3D printing technology evolved rapidly from its grayscale prototyping origin to an essential full-color, functional, and personalized fabrication process. Its evolution not only transformed design verification and coordination work between teams, but also significantly amplified the manufacturing capability of finished products.

Today, multi-color 3D printing, with its beautiful visual appeal and structural accuracy, is unleashing enormous potential in medical models, teaching materials, cultural creativity, and consumer goods, offering new solutions to meet the challenges of personalization and high performance.

As an innovator in high-precision additive manufacturing, LS Precision Manufacturing has gained profound practical experience in multi-color 3D printing and is committed to the research and development of multi-color, multi-material integrated molding technology. Leaning on its deep technical experience and project background, this manual hopes to provide readers with rich and reliable color 3D printing knowledge and practical experience. To save you time, here’s a quick overview of the core conclusions.

Multi-Color 3D Printing Technology Quick Reference

| Technology Type | Color Implementation Principles | Precision and Strength | Cross-Industry Applications |

| Material Jetting (MJ) | Similar to industrial inkjet printing, simultaneously ejecting microdroplets of CMYKW photosensitive resins and curing them with UV light. | High precision (layer thickness 16μm), medium strength, similar to engineering plastics. | Suitable for medical (anatomical models), creative arts (high-fidelity prototypes), and consumer electronics (appearance verification). |

| Binder Jetting (BJ) | Spray a colored binder onto a powder bed, bonding the powder layer by layer. | High precision with a grainy surface; low strength and brittleness, requiring adhesive reinforcement. | Suitable for education (teaching aids), creative arts (portraits, artwork), and architecture (sandbox models). |

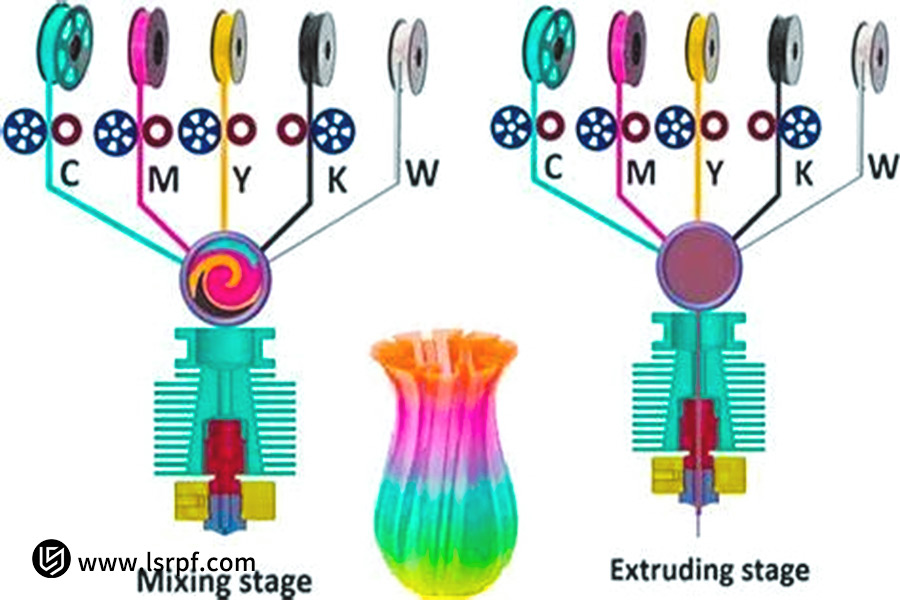

| Multi-color FDM/FFF | Use multiple extruders to switch or blend different colored thermoplastic filaments. | Average precision with visible layer marks; high strength, depending on the selected filament properties. | Suitable for industry (functional prototypes), education (low-cost models), and DIY (customized parts). |

| Multi-color SLS | Use pre-dyed nylon powder and laser sintering to create the desired color. | High precision with a slightly rough surface; extremely strong, fully dense functional parts. | Manufacturing (high-strength functional parts), Automotive (lightweight components) (Note: Full-color options are limited) |

LS Precision Manufacturing sets high-precision multi-color printing technology in Binder Jetting with precision perfectly combined with full-color capability and production efficiency. It allows consumers from sectors such as cultural and creative industries, health, and education to possess mature solutions with visual and practical merit.

Why Trust This Guide? — Practical Experience From LS Experts

The credibility of this guide rests in the over 20 years of real-world experience in additive manufacturing by LS Precision Manufacturing. As a renowned industry supplier of color 3D printing technology, LS Precision have built a comprehensive portfolio of industrial-grade machines, from high-end products such as the HP Multi Jet Fusion full-color print system and the 3D Systems Color Jet Pro series. We have completed thousands of successful cases for medical, automotive, cultural and creative industries, and consumer electronics industry customers.

The technical staff of LS Precision not only master the operation of equipment but also can provide professional suggestions from product design stage, full-process technical services from structure optimization, material selection, color management, to post-treatment. Every practical tip and technical explanation in this manual is born out of our day-to-day experience working on real projects, so you can be certain that you're receiving production-proven solutions.

By choosing LS Precision, you're choosing an experienced partner capable of helping you communicate your creative ideas into quality, full-color products reliably.

How Does Multi-Color 3D Printing Achieve Millions Of Colors?

To observe how multi-color 3D printing can generate millions of colors, we must begin by analyzing the technical principles of multi-color 3D printing and the color developing mechanisms of common technologies, thereby clarifying its fundamental differences with traditional post-dyeing methods.

1. Principles of Color 3D Printing Technologies:

Main multi-color 3D printing technologies essentially employ the following two principles:

- FFF/FDM principle: The process of printing various colors of thermoplastic material in molten form in layers, which are stacked layer by layer and thus a colored object is created.

- Multi-nozzle principle: There are several nozzles in 3D printing equipment, and different nozzles dispense different colors of hot-melt ink or pigment, and the model is colored layer by layer when the printing is going on.

2. Color Development Mechanisms of Color 3D Printing Technology:

Multi-color 3D printing technology achieves a million-color look, primarily deriving from the color creation mechanisms of the two dominant technologies: binder jetting and material jetting. It is radically different from 3D printing and painting afterward. The latter is surface-adhering, while the former is voxel (3D pixel) color interpolation into the model with a smooth, gorgeous color gradation from inside to outside.

- Binder jetting: A printer initially lays down a layer of white base powder (plaster or nylon, for instance). Subsequently, using a nozzle identical to the one used in normal 2D printing, a colored liquid binder (typically CMYK) is selectively dropped onto the respective powder cross-sections. The color and adhesion build up to create a completed, full-color model layer by layer. Each powder layer is essentially a canvas, yielding a solid, if somewhat grainy, finish.

- Material jetting: It is even more precise. It sprays millions of tiny droplets of photosensitive resin, pre-mixed CMYK (with white and clear), onto the print stage and immediately cured with UV light. By tightly regulating the ratio of resin color per pixel, it is able to mix the target color on a single voxel level, with very smooth surfaces and highly colored details, including fine texture and transparency simulation.

LS Precision 3D printing technology embraces these new process concepts in full. Based on industrial-strength hardware and state-of-the-art color management and material science, we offer exceptional color accuracy from digital model to physical part.

What Are The Advantages And Disadvantages Of Different Multi-Color 3D Printing Technologies?

When selecting a multi-color 3D printing technology, one should consider the features of various technologies against the requirements of the project. All the well-known technologies have distinct features, with great variation in color ability, strength, surface finish, and price.

1. Material jetting technology:

Material Jetting technology jets colored resins from several nozzles at one time, offering the maximum surface detail and color fidelity, with a possibility of millions of colors. The product strength is moderate, however, and the equipment cost and cost of material are relatively high.

2. Binder jetting technology:

Binder Jetting technology utilizes colored binder to cure powder material and the color is precisely replicated. It is very useful for producing medium- to large-sized full-color models at relatively low cost, even though the final product is weaker and less grainy.

3. Multi-color FDM technology:

Multi-Color FDM technology implies color printing through multi-nozzle switching or blended color extrusion. It is economical and material strength is high and therefore applied for functional prototypes. It is low on color accuracy and surface finish, and layering can be seen.

4. Multi-color SLS technology:

Multi-Color SLS technology is pre-dyed nylon powder-based and is able to print functional parts with good strength, but it has relatively low color gamut and medium cost.

5. Technology selection guide:

A proper choice of a multi-color 3D printing technology requires adequate research of project needs and quality requirements:

- For the definitive color and detail enthusiasts: Material Jetting technology is best suited, particularly for medical models and high-accuracy display prototypes.

- For a compromise between color and affordability: Binder Jetting technology offers the most cost-effective color and is suitable for educational models and cultural and creative products.

- Prioritized function and strength: Multicolor FDM and SLS technologies are preferable for functional prototype and heavy-duty components, with SLS being preferable for complex structures.

- Requirement for small-series production: Binder Jetting is most suitable for mass production, while Material Jetting is most suitable for a single piece of high value.

The LS color 3D printing technology platform is a culmination of several advanced processes to provide you with the most advanced technology solution for your specific application.

To What Accuracies And Strengths Can Color-Printed Parts Be Produced?

The characteristics of 3D-printed multi-color parts are technology-dependent, but dimensional precision, resolution of detail, and mechanical integrity can handle a wide range of requirements, from display models to finished-use parts. The following present comparative facts for market-leading technologies:

| Technology Type | Dimensional Accuracy | Layer Thickness | Resolution Tensile | Strength (MPa) Features |

| Material Jetting | ±0.1% or ±0.2 mm | 16 microns | 50-60 (ABS-like) | Smooth finish and good detail, but comparatively brittle material |

| Binder Jetting | ±0.5 mm | 0.1 mm | 14.2 (gypsum-based, before adhesive bonding) to 26.4 (after-adhesive bonding) | Good color, but self-brittle parts, with subsequent process adhesive bonding required for part strengthening |

| Multi-color FDM/FFF | ±0.5% or ±0.2 mm | 0.1-0.3 mm | 50-72 (PLA) | High strength, but there are visible layer lines, poor color and surface finish accuracy |

| Multi-color SLS | ±0.3% or ±0.3 mm | 0.08-0.15 mm | 40-48 (nylon) | Excellent isotropic and strength properties, yet still color saturation limited. |

The data in the table indicates:

- Precision: Material Jetting is presently leading in terms of precision with its excellent very high resolution and good dimensional accuracy. Its resolution of layer thickness can be up to 16 microns, which supports very small details.

- Strength: Mechanically, multi-color FDM and multicolor SLS technologies, being based on thermoplastics (such as PLA or nylon), have superior mechanical properties and are more capable of producing functional multi-color 3D printed parts. Parts produced using Binder Jetting are brittle in nature and require post-processing such as adhesive bonding (such as ColorBond or StrengMax) to significantly enhance their strength.

The color character of parts manufactured by 3D printing is now equivalent to or even better than the majority of traditional single-coloring methods, particularly the printing of small details at the expense of no color adhesion compromises. Their resilience, however, is heavily technology and post-processing dependent.

Which Industries Are Best Suited For Multi-Color 3D Printing?

Multi-color 3D printing technology, with its unprecedented full-color expressiveness and prototyping speed, is revolutionizing many industries, providing an impeccable solution for complex color models with challenge in achievement via traditional manufacturing processes.

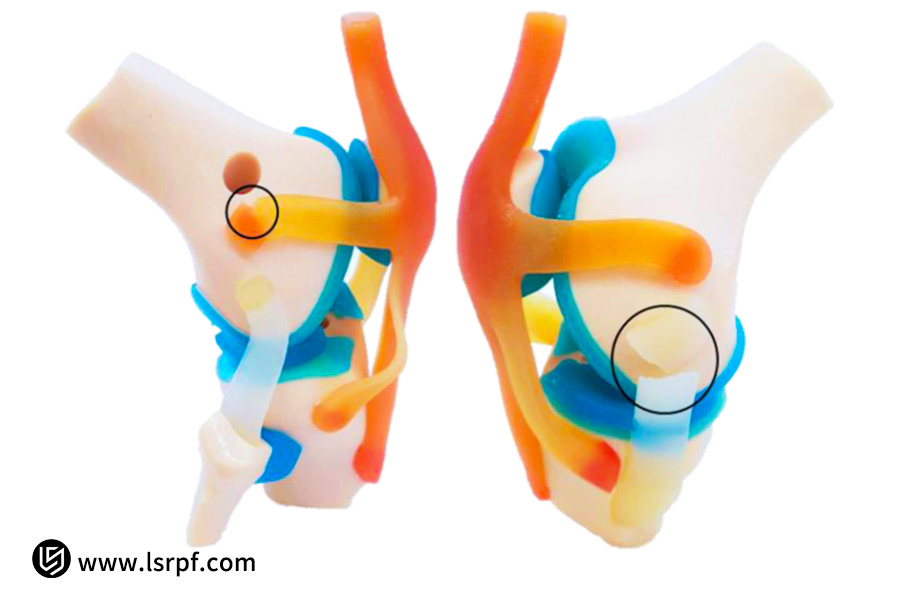

1. Medical industry:

The most apparent application area is in the medical industry. Color-printed anatomical models contrast nerves, blood vessels, muscles, and tissues, providing the best intuitive tools for planning surgery, medical education, and patient communication, enhancing medical accuracy and communications effectiveness immensely.

2. Architecture and urban design:

Architecture and urban planning have also been greatly enhanced. Architects make use of full-color 3D printing capability to develop lovely sand tables and planning models that display different functional zones, landscape features, and even lighting levels in a graphical manner, thus rendering their designs far more expressive and authentic.

3. Product design and manufacturing:

In manufacturing and product design, technology of multi-color 3D printing can be used to create life-like prototypes of products. Designers can incorporate brand colors, user interfaces, and material textures into prototypes ideally, enabling efficient appearance verification, market testing, and investment appraisal, significantly saving the R&D process.

4. Cultural creativity and artistic creation:

This technology particularly fits cultural, creative, and art industries. It allows designers to break through the limit of traditional manufacturing and make intricate, multicolored artwork installations and personalized works immediately, with unprecedented creative realization freedom.

LS Precision multi-color 3D printing technology, the best in color performance and most experienced in the industry, helps clients across various industries excel at turning ideas into quality end products.

Any industry with visualization of complex information, high-fidelity verification of product look, or high customization requirements is an ideal application of multi-color 3D printing technology.

What Is The Complete Process Of Our Online Color Printing Service?

LS Precision's online 3D multi-color printing service transforms design files into digital full-color high-quality objects. Our online 3D multi-color printing service is founded on technical processing and accurate color control by professional experts. The whole process of our online 3D multi-color printing service consists of the following chief steps:

1. File upload and color proofing:

After uploading of customers' 3D model files (usually OBJ, VRML, or GLTF), LS Precision's technical staff will put them through color proofing as the first process. This is the first step in digital color management, ensuring the RGB color values in the model file exactly match the CMYK color system of the printing machine so that from day one there is color accuracy.

2. Professional slicing and color voxelization:

The model is then cut by the particular software. Mono printing is different from full-color slicing in the sense that color information is allocated to each voxel (3D pixel), producing a data file made up of millions of points of color which provides the printhead with accurate jetting directives.

3. Precision printing and real-time monitoring:

From slice information, the machine creates the full-color model in layers through material jetting or binder jetting processes. Color deposition and printing status are monitored in real-time during printing by the system for ensuring color consistency and print stability.

4. Post-processing and color enhancement:

Post-processing by the technicians will then be performed after printing, in which powder removal, curing (in case of photo-sensitive resin) or infiltration improvement (for color sandstone) will be based on the material properties. Not only does post-processing enhance part durability but also color saturation and lifespan with special adhesive or spraying methods.

A world-class online multi-color printing service is not a commodity manufacturing process but a rigorous engineering effort with digital color management integration, precise mechanical control, and material science.

Multi-Color 3D Printing Pricing And Optimization Strategies

The pricing model online for the multi-color 3D printing services is very complex, with three most determinant factors being model size (material consumption), complexity of colors (number of gradients and colors), and post-treatment requirements (i.e., sanding and adhesive infiltration). Keeping these in mind will facilitate cost management as well as project planning.

1. Major price factors:

The multi-color 3D printing price is mainly affected by material cost, machine time consumption, post-processing costs and color complexity:

- Material Cost: Color printing demands special materials (i.e., composite powders and colored resins), which are more expensive compared to regular materials.

- Printing Time: The more complex the color, the more complex the print head movement and the longer the print time.

- Post-Processing Cost: Cost of cleaning, curing, and infiltration strengthening.

- Color Complexity: One color < two-color < full-color gradient; the more colors, the higher the cost.

2. Practical strategies for cost optimization:

Optimizing the multi-color 3D printing cost can start from the following aspects:

-

Designing Hollow Structures: Cut material without compromising strength.

- Simplifying Color Schemes: Eliminate unnecessary color gradients and complex textures.

- Choosing the Right Technology: Employ the most cost-effective printing method available to your advantage.

- Batch Printing: Print several parts in one run.

- Optimizing File Accuracy: Optimize excess polygon reduction without sacrificing detail.

The key to cost-effective multi-color 3D printing is early design optimization and solution determination. By full disclosure of your needs to a capable service provider (e.g., LS Precision), you are able to achieve best cost-effective printing solution with quality obtained and cost tracked.

LS Case Study: How To Create Accurate Anatomical Models For Medical Education?

Conventional anatomy learning devices employed in medical school lack ample storage capacity for specimens, have low resolution, and cannot be reused. All of these drawbacks have direct impacts on learning by the students as well as the quality of education. Medical school required an instructional device in earnest that could display human tissue structure clearly, store it for a long period of time, and be reproducible in large volumes. This is a great example of the usefulness of special multi-color 3D print materials.

1. Customer challenge:

The school needed to produce a series of human anatomy models that distinguished between nerves, blood vessels, muscles, and organs clearly. The models needed to have not just precise dimensions, but also closely similar biological tissue color characteristics, yet still be durable enough for long-term teaching uses.

2. LS Precision's innovative solution:

LS Precision's technical team used high-precision, multi-color 3D printing technology. They worked laboriously with the medical imaging information and used special software to color-code the different tissue structures: blue for the venous system, red for the arterial system, yellow for the nervous system, and pink for muscle tissue.

Next, Material Jetting technology was used to print, which simultaneously achieved 0.1mm accuracy printing and millions of colors, with each anatomical detail being clearly distinguishable.

3. Resultant outcomes and value:

The resultant custom multi-color 3D printed product not only simulates the human anatomy with accuracy but also offers the following benefits:

- Teaching effectiveness was enhanced by 40%, and students could better comprehend intricate anatomical relationships using colored models; the model durability increased to more than five years, significantly lowering costs of teaching;

- Customization is allowed, which means that models of anatomy for a particular part can be produced based on course needs.

This illustration perfectly represents the unlimited value of multi-color 3D printing technology in professional training. LS Precision Manufacturing possesses rich experience in multi-color 3D printing and can provide you with precise models and processing of products.

What Are The Key Points To Consider When Designing Multi-Color 3D Print Files?

Good color 3D print file creation should also follow some technical specifications, which have a direct influence on the color accuracy and print rate of the output. Following are the crucial technical points that you should know for arriving at the ideal full-color printed result:

- File format selection: OBJ or FBX file format supporting color information is preferable, and file formats such as STL containing only geometry data should be avoided. Color models can also employ VRML/WRL formats, but ensure to include texture maps.

- Color mode settings: You must always work in the RGB color mode, not CMYK. We recommend using the sRGB color space, as most 3D printing equipment supports this as a standard color profile and offers color stability.

- Minimum detail size: Minimum detail requirements vary depending upon the printing technology. For full-colour printing, we recommend that the wall thickness should be at least 2mm, the minimum detail size should be 0.5mm, and the minimum text line width should be 1mm.

- Model integrity: Ensure the model is a manifold, closed geometry and that it has no inverted normals, overlap, or broken faces. Software automatic verification should be employed to correct model flaws and avoid print failure.

- Texturing and color assignment: If texture maps are utilized, suggest 300dpi resolution, and there should be great UV mapping. While assigning color to the surfaces of the model, be careful how the transitions of the color are handled.

Successful multi-color 3D printing begins with properly prepared design files. Conformity to these technical specifications not only improves print success rates but also accurate and reproducible color representation.

A pre-print consultation with the technical specialists at LS Precision is strongly recommended to get optimized design advice for your specific project.

FAQs

1. What level of color deviation control can be achieved for color printing?

LS Precision multi-color 3D Printing has an international-standard professional color management system. Through device calibration, color profile optimization, and closed-loop control technology, it can stably maintain the color deviation at a level of ΔE < 3, professional-grade level. The standard replicates professional printing products' color reproduction and ensures stringent color reproduction needs of applications such as medical models and product prototypes, effectively preventing misunderstandings due to color deviation.

2. Do multi-color prints require post-processing?

Multi-color prints usually require post-processing based on the application environment. For display components, UV protective coating and polishing might be applied to decorate the surface texture. For functional components, secondary curing (photosensitive resin) or reinforcement by adhesive (e.g., full-color sandstone material) needs to be performed in order to significantly improve mechanical properties. Properly executed post-processing not only enhances product durability but also improves color saturation and details further.

3. What is the maximum printable size?

LS Precision currently has a maximum full-color printing capacity of 380 × 250 × 200 mm with HP Multi Jet Fusion full-color printing technology. A size as big as that can satisfy the majority of medical anatomical models, architectural sandbox models, and product prototypes. For extremely large models, we also have precise segmented printing and professional assembly services to ensure the overall quality and structural integrity after final assembly.

4. How do we ensure detailed color models?

LS Precision harnesses the use of high-definition printing technology with a layer thickness of 0.1mm, complemented by a professional color management process, to achieve a minimum feature size of 0.3mm. Through the utilization of optimized slicing algorithms and precise color mapping technology, we can precisely render subtle color transitions and fine anatomical details.

Summary

3D multi-color printing technology surpasses the boundaries of traditional manufacturing processes through the optimal combination of precise rendering of colour and complex three-dimensional shapes. From highly realistic replicas of anatomy, through genuinely lifelike product models, to creativity-stimulated productions based upon art, 3D multi-color printing offers efficiency and accuracy never before attainable through traditional techniques.

Visit the LS Precision Manufacturing website now, upload your 3D design file, and we will provide you with a custom color optimization solution and immediate quote. Allow us to utilize our most advanced LS Precision multi-color 3D printing technology to help you turn your ideas into stunning, life-like products, and experience the next generation of product development and innovation.

Upload your design drawings now and get an instant 3D printing quote ( 3D priting price), let LS be your strong backing in pursuit of ultimate 3D priting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com