Resin 3D printing, as a key exemplar of photocuring technology, is transforming the paradigm of product development and manufacturing with high precision and high-quality surface finish. By curing layer upon layer of photosensitive polymers, this technology has the capability to rapidly produce models of fine detail and complex geometries. This not only greatly accelerates prototype verification and design iteration cycles, but has also been widely used for direct manufacture of high-performance end products in fields such as medicine, dentistry, jewelry, and consumer electronics.

In this high-precision additive manufacturing field, LS Precision Manufacturing has been at the forefront of the industry for a long time. With its professional technical strength and high-quality printing technology, it provides customers with a whole chain of services from concept to product and continues to enable the combination of innovative design and precision manufacturing in an unhindered way. To save you time, here’s a quick overview of the core conclusions.

Quick Reference: Choose Your Tap At A Glance

| Type | Suitable Process | Typical Applications | Material Properties |

| Standard Resin | Standard Resin | Concept models, visual verification, display parts | High hardness, smooth surface, fine detail, relatively brittle, average mechanical properties. |

| High-Toughness Resin | SLA, DLP, LCD | Functional prototypes, fasteners, housings, fixtures | High impact resistance, fatigue resistance, high ductility, and can simulate engineering plastics. |

| High-Temperature Resin | SLA, DLP | Thermal fluid testing, molds, engine peripheral parts | High heat deflection temperature (>200°C), high-temperature structural stability |

| Biocompatible Resin | DLP, LCD | Surgical guides, dental models, hearing aid housings | Bio-certified (e.g., ISO 10993), suitable for human contact |

Resin choice depends on the end-use application, not on printing technology:

- For functional parts, choose high-toughness resins;

- For high-temperature stability, choose high-temperature resin;

- For human contact, choose biocompatible resin.

- For general visual inspection, standard resins offer best economy.

All resin parts require aggressive post-processing to achieve optimum performance. Collaboration with experts like LS Precision Manufacturing, with extensive material expertise, is crucial to success on complex projects.

Why Trust This Guide? LS Experts' Practical Experience

As technical experts at LS Precision Manufacturing, we've been deeply engaged in high-precision additive manufacturing for over a decade. With world-class industrial-level SLA, DLP, and large-volume LCD printing equipment, we also established a comprehensive material library from standard resins to specialized materials, providing thousands of precision manufacturing solutions for medical, aerospace, and consumer electronics industries, among others.

LS Precision have a deep understanding of how to optimize equipment parameters, select materials, and optimize post-processing for diverse applications. This guide is a systematic summary of our years of project experience and accumulated expertise.

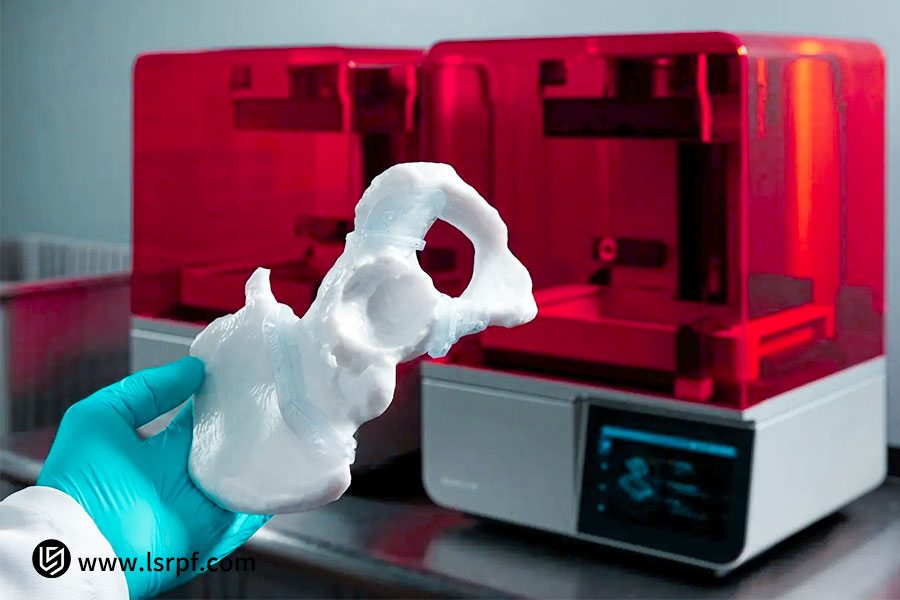

In a real-world situation, LS Precision once urgently printed a complex surgical guide for a surgeon. The model required not only extremely high dimensional accuracy (less than 0.1mm error) but also biocompatibility. Through our deep understanding of material properties and rigorous process control, we were able to deliver a fully qualified part, from data review and printing to post-processing, in a matter of hours, which assisted in supporting the successful surgery.

These types of case studies reinforce our conviction that genuine expertise is about translating technical know-how into reliable product value. This is precisely what you are going to find out in this guide, founded on real project validation.

What Is Resin 3D Printing? How Does It Differ From FDM?

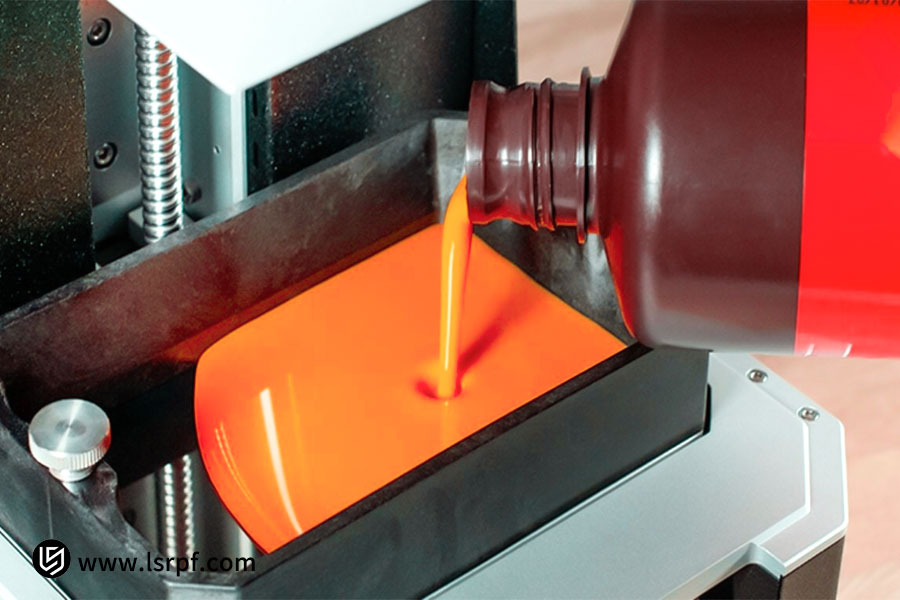

Resin 3D printing, also known as stereolithography (SLT), relies on the selective irradiation of the surface of a liquid photosensitive resin using a light source of a specific wavelength (e.g., laser or projection). This causes a thin layer of resin in the illuminated area to photopolymerize and harden, layer upon layer, to form a three-dimensional solid.

Compared with FDM (fused deposition modeling), which primarily manufactures a product by melt-extruding plastic filaments, the two are fundamentally different in working principles, output effects, and applications. The key differences between the two popular 3D printing technologies are well laid out in the following table:

| Features | Resin 3D Printing (SLA/DLP/LCD) | FDM 3D Printing |

| Working Principle | Photopolymerization: Liquid resin is cured by UV light | Melt Extrusion: Solid plastic filament is melted and extruded by a heated head |

| Precision/Detail | Very high, with the capability to exactly reproduce complicated, fine details and smooth curves | Lower, with layering visible and less detail |

| Surface Quality | Extremely smooth, with little post-processing needed for a high-quality surface | Visible layering, with polishing required to achieve a smooth surface |

| Material Properties | Various specialty resins (high toughness, high heat resistance, clear, biocompatible, etc.) | Various thermoplastics (PLA, ABS, PETG, nylon, etc.) |

| Applications | High-precision parts, jewelry casting, dental models, high-accuracy functional prototypes | High-precision parts, jewelry casting, dental models, high-accuracy functional prototypes |

| Post-Processing | Requires cleaning and secondary curing, which is somewhat complicated | Once printed, the overall shape is finished, and post-processing is primarily support removal and sanding. |

If you need creating large parts with relatively fewer requirements on surface detail but high requirements for strength, FDM is a cost-effective option. If your project demands final accuracy, smooth finish, and very fine detail (i.e., precision assemblies, molds, or artwork), resin 3D printing is a better technology.

What Are The Mainstream Resin 3D Printing Processes?

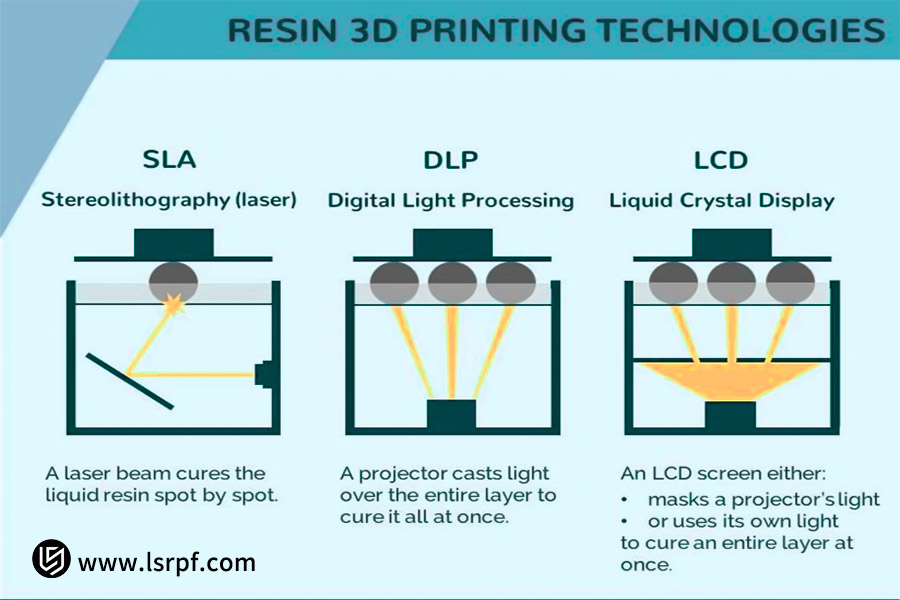

Although they all derived from the photopolymerization idea, mature resin 3D printing technologies by and large belong to the SLA, DLP, and LCD categories based on the light source and imaging technology. They all cure with high precision in various ways and both have advantages and disadvantages.

| Features | SLA | DLP | LCD/MSLA |

| Working Principle | Point scanning: The surface of the resin is scanned point by point with a laser beam to create each layer's shape. | Surface forming: The entire layer image is projected directly onto the liquid surface by a digital projector and cured in one layer at a time. | Surface forming: A matrix of high-intensity LEDs projects the entire layer image onto the liquid surface through an LCD screen mask. |

| Light Source | High precision UV laser | UV digital projector | UV LED array + LCD screen |

| Advantages | Extremely high accuracy, excellent surface quality, industrial gold standard. | Excellent print speed (full-layer curing), excellent speed-accuracy trade-off. | Extremely cost-effective (low-cost equipment), high printing speed, and desktop accessibility. |

| Disadvantages | Expensive hardware, relatively low rate of printing (point scanning), service is advanced. | Potential pixelation (high-resolution projector needed), more expensive hardware than LCD. | LCD displays are limited-life consumables, and resolution is screen-dependent. |

| Applications | High-end industrial applications: aerospace, medical, and precision components. | Professional and industrial application: dental, jewelry, and functional models. | Desktop and entry-level industrial: Rapid prototyping, model building, education, and low-series production. |

The process you use depends on your requirements: For optimal accuracy and surface finish and enough budget, industrial-grade SLA is ideal; for an ideal balance of speed, accuracy, and price, DLP technology is best; and for best value for money and small-batch print speed, LCD/MSLA technology is the best.

How To Choose The Right 3D Printing Resin Material?

Choosing the proper resin material is the most important part of successful printing and end-use application. Each of the photosensitive resins has different mechanical, thermal, and biocompatibility properties, so you will want to make an informed choice depending on the final application and environment your product will be exposed to.

1. Standard Resin:

Most general purpose and inexpensive choice. It is tough and rough on the surface, but mediocre in print resolution, but brittle and not shock-resistant. It is particularly well-suited to concept models, display models, and visual inspection, but not for functionality testing with shock or force resistance.

2. High-Toughness Resins:

They mimic the response of engineering plastics (like ABS or PP) with excellent impact resistance, fatigue resistance, and high ductility, even allowing firm snap-fit structures to be created. They are most suitable for functional prototyping, assemblies, housings, and fixtures.

3. High-Temperature Resins:

Such resins typically achieve a heat deflection temperature (HDT) of over 200°C when cured the second time. This means that they do not distort or change shape when subjected to high temperatures and are typically used for thermal fluid testing, mold making, and engine peripheral part prototyping.

4. Biocompatible Resins:

These specialty resins are certified (e.g., USP Class VI or ISO 10993) for safe contact with human body fluid and skin. They are the first choice in dentistry (surgical guides, dental models) and the medical field (hearing aid housings). When selecting a material, make sure to confirm the compatibility of the level of certification with the application.

When selecting a material, pose the following questions in order:

- Will it need to support loads? (Yes → High-Toughness Resin)

- Will it be subject to heat? (Yes → High-Temperature Resin)

- Will it be in contact with the human body? (Yes → Biocompatible Resin)

If it is a cosmetic model, stock resins are fine. For larger requirements, consulting with professionals like LS Precision Manufacturing can help you properly match the material to the project without the financial burden of trial and error.

In Which Industries Is Resin 3D Printing Most Widely Used?

Its precision, surface finish, and rapid prototyping have made resin 3D printing a productivity and innovation driver in numerous various industries. Resin printing beats other technologies at printing complex parts with high detail, revolutionizing some sectors.

In the medical and dental fields

Its uses are particularly prominent in medical and dental applications. It is utilized for the creation of surgical guides customized from patient CT data, which precisely directs the surgery and significantly improves the success rate and safety of complex surgeries. In dentistry, dental models, hidden orthodontic appliances, and surgical guides are printed directly, enabling high-accuracy, mass-produced, and cost-effective customized manufacturing.

Jewelry industry

The jewelry industry was the initial industry to use this technology. Designers print fine wax patterns with high-precision resin. With traditional lost-wax casting, they can replicate every detail perfectly, dramatically accelerating new product development times and allowing mass production of fine artworks.

In industrial manufacturing and R&D

Industrial manufacturing and R&D engineers print high-precision functional prototypes directly with high-toughness or heat-resistance resins for assembly testing, fluid analysis, or heat resistance testing. It allows them to determine and correct errors in time, thus not incurring much cost and time prior to opening product molds.

In education and research

In education and research, it is also used for making molecular models, casts of archeological discoveries, and anatomical models, providing intuitive and precise instruments for teaching and research.

The worth of resin 3D printing is that it can quickly transform digital designs into top quality physical products for functional or decorative purposes. Whether increasing clinical precision, unleashing design creativity, or accelerating product development, it is now a central component of contemporary production.

Partnering with experts like LS Precision Manufacturing, who are familiar with the requirements of various industries in and out, can help companies get the best out of this technology.

What Are The Key Factors Affecting The Accuracy And Strength Of Resin 3D Printed Parts?

A good 3D print of resin is so much more than simply clicking the "Print" button. Its final precision and strength is a process, dependent on meticulous control of every step from design to post-processing.

1. Model design and oreparation

Model preparation and design are crucial. Support structure matters. It not only prevents deformation or collapse during printing but also the position affects the surface quality, and improper removal causes scars. Wall thickness must also be properly designed. Thin walls are fragile and easily deformed, and too thick causes cracking due to the build-up of internal stresses.

2. Print parameter settings

Print parameter settings matter. Z-axis resolution and surface smoothness are directly affected by layer thickness. Increased detail is obtained using thinner layers but at the cost of considerably longer print time. Exposure time dictates the degree of curing of each layer. Too brief exposure time results in poor interlayer bonding, making the part brittle and susceptible to collapse. Too much exposure, on the other hand, smears detail and induces more internal stress, making the part warp.

3. Post-processing

Post-processing is final but is what constitutes final performance. Parts, post-print, must be thoroughly cleaned of the surface of any unpolymerized resin. Surface tack will be induced by any residue and affect final cure. Secondary curing at a later point is highly critical, permitting sufficient photocrosslinking within the material. It is an essential step for the resin to achieve its nominal peak strength, hardness, and heat resistance. Undercured parts will reduce their mechanical properties significantly.

To produce high-precision, high-strength printed parts, the three elements of design, parameters, and post-processing need to be optimized in a systematic way. These elements are inseparable and interact with each other.

How Does LS Achieve High-Precision Customization Using Resin 3D Printing Technology? A Precision Medical Device Prototype Case Study

1.Client challenge:

A medical device company faced an exceptional challenge in developing a new handheld endoscope. Its key component, a transparent housing filled with complex microfluidic channels and optical structures, had to be completely transparent, biocompatible (ISO 10993 certified), and extremely precise dimensionally (±0.05mm tolerance). Traditional CNC machining was not able to achieve this complex internal geometry, while typical 3D printing was not capable of meeting both stringent material and precision requirements.

2. LS Precision's creative solution:

Presented with such a challenge, the LS Precision manufacturing team developed a creative solution:

- In material selection, we carefully selected a high-performance, Class I biocompatible, clear medical resin that achieves optical clarity upon curing.

- In process, LS Precision employed high-resolution DLP printing technology. By precisely calculating and optimizing the exposure parameters layer by layer, the certain formation of the microfluidic structure with less internal stress and without cracking and warping was achieved.

- In the post-process, several repeated isopropyl alcohol washing and a carefully temperature- and time-controlled secondary curing process were performed by the team to ensure the complete reaction of materials, final mechanical properties, and no residue.

3. Final result and value:

Lastly, the LS team managed to produce a component that met all the requirements on the first try. The prototype possessed a clear internal structure, smooth surface, and great transparency, and passed biocompatibility tests with ease. Not only did this move save the client a significant amount of mold costs, but also reduced their product development cycle by weeks, paving a solid way for future clinical verification and rapid product iteration. This fully demonstrates the huge potential of high-accuracy resin 3D printing for the custom fabrication of complex medical devices.

Should I Buy A Resin 3D Printer Or Opt For A Professional Printing Service?

When companies need high-precision resin 3D prints, they have a vital decision to make: Whether to print in-house with their own printer or outsource to a professional service bureau. While desktop printers are more affordable than ever before, the real expense is far more than one investment. A basic economic calculation will determine that for less frequent daily use, having a professional service is usually a better strategy.

Purchasing equipment yourself means you'll have ongoing and random incremental costs:

- Equipment does depreciate, and FEP film in the resin tank and LCD screen are consumables that will need ongoing replacement.

- Opened resin materials do have a shelf life, and unused material is waste.

- There is always a print failure risk, and one failed intricate model means a loss of time and material.

- In addition to that, you'll need to invest in post-processing equipment (washers and curing chambers), let alone valuable time and learning cost—from trial-and-error tweaking parameters and designing support structures to handling toxic chemicals, all of which require expertise and experience.

Opting for a professional service bureau like LS Precision Manufacturing eliminates any instance of hidden costs. Not only do we have industrial-grade equipment, an extensive library of specialty materials, and developed process parameters, but we also ensure that every part undergoes standardized post-processing procedures for optimum performance.

What Are The Common Post-Processing Steps For Resin 3D Printing?

Resin 3D printing is not complete when the build platform is lifted. "Raw" parts removed from the build platform generally possess uncured resin and less-than-optimal performance. They must undergo a series of standardized post-processing steps to achieve their final design strength, stable optics, and functional properties. These steps have a direct influence on the final quality of the product.

The complete post-processing process includes:

- Cleaning: Soaking the part in denatured alcohol or cleaning fluid removes any sticky resin residue from the surface. Inadequate cleaning can result in a sticky surface and undermine subsequent curing.

- Removing support structures. Care should be taken not to leave noticeable scars on the model surface.

- Post-curing: The part is placed in a UV curing chamber to finish the cross-linking of the resin within, achieving the ultimate mechanical strength, hardness, and chemical resistance.

- Parts with extremely high aesthetic requirements require additional grinding and polishing to eliminate layer marks, or coatings (e.g., primer, glossy or matte paint) to achieve final appearance.

Not only are LS Precision equipped with specialized equipment such as ultrasonic cleaning machines and temperature-controlled curing ovens, but also, drawing on abundant project experience, establish precise cleaning and curing parameters for components with various materials and structures.

FAQs

1.Are resin 3D printed parts truly fragile?

Not always. Mechanical performance of resin 3D printed parts is highly dependent on the selection of resin material. Recent high-performance resins (e.g., high-toughness resins and ABS-like resins) have significantly improved in mechanical performance, with impact strength, ductility, and fatigue strength comparable to that of some traditional engineering plastics like ABS or polypropylene.

2. How can I effectively control the overall cost of a resin printing project?

LS Precision can help customers save over 30% of printing expenses by reducing print times through intelligent layout, reducing support structures to conserve resin, recommending the most cost-saving material based on functional requirements, and reducing model wall thickness without compromising strength.

3. Is resin 3D printing technology suitable for mass production?

It is particularly suitable for small-volume customized production. For large-volume production, we recommend rapid tooling solutions. LS Precision can provide complete mass production solutions, such as printing and re-molding, based on customer production volumes and cycle times, to help customers expand production efficiently.

4. How do I choose the most suitable resin material for my project?

The best method is to consult with LS Precision's application engineers and let us know your performance requirements (e.g., strength, temperature resistance, and biocompatibility). From our extensive material database and test experience, we will suggest the most cost-effective material solution and provide material samples and print test services to validate the final part will meet expectations.

Summary

Resin 3D printing, with its unparalleled precision, excellent surface quality, and extreme detail, is an irreplaceable part of modern precision manufacturing. LS Precision Manufacturing, with a full set of industrial-grade light-curing equipment (SLA/DLP/LCD), a dense material library covering general and special applications, and a mature technical team, is committed to providing customers with one-stop service from design optimization and material selection to precision printing and professional post-treatment.

If you have any product development manufacturing problems or seek the optimum rapid prototyping solutions, the professionals at LS Precision are here to help. Contact our technical consultants today to upload your 3D design files to get a quote immediately and free technical consultation from an expert. Let us accelerate your innovation through our precision manufacturing services!

Upload your design drawings now and get an instant 3D priting quote (3D priting price), let LS be your strong backing in pursuit of ultimate 3D priting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com