In today's highly competitive manufacturing industry, the pursuit of efficiency, lightweighting, and component performance may be more critical than ever before. Traditional manufacturing methods fail when confronted with complex geometries, long production times, and weight reduction needs. Aluminum 3D printing technology is especially the best solution to the most critical concerns.

LS Manufacturing, a pioneer industry partner, leverages state-of-the-art aluminum 3D printing technology to empower customers across diverse industries in pushing through traditional design limits. We allow you to produce groundbreaking designs rapidly, simply creating working parts with complex internal geometries, greater strength, and record-breaking light weight.

With our aluminum 3D printing solutions, choosing us will significantly shorten R&D and production leadtimes, enabling you to receive unparalleled, high-power components within a short period and injecting core competitiveness into your products. To save you time, here's a quick overview of the core conclusions.

Aluminum 3D Printing Core Quick Reference

| Dimensions | Key Points |

| Technology Positioning | One of the key additive manufacturing technologies having solved efficiency, lightweighting, and performance problems. |

| Core Advantages | Design freedom, lightweighting, high strength, and quick delivery. |

| Key Capabilities | Forms complex geometries (e.g., hybrid parts and lattices) not possible using traditional methods. |

| Material Properties | High-strength aluminium alloys (e.g., AlSi10Mg) are typically used, with attributes analogous to forgings. |

| Key Benifits | Shortens significantly R&D and manufacturing cycles, instilling inner competitiveness into products. |

| Applicable Customers | From small startups to large manufacturers, in numerous industrial sectors. |

The value of aluminum 3D printing is to break the gap between design and production. It's not just a production process; it is an innovation enabler. With its ability to provide maximum lightweighting and function integration, it allows businesses to accelerate product innovation quicker, improve performance, and achieve competitive advantage in the fiercely competitive market.

Choosing aluminum 3D printing means choosing a wiser, quicker means of production.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Each recommendation offered in this guide is the result of the decade and widespread success that LS Manufacturing has enjoyed using industrial-strength aluminum 3D printing. We do not simply have access to the latest print technology, but far more importantly, a group of engineers with intimate knowledge of design and manufacturing processes by which we can successfully translate your ideas into robust and dependable end-use parts.

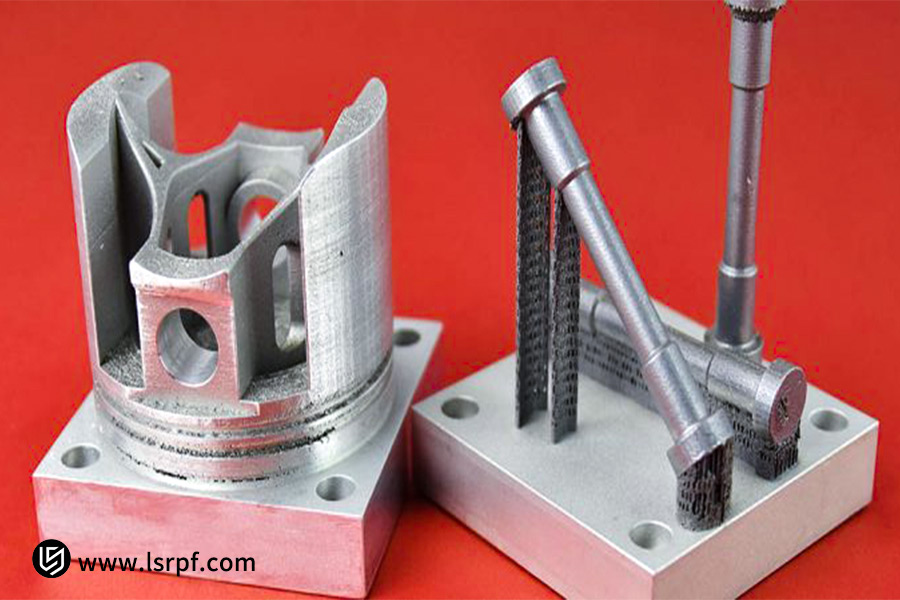

LS Manufacturing's practical experience has been proven through numerous projects. For example, we optimized a critical bracket for an aerospace client, achieving a 48% weight reduction through an innovative lattice structure design and passing rigorous testing. We also printed a complex 12-part assembly for a medical device manufacturer in a single process, completely eliminating assembly errors and reducing lead times from weeks to days.

These experiences enable us to accurately forecast and solve hands-on issues from design through production. We also pass on to you the process and methods that we use in creating real value to our customers on a daily basis.

How Does Our Aluminum 3D Printing Service Quickly Produce High-Strength Parts?

Maintaining component integrity through lightweighting is the essence of our aluminum 3D printing service. Thus, how does our aluminum 3D printing service make high-strength components so quickly? It does so with efficiency through the following processes:

1. Precision molding technology:

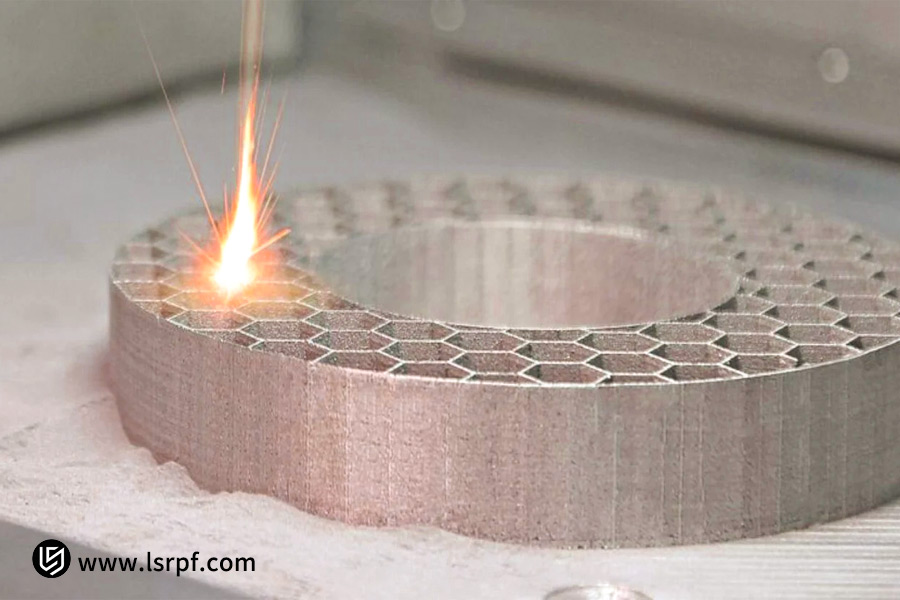

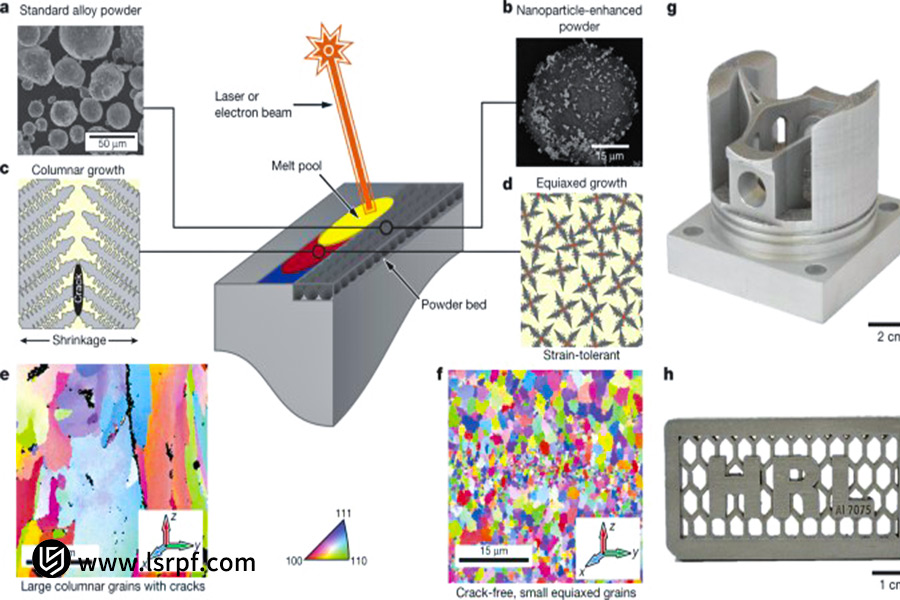

LS Manufacturing uses SLM (Selective Laser Melting) technology, whereby a high-definition laser is used to fully melt thin layers of aluminum metal powder, creating parts of near-100% density directly. This near-dense microstructure forms the foundation for high-strength aluminum parts, whose mechanical properties are equivalent to or even better than conventional castings.

2. Advanced Equipment and Proprietary Materials:

LS Manufacturing invests in high-speed laser printing machines, industry-grade, with highly stable and accurate laser positioning and scanning. We utilize high-strength, additive manufacturing-compatible AlSi10Mg aluminium alloys. The product produced has added strength, stiffness, and fatigue characteristics while maintaining lightness characteristics with optimized process parameters.

3. Process Optimization for Fast Delivery:

Aluminum 3D printing capabilities bypass the lengthy phases of traditional manufacturing such as mold opening and fixture setup to enable smooth flow from digital model through to finished product. Not only are traditional rapid aluminum prototyping cycles reduced to days, but product development and time to market are reduced significantly. Tooling cost is also eliminated. This makes it particularly well-suited to produce small quantities of exacting, high-strength aluminum parts, with total optimised cost.

If you need a solution to manufacturing that unites performance and efficiency, please get in touch with LS Manufacturing's engineering staff for technical professional support and a quote.

Why Is Aluminum An Ideal Choice For Lightweight Metal 3D Printing?

Among many metal materials, aluminum, due to its unusual combination of properties, has become the go-to solution for light metal 3D printing. So, what are the key features and advantages of aluminum? Below, we will outline its most significant advantages:

1. Excellent strength-to-weight ratio:

Aluminum alloys have a low density of approximately 2.7 g/cm³ and very good specific strength, i.e., components' capability to sustain heavy loads while enabling substantial weight saving. Using aluminum 3D printing filament (metal powder) and SLM technology, intricate functional components can be manufactured which are lighter in weight than castings but stronger than most of the steels, making it a great choice for maximizing performance and weight saving.

2. Meeting the needs of top industrial lightweighting:

This quality has made aluminum so popular among aerospace and motor vehicle sectors. LS Manufacturing uses air-grade aluminum materials, such as high-strength AlSi10Mg and AlSi7Mg, to achieve stable forged-level mechanical properties. We have successfully developed lattice structure and topology optimization for several projects with up to 30% weight savings of critical components while fully meeting rigorous industry safety standards.

3. Excellent Thermal and Processing Properties:

There are exemplary thermal attributes and corrosion resistance, too, in aluminum alloys. Through 3D printing technology, it is possible for designers to break through traditional limitations and design with several parts integrated into one entity comprising complex features such as conformal cooling passages. It not only reduces overall weight further but also improves component heat dissipation efficiency and dependability with an optimal balance between functionality and light-weighting.

With the inherent benefits of the material and our expert craftsmanship, aluminum 3D printing is definitely a guaranteed means to achieve breakthrough lightweight design.

How Does The Cost Of Aluminum 3D Printing Affect Your Project Budget?

It is most important to comprehend the cost structure of aluminum 3D printing in order to ensure successful projects. In contrast to traditional manufacturing processes, its cost structure is more transparent and controllable, with the following factors being the primary determinants:

| Cost Factor | Impact Explanation | LS Manufacturing's Optimization Solution |

| Material Cost | Destructive and costly metal powder is a major cost driver. | There are various material options, and maximized utilization design increases efficiency. |

| Equipment and Labor Hours | Equipment depreciation and printing time are expenses. | Effective equipment utilization is maximized by smart scheduling. |

| Design Complexity | Support structures and print complexity drive costs. | Professional design optimization is provided to maximize performance and cost. |

1. Transparent Quotation and Design Optimization:

LS Manufacturing utilizes an open aluminum 3D printing cost quoting system in which all costs are clearly detailed, starting from materials and post-processing. Special aluminum parts enjoy expert design optimization recommendations by our engineers, ensuring performance while being efficiently controlled through lightweighting and support minimization.

2. Economic Advantages of On-Demand Manufacturing:

On-demand metal production eliminates mold investment, with a huge saving on upfront cost of the project. This kind of model is best suited to small-batch production and prototyping, where you can order with flexibility based on immediate demands, thereby avoiding backlogs in inventory and wasting capital.

3. Lifecycle Value:

Where costs are a consideration, the overall dollar value of aluminum 3D printing has to be considered: shorter R&D cycles and faster time to market; energy savings through light weighting; and increased product reliability by integrating parts and eliminating assembly operations. All these advantages can yield a good return on investment.

The cost advantage of 3D printing with aluminum is in its flexibility and optimizability. Through on-demand metal production and professional design optimization, we allow you to achieve high-performance, customized aluminum parts at a reasonable price and with higher return on investment for projects.

How Can Complex Geometries Be Achieved Through Aluminum 3D Printing?

Traditional manufacturing technologies often cannot achieve complex internal flow channels, slender walls, or non-uniform-shaped structures. This is the inherent advantage of aluminum 3D printing services. Its layer-by-layer manufacturing technology comprehensively disrupts design limitations:

1. True Design Freedom:

Unlike subtractive manufacturing, 3D printing adds material one layer at a time to form parts. This means that even the most complex and advanced aluminum parts, including internal cavities, freeform surfaces, and organic lattice structures that cannot be achieved using traditional machining, can be precisely created, achieving optimized design concepts.

2. Breakthrough Internal Structure Manufacturing Capabilities:

LS Manufacturing can directly print integrated components with closed internal cavities, conformal cooling channels, or lattice infill. This enables customized aluminum parts to be extremely light in weight without affecting strength, or to have efficient heat dissipation channels, enhancing the performance and efficiency of the final product significantly.

3. Professional Collaborative Design Support:

LS Manufacturing offers professional design optimization, and our engineers will work closely with you. Depending on the process behavior of the aluminum 3D printing process, we will do topology optimization, lightweight design, and support structure optimization on the model in such a way that structural integrity is maintained and your complex aluminum parts are printed successfully and exhibit excellent performance.

Leaning on its unique forming principles, aluminum 3D printing redefines design complexity as a manufacturing constraint into a performance driver, liberate you from traditional constraints and design customized aluminum parts with improved performance and more functionality.

What Are The Specific Applications Of Aluminum 3D Printing In The Aerospace Industry?

Aluminum 3D printing technology, as a light metal 3D printing process, is transforming aerospace part design and manufacturing to a large extent, marking the beginning of a new method of pursuit of absolute lightweighting and performance.

1. Aviation-grade materials and testing that meet stringent standards:

Real aviation-grade aluminum printing must satisfy stringent industry requirements and certification testing. As an example, aerospace product aluminium alloy parts have specific treatments such as anodizing to resist corrosion in line with ISO standards. In actual use, safety testing such as FST (smoke toxicity) and heat release of essential parts such as aircraft interiors must be conducted in flammability laboratories following aviation standards in order to attain complete safety.

2. Key Components: Lightweight Applications from Engines to Cabins

Engine and Structural Parts: New lightweight metal 3D printing technology has produced new high-strength aluminum alloys with strengths as much as five times higher compared to standard cast aluminum. These are particularly suited to weight and strength critical components such as jet engine fan blades. Not only is considerable weight saved, but stability up to 400°C is also maintained because of the presence of fine precipitates in their structure.

Aircraft Interiors: With 3D printing technology, large-scale manufacturing of certified aircraft interior components is made possible. With this approach, there is scope to produce complex structures at a faster rate as well as integrate functionality of the parts while ensuring conformity to aviation safety standards.

3. Professional Collaboration and Certification Assurance:

Integration with aircraft maintenance, repair, and overhaul (MRO) service providers and professional printing service businesses is key to promoting the adoption of aviation-grade aluminum printing. The collaborative model spans the entire process, from part design and material selection to printing and final certification, establishing a holistic manufacturing and testing dataset and providing substantial technical assistance to aerospace engineers in their utilization of additive manufacturing.

Aluminum 3D printing not only supports the production of safe, compliant, high-strength aluminum components and interior parts, but also allows for revolutionary ground-breaking lightweight core component designs, including engine blades, to bring new opportunities for aircraft performance improvement.

Aluminum 3D printing, by adhering to strict aviation-grade aluminum print quality requirements, has been successfully applied in a number of critical situations throughout the aerospace industry.

How To Choose The Right Aluminum 3D Printing Material For Your Project?

Choosing the right aluminum 3D printing material is a crucial choice that will guarantee the performance of the finished part. Different aluminum alloys have unique properties that directly influence the quality and application of high-strength aluminum components.

1. AlSi10Mg: Versatility and Good Overall Performance

This is the most widely used 3D printing metal of aluminum. Owing to its silicon-magnesium composition, it is highly strong, hard, and heat resistant, along with excellent fluidity in casting. It is best suited to creating complicated components such as housings and brackets and is hence applied in the majority of aluminum 3D printing solutions.

2. AlSi7Mg: Improved Toughness and Dynamic Performance

Compared to AlSi10Mg, AlSi7Mg possesses reduced silicon content but increased ductility and impact toughness. Also, its improved fatigue life makes it a good candidate for the manufacture of vibrating or cyclic loading moving parts and hence a best choice in manufacturing high-performance, high-strength aluminum parts.

3. Professional Material Consulting Ensures the Optimal Selection

Having a wide range of materials to choose from, LS Manufacturing provides professional material consultation. Our engineers will recommend the ideal aluminum 3D printing filament based on your specific needs—be it high strength, better thermal conductivity, or specific corrosion resistance requirements—to enable your high-strength aluminum parts to achieve optimal performance, price, and production efficiency balance.

Choosing the right material is the secret to successful utilization of aluminum 3D printing services. With knowledge of the properties of different aluminum alloys and our professional consulting, you can determine the most suitable material for your project precisely, and get high-quality parts with higher performance and longevity.

How Does Aluminum 3D Printing Support Rapid Prototyping And Low-Volume Production?

Aluminum 3D printing technology is revolutionizing product design and low-volume manufacturing with its unique manufacturing advantages. The following are some examples of employing aluminum 3D printing services in rapid aluminum prototyping and on-demand metal manufacturing:

1. Rapid Prototyping Process and Time Advantages:

The key of rapid aluminum prototyping lies in the direct translation from computer model to the end product. Unlike traditional production that requires 2-4 weeks to prepare mold, the aluminum 3D printing does not require mold preparation and can begin printing within 24 hours after receiving the design files, shortening the cycle of prototyping to 2-5 days and significantly accelerating design verification and iteration.

2. Flexible Response for Small-Batch Production:

For low-volume production needs, on-demand metal production offers flexibility that cannot be matched. LS Manufacturing's sophisticated scheduling software offers rapid turnaround on order revisions, enabling efficient production of lots of 50 or fewer. This method avoids mold investment for traditional mass production and yet offers flexible means for adapting production to market feedback with much reduced inventory risk and capital holding.

3. End-to-End Fast Delivery Guarantee:

LS Manufacturing's 3D printing aluminum service offers an optimized and agile service, from design to post-processing. Specialized engineers provide a manufacturing solution within 24 hours of receiving the order, and traditional post-processing processes allow for rapid delivery of parts. This combined service condenses traditional lead times of months into weeks, allowing customers to take advantage of market opportunities.

Aluminum 3D printing offers an ideal solution to rapid prototyping and low-volume manufacturing by ideally combining rapid aluminum forming with on-demand metal manufacturing.

What Are LS Manufacturing's Unique Advantages In Aluminum 3D Printing?

In the aluminum 3D printing services business, LS Manufacturing integrates meticulous machinery, rigorous quality control, and qualified customer service to provide customers with cost-effective yet trusted customized aluminum part solutions. Our unique strengths are best summarized in the following statements:

1. Precision Equipment and Processes Ensure Part Performance:

LS Manufacturing employs cutting-edge technologies like industrial-grade Selective Laser Melting (SLM), along with optimized process parameters, to guarantee that aluminum parts can obtain mechanical properties approaching forging levels. This allows us to produce complex and high-strength aluminum parts consistently that meet your end-use needs directly.

2. Strict Quality Control System:

On the basis of mature metal 3D printing quality management experience, we strictly examine every batch of aluminum powder in terms of chemical composition, particle size distribution, and flowability in order to ensure the credibility of the material source. What's more, with a closed-loop control system and real-time monitoring, we supply a steady output of high-quality customized aluminum parts through a stable printing process.

3. Full-Process Professional Service Support:

One-stop service from design optimization to post-processing is offered by LS Manufacturing. Our engineers collaborate with you closely to optimize the structure to suit the process characteristics of aluminum 3D printing, enabling you to achieve lightweighting and control manufacturing costs while keeping the part performance intact.

LS Manufacturing, with its complete line of excellence in precision manufacturing machinery, quality inspection, and full-service customer care, ensures that every high-strength aluminum component you receive has top-performance and reliable quality, providing excellent manufacturing services for your project.

How Does LS Manufacturing Create A Lightweight Bracket For An Aerospace Customer?

In aerospace, intense lightweighting of all components has a direct influence on overall performance. Using lightweight metal 3D printing technology, we actually help customers break through common bottlenecks in production. The following is an actual example of how LS Manufacturing created a lightweight bracket for an aerospace customer:

1. Customer Dilemma:

An aerospace equipment company required a rapid shipment of a crucial bracket that needs to be stable in extreme conditions. The component needs to be reduced in weight by more than 15% from its current weight as well as carry high vibration loads. Conventional machining and casting were not able to give the complex internal reinforcement structure, while long lead times and high mold-making costs severely hampered R&D.

2. LS Manufacturing Solution:

The LS Manufacturing engineering department used aircraft-grade aluminum printing technology, utilizing high-strength AlSi10Mg material, to provide the client with a tailored solution:

- Utilizing topology optimization technology to re-design the structure, we maximized weight reduction while maintaining strength;

- Highly precise control printing parameters and grain orientation yielded optimal mechanical properties in primary load directions;

- Complemented with CNC finishing, we ensured dimensional accuracy and surface quality on critical mounting surfaces.

3. Results and Value:

The resulting bracket component achieved record-breaking performance improvements:

- A 22% weight reduction, significantly higher than the client's expectations;

- A 30% strength enhancement, perfectly passing all vibration and fatigue tests;

- From design completion to shipping of the first operational parts in three weeks;

- Significantly shortening the client's R&D cycle time and reducing overall manufacturing costs.

This case highlights the technical advantages of our aluminum 3D printing service to manufacture high-strength aluminum parts, providing a tried and tested lightweighting solution to aerospace customers.

How Can I Find A Nearby Aluminum 3D Printing Service And Start Working With Them?

It is not a challenging task to locate a reliable, local 3D printing facility for aluminum. LS Manufacturing provides customers with an easy avenue of partnership through which they can easily respond to their aluminum 3D printing needs near me.

1. Convenient Local Service Connection:

You can contact our local technical support team directly through our official website online or by calling our service hotline. LS Manufacturing provides professional aluminum 3D printing service consultation, ensuring rapid project support regardless of your location.

2. Simplified Project Startup:

The cooperation starts with a discussion of your specifications in detail. Just give your 3D model files and technical specifications, and the engineers at LS Manufacturing will make a 24-hour proposal evaluation and present a quote breakdown and production timeline, including on-demand metal manufacturing. The whole process is seamless and transparent.

3. Professional Full-Time Support:

From the selection of materials and design optimization to post-processing, your project will be overseen by a dedicated project manager. LS Manufacturing knows the right way to attain the best balance of cost and efficiency with on-demand metal manufacturing so that each of your custom aluminum parts will meet your exact specifications.

Chosing LS Manufacturing's 3D printing in aluminum is not just looking for an aluminum 3D printing supplier near me, but a reliable manufacturing partner. Contact us today to start your project and experience efficient, reliable on-demand metal manufacturing services.

FAQs

1. Is aluminum 3D printing expensive?

Aluminum 3D printing is cost-proportional with design complexity and production volume. In comparison with traditional open mold casting, aluminum 3D printing for complex structures or small runs becomes economical. LS Manufacturing offers competitive pricing through optimized process parameters, improved material utilization, and intelligent layout. Our aim is not just to stay within budget but also to allow customers to have faster time to market and fast return on investment through the utilization of rapid prototyping and on-demand manufacturing.

2. How strong can aluminum 3D printed parts be?

By employing aircraft-grade aluminum alloys such as AlSi10Mg and the latest SLM technology, LS Manufacturing produces 3D printed aluminum components with homogeneous tensile strength in excess of 500 MPa, equal to or superior to that of typical forgings. Such tensile strength is adequate to meet the harsh requirements in aerospace, high-speed racing, and other fields and ensure component longevity and long-term strength in adverse operating conditions.

3. Is aluminum 3D printing suitable for small-batch production?

Yes. LS Manufacturing provides on-demand, flexible manufacturing services to custom and small-batch production only. Without tooling investment, production can quickly get underway, significantly reducing lead times (to a few days). The business model is particularly appropriate for R&D trials, market testing, or customized production, significantly reducing up-front costs while allowing flexible response to design modifications and market demands.

4. How do we ensure the quality of aluminum 3D-printed parts?

LS Manufacturing has been rigorously insisted on quality control process step by step. Right from raw material powder certification to real-time print monitoring to CMM inspection, X-ray non-destructive testing, and mechanical testing on complete product, we ensure that every delivered aluminum 3D-printed part strictly meets your technical requirements and high industry standard for dimensional tolerance, internal flaw control, and mechanical properties.

Summary

Aluminum 3D printing technology has moved beyond the prototyping level and is increasingly being employed for the production of end products as a tried-and-tested method to develop high-strength, lightweight, and complex functional parts. The technology is transforming the manufacturing world with unprecedented design freedom and never-before-imagined weight reduction.

By choosing LS Manufacturing, you're not simply acquiring an outsourced component; you're acquiring a company that recognizes the entirety of material properties and manufacturing processes. With our highly advanced equipment, rigorous quality control procedures, and history of performing aerospace-quality work, we assure that each component exceeds the highest level of performance, giving you the competitive advantage in the market.

Act now to ignite your creative ideas with fire! Contact LS Manufacturing for a tailored manufacturing solution consultation and detailed quotation. You may also email your design files and let us demonstrate the endless possibilities of aluminum 3D printing technology. Upload your design drawings now and get an instant 3D printing quote ( 3D printing price), let LS Manufacturing be your strong backing in pursuit of ultimate 3D printing precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.