic contacts: In electronic microcontacts, gold resists arc erosion; silver resists inhibition of electromigration; and platinum resists oxidation from high temperatures. Such noble metals, likewise, are being utilized in aerospace relay contacts and platinum superconductor connectors in nuclear magnetic resonance imaging machines.

Biomedical devices for research: Implanted sensors (gold), platinum anticancer drug release devices, and antibacterial silver surfaces.

Copper alloys (pure copper, CuCrZr)

Highly conductive to electricity and heat, and are utilized in motor parts, heat sinks, heat exchangers, and in induction coils. Cobalt-chromium alloy (CoCrMo) is extremely resistant to wear as well as extremely biocompatible, and is being utilized in dental restorities as well as certain orthopaedic implants.

Appropriate processes: SLM (special parameters required), BJ (valuable metals), and DED (copper).

FQAs

1. Will be the strength of 3D printed metallic components similar to forged components?

Yes. Proper post-treatment optimalization of processes, e.g., by heat treatment, can make the resulting metal parts produced by processes like SLM or EBM, e.g., strength and fatigue attain and even exceed that of the traditional forged part analogs.

2. Can you replace conventional manufacture (e.g., casting and CNC) completely with metallic 3D printing?

Not yet, it can't. It's better for complex shape, customization for short production, and challenging-to-machine alloys. Mass production of mundane parts, however, is less costly and quicker with conventional methods, and both processes are complementary.

3. Does 3D printed metal need post-processing?

Yes, with extremely rare exceptions, all metal 3D printed components require post-processing. Common processes associated with 3D printing of metals are support structure removal, relieving of stresses, heat treating, surface finishing (machining, polishing, sandblasting), and HIP (with an intent to improve density and eliminate pores).

4. Is metal 3D printing costlier due to its material cost?

Its cost is usually significantly higher than that of bar or block metal that it would be manufactured from. It adds a non-negligible amount to the cost of a metal 3D print, though its overall value for money needs to be assessed as a package together with its freedom of design and its material-saving role.

Summary

Metal 3D printing materials library continues to grow exponentially, from conventional titanium alloys, aluminum alloys, stainless steel, and high-temperature alloys, through rare tool steels, noble metals, to copper alloys. Each of them provides, in an individual combination, a selection of properties like strength, lightweighting, high-temperature capability, corrosion resistance, electrical conductivity, thermal capability, and biocompatibility for specified high-tech applications. Breakthrough technologies enable processing said materials, efficiently, into highly complex geometry impossible through conventional processes, changing design, prototype, and make high-performance components.

When breakthrough design constraint is your issue, lightness, lead time reduction, or machining hard-to-cut material is your challenge, your metal 3D printing and material selection are solution powerhouses. Deep understanding of your materials' properties and applications is your key to unlocking this paradigm-shifting technology for creating and differentiating. Selecting the right metal opens us up to an infinite additive manufacture capability!

In the face of these higher challenges, LS's 3D priting service is your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized. Choosing LS is to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instant 3D priting quote (3D priting price), let LS be your strong backing in pursuit of ultimate priting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com