In small-batch manufacture (typical production quantities of fewer than a few thousand), cost-effectiveness is then the driving motivation for technology choice. Injection molding is founded on costly mold tooling and is suited well to large production to spread the cost per unit. 3D printing has no molds whatsoever and is founded on an expected per-unit cost, thereby making it extremely cost-effective for small quantities. In addition, 3D printing outperforms in design freedom and speed of iteration, but injection molding is still cost-effective per part in high-volume production.

As an industrial additive manufacturing professional service provider, LS Precision leverages its extensive expertise in high-precision and high-performance 3D printing technologies to provide users with stable solutions from small-batch rapid prototyping to end part production, while reducing development and production costs. To save you time, the following is a brief summary of the findings.

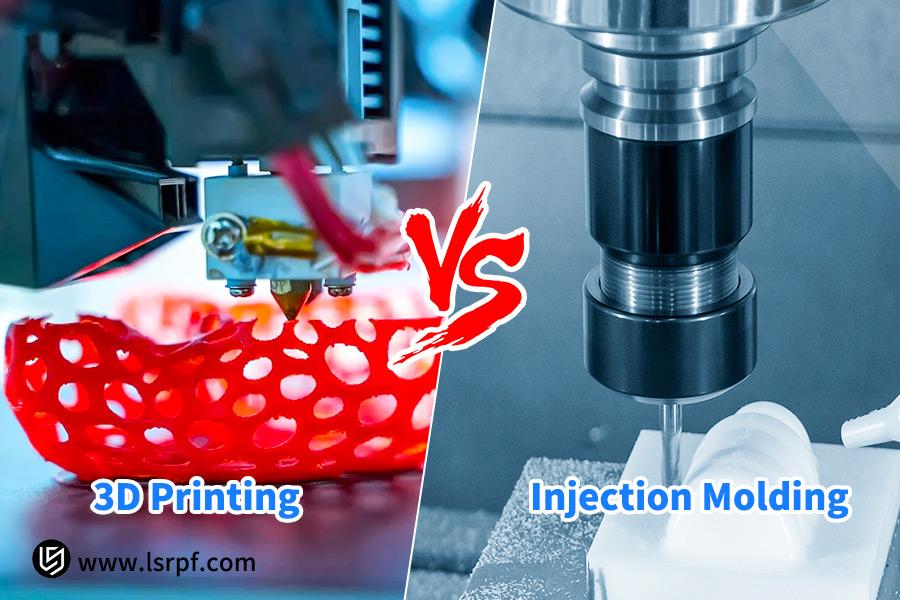

3D Printing vs. Injection Molding: Key Selection Guide

| Comparison Dimensions | 3D Printing (Additive Manufacturing) | Injection Molding (Subtractive Manufacturing) |

| Core Costs | No mold expense, fixed cost per article. | High initial mold expense, very low cost per article. |

| Economic Volume | Small quantities (typically <1,000-10,000 units) | Large production volumes (typically >10,000 units) |

| Production Speed | Rapid first-part rate, slow production rate for large quantities. | Slow first-part rate (mold creation), very high mass production rate. |

| Design Freedom | Extremely high, suitable for complicated shapes and composite structures | Limited, draft angle consideration, parting lines, etc. required |

| Iterative Flexibility | High, digital information can be altered without penalty at any moment, zero-cost iteration. | Low, design modification requires re-molding, which is costly. |

| Materials and Performance | Restricted material selection, anisotropic material behavior, maybe not optimal relative to traditional materials. | A wide variety of materials are available, offering isotropic performance of the part and excellent strength. |

- 3D printing: Ideal for small batches, prototypes, high complexity, rapid iteration, and custom manufacturing.

- Injection molding: Ideal for mass production requiring the ultimate in cost per unit, wide materials selection, and highest strength.

For small batch production, 3D printing tends to be more cost-effective with less costly molds. LS Precision's industrial-grade accuracy 3D printing technology provides efficient and affordable professional solutions to these needs.

Why Trust This Guide? Practical Experience From LS Experts

The knowledge in this guide comes from LS Precision's experience spanning decades of combining additive and subtractive manufacturing. Not only do we have a complete set of precision 3D printing machines, such as SLS, MJF, SLA, and industrial FDM, but we are also heavily engaged in many small-batch production projects, from automotive prototypes to end-use medical device components.

This extensive cross-technology expertise enables us to transcend a singular perception of technology and provide truly unbiased, fact-driven selection guidance on total cost of ownership (TCO), rather than sell technology. For example, LS Precision assisted an auto parts customer in designing a complex sensor bracket. With our HP MultiJet Fusion 3D printing capability, the customer iterated five times through their design within two weeks and printed 200 end-use parts available for road testing in one production run at a total cost of mere thousand yuan.

Traditional injection molding would have cost tens of thousands of yuan and a month in lead time to create the molds. This real case fully shows the dual advantage of 3D printing in terms of speed and expense at the stage of small-batch production, and is the hands-on basis of our decision-making process.

What Is Small-Batch Production? How To Choose Between 3D Printing And Injection Molding?

For low-volume production (typically production runs of 100 to 10,000 units), companies must make precise decisions in process selection in order to balance cost, efficiency, and quality. Cost is a significant component in making the decision.

1. Basic Principles of 3D Printing and Injection Molding:

- 3D printing (additive manufacturing) builds parts directly through layer-by-layer deposition, obviating the use of molds. It is ideally used for products with high-frequencynumber of design changes and intricate geometries.

- Injection molding, however, uses precision molds to mass-replicate. Although the part cost goes down very dramatically with increasing production, the startup mold cost is more.

2. Factors to be Considered:

Comparing 3D printing and injection molding, it's required to comprehensively evaluate a number of aspects:

- Cost Structure: 3D printing does not have mold costs, therefore the cost is per part fixed. Injection molding requires mold investment (generally between 8,000 and 50,000 yuan), but the unit cost per part is extremely low in quantities.

- Timeline: 3D printing does not require mold development, and hence can start production with speed. Injection molding takes 2-5 weeks to create molds, and hence ideal for long-term stable orders.

- Materials and Performance: Injection molding offers a wider selection of materials (e.g., PP and ABS) offering excellent strength consistency. 3D printing materials (e.g., nylon and resin) are in continuous development, and hence ideal for light-weight, integrated functional components.

As an integration service provider with a multi-process capability, LS Precision has a close interaction with the manufacturing process from prototype through finished part. We recommend: 3D printing is optimum for complex product structures, where quick iteration is required, or low volume manufacturing (e.g., <2,000 pieces). Injection molding is lower cost for high-volume production, established designs, and maximizing the final per-part cost.

With industrial-level 3D printing machines (such as HP MJF and SLS) and an ecosystem of injection molding partners, LS Precision offers customers objective technology choice consultation and single-source production to help you effectively control cost and minimize time to market during the low-volume phase.

Why Is 3D Printing Preferred For Small-Batch Production?

Under conditions of small-batch production, with the characteristic technological advantage and economic benefit of 3D printing, more and more enterprises are applying 3D printing technology. In contrast to traditional manufacturing processes, 3D printing directly prints parts from digital models without mold investment. This significantly reduces the up-front investment and shortens the production cycle, hence being appropriate for small-batch production.

Especially, the key merits of 3D printing exhibit themselves in three aspects:

- No mold costs. Injection molding entails high mold costs, while 3D printing entails no molds and is thus especially well-suited to low-volume manufacturing and tightly controlling overall cost.

- Rapid iteration and adaptable manufacturing. 3D printing significantly reduces the product development cycle, thus especially well-suited to rapid prototyping and design validation, wherein multiple rounds of design refinement and physical verification can be completed in a matter of days.

- Complete design freedom. This technology easily achieves intricate forms, light-weight structure, and molding integration, which defies the limitations of traditional processes such as draft angles and parting surfaces, thus expanding the boundaries of product functional innovation.

Whether for functional prototypes or small-batch production of finished goods, LS Precision can help businesses achieve their goals cost-effectively and dramatically reduce the development risks and time cost.

For small-batch production thus, implementing the application of 3D printing technology is not just a technological innovation but also a strategic choice to improve rapid product iteration and competitiveness in the market.

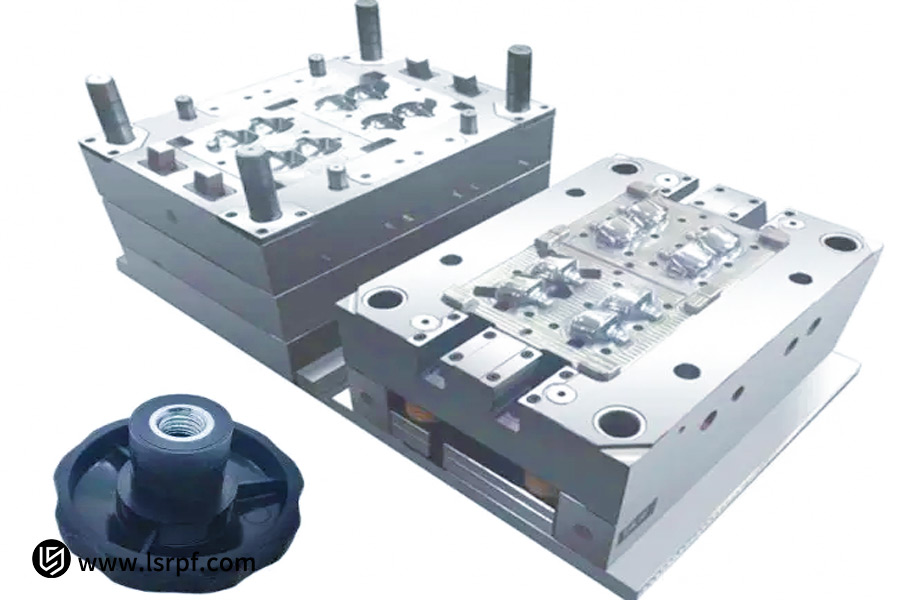

What Is The Cost Structure Of Injection Molding?

The cost structure of injection molding has a direct impact on the extent of technology selection possible for it, particularly in small-scale production. Simple injection molding costs mainly have three components: mold cost, material cost, and cost of labor for production.

1. Mold Cost:

Mold cost is the largest one-time investment involved with injection molding. A precision mold set typically falls between thousands and tens of thousands of yuan, or even more. While there are economical mold-making techniques in the market, such as aluminum molds or streamlined steel molds, that can reduce the initial investment to some extent, their usability and precision will typically be inferior to those of normal molds. This trade-off needs to be made based on the scale of production and quality demand.

2. Material and Labor Costs:

Material and labor costs are amortized as the production volume increases. Once the mold is complete, raw material cost (ABS, PP, etc.) and machine labor per product unit are relatively low, and therefore injection molding's cost per unit is highly competitive when manufacturing high volumes. However, in low-volume production, the cost of molds is difficult to amortize, significantly increasing total costs.

The cost profile of injection molding benefits high-volume parts with established designs. If your company is making small lots to accelerate verification or to iterate frequently, injection molding might not be the economical choice.

With experience in multi-process as a supplier, LS Precision is able to provide expert cost analysis and mold solution optimization to customers, allowing you to make a cost-saving and more effective decision between 3D printing and injection molding.

How Does Production Volume Influence Technology Selection?

In selection among production processes, analysis of the production volume is an important consideration in determining whether a 3D printing or injection molding process should be used. Usually, a cost-to-performance curve for the two processes, their "critical volume," dictates which method is cheaper.

- By a typical production quantity analysis, if production runs are small (for example, less than 500 pieces), 3D printing will offer lower total cost since it has no investment in the mold and has fixed costs per piece.

- When production volumes exceed the break-up point (e.g., 500-2000 pieces, depending on the part size and complexity), injection molding, although costing more in initial mold investment, holds the potential for much lower per-piece cost with higher production volumes, eventually leading to total costs less than 3D printing.

Companies can utilize an initial production quantity analysis to determine their technology path: 3D printing for successive iterations and small series, injection molding for stable manufacturing and large series.

LS Precision, with its ability to integrate multi-processes, provides customers with accurate critical volume calculations and cost simulations to help you make informed decisions based on actual order sizes and optimal cost and efficiency equilibrium.

LS Precision Case Study: 3D Printing Saves Client 30% Costs

During the development of a new product for a smart device manufacturer, one of the biggest issues was how to cost-effectively produce 500 sensor housings. The client had normally thought of injection molding, but was struck by high mold expenses and long lead times and needed a more creative solution right away.

1. Client Challenge:

The customer needed a production of 500 high-strength, light-weight sensor cases in a limited amount of time. Injection molding not only entailed a mold investment of about 20,000 yuan but also a 3-4 week mold building process, which would severely impact time to market. Additionally, the customer had possible design-for-optimization needs of the part design, introducing the possibility for late-stage modifications and further endangering the risks of traditional mold development.

2. LS Precision Innovative Solution:

LS Precision engineers, in accordance with professional production quantity analysis, recommended industrial-grade 3D printing using high-performance nylon material (PA12) and HP MultiJet Fusion technology. This solution eliminated mold investment completely, taking full advantage of the low-cost advantages of 3D printing for small-batch manufacture, with excellent structural strength and dimensional accuracy.

3. Final Results and Value:

Using a 3D printing solution, the customer shipped all 500 parts in two weeks, two weeks earlier than the initial injection molding deadline. Figure calculated precisely, the entire cost came out to be 30% lower than the injection molding solution, precisely within the customer's budget and time constraints.

LS Precision's expert technical counsel not only assisted the client in the realization of cost savings and efficiency improvements, but also retained complete design freedom for follow-on product versions. The value of choosing an appropriate additive manufacturing solution within a production plan is clearly illustrated by this case study.

How To Smoothly Transition From Prototyping To Mass Production?

While product development is underway, seamless transition from prototype proving to mass production is crucial to ensuring a project's success and market responsiveness. LS Precision, leveraging its extensive cross-process manufacturing expertise, provides companies with a single-stop solution for the problem of seamless transition.

LS Precision proposed a stepwise, homogeneous data approach to seamless transition:

- To begin with, 3D printing technology was utilized in rapid prototyping and functional proving. This phase allowed rapid design cycling and exhaustive product performance testing with no capital investment in molds, reducing early development risk significantly.

- LS Precision then leverages its list of partners and team of mold experts to recommend or develop low-cost mold alternatives (such as aluminum molds or feature-reduced steel molds) suitable for mid-volume production, allowing cost-efficient high-volume manufacturing by injection molding.

This combined service, besides reducing communication and time costs for repeated data conversion and supplier switches in traditional models, also gives a single technical strategy and closed-loop quality assurance from prototype to mass production.

Relying on its in-depth understanding of additive and subtractive manufacturing, LS Precision allows customers to reduce their time to market, control total cost, and preserve consistent production quality at all levels.

Which Is Faster, 3D Printing Or Injection Molding?

Speed of delivery is a governing factor in the selection of manufacturing technology, and 3D printing and injection molding's speed advantage changes with production level and technical requirement.

1. 3D Printing Delivery Time:

3D printing offers significant time advantage in rapid prototyping and small-volume production. Through an entire elimination of the mold design, machining, and testing process, it enables "design-to-production," typically developing prototypes or small batches of parts in 1-3 days. This makes it best suited for design verification and rapid iteration in the product development cycle.

2. Injection Molding Delivery Time:

Injection molding has a significantly different speed profile: It requires more time in the beginning to create the mold (typically 2-5 weeks), but once the mold is made and mass production begins, the cycle time is extremely high, which creates hundreds or thousands of pieces per hour.

The choice between which technology is "faster" is about specific production quantities:

- 3D printing is quicker at rapid prototyping or production of limited quantities fewer than a couple hundred parts.

- For high-volume production runs more than thousands of parts, although injection molding does involve a longer lead time, its volume production capability is better in overall cycle time.

LS Precision, owing to its multi-process integration capabilities, can provide you with the best technology route based on your project needs so you can precisely manage time costs and accelerate the entire product development to market.

How Can I Further Reduce The Cost Of Small-Batch Injection Molding?

For small-batch production requirements, the excessive cost of standard steel molds would usually be a limit on the use of injection molding. With innovative mold solutions, initial investment can be greatly reduced, allowing injection molding production of small batches to become economically more acceptable.

LS Precision offers customers expert, cost-effective solutions for mold production, primarily comprised of two technical solutions:

1. Aluminum Molds:

In comparison to traditional steel molds, aluminum molds possess the benefit of reduced material expenses and more rapid machining time. While their mold life is reduced (typically manufacturing 5,000-10,000 parts), they are most appropriate for tiny series runs of hundreds to thousands of parts.

2. 3D Printing Soft Mold Technology:

Direct printing of mold inserts using high-performance resin or metal 3D printing is most suitable for short-run trials or tiny production runs (typically smaller than 500 pieces). This is extremely rapid and cost-effective and is most appropriate for the final product validation stage.

With these cost-effective mold making options, companies can enjoy the material characteristics and manufacturing efficiency of injection molding without incurring huge upfront investment and risk.

LS Precision recommends the use of cost-effective molds in conjunction with 3D printed prototypes. Initially, prove out designs by 3D printing, and then utilize aluminum molds or soft molds to make small quantities through injection molding, thereby getting the optimal cost vs. speed ratio from design to production.

FAQs

1. For small-batch production, should I choose 3D printing or injection molding?

It depends upon production volume and nature of part. If the production quantity is less than 500 parts and the geometry is complex (such as those with conformal cooling channels or design incorporated), 3D printing is recommended because it eliminates mold costs and offers greater flexibility. When the volume of production is over 1,000 units and the complexity is not high, injection molding offers lower per-part prices. Multi-process cost simulations can be offered by LS Precision to help you make informed decisions.

2. Can 3D printing be used for final parts?

Yes. Parts printed with industrial-grade 3D printing (such as SLS nylon and photosensitive resins) possess better mechanical characteristics and geometry precision and are often employed for functional end parts (such as fixtures and housings). LS Precision offers a range of high-performance materials (such as wear-resistant nylon PA12 and high-toughness resins) to suit various occasions.

3. What is the minimum cost for an injection mold?

Costly custom steel molds notwithstanding, LS Precision offers cost-effective mold solutions (aluminum molds and soft molds) at a few thousand yuan per unit for pilot production in small batches (500-5,000 units). While it is non-durable, it conserves initial investment to a large degree and is the best for the product validation phase.

4. Can 3D printing be used for validation before injection molding?

Yes, and this is the recommended procedure. You can quickly prove out and streamline your design on 3D printing and go directly into injection molding for volume production through LS Precision's one-stop capability. This approach avoids dangers of direct data mold making with process integrity and continuity from a single supplier, saving time and money.

Summary

For small-batches production, the choice between 3D printing and injection molding is merely one of cost, time, and complexity. With advantages of no mold cost, rapid response, and improved design freedom, 3D printing is ideally suited for small-batches production, complex structures, or those that must be iterated frequently. Injection molding, on the other hand, demonstrates cost-effectiveness in producing large quantities, maintaining fixed structures, and optimizing the best in unit cost.

If you're faced with a technology problem in small-batch production, LS Precision is committed to providing you with impartial and authentic solutions through our cross-process expertise. LS Precision Manufacturing combines industrial-grade 3D printing and affordable injection molding services to enable you to accurately predict costs and chart the most effective method of production.

Contact our technical consultants today for a tailored quote and sample support to guarantee your project meets efficiency and cost-effectiveness. Upload your design drawings now and get an instant 3D printing quote ( 3D printing price), let LS be your strong backing in pursuit of ultimate 3D printing precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com